AIR Studio

description

Transcript of AIR Studio

AIR

Bohemia HookhamSemester 1, 2014

Contents1 About me

4 Part A1: Design Futuring

10 Part A2: Computation

16 Part A3: Composition/Generation

26 A4: Conclusion

26 A5: Learning Outcomes

28 A6: Appendix - Algorithmic Sketchbook

30 Bibliography

34 Part B1: Research Field: Tessellation

38 Part B2: Case Study 1.0

46 Part B3: Case Study 2.0

52 Part B4: Technique: Development

62 Part B5: Technique: Prototypes

72 Part B6: Technique: Proposal

78 Part B7: Learning Objectives and Outcomes

80 Appendix - Algorithmic Sketchbook

82 Bibliography

86 Part C1: Design Concept

92 Part C2: Tectonic Elements

96 Part C3: Final Model

99 Part C4: Additional LAGI Brief Requirements

104 Part C5: Learning Objectives and Outcomes

106 Bibliography

About meArchitecture has always been something that I’ve been drawn to. Before beginning this degree, however, I took a gap year to “find myself” in the beautiful country of Argentina. There, I fell in love with Spanish and Latin American culture, even the more gritty parts of it that most tourists never see – the realness.

From my year in Argentina I realized that I definitely wanted to study architecture, but that I didn’t ever want to work in a desk job. I want to be able to travel and work in developing countries, particularly in the architectural field.

In saying that, I also find myself constantly being inspired by parametric designs, whether it’s actually a building, furniture, an art installation, or whatever. Incorporating “sustainability” into my designs is also something I want to achieve in the future and I’m looking forward to exploring these fields in this class.

As well as my love for anything Spanish related I also enjoy rock climbing on a weekly basis, photography, art, philosophy, sleeping in, and wine.

1

Part A: ConceptualisationThis section of the journal examines parametric approaches to design in comparison to traditional methods

A1: Design Futuring

The world we live in today is no longer one with unlimited resources. In fact, it never was, but we never saw the possibility of causing such ecological damage to our planet. Our future on this planet depends on our ability to successfully create a “sustainable” environment, as we can no longer depend on nature alone to sustain us. As we are living now, we depend too much upon the artificial worlds that we have designed, fabricated and occupied. And it is through this process of creation that we have damaged our own environment, e.g. – “the omelette at the cost of the egg, the table at the cost of the tree, through to fossil fuel generated energy at the cost of the planet’s atmosphere” [1].

With this damage of the planet’s atmosphere, not only do we see changes in temperatures globally, weather patterns, melting of polar ice shelves, etc., but we also see damage to biodiversity, human settlement patterns, agricultural systems, human health and more [2].

To address these problems in a more immediate fashion, the design world needs to take a more active part. But here is the problem – we have no idea how bad things will get, or when they will get to the ‘tipping point’ and cause huge environmental issues globally. So the time to act is now.

By rethinking the way we think about designing and all of its true possibilities, we can begin to work towards a more sustainable future.

The LAGI - Land Art Generator Initiative - in Copenhagen gives us an opportunity to explore what we, as designers can achieve in terms of art for sustainable cities. By 2025, Copenhagen will become the first carbon neutral capital. Asking us to take a multidisciplinary approach, the competition allows designers to think outside the box and requests that the art installation generates clean energy.

4

InteractiveWallHyberbody Research Group

The InteractiveWall is an interactive wall of seven individual parts, each 1.2m wide and 3.6m high that taper up from 300mm thick to a thin edge along the top. The project uses hidden pneumatic ‘muscles’ that contract in length when pressurized and it picks up signals from sensors that respond to movement, light and sound. Each wall component can also move at it’s own will. But it allows users to interact with the wall in a very sensitive way.

6

http://studiolab.ide.tudelft.nl/ie/2011/09/interactive-wall/

http://studiolab.ide.tudelft.nl/ie/2011/09/interactive-wall/

Rather than focusing on being a “sustainable” art installation, this project draws its attention to the exploration of “emotive architecture”. One that can simulate human emotions and somewhat evoke an emotional response in the viewer.

The goal is to personify the architecture and make it more relatable to people. This idea of personification in terms of the walls’ movements draws viewers in. It creates interest and intrigue in the way that it responds to human movement and sound, but also in the way that it can move by itself, as if it is a real, living wall.

By taking the interaction principals of this design and applying them to an art installation that aims to inform the public about sustainable options, people can take a much more active part in understanding the current resource problems and solutions.

There are limitations to producing a “wall” similar to this, however, as it requires some kind of energy source that is not incorporated into the design. The design also forces the project to be displayed in an environment that protects it from the elements and realistically is only suitable for a handful of viewers at once.

7

http://studiolab.ide.tudelft.nl/ie/2011/09/interactive-wall/

http://studiolab.ide.tudelft.nl/ie/2011/09/interactive-wall/

StrandbeestTheo Jansen

Since 1990, Theo Jansen has been making these “strandbeests” which he sees as life forms, out of plastic yellow tubes. They are designed to walk on the beach on their own, only being powered by the wind. In the design of these “strandbeests”, meaning “beach beasts” in Dutch, Jansen combines his engineering knowledge and art to bring them to life.

Compared to other projects that generate energy or use energy in some kind of way to do something, this one is quite different in that it simply uses wind power to move. There is no further generation of energy and it’s as if it’s a single organism that only needs a gust of wind to survive.

It was Theo Jansen’s aim, in fact, to construct a number of these “stranbeests” and leave them in the “wild” to their own devices. He wanted to explore how these objects can learn, develop and evolve over time on their own.

A similar system to these strandbeests could be designed, but instead allowing them to somehow generate energy from wind and move about the site in a more ordered fashion. This would engage users more with the design – perhaps allowing them to have some form of “interaction”.

8

While at the moment the strandbeests currently do not produce energy, they are admired as a piece of art. A living art.

The engineering side of the strandbeests also generates further research areas into new forms of wind generation. In their design, Jansen used sail-like materials to control the strandbeests movement. Most wind technologies today, however, are huge fiberglass turbines placed in some kind of “wind farm” far away from the general public’s eyes.

Incorporating the element of art in wind generation design allows designers to think more creatively about the end product. They are required to think about their users. For example, the consumers of the energy, who will see the wind turbine or “strandbeest” wind generator in their daily lives.

http://www.purselipsquarejaw.org/2008/01/making-new-forms-of-life.php

http://www.strandbeest.com/

http://inhabitat.com/strandbeest-theo-jansens-kinetic-sculptures/

A2: Computation

“Design is the epitome of intelligent behaviour” [3].

Over the last two decades digital design has developed to bring us far more options than we ever could have imagined.

There is a difference, however, between computerization and computation [4]. Computerization is somewhat like using old forms of architecture and then translating it into new software. Computation, on the other hand, takes advantage of algorithmic functions that these programs provide us with and allows us to design forms and shapes that the human mind could not do alone.

Curvilinear surfaces and volumes became the preference for digital design with Gehry’s Guggenheim in Bilbao being one of the first designs to achieve this using such software. The parametric forms of these computation designs mean that previous limitations can be breached and we, as designers, can explore the possibilities of using algorithms. In designing using the computational technique, however, “designers might not need to use matrix mathematics directly” [5] but knowing the basic principals is still quite useful.

There are some situations when using a computer for the purpose of design is not that beneficial. For example, they lack the creativity that we have as human beings. In an ideal design world, we would make use of our skills in “creativity and intuition”, and where we fall short, we would use the “superb rational and search abilities” of computers [6].

10

Bloom

Alisa Andrasak & Jose Sanchez

Bloom, commissioned by the Greater London Authority during the summer of 2012 in celebration of the London Olympics, and designed by Alisa Andrasek and Jose Sanchez is a toy that encourages creative play. It is a reconfigurable system of 60,000 recyclable plastic cells in the official Olympics colour of neon pink. As Andrasek herself says, “it’s a game, and, as in complexity theory, the simplest generic element can recombine”.

