alcoa Annual Reports 2004

-

date post

21-Oct-2014 -

Category

Economy & Finance

-

view

638 -

download

2

description

Transcript of alcoa Annual Reports 2004

Alcoa is…

…focused on customers

Annual Report 2004

Alco

a A

nn

ua

l Rep

ort 2

00

4

At Alcoa, we blend business perfor-mance with environmental, social, and community leadership every day.Through a unique process that involvednumerous governmental agencies,local communities, and environmentalorganizations, Alcoa enabled the con-tinuation of its Tapoco HydropowerProject in Tennessee and North Carolina, while simultaneously protecting the environment.

Following legislation signed by U.S.President George W. Bush, Alcoa’sTapoco Project and its four hydro-electric dams received a new 40-yearlicense in exchange for Alcoa’s

preservation of more than 10,000acres of land in the Great SmokyMountains National Park through a land exchange and conservationagreement.

Major features of the agreement include:

• Preservation of Alcoa’s ability togenerate power to support its aluminum smelting operations in Tennessee

• Protection of 10,000 acres of pristineand ecologically significant landsadjoining the Great Smoky Moun-tains National Park and CherokeeNational Forest

• Restoration of flows in two mountain rivers – the Cheoah and Little Tennessee rivers

• Fish and wildlife habitat improve-ments to enhance speciesbiodiversity, including the restora-tion of four, federally listed,endangered fish species

• Enhanced recreational opportunitiesin a remote and primitive setting

• Protection of cultural resources of historic importance to the region and of tribal importance to the Eastern Band of Cherokee Indians.

Managing Resources for a Sustainable Future

Great Smoky Mountains National Park

Chilhowee Dam and Powerhouse Calderwood

Powerhouse

CalderwoodDam

Chilhowee Reservoir

Littl

e Te

nnes

see

Rive

r

Chilhowee Reservoir

Little

Tenn

esse

e Ri

ver

% dollars in millions, except per-share amounts 2004 2003 change

Financial and Operating Highlights

* Book value = (Total shareholders’ equity minus Preferred stock) divided by Common stock outstanding, end of year

† As of February 2005, the Company has 131,000 employees due to the acquisition of two Russian fabricating facilites from RusAL.

Alcoa at a GlanceAlcoa is the world’s leading producerof primary aluminum, fabricatedaluminum, and alumina and is active in all major aspects of the industry.

• Alcoa serves the aerospace,automotive, packaging, building and construction, commercialtransportation, and industrial markets,bringing design, engineering,production, and other capabilities of Alcoa’s businesses as a singlesolution to customers.

• In addition to aluminum products and components, Alcoa also makesand markets consumer brandsincluding Reynolds Wrap®, Alcoa®

wheels, and Baco® household wraps. Among its other businesses are vinyl siding, closures, fasteningsystems, precision castings, and electrical distribution systems for cars and trucks.

• The Company has 131,000†

employees in 43 countries. For moreinformation, go to www.alcoa.com

2004 Revenues: $23.5 BillionContents

1 Letter to Shareowners4 Alcoa is…

16 News21 Financial and Corporate Data66 Directors67 Officers68 Shareowner InformationIBC Vision and Values

On the CoverAlcoans across the world arefocused on customers includingAirbus (A380), Ferrari (F-430),Pittsburgh Brewing (Iron City aluminum beer bottles), Ford (F-650/750 trucks), DeVos Place in Michigan, USA, and customers of the Pinjarra alumina refinery in Australia, to name just a few.

By Segmentbillions

$6.3 Engineered Products

$5.9 Flat-Rolled Products

$3.8 Primary Metals

$3.2 Packaging and Consumer

$2.3 Other

$2.0 Alumina and Chemicals

By Geographic Areapercent

61% United States

22% Europe

11% Pacific

6% Other Americas*

$6.3

61%22%

11%6%

$5.9$3.8

$3.2

$2.3$2.0

*Includes Canada, Caribbean, Mexico and South America

Values

Alcoa aspires to be the best company in the world.

IntegrityAlcoa’s foundation is our integrity. We are open, honest and trustworthyin dealing with customers, suppliers, coworkers, shareholders and thecommunities where we have an impact.

Environment, Health and SafetyWe work safely in a manner that protects and promotes the health andwell-being of the individual and the environment.

CustomerWe support our customers’ success by creating exceptional value throughinnovative product and service solutions.

ExcellenceWe relentlessly pursue excellence in everything we do, every day.

PeopleWe work in an inclusive environment that embraces change, new ideas,respect for the individual and equal opportunity to succeed.

ProfitabilityWe earn sustainable financial results that enable profitable growth and superior shareholder value.

AccountabilityWe are accountable – individually and in teams – for our behaviors,actions and results.

We live our Values and measure our success by the success of our customers, shareholders, communities and people.

Vision

1

Last year I wrote about how Alcoa’s Vision of aspiring to be the best company in the world

is about delivering sustained financial performance, while building for thefuture and delivering on all of Alcoa’sseven Values. This is the goal that all 131,000 Alcoans across the globe are striving for every day.

In 2004 – facing the headwinds of rising costs and currency challenges –Alcoans delivered the highest annual revenue and the second-highest prof-itability in the Company’s history. Strongcash flows allowed us to not only reducedebt by approximately $2 billion over the last two years, but also to invest innumerous growth projects around theworld for the Company’s future. And wedid all of this while we continued to livethe Values that are the coreof our Company, achiev-ing, for example, a LostWorkday rate of 0.09 for the first time, whileimproving our TotalRecordable Rate for the18th year in a row.

2004 Financial ResultsOur 2004 financial results included:

• Income from continuing operations of $1.4 billion, a 33% increase vs.2003, and our second straight year ofdouble-digit earnings growth;

• Revenue of $23.5 billion, an 11%increase vs. 2003;

• A debt-to-capital ratio decline to 30.0%, the lowest in five years;

• Disciplined use of capital to fuelgrowth projects. 2004 capital spendingwas $1.1 billion, or 95% of deprecia-tion, with approximately one-thirdused on growth initiatives. In 2005, we expect to invest approximately $2.5 billion on capital projects, with nearly two-thirds dedicated to growth projects; and

• Improving the Company’s return oncapital (ROC) to 8.4%, up 140 basispoints from last year.

Fellow Shareowners:Alain Belda, Chairman and Chief Executive Officer

A favorable external business environment contributed to our per-formance. The global economy grew at its fastest pace (+4.4%) in the last two decades. Aluminum consumptionincreased by almost 9%, and aluminumprices were up 21%. Several of our key markets – notably aerospace andcommercial vehicles – moved to a cyclical upturn after declining trendsover the past two to three years.

However, these favorable trendswere countered by a weakening U.S. dollar and significant cost issues,notably energy and input costs such as resins, carbon-based materials, andalloy materials. Currency and energyalone in 2004 negatively impacted ourearnings by more than $300 millioncompared to 2003.

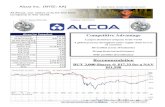

As strong as our 2004 financialresults were, we are confident we can do better. The ultimate measure of success is growth in shareholder value during the year and over a period. Our2004 return was –15.7%, obviously adisappointment. However, the combined2003/04 return is +44% compared to+31% for the S&P 500.

Stock performance is a mix of pastperformance, future expectations, andshareholder options. The best answer toimproved shareowner returns is consis-tent, transparent, and improved perfor-mance. And this is what our plans are allabout. We remain committed to our keyfinancial goals:

• Profitable Growth – Continuing thedrive to profitably grow revenues as well as to join the first quintile of theS&P Industrials, measured in terms ofROC; and

• Cost Savings – Achieving $1.2 billionin cost savings by 2006. In 2005, thiscost-savings initiative – our third three-year program since 1998 – will be used to help offset cost increases acrossthe business and bolster profitability.

On our ROC goal, we againimproved this year, but we have morework to do. Our 2004 ROC was8.4%, which improved from 7.0% ayear ago. However, the first quintileentry point is currently 18.5%, so wewill continue to work to profitablygrow and improve our results.

Our cost-savings program, as previously mentioned, was held back

by rising costs in 2004.We expect this to contin-ue to be a challenge in2005. We project approx-imately $600 million incost increases from ener-gy, labor, raw materials,and currencies. Our

cost-savings plans for 2005 indicatewe will be able to offset most, if not all,of these increases. But this will requiresubstantial effort in planning, focusingeffort, and execution at all levels of the organization and across our globalbusinesses, which is why our structureand culture are so vital.

Building for the FutureWe have taken many steps to positionand align your Company to capturegrowth opportunities and expand – both through new geographies as well as expanding current assets.

In late 2004, we realigned the Company along six global platforms tobetter serve customers and increase theability to capture efficiencies. We alsocentralized purchasing on a global basisto improve our costs and better use ourleverage. As we moved to strengthen theglobal business structures, we also creat-ed strong regional leadership to ensurethat we maintain optimum relationships.