At each of the three venues in London during the summer of 2012 – the UCL quadrangle, Victoria Park near the Olympic Park site and in Greenwich, these pink plastic toys could be found. People could also potentially take them home as a souvenir, but what the components really symbolize is the participation in collective play. In comparison to typical art projects where viewers are not permitted to touch anything, in this circumstance, that was the whole point.

12

http://www.archdaily.com/269012/bloom-a-crowd-sourced-garden-alisa-andrasek-and-jose-sanchez/

Each of the components is of the same shape and thousands of possibilities exist in the act of “play”. In a way, the design team uses a form of tessellation and fractals to understand the design’s capabilities in terms of its joinery.

In fact, the team used both Rhino and Grasshopper to realize their concept. Even taking a fairly straightforward shape and repeating it through computation, the design possibilities become endless with parametric programs such as Rhino and Grasshopper.

Without applying computational techniques to the design, it could still have been produced, however. It would just have taken much more time.

These individual tessellating pieces could have been pre-designed and then put into the computer (a computerization approach) to then be digitally fabricated. The design team, however, would not have come up with the same result. Theirs would have probably been much more simplified if using computerization methods.

By computationally approaching their challenge, the Bloom team was able to produce unexpected results. Results that were optimized for their goal – a plaything of thousands of identical pieces with unlimited design possibilities.

http://www.designboom.com/design/bloom-urban-toy-sculptures-by-alisa-andrasek-and-jose-sanchez/

One Main Street

dECOI Architects

This project was a refurbishment to an office floor in Boston, Massachusetts. Using digital manufacturing processes, the architects were able to explore new design options that were perhaps not as prevalent in previous times with more analogue forms of design and production.

By using one system of fabrication for the whole building (except for the glass), a streamlined affect is achieved that makes the project feel as if it is one singular living organism. Also by doing this speed and economy are kept in mind to improve the efficiency as much as possible.

The materiality is the main focus of this project as the clients were interested in clean energy and green buildings and wanted the interior to reflect alternative ways of achieving this. What is really beautifully done in this project is the way the plywood appears to have qualities of plasticity and malleability. The pristinely cut curved forms and lines (typical of parametric design) of the plywood when put together adds a sense of environmental awareness and admiration.

The ceilings, walls, floors, furniture, door handles, etc. were all manufactured from sustainably forested plywood. The floor and ceiling are articulated as continuous surfaces that, as well as being aesthetically pleasing, form functional parts in the form such as benches.

The parametric form also works in a variety of other functional ways, e.g. – the ventilation grills that warp to the shape of the ceiling, or the bumps and valleys in the floor used to capture the glass. Both of these components could have been designed both computationally or computerized, but the benefits of doing it computationally are always focused on the element of time.

14

15

The design as a whole could have also been achieved using either a computational or computerized approach. The end results, however, would have been quite different. In starting the project, the architects obviously had quite a clear idea of the kind of results they wanted to achieve. So, it may be considered that they used computerization methods. In the process of designing, results could have been changed by then applying at computational approach. Inconceivable geometries – ones that the human mind cannot think of alone – are often the result of this.

In this project, the architect became fully in control of every detail of the fabrication process. “Machine-age manufacturing logic shifts to digital fabrication processes” [7].

http://tomorrowawards.com/showcase/555/one-main-street-interior http://www.decoi-architects.org/2011/10/onemain/>

16

A3: Composition / Generation

“When architects have a sufficient understanding of algorithmic concepts, when we no longer need to discuss the digital as something different, then computation can become a true method of design for architecture.” [8] Architecture is making a huge shift in the way that it is being redefined by computation. Software and tools are being developed that give architects the opportunity to simulate building performance, construction methods, and to visualize their designs like never before.

This method of computation, as defined by Sean Ahlquist and Achim Menges is “the process of information and interactions between elements which constitute a specific environment; it provides a framework for negotiating and influencing the interrelation of datasets of information, with the capacity to generate complex order, form, and structure”. [9]

Computation can provide us with inspiration and can go beyond our own design intellect to generate unexpected results. [10] In terms of construction methods, computation has now become necessary in a lot of built projects (in particular larger ones) all over the world. As Mouzhan Majidi said “this hasn’t simply transformed what we can design – it’s had a huge impact on how we build” [11]

It also enables new ways of thinking, but computation still needs to be integrated as an intuitive and natural way to design. People tend to still look to older methods of design and architectural practice because it is the known. What we need to do is look towards the future – the algorithmic future of architecture.

When investigating new ways to generate “clean energy”, there are a few main categories that need to be noted – solar, wind, water, bio and other. Within each of these categories a variety of systems are available, some obviously being more effective than others.

Designers and architects in today’s society are becoming more and more interested in these options. In making their projects have some kind of quality that allows them to put the stamp of “sustainability” on them. But is this enough? We need to make a collective effort worldwide to create a carbon neutral environment. We need to put the focus and importance back onto nature because we are running out of these natural resources that we are desperately in need of with our ever-growing population.

These new and innovative forms of generating energy allow us to make a difference, however somewhat small, to the environment. Designing a public art space that generates clean energy might be a small step towards a sustainable future, but it is a step in the right direction.

By using computation techniques to create interesting forms and new architectural ideas, and focusing on our goal of a sustainable future, we have the ability to make drastic changes to the design world and the real world.

17

ColumnsMichael Hansmeyer

18

http://www.yatzer.com/Ornamented-Columns-by-Michael-Hansmeyer

19

In this project, Michael Hansmeyer explores subdivision processes in designing a new column order. The architect, in this instance, designs a process that produces a column (or form), rather than the column directly. In this process in particular, Hansmeyer chose to look to nature for inspiration, but avoiding biomimicry. He wanted to see what kinds of forms we as architects could create if we could free ourselves from our experiences, our education and if we had no biases, preconceptions or references.

What’s different in this design process compared to traditional ones is that subdivision generates a form at all scales – from the overall design, to the microscopic. This is something that computer technology allows us to do in minutes, but with traditional analogue methods would take hours and hours. So, what Hansmeyer does, is he brings the structure into the computer using algorithms and starts with a simple volume (a cube, for example) and folds the surfaces. By using the computer, we free ourselves from physical restraints.

These columns show us how algorithmic subdivision allows us to create a variety of forms using similar techniques and algorithms. Even with slight variations, the results can be vastly different and by undertaking this process we can further understand our design process. We can eliminate those that are perhaps not as aesthetically pleasing or functional, and we can cross-breed the results to create even more.

But in terms of the production process, technology is still a lot slower. The full-scale prototype measuring 2.7m high was fabricated using 1mm sheet and each was individually cut using a laser cutter. These sheets were stacked on top of one another and poles run through the middle of each column to create the core and hold them together. Six million faces of the 3D model were intersected to fabricate the sheets. It is improving, however, and one day we will be able to create forms like these that we couldn’t have even dreamt of with ease.

Responsive Technology

20

The following two precedents use parametric software, taking on a computational approach. They are both related to responsive technology, an interactive form of architecture that enables users to learn from the space in real-time. With inbuilt sensors to detect motion, light, and sound, these projects and other similar ones react according to their changing surroundings or users.

This kind of technology is extremely beneficial in a learning environment, particularly when in relation to subjects of clean energy. In some projects, people can generate the energy themselves that is then used to power the project in some kind of way.

http://www.evdh.net/sonohouse/

http://www.designboom.com/design/ecologicstudio-algorithmically-conceive-meta-follies/

Son-O-House

NOX

22

http://unamaquinalectoradecontexto.wordpress.com/2011/08/27/nox-lars-spuybroek-3/

The Son-O-House, located in Son en Breugel, the Netherlands is a public pavilion designed by NOX. The structure is not only an architectural installation, but also a sound installation that uses sounds composed by Edwin van der Heide. The building continuously generates new sound patterns that are activated by sensors picking up actual movements of the visitors. The visitors, however, do not directly influence the music, as it common for interactive art. Instead, the “score is an evolutionary memoryspace that develops with the traced behaviour of the actual bodies in the space” [12].

To achieve the form, computation techniques would have been adopted. The form is very free flowing and natural, but is juxtaposed with the choice of materials that give it a harsh edge. The steel and metal structural and aesthetic elements of the design make it seem quite industrialized, which is actually quite fitting as it’s located in an industrial park.