In 2004 – facing the headwinds of rising costs andcurrency challenges – Alcoans delivered

the highest annual revenue and the second-highestprofitability in the Company’s history.

In addition, we combined functional groups such as ABS (AlcoaBusiness System), Customer andMarketing Services, EHS, People, andQuality to accelerate the culture changesin order to achieve our Vision andemphasize the ABS philosophy that“people are the linchpin of ABS.”

As you will see in the pages of this report, we are expanding across our markets, using the tenets of ABS, to help our customers grow their businesses.We expect the combination of our global business structure, our functionalresources, and our R&D expertise tocontinue to spur profitable organicgrowth and share gains across the world.

Upstream – Restarts and Growth ProjectsTo take advantage of the strong alu-minum market, we are restarting severalsmelters. When complete, these restartswill add 220,000 metric tons per year(mtpy) of production in 2005, leaving us with idle capacity of 361,000 mtpy. Restart progress has been made at: 1) the Aluminerie de Bécancour, Inc.(ABI) facility in Quebec, following theend of a strike there. This strike resultedin a significant cost to the Company,but was necessary to enable the long-term flexibility we need to operate efficiently; 2) the Wenatchee smelter inWashington, USA, after the successfulresolution of an issue regarding health-care cost-sharing. The plant had beenidle since 2001, and the resolution of this issue helped save 400 jobs; and 3) the Massena East and West smeltersin New York, USA, where we are now running at full capacity.

In addition to restarts, we begansteps to expand our upstream operationsthat will benefit the Company for years, if not decades, to come. For example, we broke ground in Iceland on AlcoaFjar aál, the Company’s first greenfieldsmelter in more than 20 years. Thishydropowered smelter, which is sched-uled to come on line in 2007, will be among the most environmentallyfriendly in the world.

In Norway, we have agreed to builda new anode plant in Mosjøen, togetherwith Elkem ASA, that will supply theAlcoa Fjar aál smelter in Iceland andthe Mosjøen smelter in Norway, which is50% held by Alcoa and Elkem.

2

Alcoa Aluminio in Brazil also broke ground on an expansion that willincrease its share of the Alumar smeltingoperations in São Luis by 30%, or63,000 mtpy, bringing Alcoa Aluminio’sshare of smelting capacity there to262,000 mtpy, and Alcoa’s share ofoverall output will grow from 54% to60%. The expansion was facilitated by completion of a new, 20-year hydropower agreement.

We signed a memorandum ofunderstanding (MOU) under whichAlcoa and the Government of theRepublic of Trinidad and Tobago willbuild a state-of-the-art, environmentallyfriendly aluminum smelter and relatedfacilities in Trinidad. The smelter willutilize power produced by Trinidad andTobago’s vast natural gas fields, whichwill then be converted into low-cost electricity for the smelter. We are nowworking with the government to finalizethe project plan.

In Ghana, we have signed an MOU with the Government of theRepublic of Ghana to develop an inte-grated aluminum industry that wouldinclude bauxite mining, alumina refin-ing, aluminum production, and railtransportation infrastructure upgrades.We have begun expedited feasibilitystudies that are expected to be complet-ed in 2006, at which time both partieswill negotiate definitive agreements as well as total investment costs. TheMOU calls for the initial restart of120,000 mtpy at the jointly owned200,000 mtpy Valco smelter in Tema,Ghana, which is currently idled.

Our alumina refining system is also expanding significantly with an eye toward sustained, long-term growth. In all, we are working on expansionsthat total more than 4 million mtpy. InJamaica, for example, following on theheels of a 250,000 mtpy expansion ofthe Jamalco alumina refinery in

Clarendon, we announced plans to fur-ther expand by at least an additional 1.5million mtpy. This new expansion wouldmore than double the refinery’s totalcapacity to at least 2.8 million mtpy. Inaddition, Alcoa World Alumina andChemicals (AWAC) ownership in therefinery will move from 50% to 70%.

AWAC is also a lead partner in aproject exploring the feasibility for devel-oping jointly with the Government of theRepublic of Guinea a 1.5 million mtpyalumina refinery there. A detailed feasi-bility study for the refinery is expected to be completed by mid-2005, with finalcosts, investment decisions, and con-struction to begin shortly thereafter.

A 600,000 mtpy efficiency upgradeof the Pinjarra, Australia, alumina refinery continues to be on-track forcompletion by the end of 2005. AndSuralco, owned by AWAC, completed a 250,000 mtpy expansion to itsParanam alumina refinery in Surinamewell ahead of schedule. This brings thatfacility’s total capacity to approximately2.2 million mtpy.

Portfolio Realignment and Expanding our FootprintWe continued to review and rebalanceour portfolio to better focus on our corebusinesses, while also making progresson acquisitions that will enhance ourcompetitive position.

In 2005 and for a few years there-after, one of our chief challenges will be the successful and ongoing integrationand investment in two fabricating facili-ties that we purchased this year inSamara and Belaya Kalitva in theRussian Federation. The addition of thetwo Russian fabricating facilities – which feature cast house, flat-rolled products,extrusions, tubes, and forgings capabili-ties – will allow the Company to serveboth the growing Russian market andglobal customers in Europe, Asia, andthe Americas, giving us substantial com-petitive and comparative advantages.

We reached an agreement withFujikura Ltd. that paves the way forAlcoa to obtain full ownership of the Alcoa Fujikura (AFL) Automotive business. In return, Fujikura will obtain complete ownership of the AFLTelecommunications business. AFLAutomotive is a large part of Alcoa’sapproximately $3 billion automotivefranchise, and this transaction increasesour position in this market.

Bloomberg Methodology calculates ROC based on the trailing 4 quarters

02 03 04

0

5

10

15

20

Return on Capitalpercent

Top Quintile S&P IndustrialsTop Quintile S&P Industrials

Alcoa ROCAlcoa ROC

During the course of 2004, we completed the portfolio restructuringefforts announced in January 2003,including the sale of PackagingEquipment, Huck Automotive Fasteners,Specialty Chemicals, the Russellville (AR)and St. Louis (MO) foil locations, andItaipava. In addition, we completed the sale of Integris Metals to RyersonTull and transferred our interest in theJuruti bauxite reserves that had beenacquired through the Reynolds acquisi-tion to AWAC.

In China, we received approval to form our joint venture with theAluminum Corporation of China, Ltd.,(Chalco) at Pingguo and continue tomove this project, as well as our Bohairolling mill initiative, through variousgovernment approvals and negotiations.Both of these projects will enhance ourposition in the fastest-growing marketsin the aluminum industry.

Within other businesses of the Company we also continued to expandour footprint, opening facilities in newgeographies in order to serve customerseffectively and efficiently, including operations in Romania (extrusions),Honduras (wire harnesses), and Egypt(closures).

Living our ValuesAt Alcoa we live our Values every day.They are the guide to how we operateour business. Our Values require us to think and act not only on the presentchallenges, but also with the legacy inmind that we leave for those that willcome after us… as well as the commit-ments made by those that came beforeus. We think of it in terms of a relayrace, where each one of us adds valuetoday and long term for all shareowners,Alcoans, and the communities in whichwe operate.

Environment, Health and Safety – Ourlost workday rate of 0.09 (injuries per200,000 work hours) for 2004 was thebest in our history. During the year, wehad 258 million hours worked with 116 incidents, and more than four out offive Alcoa locations did not have a singlelost workday. Despite that significantprogress, we suffered three fatalities: twoAlcoans and a contractor working onour site. We continue to investigate theseincidents to root cause, as well as otherincidents with significant fatality risk, to eliminate or control them in our

3

workplace. We can do better, and weowe it to ourselves and our families tomove more rapidly toward creating azero-incident workplace. In 2005, wewill place further focus on this vital area.

This year we maintained Alcoa’sleadership position on climate change by meeting and holding the goal ofreducing greenhouse gas emissions by25% from 1990 levels. We helped devel-op a global sustainability model with the International Aluminium Institute.Under the most likely scenario in thatmodel, the industry will become “green-house gas neutral” by 2017 – the firstand perhaps only industry that will beable to make that claim. A presentationon the model received “Best Paper” honors at The Minerals, Metals &Materials Society (TMS) conference in Washington, D.C.

SOX and Internal Audit – Regulatoryrequirements associated with Sarbanes-Oxley (SOX) represented one of themost significant challenges faced in2004. Responding to these, we devel-oped and implemented a comprehensiveset of controls through the use of self-assessment documentation and testing.In addition, we conducted over 140Finance and IT SOX reviews, as well as300 scheduled process/location audits.As of year-end, Alcoa was able to clearlydemonstrate an effective internal controlsystem. To ensure compliance through-out the organization, we spent nearly$10 million this year auditing and testingour controls. The result is an evenstronger control environment, with lessrework and waste.