The three-dimensional porous structure [13] looks similarly like the effect when combing, curling or parting hair. The vaults are interlaced with one another and sometimes intersect, or simply rest on the adjacent one.

23

The pavilion acts as a place of rest for users who work around the area. The sounds are calming and the interesting parametric form draws people in. As stated earlier, parametric forms like these interest people, as they are unimaginable. They can only be designed and understood completely in a 3D form, which the computer allows us to do.

The Son-O-House almost becomes an individual organism. In the same way as other organisms live off one another, the Son-O-House needs interaction with people to generate its sounds. It is an architecture that explores forward thinking in technology.

The form of the design could have come about either computationally or by being computerized, but the technical elements of the design – the sensors, etc. would have been thought out beforehand, and then computerized.

META-follies

ecoLogicStudio

META-follies was conceived algorithmically as a spatial mechanism that aims to engage the user in a playful dialogue. Over time, it will keep evolving algorithmically across different regions, cultures, languages and environmental contexts. The project attempts to substitute nature and confronts the artificial world we ourselves have created in our urban landscape. Embedded in the architectural skin are 300-piezo buzzers in 4 different tones that collectively sound like a swarm of crickets.

The main principal of the project was to confront users with the idea of urban trash in our artificial world. In a big city like Melbourne, you can still find “natural green spaces”, but more often than not, these have been planned. They are therefore some kind of artificial nature.

The idea of urban trash is one that is now so integrated into our society that we barely even notice. We dispose of products, landscapes, media content, attitudes and lifestyles without considering the outcomes of such disposal. The project makes use of this “urban trash” and was fabricated using recyclable materials to create artificial nature.

A project like this, however beautiful it may be, does bring awareness to people about the environment and the damage we are doing to it, but only if the project is fully understood. This is the problem with a lot of public art. It is aesthetically pleasing and people tend to appreciate it for just that, rather than delving into the true meaning and aim.

24

META-folly attempts to answer questions about the future convergence of cybernetics and environmental psychology, digital computational design and parametricism, digital craftsmanship and DIY interaction design, radical ecological thinking and material activism [14].

The world of architecture is heading this way, too; towards a multidisciplinary approach that push designers to create things that have never been seen before. Environmental psychology is something that is currently influencing the whole world as we’ve come to a realization that our resources are limited. The design world is adapting to this, in particular architecture, to create designs that somehow benefit our environment (or perhaps don’t do as much damage to it as before).

As architecture shifts into the digital age more and more every day, these fields have combined to bring about a new architecture that embodies the Zeitgeist. In the future, similar experimental projects like this one will become more common, especially with the focus of environmental sustainability and computational techniques.

25

http://www.ecologicstudio.com/v2/project.php?idcat=3&idsubcat=66&idproj=120

A4: Conclusion

A5: Learning Outcomes

The field of architecture is currently in a stage of transition to digital design. But the design world also needs to focus on ways to generate clean energy if we want to have a foreseeable future on this planet. We are depleting our resources and need to come up with new solutions fast. By combining new technology in energy generation with computational architecture we can theoretically build highly successful spaces that attend to our needs. Designers, architects, engineers, etc. need to focus on sustainability to create functional and aesthetic designs.

In attempting to understand Grasshopper and how algorithmic design works, I have developed a new respect for the field. I feel as if I now understand a lot more about computation design in comparison to computerization. Before this I didn’t really expect that designers go into a project not knowing what the results would be. I always imagined that there would be some kind of idea of the end point. This technique still seems quite alien to me, but I have learnt to appreciate it and admire the resulting designs.

26

27

A6: Appendix - Algorithmic Sketchbook

28

A6: Appendix - Algorithmic Sketchbook

29

Bibliography

dECOi Architects: One Main Street, 2011, < http://www.decoi-architects.org/2011/10/onemain/>

Definition of ‘Algorithm’ in Wilson, Robert A. and Frank C. Keil, eds (1999). The MIT Encyclopedia of the Cognitive Sciences (London: MIT Press), pp. 11, 12

Ferry, Robert & Elizabeth Monoian, ‘A Field Guide to Renewable Energy Technologies’’, Land Art Generator Initiative, Copenhagen, 2014. pp 1 – 71

Ferry, Robert & Elizabeth Monoian, ‘Design Guidelines’, Land Art Generator Initiative, Copenhagen, 2014. pp 1 – 10

Frac Centre: META-FOLLIES, < http://www.frac-centre.fr/_en/exhibitions/in-site/archilab/ecologicstudio/meta-follies-580.html>

Fry, Tony (2008). Design Futuring: Sustainability, Ethics and New Practice (Oxford: Berg), pp. 1–16

Hyperbody: InteractiveWall, 2009, <http://www.hyperbody.nl/research/projects/interactivewall/>

Issa, Rajaa ‘Essential Mathematics for Computational Design’, Second Edition, Robert McNeel and associates, pp 1 - 42

Kalay, Yehuda E. (2004). Architecture’s New Media: Principles, Theories, and Methods of Computer-Aided Design (Cambridge, MA: MIT Press), pp. 5-25

Materiability, research network, 2014, <http://materiability.com/>

Michael Hansmeyer, 2014, < http://www.michael-hansmeyer.com/>

Oxman, Rivka and Robert Oxman, eds (2014). Theories of the Digital in Architecture (London; New York: Routledge), pp. 1–10

Pavegen: Technology, 2014, <http://www.pavegen.com/technology>

Peters, Brady. (2013) ‘Computation Works: The Building of Algorithmic Thought’, Architectural Design, 83, 2, pp. 08-15

Review: Land Art Generator Initiative Competition Entries, 2012, <http://landartgenerator.org/LAGI-2012/>

Son-O-House, 2002, <http://www.arcspace.com/features/nox/son-o-house/>

Terzidis, Kostas (2003). Expressive Form: A Conceptual Approach to Computational Design (New York: Spon Press)

Theo Jansen’s Strandbeest, <http://www.strandbeest.com/>

30

Footnotes

1 Fry (2008), pp. 4

2 Fry (2008), pp. 4

3 Jacob Bronowski, in Kalay (2004), pp.1

4 Terzidis (2003)

5 Issa, pp.16

6 Kalay (2004), pp. 3

7 dECOi Architects: One Main Street, 2011, < http://www.decoi-architects.org/2011/10/onemain/>

8 Peters (2013), pp. 12

9 Peters (2013), pp.10

10 Peters (2013), pp.10

11 Peters (2013), pp.14

12 http://www.arcspace.com/features/nox/son-o-house/

13 http://www.arcspace.com/features/nox/son-o-house/

14 http://www.frac-centre.fr/_en/exhibitions/in-site/archilab/ecologicstudio/meta-follies-580.html

31

Part B: Criteria DesignThis section of the journal explores how major options are evaulated, tested and selected.

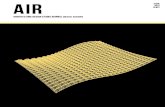

B1: Tessellation

This week, the team has chosen to focus on the research field of tessellation. It may also be explored for the continuation of Part B and was chosen due to the versatility and the possibilities, in particular by using parametric design. Tessellation and other research areas such as patterning, strips/folding, sectioning and geometry all overlap with one another in some way or another, but tessellation focuses more directly on the way the different components interlock. The way they create a repeated pattern (that may differ slightly) to construct one overall form.

There are major benefits in utilizing parametric design tools as opposed to conventional and more traditional ways, in particular when focusing on tessellation. If the designer was using conventional design tools, while in the design process and constantly changing and adapting components, “this reworking [would be] manual”1 and extremely time consuming. “Tools like these can limit exploration and effectively restrict design.”2

The elements of these conventional works are independent from one another, and make use of generic concepts such as cut, copy and paste for editing purposes. Parametric modeling, on the other hand, focuses on the design as a whole and works off the relationships each component (or, element) has with each other. In terms of tessellation, the parametric approach allows for quick changes to the overall outcome, a highly rewarding and beneficial technique to explore options.

The system, while may be challenging for those used to conventional methods, is a very practical one, forcing the designer to think logically about how the components relate and interact. But, like any skill, such as drawing, with practice comes perfect.

The concept of sketching as something that designers have always done and as the way that they work3 does become slightly challenged with parametric modeling. It’s easy and natural for anyone to pick up a pencil and scribble or sketch something out, as it’s what they’ve done since a child. But new generations, especially architects, see the digital sketch as something more natural as the media at hand available to students is mainly of that nature.

34 http://www.suckerpunchdaily.com/2014/03/27/p3-workshop-p3-pavilion/

B1: Tessellation

The P3 Workshop/Pavilion project to the left focuses on applied physical forces to generate catenary arches which influence the form. It uses tessellation techniques, composed of 570 triangular elements of plywood that use classical wood joint systems. This reduces the labour and time needed to construct other elements of joinery in different materials.

Each of these plywood panels join together seamlessly in a way that would not have been quite so simple to adapt and change without the aid of parametric modeling techniques. The joinery is particularly interesting in this project and should be explored once the team arrives at the iterations and designing stages.

These kinds of fabrication options are readily available to us and would be much simpler than trying to obtain unconventional materials. We do need to keep in mind, however, that our project needs to be interesting and to generate energy in some kind of way to fit into the LAGI brief.

As a team, we have decided that we want our project to move in some kind of way that will be used as an educational tool for visitors to the site, teaching them about energy generation. In the next section I will discuss our selected material system.

It is, however, also interesting to note that the people involved in the project claim to be influenced by Gaudi, Frei Otto, Buckminster Fuller, David Rutten and Daniel Piker, almost all associated with parametric design in some way or another.

They also comment that during the process of the project they were reading texts such as Kostas Terzidis’s Algorithmic Architecture, a text that we have been asked to confront to aid us in our own explorations throughout this project.

This shows how around the world, other students are confronting the new world of parametric design in a similar way to us, and thus making parametric design approaches global.

P3 Workshop / P3 PavilionSebastion Bialkowski, Tudor Cosmatu, Alexander Kalachev

35http://www.suckerpunchdaily.com/2014/03/27/p3-workshop-p3-pavilion/

B1: Material SystemElectroactive Polymers with Solar Film

http://materiability.com/phototropia/

B1: Material System

Electroactive Polymers change their size, shape or volume in response to strong electrical fields. They can be easily deformed, have a low density, and are extremely lightweight. They have a rather slow response speed, however.

The fabrication process requires several different layers for each “panel” or “tile” – a silicon insultion layer, conductive powder, 5x prestretched acrylic polymer film, another layer of conductive powder, another silicon insulation later, an acrylic frame and a 5,000 V power connection. For us, this makes the fabrication process quite challenging, as we are limited with time and money.

They have a natural or organic movement, which is what we want in our design, but after finding this project on the left, we saw many limitations in the actual design possibilities.

We wanted to use these electroactive polymers with a layer of solar photovoltaic film attached to the outer skin, which would mean that the composite system would be generating its own energy to move itself.

Phototropia is only at early stages of development and research, however, so our project may not be physically possible in terms of the way we want it constructed. It’s an interesting project to keep an eye on, though.

With further exploration of our design in the next stages of part B we will be exploring our design’s form and tessellation patterns, which will in turn inform the mode of energy generation, as will be seen later on.

PhototropiaManuel Kretzer

37

B2: Case Study 1.0

The Voussoir Cloud’s tessellation was achieved first by establishing the form, very similar to the vaulted ceilings of Gaudi. Triangular shapes cover the form (referred to as petals), growing in size from the base where they connect to the ground, up to the “ceiling”.

The triangulated forms are somewhat misshapen, in that they have curved edges, some which are more curved than others. The removal of some of these “tessellation” triangles also opens up the space, making it feel more light and airy for users.

The team used a geometric and computational strategy in Rhino to develop the curvature of each petal. The petals have greater offsets and more curvature towards the top of the structure which aids in creating the “dimpled effect”4 on the interior.

The project aims to produce “sensorial effects”5 upon visitors by using light and porous materials in compression. The overall aesthetic quality of the space is thus very visually pleasing.

In terms of the fabrication of this project, once each of the 2,300 petals is laser cut, they are folded along the curved score lines and zip tied together. This makes the fabrication process quite fast and simple.

If zip ties were used in our project, however, we’d need to make specific holes for joinery for them in the computational design stage. For our project in particular, the joinery of each tessellated component is very important. It needs to be thought out carefully to allow for some movement of the components.

The following pages include our team’s explorative iterations of the Voussoir Cloud project using Grasshopper. This allowed us to explore the numerous possibilities of the initial design stage when in Grasshopper, which will be highly beneficial in the next following stages.

Voussoir CloudIwamoto Scott

38

B2: Case Study 1.0

http://www.iwamotoscott.com/VOUSSOIR-CLOUD

39

B2: Case Study 1.0 Voussoir Cloud

Cull Faces Boolean set at false, false, true, false

Cull Faces Boolean set at true, false, false, true

Cull Faces Boolean set at true, false, true, true, true

Cull Faces with change to (F) factor on scale to 1

Cull Faces with change to Z-value on Move to -6

Popgeo added to loft Sphere (smaller)

Popgeo added to loft Sphere (larger)

Cull faces - Deconstruct Mesh - Surface Grid. An attempt to turn mesh to surface for panelling

Cull faces - Deconstruct Mesh – SrfGrid – Map Srf - From TriGrid – Con – Map Srf. Failed attempt to turn mesh into surface

Cull Faces – Medges – EdgeSrf – Cull Faces – false, false, false, true, false, false

SubdivisionWblaplace - L set at 2WbThicken

Subdivision - Wblaplace - L set at 2 - WbThicken - Wblaplace

Species 1

B2: Case Study 1.0 Voussoir Cloud

Cull Faces Boolean set at true, false, true, true, true

Explode (Offset)Normal Loft from Vertices

Offset - Original Surface

As before, change to height

Create Brep - From Offset Attractor point - positioned at center of BrepExtrude: Vector = Attractor point

Offset: Distance = 1.6Divide Srfs - Edges - Edges Srf

As before. Arbitrary changes to Number SlidersExtrude, Z plane: Height = 7.80 units, Cell

Width = 0.686.

Offset: Height = 7.80, Width = 0.686Explode - Loft with Edges

Species 2

41

Scake (R-Int): -0.470Move (In Z): -6.0MeshUV: U=3, V=3

Attractor Point: Dist to PointMove = 0.392, Pt at 0,0,3, 0 00Geometry Moved in Trans Vec

Loft Styles: Straight, Rebuild Point Attractor: Moved randomly

Voronoi: Radius = 3.0 + Addition of 14 pointsCrv (R-Int)= 1.5, Z Move) = 8.2

Loft Styles: DevelopableMesh Edges - Preview On Scale (R-Int) - 0.67

Loft Styles: Re-build CurveVoronoi - Radius = 1.5

Species 3

Voronoi: Radius = 6.0 Attractor Point: Moved randomly

B2: Case Study 1.0 Voussoir Cloud

42

Loft (from new Rhino Curves)TimSolid - With new LoftExtrude (in Z-Vector): 6 units

WarpWeft: Trimmed MeshTrimmed Mesh: Preview Off

Extrude Trimmed Mesh: 10.0Trimmed Mesh: Preview On

Voronoi: Radius = 2.0Trimmed Mesh: Preview Off

Species 4

Scale (R-Int): 1.0Loft Styles: Developable, Align Sections

Offset Curve (from scaled geometry) = 0.25BoundarySrf: from Offset

SrfDiff (Boundary Offset Crvs) DeBrep - Explode Tree - Faces - SurfDiff: 01, 05, 08, 10, 14, 15, 17

Original Mesh: Preview Off Extrude (in Z Vector): 5 UnitsVoronoi: 12 Points removedSurfDiff: 00, 01, 03, 05Attractor point: Moved randomly

B2: Case Study 1.0

1 2

3 4

44

In doing these iterations of the Voussoir Cloud, it seemed as if each of us individually were less interested in the idea of tessellation. The iterations on the last page somewhat resemble a tessellated form, but in a much more rudimentary way. Perhaps in doing these iterations in Grasshopper, it proved much easier to simply change the form, rather than the tessellation.