Alcoa Foundation, CommunityFramework, and Sustainability – AlcoaFoundation increased its 2004 payout by14%, with grants totaling $17 million in34 countries, up from nearly $15 millionin 2003. Alcoa’s employee engagementactivities reached new heights in 2004.Our programs, designed to encourageand reward active participation in com-munities, saw a 39% increase in 2004,

resulting in more than $2 million beingcontributed on behalf of Alcoans.

We also made great strides inincreasing the understanding of bothexternal and internal audiences of oursustainability activities across the globe,including the online publication of fiveregional reports to augment our corpo-rate report on our social, economic, and environmental impacts. Our overallsustainability efforts have been recog-nized as among the best in the world byInnovest and Corporate Knights at a ceremony held at the World EconomicForum in Davos, Switzerland.

Delivering Both Short- and Long-TermAs we look into 2005, market conditionsremain strong. Both the alumina and primary aluminum markets continue tobe in a deficit where demand exceedssupply, and key downstream markets are recovering.

While we will continue to experi-ence cost and currency pressures, we areapplying rigor toward sustained cost-savings programs to help offset externalmarket conditions. Your Company isactively pursuing growth opportunities –both in operations and through helpingour customers succeed in the market-place. And our focus is on deliveringboth short-term and long-term results.

I am confident that Alcoa willachieve its goals. I can express this confi-dence knowing how Alcoans deliverwhen we focus on the task at hand,using the tools at our disposal, and withtotal commitment. Our personal andprofessional pride drives our talentedpeople across the globe as we strive tobecome the best company in the world.

Alain J. P. BeldaChairman and Chief Executive OfficerFebruary 18, 2005

96 97 98 99 00 01 02 03 0405Milestone

Alcoa*Alcoa*

Lost Workday (LWD) Incident Rateinjuries per 200,000 work hours

Including AcquisitionsIncluding Acquisitions

* Excludes recently acquired locations

.49.46

.36

.23.18 .16 .15

.12.09 .09 .075

.16.19

116 LWD in 258 millionhours worked in 2004

0

4

Pratt & Whitney awardedAlcoa Fastening Systems a life-of-program contractto supply its Weld-StudFastening System for the F119 engine nozzleassembly.

The ARJ21, China’sadvanced regional jet, is arobust, low-cost aircraftdesigned for decades ofservice. New Alcoa alloysplay an important part in meeting fuel and weight-saving objectives.

Airbus officially introducedits A380, the world’slargest commercial air-craft, in January 2005.Innovative Alcoa products,developed to meet uniquetechnical challenges, are used throughout theairliner.

Under a long-term agree-ment, Alcoa HowmetCastings supplies Rolls-Royce with precisioncastings components fornine of the company’s civiland defense aerospaceengines, including theRolls-Royce Trent 500.

Alcoa Fastening Systemsdelivers new fasteners and fluid-fitting designs forthe high-performance F-35Joint Strike Fighter (JSF)that are stronger, lighter,and quicker to install, join-ing other Alcoa businessesthat supply forgings, castings, plate, and airfoilsto the JSF program.

Alcoa is…

5

Xian Aircraft Companyawarded Alcoa a multiyearcontract for extrusions for the Boeing 737 tailassembly. Xian is a long-time customer for Alcoa’saluminum sheet, plate,and aerospace fasteners.

Alcoa signed an agreementwith Babcock & Brown Air-craft Management for theconversion and sale of the initial prototypes of Alcoa’s14Plus Boeing 757 passen-ger-to-cargo conversion.Long a reliable, cost- effectivepassenger aircraft, a con-verted B757-200 will offeroperational savings overmany older freight carriers,as well as other benefits.

Alcoa Fastening Systems’XPL Lockbolts touch the Airbus A380 in one million places. Each of the new airliners features one million of the new fasteners to tie composite and metallicparts together.

Eclipse Aviation plans toenter the new Very LightJet market with its Eclipse 500 aircraft,employing revolutionarymanufacturing techniquesand high-volume produc-tion. Alcoa Mill Productsworked with the companyduring the design and certification process.

…Aerospace

As part of the U.S. Air Force AdvancedAerostructures Initiative,Boeing and Alcoa busi-nesses introduced animproved, lower-cost crew emergency escapedoor for the Boeing C-17 aircraft.

6

The spaceframe on Ferrari’s upcoming F430from Alcoa AdvancedTransportation Systemssets new performancestandards for automotivealuminum structures.

Volkswagen’s Golf V wasthe first car with an inte-grated cooling fan. AFLAutomotive Europe broughtits electronics, wire har-nesses, and plastic com-ponents together to createmultiple environmental and cost-savings benefits.

Audi A6 buyers enjoy thechoice of many individualoptions – resulting in millions of possible combi-nations in the car’s complexelectrical wire harnesses.AFL Automotive plants inGermany, Hungary, andRomania supply some160,000 vehicle-specific harnesses annually.

The Chrysler 300C is one offour of Chrysler Group’smost popular 2005 models tofeature components made of a patented Alcoa alu-minum alloy with improvedstrength, formability, and corrosion resistance.

Alcoa is…

Stylish Alcoa cast aluminum wheels are standard equipment on Nissan’s 2005 Altima,Frontier, Pathfinder, and Xterra models.

7

General Motors choseAlcoa’s automotive cast-ings business for the front and rear subframes of its 2005 Corvette andCadillac XLR models.

Toyota honored Alcoa Engineered Products with a Multi-Year AchievementAward for its work on the automaker’s Tundraand Sequoia vehicles.

Alcoa is helping GeneralMotors extend its innova-tive Quick Plastic Formingprocess for aluminumbody and closure panels,enabling the company tooffer complex styling fea-tures on high-volume cars,such as the lift gate on theChevrolet Malibu Maxx.

Corvette’s reputation forperformance is supportedby Alcoa’s more than 20 years of experience invehicle electrical systemtechnology and just-in-time supply of customized wire harnesses.

Subaru of America usesAlcoa’s proprietary alloy6022-T43 for the hood andliftgate of its 2005 Legacyand Outback models tofurther enhance its luxuryperformance brand image.

…Automotive

8

Alcoa is…

Alcoa Dura-Bright wheelscontinue to give truck fleet owners and operatorsthe closest to a mainte-nance-free shine. It’s the firstaluminum wheel you don’tpolish or scrub – just spraywith soap and water –thanks to a patented treat-ment that penetrates thealuminum. Harvey Zander’sworking commercial truckwith Dura-Bright wheels isfeatured in the 2005 Over-drive magazine and 2004SuperRigs calendars.

Truckers value AlcoaWheel Products’ Dura-Flange wheels for theircost-saving performanceand their good looks. The aluminum wheels feature a rim treatmentthat guards against excessive wear and maydouble their service life.

Honda all-terrain vehicles,like this Rubicon model,are now traveling on aluminum wheels with thehelp of Alcoa Mill Products.

9

…Commercial Transportation

Ford’s newest medium-duty F650/750 truck models use Alcoa Fasten-ing Systems’ Huckbolts to assemble the chassisunits. As a Ford ad puts it,

“Huckbolts stay tight tentimes longer than ordinarynuts and bolts.”

Select 2005 and 2006 gasoline and diesel-poweredFleetwood Class A motorhomes rely on AFL Automotivewire harnesses to meet theneeds of recreational drivers.

Alcoa Wheel and ForgedProducts supplies wheelsto Heil Trailer plants infour countries.

Sightseeing company Hato Bus chose Alcoa 10-stud aluminum wheels for its new buses, enjoying advanced designwhile meeting its fuel savings and emissionreduction goals.

Sterling Truck, a unit ofFreightliner, named AFLAutomotive its full-serviceelectrical distribution supplier for right-handdrive models, sold primarily in Australia and New Zealand.

Trailer manufacturer Great Dane gave AlcoaWheel Products its Valued Vendor Award.

10

Alcoa is…

The Warsaw headquartersof TPSA, Poland’s nationalstandard telephoneprovider, includes 13,000square meters of AlcoaArchitectural Products’Reynobond aluminum composite material.

Specialist contractor SIAC Façades usedKawneer’s curtain wall, silicon glazing, and win-dows for the exterior of the new ground transportinterchange at ManchesterAirport in the U.K.

Alcoa products helped its customer, Metalsigma, meet the challenge of facilitating natural lightingwhile managing solarimpact and thermal andacoustical requirementsfor a new hospital in Strasbourg, France.

Businesses, such asVictoria’s Secret, that wantto catch eyes call on Alcoa Architectural Products’Reynobond aluminum composite material. It provides the strength, flatness, longevity, andprecise image consistencycorporate brands require.

Alcoa Arquitectura in Spainand Alcoa Architectural Prod-ucts in Merxheim, France metspecial design needs for thenew Forum 2004 building inBarcelona, Spain. The busi-nesses supplied customizedReynobond cladding panelsand a new fixing system to integrate the panels into the curtain wall.

A stylish Alcoa aluminumfaçade makes clothingretailer PRADA’s new flagship store in BeverlyHills (CA) a standout amid the more typical gold leaf and granite on Rodeo Drive.

11

…Bu

ildin

g &

Con

stru

ctio

n

Alcoa Home Exteriors’ new DreamColor premium siding and acces-sories are available inmore than 700 colors, letting homeowners cus-tomize color combinationsto suit their tastes and the style of their houses.

Mexican artist ManuelMarin, inspired by the flexibility of Reynobondaluminum composite panels and their bright colors, created Comunica-cion Cruzada (InteractiveCommunication) from the products supplied by Alcoa.

The bold design elementson the Boise (ID) Airportwere achieved withReynobond aluminum composite material fromAlcoa in a platinum color.

Conoco Phillips choosesAlcoa’s Reynobond alu-minum composite materialto enhance its public image,selecting Alcoa ArchitecturalProducts as a preferred sup-plier for 2005. Customersalso may choose Reynolux,a heavy-gauge, coil-coatedaluminum sheet, and pro-filed aluminum wall panels.

The architect of DeVosPlace (MI) used Alcoa’sReynobond aluminum composite material toachieve a curved designnot possible with lessformable materials.

12

Alcoa is…

Pittsburgh Brewing Company and Alcoa teamedup to present the first beerin an aluminum bottle toNorth America – reminiscentof their 1962 partnership onthe aluminum pull-top can.The bottles keep beer colderlonger than glass, weighless, and won’t break.

Wine bottles closed with natural corks are subject to

“cork taint,” a contamina-tion that affects the tasteof the wine. Alcoa ClosureSystems International’snew Vino-Lok, a glass stop-per and aluminum overcapsystem, eliminates theproblem. Vino-Lok alreadyis being used on premiumwines and has won severalawards for innovation.

Since 1995, Alcoa’s Southern Graphic Systems’separation technology has helped Santa smile onCoca-Cola holiday cansthroughout North America.Alcoa also is the leadingsupplier of sheet to the aluminum can market.

Alcoa Closure SystemsInternational’s new facilityoutside of Cairo, Egypt,can produce 800 millionclosures annually to supplybeverage customers inNorth Africa.

Reynolds Food Packagingmet retailer Marks &Spencer’s challenge in theU.K. to develop a tamper-resistant package for saladsand sandwiches to keepfood fresh and safe. Alcoa’ssolution won the bid and an industry award.

Alcoa Consumer Products,through its Presto Products business, sup-plies its thermoformedFRESH-LOCK containers to ConAgra Foods for its Healthy Choice line of thin-sliced deli meats.

13

…Packagingand Consumer

Reynolds Food Packagingprovided catering productsand serving utensils forthe estimated two millionmeals necessary to feedathletes and other groupsduring the August 2004Summer Olympics and theSeptember Paralympics.

Pharmaceutical maker Novartis supplies safer, moreconvenient, and more cost-effective physicians’ samplesof its diabetes medicationthanks to an award-winningbottle/closure packaging system labeled in a colorfullyprinted Alcoa Flexible Packaging shrink sleeve.

Home cooks now can enjoythe benefits of ReynoldsParchment Paper that pro-fessionals have known foryears. A grease-proof, silicone-coated, vegetablepaper product, it is excellentfor purposes from baking to covering foods for themicrowave.

Alcoa Flexible Packagingis the exclusive distributorand seller of Korean manufacturer KSP’s spoutpouch products in the U.S. and Canada. Spoutpouches are especiallysuitable for single-servebeverages, health andbeauty products, andindustrial and medicaluses.

By reducing the size of the core tube in individualReynolds Wrap aluminumfoil packages, Alcoa Consumer Products alsocould shrink the bulk container – giving shoppersat warehouse clubs thesame amount of foil, butmaking it easier to handleand store.

14

Alcoa is…

Alcoa broke ground for its new Fjar aál aluminumsmelter in Iceland, its firstgreenfield smelter in 20years. The facility will beone of the most efficient,environmentally friendly,and safest smelters in the world.

Alcoa and the Governmentof the Republic of Trinidadand Tobago signed a mem-orandum of understandingto build a state-of-the-art,environmentally friendlyaluminum smelter inTrinidad. The smelter willuse low-cost electricity generated from power produced by the nation’svast natural gas fields.

Alcoa World Alumina andChemicals completed a250,000 mtpy expansionof the Jamalco aluminarefinery in Clarendon,Jamaica, and is exploringdoubling the size of theexpanded facility.

Alcoa Aluminio began anexpansion of the Alumarsmelting operations in São Luis, Brazil, that willincrease its share in those operations by 30%.

The Massena East andWest smelters in New Yorkstate were restarted and now are running atfull capacity.

15

…Aluminum andAlumina

In partnership with Elkem ASA, Alcoa plans to build an anode plant in Mosjøen, Norway. The new facility will supplyAlcoa’s new Fjar aálsmelter in Iceland and the two companies’Mosjøen smelter.

A 600,000 mtpy efficiencyupgrade at the Pinjarra,Australia, alumina refineryis scheduled for comple-tion by year-end 2005.

Alcoa’s Wenatchee smelter in Washingtonstate, idle since 2001,resumed production.

Alcoa World Alumina and Chemicals’ Suralcobusiness completed a250,000 mtpy expansionof its refinery in Suriname well ahead of schedule.

A memorandum of understanding with theGovernment of the Republic of Ghana pavedthe way for feasibilitystudies on developing anintegrated aluminumindustry in that country.

16

Expanding in MexicoAlcoa Wheel and ForgedProducts completed con-struction and productionramp-up at its Monterrey,Mexico, plant to meet cus-tomer demand. Employeesthere turned in outstandingquality and delivery per-formances, and have not had a single lost workday during construction and since production began.

Building Futures The Alumar smelter in São Luís, Brazil, is helping toconstruct the first local highschool in the rural area. TheMário Martins Meireles HighSchool Center, which willserve 1,200 students, is a part-nership between Alumar and the Maranhão government.Alumar is providing the facilities and operationalequipment, and the govern-ment will be responsible for ongoing activities.

Gains for Aerospace MarketAlcoa Mill Products used ABS to avoid a potentialprocess bottleneck at its Davenport (IA) Works andachieve increased revenues,while reducing costs. Theeffort centered on improvingthe operational availability of the ultrasonic inspection (USI) station, which inspectsDavenport’s aerospace components in accordancewith U.S. FAA requirements.The USI team posted a 26%improvement, surpassing its goal.

Alcoa is Global: News’04• 43 Countries • 350-plus operating locations •131,000 Employees

17

Refinery StudiedAlcoa World Alumina andChemicals is a lead partner in a project exploring possible joint development of an alumina refinery with the Government of the Republic of Guinea. A feasibility study should be completed in 2005. Thestudy includes communityconsultations.

Growing Presence Growing Alcoa operations in Romania include two AFL Automotive plants thatproduce wire harnesses forthe automotive market. Thesefacilities increasingly areinvolved in their communitiesthrough Alcoa Foundationgrants and employee volun-teerism. Alcoa’s EuropeanExtruded & End Productsbusiness now is building anextrusion facility in north-west Romania to serveEuropean commercial andresidential building and construction markets.

Acquisition in RussiaAlcoa completed its acquisitionfrom RusAL of two fabricatingfacilities in Samara and Belaya Kalitva in the RussianFederation. The Companyplans to invest capital and tech-nology in the plants in 2005,while also investing and trainingto make the operations consis-tent with those of other Alcoaoperations and strengthen theircompetitive position.

Waste vs. Waste Alcoa’s Kwinana, Australia,alumina refinery reduced the need for ongoing manage-ment of closed bauxite residue storage areas using waste carbon dioxide (CO2) from a nearby industrial facility.Mixing high concentrationCO2 with bauxite residuebefore it is deposited in dryingbeds creates a more benignbauxite waste.

New Plant in ChinaAlcoa Closure Systems Inter-national opened a new plantin Hangzhou, its second plantin China. The facility presentlyproduces plastic closures, primarily for export to bever-age producers in Japan.

News’04

18

• Alcoa Aluminio S.A. sold Itaipava, its flexiblepackaging business, toLatin American-based Dixie Toga.

• Alcoa World Alumina and Chemicals sold AlcoaSpecialty Chemicals to twoprivate equity firms led byRhone Capital LLC.

• Alcoa sold its U.S. Russellville (AR) and St.Louis (MO) aluminum foilplants to JW Aluminum.