At the end of the process, the iterations did not resemble the initial Voussoir Cloud project, showing how we, as architects, can create unexpected results that have not been preconceived.

In our selection process of the iterations, we used to following criteria;

1. ABIDES BY BASIC TESSELLATION PRINCIPLES

2. CAN BE UNROLLED / DEVELOPABLE POTENTIAL

3. IS VISUALLY INTERESTING COMPARED TO OTHERS

4. HAS STRAYED FAR FROM ORIGINAL ALGORITHM

5. CAN INCORPORATE PREFERENCED MATERIALS

6. CAN BE ENHANCED FURTHER IN GRASSHOPPER

B2: Case Study 1.0

The first chosen iteration was selected due to it’s form, which if using Electroactive Polymers for the tessellation panels, would fold into one another and then expand when an electrical current runs through them. The form implies folding of elements onto one another to create a layered effect, which could be achieved using Electroactive Polymers.

The second iteration was a fairly simple tessellation pattern and had the potential to be developed and/or unrolled. In a way, this iteration implies how the underlying structure could function underneath our tessellated pattern.

The next iteration was chosen due to its aesthetic qualities and the ability to change results quite quickly with a point attractor. This iteration could be used as an interactive system that changes shape due to changing environmental conditions. Spaces could be made between each of the jutting our forms in order to allow for pedestrian access through the site.

The final iteration was chosen due to its visual interest, and tessellation pattern. It doesn’t expand enough, however, from the original Voronoi input. This kind of pattern however could be used for stairs in the site leading up to a specific point.

45

B3: Case Study 2.0

B3: Case Study 2.0 Dragon Skin PavilionEmmi Keskisarja, Pekka Tynkkynen & LEAD

The Dragon Skin Pavilion originated as a workshop with Finnish architecture students and developed to form an experimental pavilion. It was constructed with 163 unique pieces of post-formable plywood and each piece somewhat seamlessly slides into the next. The plywood components each form a triangulated shape, that when put together look like scales, thus earning its name – Dragon Skin Pavilion.

The design intent of the project was to explore spatial, tactile and material possibilities in the architectural world of digital fabrication and manufacturing technology.

The patterns formed in the naturally occurring tessellation create ornament in the structural elements. So, in this way, the scales act structurally and aesthetically, different to conventional architecture, which typically separates the two.

The design team also used algorithmic methods to script each rectangular (or, triangular) component so that they would precisely fit into their calculated slots (sliding joints), which gradually shift positions and angles to give the pavilion its curved form.

The Dragon Skin Pavilion has an overall tessellated form that shows us how environmentally friendly materials (such as the plywood they used) can create interesting parametric designs. Aesthetically, the project is quite intriguing, but once examined closely seems to be much simpler. It is only once the differing sizes and angles of joints are realized when the project can be fully appreciated and understood.

From the exterior, the joint system can be quite difficult to determine, but once inside, the sliding joints make perfect sense. When using a material like plywood, this system seems the most logical, yet also efficient in terms of fabrication and construction.

The tactile appearance of the pavilion adds interest to the form and the material possibilities have been explored very well.

Perhaps in our project similar sliding joints with tessellation components made from plywood could be used. We want our project to move, and these sliding joints could allow for a limited amount of motion applied in a particular direction. http://dragonskinproject.com/

http://www.arch2o.com/dragon-skin-pavilion-students-of-tampere-university-of-technology/47

Reverse Engineering Process

Curves drawn in Rhino Curves lofted together to create base form

Base Form

Curves drawn in Rhino Curves lofted together to create base form

TessellaTion PaTTern

Linear Array Brep in X axis with Factor of 1.2, at Count of 7

Linear Array previous Linear Array in Y axis with Factor of 0.9 at Count of 15

Reverse Engineering Process

Mirror Brep so that tessellation faces correct way on loft

Linear Array previous Linear Array in Y axis with Factor of 0.9 at Count of 15

Components connected to Surface MorphCompleted form without Mirror component (Tessellation Pattern had been reversed)

Final Form

49

CURVES DRAWN IN RHINO

CURVES REFERENCES IN GRASSHOPPER

CURVES LOFTED TOGETHER TO CREATE BASE FORM

Reverse Engineering Process

TWO V-SHAPED POLYLINES CREATED IN RHINO AND REFERENCED INTO

GRASSHOPPER THEN LOFTED

LINEAR ARRAY OF LOFTED FORM IN X AND Y AXIS

LINEAR ARRAY BREP MIRRORED IN XY PLANE AND CONNECTED TO

‘SURFACEBOX’

BOUNDING BOX CREATED AROUND BREP AND REFERENCED TO ‘SURFACE MORPH’

DECONSTRUCT BOX TO FIND W VALUE FOR ‘SURFACE MORPH’ COMPONENT

DECONSTRUCT DOMAIN OF LOFTED SURFACE TO FIND U AND V VALUES FOR

‘SURFACE MORPH’

COMPONENTS LINKED TOGETHER TO CREATE FINAL FORM

50

Reverse Engineering Process

51

B4: Technique: Development

The following pages show iterations made from the reverse engineering algorithm made in Grasshopper in Part B3.

The first set of iterations simply explores the paneling options without a base form. The second set explores alterations to the original base form of the Dragon Skin Pavilion. Finally, the third set of iterations explores a potential form for our final design.

‘Search is a process we engage in when the outcome of an action cannot be fully ascertained in advance’6. This is exactly the process that we will be engaging in throughout the next stage of this design process.

By creating numerous iterations by using the same base algorithm, we can then make a selection from those as to which would be the most successful.

‘Search processes involve two steps: (1) producing candidate solutions for consideration, and (2) choosing the “right” solution for further consideration and development’7. This is where our selection criteria comes into play – with this we can determine which of the iterations was the most successful in achieving our goals.

It appears that we will be taking on the Breadth First method, which involves creating several alternative ways to a solution and exploring them before one is chosen and taken to it’s conclusion. This seems the most logical method as working in a team means we can examine the results each person develops before making any decisions.

52

B4: Technique: Development

http://www.l-e-a-d.pro/research/17-finland-workshop-2/1617

New

Loft

Extr(

SrfM

orph

: D=Y

, F=1

.0Ar

raye

d, sc

aled G

eom

in (Y

)Ar

raye

d, sc

aled G

eom

in (Y

)

Diam

ond (

lunch

box):

-Trim

med G

eome

try: E

xtr to

pt

Extru

ded G

eome

try: P

revie

w

Add a

ttrac

tor po

int to

ArrL

inear

Of

fset In

tCrv

(#3)

, 0.2,

-0.1

Attra

ctor p

oint fo

r Vec

DAd

just G

eome

try:

ArrD

irec (

Y)=

6.6. A

rrEl (Y

)=7

xB (B

) = 1.

5Ro

tated

: 0.5*

pi in

XYRo

tated

: 0.5*

pi in

XY

Srf=

PtF

aces

(F) x

2

Pt=

25.90

6,15.8

02,1.

234.

Extru

de: D

=X, F

=0.6

Point

at 27

.680,-

7.204

,0.00

0Ru

le Sr

f b/w

Extru

de: D

=Z, F

=3Tr

im: S

= Ex

trusio

n in Z

Point

at -

80.14

8,-73

.558,0

.000,

Trian

gle A

ngle

ArrD

irec (

X)=

1.2 -A

rr El

(X)=

9X-

Trem

ez P

oints

from

SrfM

rph

IntCr

v Extr

emes

, Rule

Srf b

/w

Linea

r Arra

y (Y)

: F=3

.0Ar

rLine

ar (X

), N=

15Ar

rLine

ar (X

), N=

15

Extru

de (Z

), F=

1

Trim

Soli

d

B4: Technique: Development

54

Extru

de S

rf Mo

rph:

D=Y,

F=0.5

Adjus

ted or

igina

l geo

metry

Origi

nal G

eome

try A

dapte

d

Pipe

: IntC

rvs (#

1 & #3

),

Mirro

r Geo

metry

in X

Y

PtFa

ces f

rom

SrfM

orph

AxB

(B) =

1.8,

Pton

Crv =

0.34

Scale

Fac

tor (G

)

Extr

Loft b

/w in

tCrv:

D=Y,

F=0.5

Remo

ve ar

ray r

otatio

n

Lunc

hbox

2D T

RUSS

: B/

w int

erpo

lated

crvs

(#1 &

#3)

XTRE

MEZ:

Trim

and M

irror

HEX

grid

(lunc

hbox

): srf

=

CIR

x 2: P

=L &

P=H

Rule

Srf

Rule

Srf b

/w

Pton

Crv =

0.33

, Int C

urve

: both

Att P

t at 4

3.284

,31.58

1,0.00

0 Lo

ft b/w

low

Extre

me to

0.33

Ex

teme P

oints

remo

ved f

rom

Trim

Soli

d com

pone

nt

ArrL

in(Y)

: Attr

Pt 49

.756,-

-4.21

1,0.00

04.21

1,0.00

0

B4: Technique: Development

Arra

y Line

ar: X

=1.4,

N=8

Set N

ew B

rep

Prev

ious B

rep (

Itera

tion 2

)

Arra

y Line

ar, X

=2.0,

N=1

0

Extru

de in

Z, Z

=0.3

Brep

as A

bove

, Extr

as ab

ove

Arra

y Line

ar: X

=5.7,

N=9

Origi

nal B

rep

Set N

ew B

rep

As B

efore

New

Brep

Set

New

Brep

Set

2Arra

y Line

ar: N

=16

Arra

y Line

ar, X

=2.3,

N=7

Extru

de al

ong Z

, Z=0

.09

Arra

y Line

ar, N

=11

Arra

y Line

ar, X

=1.4,

N=1

2

Arra

y Line

ar: X

=1, N

=4

Arra

y Line

ar: N

=19

Join

with

Itera

tion 1

0

Arra

y as A

bove

Arra

y Line

ar: X

=0, N

=14

Mirro

r Com

pone

nt, A

dded

back

Arr L

inear.

X=1

.2, N

=11

ArrL

inear

X=0

.65, N

=11

Arra

y Line

ar, N

=16

Arra

y Line

ar, X

=0.9,

N=7

Arra

y Line

ar, N

=16

Cull B

oolea

n: Tr

ue/T

rue/F

alse

Offse

t dist

ance

, D=0

.4

Arra

y Line

ar, N

=20

Arra

y Line

ar, N

=20

Cull B

oolea

n: Tr

ue, T

rue,

False

Cull S

rf Mo

rph:

T/T/

F/F/

FJo

in Sr

fMrp

h & C

ulled

Patt

ern

Arra

y Line

ar: N

=19

Arra

y Line

ar N

=10

Arra

y Line

ar: N

=7Re

move

Mirr

or C

ompo

nent

B4: Iterations

56

Brep

as ab

ove

Brep

as ab

ove,

Arra

y as A

bove

Arra

y Line

ar, X

=1, N

=4

Arra

y Line

ar: X

=0, N

=9

Set N

ew B

rep

As A

bove

New

Brep

Set

New

Brep

Set

Arra

y as A

bove

Rotat

ed: 0

.5*pi

in XY

Arra

y Line

ar, N

=20

Arra

y Line

ar: N

=19

ArrL

in, X

=0, N

=14,A

rrLin,

N=1

9

Only

Loft e

dges

of D

eBre

p

Arr L

in: X

=0, N

=7

ArrL

in X=

0.6, N

=7,A

rrLin:

N=1

4

Loft S

rf Mo

rph &

Dom

ain U

Cull B

oolea

n: T/

F/T/

F

Cull f

rom

Culle

d: T/

T/F/

FSc

ale C

ull: F

=1.2

Take

Out

mirro

r

DBre

p fro

m Sr

fMor

ph, O

ffst 0

.5De

Brep

of O

ffset,

Loft e

dges

Arr L

inear

: N=1

4

DeBr

ep fr

om S

rf Mo

rph

Offse

t Fac

es, D

=0.3

B4: Iterations

Base

loft c

urve

s cha

nged

Arra

y Line

ar: X

=4.0

From

Fina

l Srf

Morp

h:

Same

as A

bove

From

fi nal

“SrfM

orph

”

“Arra

y Line

ar” Y

Dire

ction

New

tesse

llatio

n cur

ves

Arra

y Line

ar in

XFr

om F

inal ‘S

rfMor

ph’

New

Tess

elatio

n Cur

ves

Same

as A

bove

New

Tess

elatio

n Cur

ves

from

Rhino

Geo

metry

..

DIAM

OND

PANE

LS

U=18

, V=2

HEXA

GONA

L Stru

cture

Facto

r=3 (

chan

ged f

rom

0)Re

draw

n in R

hino

Arra

y Line

ar: F

=1.8

Mesh

Dua

lRe

draw

n with

Rhin

o...

, “Ar

ray L

inear

” Y F

actor

= 8.

0

Redr

awn i

n Rhin

o

U=16

, V=1

8U=

20, V

=3, A

djust

Shap

e=0.8

Type

=T/T

/F-P

ipe: R

adius

=0.2

Cente

r = 3.

5“A

rray L

inear

” Y, C

ount=

5

“Arra

y Lin

ear”

Y Fa

ctor =

4.0,

Do

main

Offst

: for B

, +&-

= 0.1

60

B4: Iterations

58

Skew

ed Q

uads

From

fi nal

“SrfM

orph

”

“Arra

y Line

ar” Y

dire

ction

“Arra

y Line

ar” X

dire

ction

, F=

4

Mirro

r Com

pone

nt re

move

dNe

w Te

ssela

tion C

urve

s

New

Tess

elatio

n Cur

ves

U=18

, V=2

Pane

l Fra

me

, Cou

nt=20

(fro

m 15

)

From

fi nal

Srf M

orph

: DIA

GRID

Redr

awn i

n Rhin

o...

Redr

awn i

n Rhin

o...

Scale

Fac

tor, F

=0.5

Mesh

Pipe

: Rad

ius=0

.2

“Arra

y Line

ar” Y

Fac

tor =

3.0

Arra

y Line

ar” Y

Fac

tor =

0,

Arra

y Line

ar” X

Fac

tor =

2.0

Arra

y Line

ar: X

Fac

tor =

1.8

Arra

y Line

ar in

YAr

ray L

inear

: F=4

.0

B4: Iterations

Selected Iterations

These three iterations were selected to be the most successful due to the following criteria

1. ABIDES BY BASIC TESSELLATION PRINCIPLES

2. CAN BE UNROLLED / DEVELOPABLE POTENTIAL

3. IS AESTHETICALLY PLEASING

4. HAS STRAYED FAR FROM ORIGINAL ALGORITHM

5. CAN INCORPORATE PREFERENCED MATERIALS

6. CAN BE ADAPTED FURTHER IN GRASSHOPPER

7. ABILITY TO GENERATE ENERGY FOR EDUCATIONAL PURPOSES

The first selected iteration shows how our design could work structurally. Steel framing would act as the structural members, whereas the triangulated tessellation pattern would be attached. This iteration would obviously need to then be applied to a form – possibly by using the Surface Morph component in Grasshopper.

The second chosen iteration has much more of a design to it. The form is quite aesthetically pleasing and with breaks in the tessellation pattern, the panels would have the ability to spin on their axes. The design also allows for people to be more open to the environment and to provide for specifically directed views around the site.

The last iteration resembled a folded form and could perhaps be applied with technologies such as the Electroactive Polymers. The design would need some kind of separate structural elements, too, in order to be stable, but would also need to allow for dynamic movement of the components.

61

B5: Technique: Prototypes

62

B5: Technique: Prototypes

These initial prototypes were done by hand to explore triangulated tessellation patterns and how they could interlock with each other and create interesting results such as shadow effects. Most of these were made from paper, which is likely to be used for a model in the final presentation. It also works well in conducting tests due to the paper being lightweight enough to move in wind, for example. If we were to use a composite material of hemp and plastic for the “panels” or “scales”, paper would also be a great representational material to use.