Know the Market By leveraging its knownproduct quality and Alcoabrand strength with originalequipment manufacturers(OEMs) and implementingABS principles to change itsmanufacturing processes,Alcoa Wheel Products(AWP) enhanced its positionin the growing market forcustomized wheels andachieved production mile-stones. Specialty Wheelsreduced time-to-market from the industry average of 38 weeks to as little asfive weeks. The business also launched 41 new wheelprograms, greatly outpacingtheir historical six to eight.AWP increased its revenueand profits and benefitedOEMs with enhanced original purchase and aftermarket sales.

Carefree Travel Applying knowledge gainedfrom supplying the automo-tive and heavy truck markets,AFL helped motor homemanufacturer Fleetwooddesign electrical systems tomeet the specific needs ofmotor home buyers. This is the first time AFL has supplied wire harnesses forFleetwood diesel vehicles,creating an opportunity touse ABS tools to design theassembly line for the product.AFL’s Acuña, Mexico, plantsuccessfully introduced make-to-use product assem-bly, with smaller lot sizeproduction, reduced leadtimes, and rapid changeovers.

That’s Delivering!Via ABS, the Alcoa MillProducts (AMP) Texarkana(TX) plant raised its on-timedelivery performance from56% in 2003 to 94% at year-end 2004. This achievementwas enabled by plantwideemployee involvement thatresulted in more effectivelinks between functionalareas and dramatic improve-ments in reliability at criticalproduction centers. Forexample, improved produc-tion planning connections to the shop floor ensured that task dates were met, andkaizen events and problemsolving to root cause raisedsome key reliability factors by double-digit percentages.Customers respondedstrongly. AMP gained multi-year supply agreements with strategic customers for2005 and beyond, and grew its share of the paintedproducts market.

Value Selling Using ABS to focus on specific customer benefits, Alcoa CSI Argentina achieveda 3% growth in market share– an 11% increase over itsbusiness plan – and alsoadded an important newsource of revenue. The busi-ness concentrated on 100%product quality, establishedpull systems with customers,and shortened lead time –resulting in reliable deliveryand an average 30% reduc-tion in customer-heldinventories.

Acquisitions and Divestitures • Alcoa and BHP Billiton

sold their respective equityinterests in Integris Metals,a metals service center company, to Ryerson Tull.

• Alcoa and Fujikura Ltd.signed a letter of intent inwhich Alcoa will obtaincomplete ownership of theAFL Automotive businessand Fujikura will obtaincomplete ownership of theAFL Telecommunicationsbusiness. The transactionshould be completed byspring 2005.

New ACC-U-BAR Alcoa Engineered Products,Cressona (PA) added ACC-U-BAR, a premium,high-performance extrudedbar product, to its branded bar line. The new product features superior machinabilityand straightness, suitable for applications that requiretighter tolerances and reducedtwist. Sales already haveexceeded expectations.

Sustainable PowerFollowing an agreement with stakeholders that inte-grates strict environmentaland social goals with long-term economic development,the Brazilian governmentallowed BAESA, a consor-tium of Alcoa Aluminio andfour other Brazilian-basedbusinesses, to proceed withits Barra Grande hydroelec-tric project. Under terms of the agreement, BAESA will increase its investment invarious forms of communitysupport to $51 million andits investment in environmen-tal activities to $30 million.Now with 95% of the civilconstruction completed, theBarra Grande facility willhave a capacity of 690 MW,generating 30% of the elec-tricity demand in the SantaCatarina state and the stateof Rio Grande do Sul. As part of the Company’s sustainabledevelopment practices, Alcoacontinues to work with boththose who favor and thosewho oppose the project informal and informal venues.

Fábio M. Almeida, Itajubá, Brazil

Planting trees in Soest, Germany

19

Bigger Home Benefits Alcoa Home Exteriors (AHE)and Dow Building Materialsintroduced Structure Premium Insulated Siding forresidential customers. Inaddition to low maintenance,the product offers superiorstrength and durability,increased noise reduction andwater resistance, and energysavings. AHE also addedVentura Hidden Vent Soffitto its premium line of soffitsand fascia. It delivers up to50% more ventilation thanother hidden-vent panels and better ventilation thanstandard soffit.

Flying High Alcoa Aluminio is playing a vital role in two large-scaleairport expansions in Brazil.The Itapissuma plant devel-oped aluminum profiles and coating to meet specifi-cations for the GuararapesInternational expansion. AtCongonhas Airport, a newarrivals and departuresbuilding was made withAlcoa Façade Systems.Alcoa’s Unit System technol-ogy made it possible toprefabricate panels andinstall them during the fewhours available as the airport continued to operate.

At the TopAlcoa, Toyota Motor, and BP were named the world’sbest in the first annual Global 100 Most SustainableCorporations. The listing,developed by Innovest andCorporate Knights, rankscompanies by how well theymeet “the triple bottom line,”a measure of value that bal-ances environmental, social,and economic impacts.

Thanks, Alcoans!As part of Alcoa’s program to plant ten million trees,employees at Alcoa’s Hannover, Germany, siteplanted trees with the help ofa pachyderm named Sayang.The main tree was placed nearthe elephant exhibit at theZoo of Hannover. Sayangapparently was thankful – shelent her trunk to help water it.

Home AgainRed wolves were native toNorth Carolina, but expertsbelieve that fewer than 500 of them now exist world-wide. Alcoa Foundationawarded the Rowan Natureand Learning Center nearBadin (NC) a grant to con-struct a red wolf habitat aspart of a renovation projectat the Center. Badin is hometo Yadkin-Alcoa Power Generating and Alcoa Badin Works.

Planning AheadAlcoa partnered withLandsvirkjun, Iceland’snational power company, towork with an advisory group to develop methods tomeasure sustainable perform-ance at Alcoa’s new Fjar aálaluminum smelter and therelated hydropower facility.The group comprises morethan 30 stakeholders repre-senting diverse environmental,social, and economic perspec-tives, including projectsupporters and those opposed.

Driving Down ProblemsTo eliminate ergonomic concerns, Alcoa EngineeredProducts in Lafayette (IN)improved its method of hang-ing driveshaft tubes for heattreatment. The new processuses chains and tools to holdthe tubes in place, eliminatingthe need to twist strong wires by hand. Productionalso improved because thestronger connection meansthat fewer tubes fall into thepit, reducing the need todrain the pit to retrieve them.

Protecting the Blue Danube Alcoa Foundation and AlcoaEurope donated funds to theInternational Commission forthe Protection of the DanubeRiver (ICPDR) to support theTransnational MonitoringSystem, a water managementnetwork that tracks sub-stances across countryboundaries in the DanubeRiver Basin. The funds pur-chased technical equipmentfor the Romanian WatersDepartment on the CrisuriRiver in Romania. TheICPDR facilitates coopera-tion between the EuropeanCommission and all theDanube Basin countries.

Upgrading Spanish SmeltersAlcoa is investing in technol-ogy and environmentalimprovements at three of itssmelters in northern Spain. At Avilés, the Company ismaking innovation and tech-nology improvements thatwill enable the plant to meetEuropean Union environmen-tal standards effective in2007. At La Coruña and the San Ciprián smelter andalumina refinery, Alcoa is implementing the terms of a voluntary agreementwith the regional governmentto improve emissions.

Jaz Rana, Exeter, United Kingdom

Alcoa Aluminio is playing a vital role in two large-scale airport expansions in Brazil, including the GuararapesInternational Airport.

20

Dynamic Protection Alcoa’s Deschambaultsmelter in Canada uses stormand snow-melt water in a closed-loop system in itsprocesses. The plant rentedtreatment equipment toensure that discharges of theexcess water met the normset for the effluent. Despitethis treatment, there werespikes in fluoride concentra-tion in a neighboring riverbecause the discharge wasnot synchronized with thenatural cycles of the river.Now, computerized analysisof river-water fluoride levels,water flow, and fluoride concentration in the plant’sstorage basin allowsDeschambault to adjust discharges automatically.

All-Around SafetyAttila Soós of AFL Automo-tive in Mór, Hungary, wonfirst place in the Safety cate-gory in Alcoa’s employeephoto contest, showing a360° mirror that protectsdrivers and floor workersfrom in-plant accidents. Hecaptured one of the manyways Alcoa supports its commitment to safety.

Best of the YearThe American Foundry Society honored Alcoa Automotive Castings with its 2004 Casting of the Year award for a hollow aluminum rear control armused on several BMW andRolls-Royce models.

On Deck Alcoa Home Exteriors andstrategic partner DeceuninckNorth America entered thegrowing market for engineeredwood building products withOasis Decking by Alcoa. Composed of a proprietary for-mulation of high-density poly-ethylene and pinewood flour,Oasis outperforms both woodand other composite decks instrength, weather resistance,and design possibilities.

Habitat Helpers Employees at Alcoa PrimaryMetals’ Gum Springs (AR)plant received internationalrecognition for their contribu-tions to wildlife habitatconservation from the WildlifeHabitat Council. The plant formally initiated a habitatenhancement program site in 2001.