63

B5: Technique: Prototypes

64

B5: Technique: Prototypes

This was the first prototype done which explored the form as well as the tessellation pattern. The tessellation pattern was simplified in order to observe the overall result the form would give. It was tested by bending, stretching, sagging, changes in lighting, shifting perspective, and wind (using a hairdryer). With the creation of this model, the team decided to stick with this form, as it was aesthetically pleasing, but further exploration of the paneling needed to be done. These needed to be defined properly so that energy could be produced with whatever chosen system of generation.

65

B5: Technique: Prototypes

66

B5: Technique: Prototypes

The prototypes on these pages were attempting to understand and visualize how each of the panels could rotate around the steel structural frame in order to generate energy. The balsa wood prototype on the first page proved to be too heavy to spin around one complete circle unless the wind was quite strong and at the correct angle. The paper models, on the other

hand, were much lighter and moved quite easily in the wind. The bottom right model was not very successful, as each of the panels wouldn’t sit straight on the wire. This may have been due to the joinery, but the panels were also very fragile and didn’t catch the maximum amount of wind possible.

67

B5: Technique: Prototypes

This prototype was done to examine the overall form of our design and how it can be further developed. We wanted to explore how the project would look on site from different angles and how it could be placed for accessibility. For this to be produced in the FabLab, we couldn’t simply unroll the form, we first needed to construct a waffle grid, so the file had to be changed.

68

B5: Technique: Prototypes

69

B5: Technique: Prototypes

This second FabLab prototype was to explore a static tessellation pattern. This design had the possibility of using steel framing for structural support, as well, or to simply use the tessellation pattern as both aesthetically and structurally.

70

B5: Technique: Prototypes

71

B6: Technique: Proposal

B6: Technique: Proposal

We want our project to be a dynamic system that generates energy and is made from unconventional and environmentally friendly materials.

Our project needs to emerge from the site, but also to represent the culture and vision of Copenhagen.

It needs to use computational techniques in order to extend the Grasshopper definition. And it needs to be aesthetically pleasing so that it draws people in.

We intend to design our project so that steel members run through the form as the structural members. These structural members, however, would also incorporate our energy generation system – wind power.

The spinning of each of the panels along the steel would generate wind energy. These panels would be made from some kind of bioplastic or a composite material of hemp and plastic.

Each would have it’s own generator built into the steel and a generator box would be built underneath the structure so as to not interfere with the design aesthetically.

73

B6: Technique: Proposal

Site Analysis: Tourist Attractions

Site Analysis: Views

B6: Technique: Proposal

Site Analysis: Direction of Wind

Site Analysis: Bike Paths

75

B6: Technique: Proposal

Using the information we gathered in doing the site analysis, we determined that wind energy would be the most efficient as there is a nearby site that already generates wind energy through turbines. This would make our design dynamic and perhaps interactive, making it an excellent educational tool for sustainable energy generation.

To further promote the sustainability image, we also intend to use environmentally friendly materials, such as hemp for the panels. Bioplastics are also a possible option, as seen in the project below, the ArboSkin Pavilion by ITKE in Stuttgart.

http://www.dezeen.com/2013/11/09/arboskin-spiky-pavilion-with-facademade-from-bioplastics-by-itke/

B6: Technique: Proposal

Shown above are some sketches of how the design might be put together. The generator system, however, is quite complex in terms of how it will be built into the structure. It is because of this and our limited understanding of wind power that we may decide to change our design in the next stages of progress.

The panels would be attached to the steel structure and each would be designed so that it can change directions, according to where the wind is coming from. This would make the structure more interactive and educational as well as allowing for a maximum amount of energy generation.

The innovation of this design partly comes from the use of unconventional materials used for the panels. These panels in themselves are also quite innovative as they stem from the idea of tessellation. Each of the pieces could theoretically slide into one another and it’s as if a tessellation pattern is formed through the spaces that each panel leaves between itself and the next.

77

B7: Learning Objectives and Outcomes

After presenting our proposal and considering the feedback given to us by the tutors, we have realized that there are a few things we need to change and could improve upon.

Firstly, and perhaps most importantly, is to make our design more computational rather than a computerization. This means that our Grasshopper file will need some more reworking to reorder elements and to change the way we achieved certain things. For example, our tessellation pattern was designed in Rhino, rather than making use of the computational utilities available to us. In this way, the emphasis will shift ‘from the “making of form” to the “finding of form”’8.

With these computational tools we could even examine and experiment with the winds in Copenhagen to see how our model will react. The panels may also need to be directed at a more specific angle to generate energy more efficiently, but this could also be done through mechanical systems.

Other methods of generating energy also need to be explored. For example – it may be more practical to make our panels vibrate to generate energy rather than spinning around the whole structure. This has the potential to improve the building performance, as well. With the emergence of sustainability, recent developments in technology and cultural theory, the focus on form making as the guiding design principle has shifted to building performance. This covers a multitude of areas ranging from financial, spatial, social and cultural, and of course, technical (structural, thermal, acoustic). With the analysis of our project using digital technologies, we can evaluate and improve on its performance to achieve the best possible results, in terms of wind generation in particular.

By making these performance decisions early on in the project with the aid of software tools, architects and designers have the opportunity to develop a concept that will perform as required. One of the shortcomings of this approach, however, is that these digital analyses need to be done in high-resolution and so they are rarely used in conceptual design development. 9

Throughout this subject, I believe that my understanding and respect for the computational design method has developed enormously. Before, I had never thought about the differences between computerization and computation and how the results from both methods could be so varied.

I have managed to generate a variety of design possibilities using algorithms, something that seemed like such an alien and daunting task to me before. Some of these have proved to be more successful than others, and in particular I have noticed that my natural approach to a solution is to think in a computerization manner, rather than a computational one. This shift in thinking and the design approach is something that I personally need to think about consciously. Without doing this, I noticed that for me, personally, it was easier to fall back into old habits. Over time, however, and with the continuation of using computation techniques, I believe that this will become more of a natural response to design briefs. In saying that, my skills will also improve, allowing for a larger variety of solutions to be developed.

I still feel as if there are times when more traditional methods of design are more appropriate. For example, in designing a hospital where a set out plan needs to be achieved wouldn’t be as appropriate in using computation techniques where the results can often be unexpected. Computation techniques could be used, however, to generate the overall form of the hospital, if certain limitations were set within the algorithm.

78

B7: Learning Objectives and Outcomes

B8: Appendix - Algorithmic Sketches

80

B8: Appendix - Algorithmic Sketches

81

Bibliography

1. Kalay, Yehuda E. (2004). Architecture’s New Media: Principles, Theories, and Methods of Computer-Aided Design (Cambridge, MA: MIT Press), pp. 5-2

2. Karissa Rosenfield, ‘Video: phototropia / materiability’, ArchDaily, (2012) <http://www.archdaily.com/255141/video-phototropia-materiability/> [accessed 10 April 2014]

3. Kolarevic, Branko (2014). ‘Computing the Performative’, in Theories of the Digital in Architecture, ed. by Rivka Oxman and Robert Oxman, pp. 103–111

4. Manuel Kretzer, ‘Electroactive Polymers’, Materiability Research Network, (2013) <http://materiability.com/electroactive-polymers/> [accessed 10 April 2014]

5. Manuel Kretzer, ‘Dye-sensitized Solar Cells’, Materiability Reseach Network, (2013) <http://materiability.com/dye-solar-cells/> [accessed 10 April 2014]

6. Manuel Kretzer, ‘Phototropia’, Materiability Reseach Network, (2012) <http://materiability.com/phototropia/> [accessed 10 April 2014]

7. Unknown author, ‘Dragon Skin Pavilion / Emmi Keskisarja, Pekka Tynkkynen & LEAD’, ArchDaily, (2012) < http://www.archdaily.com/215249/dragon-skin-pavilion-emmi-keskisarja-pekka-tynkkynen-lead/> [accessed 3 April 2014]