Animal Attraction Departing from the usualphotos of buildings in construction ads, AlcoaArchitectural Products USA(AAP) aimed to create morebrand and product awarenessby catching viewers’ eyeswith animals. One ad fea-tures a butterfly flutteringaround pieces of ReynobondNatural Metal Compositesshaped like wings. “Naturallybeautiful,” the ad begins.Other ads feature a rear shotof an elephant (becauseReynobond XXL is availablein 2-meter-wide panels) and a chameleon (becauseReynobond is available inmany colors). AAP saw a 15%increase in architects’ callsdirectly to its plant and morethan 1,000 postcard requestsgenerated by ads in Architec-tural Record magazine.

Excellence in SpainThree Alcoa facilities in Spainwere honored for their work-place achievements in qualitymanagement. The Alcoarolling plant in Amorebietareceived the EUSKALIT Silver Q award, which theBasque government grants to companies qualifying as aEuropean Foundation forQuality Management Modelof Excellence. Alcoa’s smelterin Avilés earned the AsturiasManagerial Quality Award2004, and the Alcoa FlexiblePackaging facility in Rubireceived the 2004 Cambra

Award from the TarrasaChamber of Commerce forits achievements in training in health and safety issues.

Tops in HungaryAlcoa Wheel ProductsEurope received the top prizein the National Quality/Excellence Award businesscategory in Hungary. Spon-sored by the Ministry ofEconomics, the award usescriteria based on the Euro-pean Foundation for QualityManagement model.

GBS Scores HighMembers of the Shared Services and OutsourcingNetwork, a global organiza-tion, named Alcoa’s GlobalBusiness Services organiza-tions (GBS) among the top ten Most Admired SharedServices organizations. GBSsupports Alcoa’s decentral-ized business unit structureby consolidating noncore systems and work in its seveninternational centers, elimi-nating redundant costs, andproviding a better platformfor decision making.

News’04

Zsolt Pittmann,Székesfehérvár, Hungary

A complete view of their surroundings keepsfloor workers safe.

21

Selected Financial Data(in millions, except per-share amounts and ingot prices)

For the year ended December 31 2004 2003 2002 2001 2000

Sales $23,478 $21,092 $19,934 $21,933 $22,010Income from continuing operations 1,402 1,055 518 904 1,451(Loss) income from discontinued operations (92) (70) (132) 4 38Cumulative effect of accounting change — (47) 34 — (5)Net income 1,310 938 420 908 1,484Earnings (loss) per share:

Basic:Income from continuing operations 1.61 1.23 .61 1.05 1.78(Loss) income from discontinued operations (.11) (.08) (.16) .01 .04Cumulative effect of accounting change — (.06) .04 — (.01)

Net income 1.50 1.09 .49 1.06 1.81Diluted:

Income from continuing operations 1.60 1.22 .61 1.04 1.76(Loss) income from discontinued operations (.11) (.08) (.16) .01 .04Cumulative effect of accounting change — (.06) .04 — (.01)

Net income 1.49 1.08 .49 1.05 1.79

Alcoa’s average realized price per pound foraluminum ingot .85 .70 .66 .72 .77

LME average 3-month price per pound foraluminum ingot .78 .65 .62 .66 .71

Cash dividends paid per common share .600 .600 .600 .600 .500Total assets 32,609 31,711 29,810 28,355 31,691Short-term borrowings 267 50 34 163 2,718Commercial paper 630 — 665 220 1,510Long-term debt 5,403 7,216 7,784 6,264 3,897

The financial information for all prior periods has been reclassified to reflect assets held for sale and discontinued operations. See Note B tothe Consolidated Financial Statements for further information.

In addition to the operational results presented in Management’s Discussion and Analysis of Financial Condition and Results of Operations,other significant items that impacted results included, but were not limited to, the following:

2004: Disposition of businesses, restructuring and other charges, changes in the provision for income taxes, the restructuring of debt andassociated settlement of interest rate swaps, the effects of the Becancour strike, the sale of a portion of Alcoa’s interest in the Jurutibauxite project, environmental charges, the termination of an alumina tolling arrangement, and discontinued operations

2003: Acquisitions and dispositions of businesses, restructuring and other charges, insurance settlements related to environmental matters,changes in the provision for income taxes, discontinued operations, and the adoption of a new accounting standard

2002: Restructuring and other charges, the adoption of new accounting standards, goodwill impairment, and discontinued operations2001: Restructuring and other charges, dispositions of businesses, and various charges to cost of goods sold and selling, general administrative

and other expenses2000: Acquisitions of Reynolds Metals Company (Reynolds) and Cordant Technologies (Cordant)

The data presented in the Selected Financial Data table should be read in conjunction with the information provided in Management’s Discussionand Analysis of Financial Condition and Results of Operations and the Notes to the Consolidated Financial Statements.

Financial and Corporate Data21 Selected Financial Data

22 Trends in Alcoa’sMajor Markets

24 Management’s Discussionand Analysis

39 Management’s Reports

40 Report of IndependentRegistered PublicAccounting Firm

41 Consolidated FinancialStatements

45 Notes to FinancialStatements

63 Supplemental FinancialInformation

64 11-Year Financial Data

66 Directors

67 Officers

68 Shareowner Information

9.4% $2.2 billion

Alcoa segments that sellproducts to this market: Flat-Rolled Products, Engineered Products, Other

Alcoa aerospace products arewidely used in the manufactur-ing of aircraft and aircraftengines, including high-technol-ogy airfoils for jet engines,fastening systems, and advancedalloys for the fuselage, wings,landing gear, and wheels. Aero-space products are also servingdefense and space applications.

More than 60% of Alcoaaerospace revenues come frompropulsion and fastening systems.

World Revenue Passenger Miles grew 11.4% in 2004 – adramatic increase from 2003negative 1.4% growth andnearly a 4% increase over 2000levels. The long-term growthtrend is expected to average 5%, driving the requirement for over 15,000 new aircraft inthe next 20 years.

Large Commercial AircraftDeliveries Rebounding – 2004marked the end of a downturnin deliveries of large commercialaircraft, increasing 3% over2003, and forecast to increase anadditional 20% for 2005, drivenby strong growth for air travel.

Alcoa Total Revenues:$23.5 billion

22

Trendsin MajorMarkets

11.5% $2.7 billion

Alcoa segments that sellproducts to this market: Flat-Rolled Products, Engineered Products, Other

Alcoa revenues in this marketcome from a range of productsfor automotive applications:from chassis, suspension, anddrivetrain components to crashmanagement systems to bodystructures, forged and castwheels, as well as wiring har-nesses and other electrical distribution systems.

A 6% to 8% fuel savings can berealized for every 10% reductionin weight from substituting aluminum for steel. Aluminumabsorbs nearly twice as muchcrash energy as steel, and duringa crash, aluminum folds like anaccordion, letting the vehicle –not its passengers – absorb moreof the crash forces. Lighter vehi-cles generally accelerate quickerand require shorter stopping distances than heavier vehicles. The Aluminum Association

25.5% $6.0 billion

Alcoa segments that sellproducts to this market: Flat-Rolled Products, Packaging and Consumer

Convenience continues to be a major trend in home food management with nearly half of U.S. homemakers saying that convenience is most impor-tant in the foods they eat.NPD Group

Reynolds brand products arewell-positioned as their primarybenefit is in ease of food prepa-ration, as underscored byReynolds Wrap achieving the #1 brand equity rating in the U.S. Harris Spring 2004 EquiTrend Brand Study.

The packaged food industrycontinues conversion from glassto plastic bottles, with packagesthat integrate the closure intothe overall bottle design. Alcoaparticipates with dispensing closures for the dairy, food, andbeverage industries. Alcoa is also a premier supplier of popu-lar printed shrink sleeve labels,designed to fit the new packages’contours and provide a 360-degree billboard for product andbrand graphics.

Alcoa supplies aluminum sheetused to make 100 billion cans each year.

Aerospace Automotive Packaging and Consumer

Aluminum Consumption for Beverage Cans billions of lbs.

Source: CRU Alcoa

0

2

4

6

8

10

03 0400 0201

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/01/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_ACforBC_02.eps

Corrections: 02/01/05: Kevin – Set up chart.

Middle East & Africa

Europe

Latin America & Mexico

U.S. & Canada

Pacific

U.S. Market – Foil, Wraps and Bags millions of dollars

Source: A.C. Nielsen – FDM with Wal*Mart Scanning

3,000

3,100

3,200

3,300

3,400

3,500

3,600

03 0400 0201

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/01/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_USM_FWB_01.eps

Corrections: 02/01/05: Kevin – Set up chart.

North American Light VehicleAluminum Content lbs. per vehicle

Source: Ducker

0

50

100

150

200

250

300

03 0400 0201

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/01/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_NALVAC_01.eps

Corrections: 02/01/05: Kevin – Set up chart.

Source: CRU Alcoa

Latin America & Mexico

Smelter-grade alumina

Total imports into CIS and China

North American Light Vehicleand Auto Sales millions

Source: Global Insight (formerly DRI)

0

5

10

15

20

03 0400 0201

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/01/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_NALT&AS_01.eps

Corrections: 02/01/05: Kevin – Set up chart.

Source: CRU Alcoa

Latin America & Mexico

Smelter-grade alumina

Total imports into CIS and China

Large Commercial Aircraft Demand 100+ passengers

Source: Various market contributors

0

200

400

600

800

1,000

05 1095 00

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/01/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_Aero_01.eps

Corrections: 02/01/05: Kevin – Set up chart.

Source: CRU Alcoa

Latin America & Mexico

Smelter-grade alumina

Total imports into CIS and China

Regional Air Travel Growthpercent

Source: Various market contributors

–5

0

5

10

15

0899 00 01 02 03 04 05 06 07

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/01/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_RATG_01.eps

Corrections: 02/01/05: Kevin – Set up chart.02/17/05: Kevin – Made minor changes.

23

6.4% $1.5 billion

Alcoa segments that sellproducts to this market: Flat-Rolled Products, Engineered Products, Other

A strengthening economy droveton-mile demand for NorthAmerica (NA) freight up in 2004.

Truck fleets and owner-operatorsare facing an even more demand-ing emissions regulations changein January of 2007.

Three elements – aging fleet (created in part due to delayedbuying around by some ownersto avoid 2002 engines), improvedeconomy, and awareness of new,even stricter emissions regula-tions – created a near-perfectstorm scenario, driving NA truckbuilds and demand up nearly50% over 2003. This pattern isexpected to continue in 2005 and 2006, with total NA heavy-duty truck builds increasing yetanother 15% above 2004 levelsin late 2005 and throughoutmost of 2006.

New products and innovationsby Alcoa will continue to helpfleets save weight and improveoverall fuel economy.

European truck build rates areexpected to increase about 5% in2005 compared to 2004, whichwere up about 5% over 2003.

Trailer builds in NA and Europe were up 29% and 5%, respectively.

10.6% $2.5 billion

Alcoa segments that sellproducts to this market: Flat-Rolled Products, Engineered Products, Other

Alcoa’s revenues in this marketare from an array of fabricatedaluminum products for commer-cial and residential applications,as well as vinyl extrusions andinjection moldings for newhomes and remodeling.

Due to slow economic recovery,nonresidential construction in Europe experienced a declineof .8% in 2004.

While most countries faced a slowdown in nonresidentialconstruction in 2004, the U.K.,Spain, and Central EasternEurope posted growth.

Nonresidential construction inNorth America increased by2.5% in 2004 to approximately$165 billion as the growingeconomy in the U.S. continues to fuel a recovery in commercialand industrial construction.

While the U.S. grew by 3%, the recovery for nonresidentialconstruction in Canada laggedbehind, posting a 20% decline.

24.7% $5.8 billion

Alcoa segments that sellproducts to this market: Primary Metals, Aluminaand Chemicals

Alcoa is the world’s largest pro-ducer of alumina, a powderyoxide of aluminum refined frombauxite ore and used to producealuminum and alumina-basedchemicals.

Alcoa alumina production in2004 rose 3.6% to 14.3 millionmtpy.

In 2004, 51% of Alcoa WorldAlumina and Chemicals’ refineryproduction was supplied to outside customers.

Aluminum ingot is an interna-tionally produced, priced, and traded commodity whose principal trading market is the London Metal Exchange, or LME.

Worldwide aluminum capacitywas 32.7 million mtpy, 8.5% ofwhich was idle.

Alcoa’s worldwide capacity isapproximately 4.0 million mtpyof which 16% is idle. With theplanned smelter restarts at ABIand Wenatchee, idle aluminumcapacity is expected to fall below 10% in 2005.

11.9% $2.8 billion

Alcoa segments that sellproducts to this market: Flat-Rolled Products, Engineered Products, Other

Alcoa’s revenues from this market include sales of aluminum sheet, plate, andextrusions to distributors andsales of products and services for power generation.

After reaching bottom in 2004,the projected heavy-duty gas turbine build rates are expectedto experience an increase of one-third in 2005. This is beingdriven primarily by the increased power demand in the Asian and Middle Eastern markets.

Growth opportunities also exist for the supply of spareparts over the next few years, as the installed turbine basefrom the U.S. boom of 1999-2001 prepares for the first round of overhauls.

CommercialTransportation

Building andConstruction

Aluminum and Alumina

Industrial Products and Other

North American Heavy Truck Production thousands

Source: ACT Research

0

50

150

100

200

250

03 0400 0201

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/01/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_NAHTP_01.eps

Corrections: 02/01/05: Kevin – Set up chart.02/02/05: Kevin – Used real data.

Source: CRU Alcoa

Latin America & Mexico

Smelter-grade alumina

Total imports into CIS and China

Aluminum Wheel Penetration in Heavy-Duty Trucks percent

Source: Alcoa

20

10

0

30

40

50

60

03 0400 0201

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/01/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_AWPinHDT_01.eps

Corrections: 02/01/05: Kevin – Set up chart.

Western Europe

Japan

North America

IGT Engine Build Schedule number of turbines

DATA:

Source: Howmet and OEM Market Analysis, January 2005

0

100

200

300

400

500

02 03 04 05E99 0100

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/17/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_IGT_EBS_01.eps

Corrections: 02/17/05: Kevin – New chart added. Set up chart.

119 32 52 12 27185 77 67 17 39284 72 96 21 23238 85 114 10 10106 69 54 5 1265 56 33 22 1288 60 60 33 17

Worldwide Aluminum Ingot Inventory millions of metric tons

Source: LME, IAI

1,000

500

0

1,500

2,000

2,500

00 02 0494 9896

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/01/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_WAII_02 .eps

Corrections: 02/02/05: Kevin – Set up chart.02/17/05: Kevin – Made chart adjustments.

LME Warehouse

Producers

Western World Alumina Demand millions of metric tons

Source: CRU Alcoa

0

10

20

30

40

50

03 0400 0201

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/01/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_ACforBC_02.eps

Corrections: 02/01/05: Kevin – Set up chart.

Latin America & Mexico

Smelter-grade alumina

Total imports into CIS and China

New Nonresidential Construction Annual Growth Rates percent

Source: McGraw-Hill Construction Data, Euroconstruct

–5.0

–7.5

–10.0

–2.5

0

2.5

5.0

03 0400 0201

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/01/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_NRCAGR_01.eps

Corrections: 02/01/05: Kevin – Set up chart.02/17/05: Kevin – Data point change, minus signs.

U.S.

Europe

U.S. Repair and Improvement Expenditures billions of dollars

Source: U.S. Census

140

130

120

150

160

170

180

00 02 0494 9896

ASA Job No. 0433Alcoa 2004 Annual ReportDate: 02/01/05Client: AlcoaJob Name: Alcoa 2004 Annual ReportFile Name: MT04_USR&IE_01.eps

Corrections: 02/02/05: Kevin – Set up chart.

Management's Discussion andAnalysis of Financial Conditionand Results of Operations(dollars in millions, except per-share amounts and ingot prices;shipments in thousands of metric tons [mt])

OverviewOur BusinessAlcoa is the world’s leading producer of primary aluminum,fabricated aluminum, and alumina, and is active in all majoraspects of the industry: technology, mining, refining, smelting,fabricating, and recycling. Aluminum is a commodity thatis traded on the London Metal Exchange (LME) and priceddaily based on market supply and demand. Aluminum andalumina represent approximately two-thirds of Alcoa’s revenues,and the price of aluminum influences the operating resultsof Alcoa. Nonaluminum products include precision castings,industrial fasteners, vinyl siding, consumer products, foodservice and flexible packaging products, plastic closures, andelectrical distribution systems for cars and trucks. Alcoa’sproducts are used worldwide in aircraft, automobiles, commer-cial transportation, packaging, consumer products, buildingand construction, and industrial applications.

Alcoa is a global company operating in 43 countries. NorthAmerica is the largest market with 64% of Alcoa’s revenues.Europe is also a significant market with 22% of the company’srevenues. Alcoa also has investments and activities in Australia,Brazil, China, Iceland, Jamaica, Russia, and Trinidad, whichpresent opportunities for substantial growth. Governmentalpolicies and other economic factors, including inflation andfluctuations in foreign currency exchange rates and interestrates, affect the results of operations in these countries.

Management Review of 2004and Outlook for the FutureAlcoa aspires to be the best company in the world. As partof that mission, Alcoa strives to attain certain financial goalsto improve both short-term and long-term profitability, whilepositioning the company to be successful in the future.