8. Unknown author, ‘P3 Workshop / P3 Pavilion’, suckerPUNCH, <http://www.suckerpunchdaily.com/2014/03/27/p3-workshop-p3-pavilion/> [accessed 27 April 2014]

9. Unknown author, ‘Voussoir Cloud’, Iwamotoscott Architecture, <http://www.iwamotoscott.com/VOUSSOIR-CLOUD> [accessed 3 April 2014]

10. Woodbury, Robert, ‘How Designers Use Parameters’, in Theories of the Digital in Architecture, ed. by Rivka Oxman and Robert Oxman (London; New York: Routledge), pp. 153–170

82

Footnotes

1. Woodbury, Robert, pp. 153

2. Woodbury, Robert, pp. 153

3. Woodbury, Robert pp. 164

4. Unknown author, ‘Voussoir Cloud’, Iwamotoscott Architecture, <http://www.iwamotoscott.com/VOUSSOIR-CLOUD>

5. Unknown author, ‘Voussoir Cloud’, Iwamotoscott Architecture, <http://www.iwamotoscott.com/VOUSSOIR-CLOUD>

6. Kalay, Yehuda E. (2004), pp.18

7. Kalay, Yehuda E. (2004), pp.18

8. Kolarevic, Branko (2014), pp. 103

9. Kolarevic, Branko (2014), pp. 108

83

Part C: Detailed DesignThis section of the journal proposes the final project and finalizes all design decisions

C1: Design Concept

In reflecting upon our interim presentation feedback, we realized that a lot of changes had to be made to optimize wind generation. Firstly, our form appeared to not be high enough to generate substantial amounts of energy. Secondly, it was recommended to us that we prove how our form was “optimized” for wind generation by using computational methods to insert Copenhagen’s wind data into the site. Another major problem of our design was that we’d somewhat arbitrarily created the form without fully utilizing the computational methods available to us. We were also asked to test how our prototypes would potentially move in the wind.

The first step to regenerating our design was to find an optimized form using computational techniques. To begin with, we added simple rectangular planes of different sizes and angles into Vasari to see how they interact with the wind. In doing these experiments, we discovered that to capture the most wind, flat planes across the southern and western borders of the site would be best. This option, however, was too simple, so instead, the southwest border of the site influenced our form, rather than defining it.

In regenerating our form, we made full use of computational methods by first using point restrictors to generate field lines. These were then adapted by changing the graph input to generate a form whose façade would be facing the southwest, where the majority of wind enters the site. This form was then lofted and adjusted to be suitable for our structure. Afterwards, the piping system was added so that arches structurally held up the tunnel, and horizontal members ran between each arch. Along this horizontal piping, we then added our propellers, which were designed in Rhino in a simplified manner to be able to be 3D printed.

86

C1: Design Concept

C1: Design Concept

C1: Design Concept

After this process, some of our previous iterations and our final form were put into Vasari to show wind data on the site. The final form proved to be the most successful due to its positioning and extreme height of approximately 100 meters. The majority of the final form, however, reaches a more realistic height of around 40-60 meters, while still being able to capture large amounts of wind energy.

To the left are images of previous iterations that we added into Vasari to see how they would work with Copenhagen’s wind.

The first row shows the wind at the lowest point we tested, and as the images progress down the page, the wind being tested is increased in height.

Each column represents a different iteration – the first column being our previous design from the mid-semester presentation.

In each of these iterations, the structure proved to not be high enough to gain large amounts of wind. The higher up the structure goes, the faster the wind speed. So this needed to be reconsidered for our final design.

We didn’t want a design that was too huge, however, as the interactive element of the design was a very important element. With the entry point to the structure being made much lower, visitors to the site can see and understand how the mechanics of the structure work from a closer view before proceeding through the tunnel.

89

C1: Design Concept

After then looking at our site plan and how the design would stand on the site, we decided that more of the site needed to be utilized in order to engage users. This was done by introducing an “interactive” part of the design that somewhat mirrors the mega structure form.

This mini-mega-structure has triangular fi berglass panels with different colours that can be spun by users. The structure does not generate a large amount of energy, but this was not the point. The aim was to educate users about energy generation and to explain, in a simplifi ed manner, how the structure moves and generates energy.

Located on the opposite end of the site, the interactive structure is split into two sections. The fi rst one, which is about 4-5 meters high, consists of four pipes running horizontally, with structural ones running vertically across them for support. At one end, this section is connected to bikes (one for each pipe), which spin some of the triangular panels along the structure and generate a small amount of energy.

The second part of this interactive structure reaches a height of no more than 2 meters. The aim was to along children (or adults) to climb on the structure or to simply spin the triangular panels around the piping.

C1: Design Concept

91

C2: Tectonic Elements

Our chosen “core construction element” to model at a scale of 1:5 was the propellers. We wanted to show how the system would work as each propeller is connected to the next one, in turn spinning both of them at the same time.

In the diagram shown here, the fiberglass propellers are welded onto the steel piping. At the ends of each section of this piping, a ball bearing with wire connected in it’s center can be seen. This wire then runs through a larger pipe (a structural one) until it meets another section of piping where the next propeller sits. At the end of each section of propellers, a generator sits in the arches and is then connected down through the structure, then transferred onto the grid.

The only serious problem with our system of construction is perhaps the cost and amount of steel needed. For our main tunnel mega structure, 3,460m of 800mm diameter steel piping would be needed. For our interactive part used for climbing, approximately 1,580m of 80mm diameter steel piping is required. And finally, 1,474m of 200mm diameter steel piping would be needed for our interactive bike section.

Steel is a reliable and structural material, so the only issue is that some lengths of steel might be too long. In which case, several smaller pipes could be welded together afterwards in the assembly process.

92

PROPELLER FIN

WELDED STEEL

BALL BEARING

STEEL PIPING

STEEL CABLE CONNECTED TO CENTER OF BALL BEARING

C2: Tectonic Elements

C3: Final Model

This final model, at a scale of 1:500 shows the site with the final design. As stated earlier, the propellers were made in Rhino in order to be 3D printed, so needed to be a simplified form of the actual propellers.

96

C3: Final Model

C4: Additional LAGI Breif Requirements

Apogee

C4: Additional LAGI Breif Requirements

Apogee is a unique, interactive and powerful piece of art and energy generating mega structure. It harnesses wind energy in Copenhagen’s breezy harbor, while at the same time educating and engaging the public in alternative energy solutions.

Visitors are drawn to the site firstly due to its colossal scale, but then upon arrival are intrigued to stay a while and interact with the structure.

People arriving are immediately drawn to the first smaller structure they see – the interactive one. This allows users to both hook up their bikes to generate a small amount of energy, or to simply play with the structure and observing how the system works.

Once users have explored this interactive section, they then move onto the main mega structure, which generates energy using multiple small turbines along several horizontal shafts.

These turbines are connected to one another through a hidden system in the steel piping and in turn, spin one another. This means that when wind is directly hitting one of the turbines at the perfect angle, it would then cause a reaction in the next turbine to turn it as well, thus generating more energy.

This main mega structure is in the form of a tunnel, which takes users on a journey through the edge of the site. Through the tunnel, lighting effects change depending on how fast the wind is blowing and views across the water towards the Little Mermaid are provided.

99

C4: Technology System

In researching wind generation systems, we came across Doug Selsam, whose research focuses on multiple turbines along a single turning shaft. He claims his reasons for doing this are that currently wind turbines are simply a refined version of a 1000 year old design and suffer from the following problems, challenges and drawbacks: [1]

1. Inordinately heavy rotor weight since larger rotors become disproportionately heavy

2. Inordinately slow blade rotation since larger rotors turn more slowly

3. Inordinately robust drivetrain reuired due to high rotor mass & high torque of slow rotation

4. Gearbox required due to slow rotor rotation, since a generator needs to turn faster

5. Not self-aiming – special apparatus required to maintain a heading into the wind

6. Inordinately complex mechanisms required to prevent damage in gale force winds

7. Excessively robust support structure required to hold up all that excessive weight