In 2004, Alcoa’s focus on long-term value creation throughliving our values, controlling costs and capital, managing ourportfolio of businesses, and focusing on profitable growthcontributed to the following financial achievements:● Significant improvement in income from continuingoperations, rising 33% from $1,055 in 2003 to $1,402 in 2004,as four of the company’s six segments increased in profitability;● Highest annual sales in company history, with revenuegrowth of $2,386 over 2003;● Strong cash flow generation of approximately $2,200 in cashfrom operations;● Strengthened balance sheet and continued cash generationthrough disciplined capital spending and payment of approxi-mately $2,000 in debt over the past two years, which facilitateda reduction in the debt-to-capital ratio from 35.1% in 2003 to30.0% in 2004; and

● The substantial completion of our divestiture plan withthe sales of the specialty chemicals business, the automotivefasteners business, the packaging equipment business, theSouth American flexible packaging business, the Russellville,AR and St. Louis, MO foil facilities, and extrusion facilitiesin Europe and Brazil.

During 2004, the company was faced with a number ofchallenges including increased costs for energy, raw materials,and a weakening U.S. dollar. Additionally in 2004, significantefforts continued in globalizing the production base as a meansto better serve Alcoa’s customers and to take advantage oflower costs to produce in certain global regions. The actionssurrounding the globalization provide unique challengesincluding exposure to foreign currency movement againstthe U.S. dollar, as well as the general business and politicalrisks involved with expanding operations in global regionswhere Alcoa does not currently have a significant presence.The company expects that it will continue to face these andsimilar challenges in the future.

To position ourselves for success in 2005 and beyond,we will work toward the following financial goals:● Continuing to reduce costs in conjunction with the three-yearcost savings challenge initiated in 2004, aimed at eliminating$1,200 in costs by the end of 2006. Cost savings are targetedto help offset anticipated higher energy and input costs formaterials such as resin and caustic. The cost savings will beachieved through continued implementation of the AlcoaBusiness System (ABS), procurement savings, and headcountreductions;● Striving to join the first quintile of S&P Industrials in returnon capital (ROC) performance and, in pursuit of that goal,we will seek to provide returns in excess of cost of capital,which is currently 9%;● Maintaining a strong balance sheet with a long-term targetfor a 25%–35% debt-to-capital ratio; and● Strengthening our asset base and improving its productivity,as well as expanding our global reach and positioning ourprimary businesses lower on the cost curve through variousstrategies including: expanding alumina refinery capacity inAustralia, Jamaica, and Suriname; constructing a smelter inIceland and expanding smelting capacity in Brazil, China, andTrinidad; expanding fabricating capabilities in Russia; investingin energy projects in Brazil, as well as various other projectsthroughout other segments of the business. Capital expendituresfor these major growth projects and other sustaining projectsare projected to be approximately $2,500 in 2005. These projectsare outlined in more detail below under Segment Information,Liquidity and Capital Resources, and Contractual Obligationsand Off-Balance Sheet Arrangements.

Forward-Looking StatementsCertain statements in this report under this caption andelsewhere relate to future events and expectations and, as such,constitute forward-looking statements. Forward-looking state-ments also include those containing such words as ‘‘anticipates,’’‘‘believes,’’ ‘‘estimates,’’ ‘‘expects,’’ ‘‘hopes,’’ ‘‘targets,’’ ‘‘should,’’‘‘will,’’ ‘‘will likely result,’’ ‘‘forecast,’’ ‘‘outlook,’’ ‘‘projects,’’

24

The company also experienced volume declines in businessesserving the commercial building and construction and industrialgas turbine markets.

Net income for 2003 was $938, or $1.08 per diluted share,compared with $420, or $.49 per share, in 2002. Net incomeof $938 in 2003 included a charge of $47 representing thecumulative effect of the accounting change for asset retirementobligations upon adoption of Statement of Financial AccountingStandards (SFAS) No. 143, ‘‘Accounting for Asset RetirementObligations.’’ Net income in 2003 also included a loss of $70from discontinued operations, comprised of a $45 impairmentcharge for the automotive fasteners business, as well as $25 ofnet operating losses from businesses to be divested.

Divestiture Plan — Alcoa’s financial statements for all periodspresented were significantly impacted by activities relatingto the planned divestiture of a number of Alcoa’s businesses.

In 2002, Alcoa performed a portfolio review of its businessesand the markets they serve. As a result of this review, Alcoacommitted to a plan to divest certain noncore businesses thatdid not meet internal growth and return measures. This planwas substantially completed in 2004 with the divestitures of thefollowing businesses: specialty chemicals, automotive fasteners,packaging equipment, South American flexible packaging, foilfacilities in Russellville, AR and St. Louis, MO, and extrusionfacilities in Europe and Brazil.

In the second quarter of 2004, certain architectural productsbusinesses in North America were reclassified from assets heldfor sale to assets held and used as management discontinuedthe plan of sale due to market conditions. The financial state-ments for prior periods have been reclassified to reflect thischange. The reclassification did not impact the Statement ofConsolidated Income, and the results of operations of thesearchitectural products businesses continue to be presented inthe Engineered Products segment.

Also in 2004, Alcoa identified additional businesses to bedivested to better focus on its core capabilities. As a result,the following businesses have been reclassified from assetsheld and used to discontinued operations for all periodspresented. See Notes A and B to the Consolidated FinancialStatements for additional information on reclassificationsfor discontinued operations.● In the third quarter of 2004, the protective packagingbusiness was reclassified to discontinued operations. A $16after-tax impairment charge was recorded to reflect the currentestimated fair value of the business. The results of the Packaging

or similar expressions. Such forward-looking statements involveknown and unknown risks, uncertainties, and other factorsthat may cause actual results, performance, or achievementsof Alcoa to be different from those expressed or implied in theforward-looking statements. For a discussion of some of thespecific factors that may cause such a difference, see Notes Nand Y to the Consolidated Financial Statements and the disclo-sures included below under Segment Information and MarketRisks. For additional information on forward-looking statementsand risk factors, see Alcoa’s Form 10-K, Part I, Item 1.

Results of OperationsEarnings SummaryAlcoa’s income from continuing operations for 2004 was $1,402,or $1.60 per diluted share, compared with $1,055, or $1.22 pershare, in 2003. The highlights for 2004 include: higher realizedprices for alumina due to a tightening of the world aluminamarket, as well as higher realized prices for aluminum as LME

prices increased by 20% over 2003 levels; increased sales acrossfive of six segments; higher volumes in downstream businessesserving the commercial transportation, building and construc-tion, aerospace, and packaging markets; improved profitabilityacross four of six segments; a $38 gain related to the retirementof debt and associated interest rate swap settlement; a $37 gainon the sale of a portion of Alcoa’s interest in the Juruti bauxiteproject to Alcoa World Alumina and Chemicals (AWAC); a $15gain on the termination of an alumina tolling arrangement; andcontinued focus on completion of divestitures, which includeda $61 gain on the sale of the specialty chemicals business.

Partially offsetting these positive contributions in 2004were: significant cost increases for energy and raw materials;the impact of a weakened U.S. dollar against other currencies,primarily the Australian and Canadian dollars and the Euro;the impact of a strike at the Becancour smelter; a $41 increasein environmental and legal reserves, principally related to theGrasse River site and El Campo; and the absence of $79 ininsurance settlements that occurred in 2003.

Net income for 2004 was $1,310, or $1.49 per diluted share,compared with $938, or $1.08 per share, in 2003. Net incomeof $1,310 in 2004 included a loss of $92 in discontinuedoperations, comprised of $89 in impairment charges to reflectthe estimated fair values of the protective packaging business,the telecommunications business, and a small casting business;net operating losses of $8; slightly offset by a net gain of $5on divested businesses. See details of the divestiture plan below.

Alcoa’s income from continuing operations for 2003 was$1,055, or $1.22 per diluted share, compared with $518, or $.61per share, in 2002. The increase in income from continuingoperations was primarily due to higher realized prices foraluminaand aluminum; improved profitability across all segments;significant restructuring charges that were recognized in 2002;higher equity income; recognition of insurance settlementsof a series of environmental matters in the U.S.; and a lowereffective tax rate. Partially offsetting these increases were higherenergy, employee benefits and raw materials costs, as well as theunfavorable impact of the U.S. dollar against foreign currencies.

25

and Consumer segment have been reclassified to reflect themovement of this business into discontinued operations.● In the fourth quarter of 2004, the telecommunicationsbusinessand a small casting business in the U.K. were reclassified todiscontinued operations. Impairment charges of $63 (after taxand minority interests) for the telecommunications businessand $10 (after tax and minority interests) for the castingbusiness were recorded to reflect the current estimated fairvalues of these businesses. The results of the Other group havebeen reclassified to reflect the movement of these businessesinto discontinued operations.