Advanced NDT Solutions Oil Gas - mistrasgroup.co.uk · bundle inspections, such as: remoTe fielD...

Transcript of Advanced NDT Solutions Oil Gas - mistrasgroup.co.uk · bundle inspections, such as: remoTe fielD...

Oil & GasProducts | Systems | Services

Advanced NDTSolutions

For more details and specifications, please visit us on the web at mistrasgroup.co.uk or call +44 (0) 1954 231612

MISTRAS Group is the recognized leader in de-livering Advanced Proprietary Products, Systems and Services to the Oil & Gas industry. Our asset protection solutions enhance the ability of critical infrastructure to comply with safety and environ-mental regulations, extend their life, increase productivity, minimize repair cost, manage risk and most importantly, help avoid catastrophic disaster.

Advanced products, systems and services are used extensively in the Oil & Gas industry for a high de-gree of reliability, which supports improved safety, drives productivity, increases process availability and helps meet regulatory compliance standards.

Our advanced technologies and techniques are utilized in Oil & Gas operations on the following critical assets to identify potential damage mechanisms:

• Tanks• Vessels• Heat Exchangers and Condensers• Piping • Rotating Equipment

Our Plant Condition Management Software, PCMS®, is the engine that drives the organization of inspection data and improvements to plant inspection plans. With the addition of the PCMS® Risk Based Inspection module, MISTRAS has the ability to assess your Mechanical Integrity program and offer recommendations to help you optimize your inspection spending. This optimization is based on utilizing the correct inspection technique for the type of damage associated with your fixed and rotating asset. This customized plan yields in-creased reliability of your assets, reduced mainte-nance costs, shorter turnaround schedules (based on minimizing equipment in the turnaround) and increased operating income to the facility.

CENTERS OF EXCELLENCEThroughout North America and the world, we maintain Centers of Excellence (COE) in NDT inspec-tion technologies. With the use of a sophisticated, collaborative intranet network, our inspectors and engineers employ technologies/software/hardware that their colleagues may have developed in any one of our worldwide locations.

aSSET PROTECTiON SOLuTiONS

aDVaNCED NDT PRODuCTS, SySTEmS &SERViCES FOR THE OiL & GaS iNDuSTRy

1

For more details and specifications, please visit us on the web at mistrasgroup.co.uk or call +44 (0) 1954 231612

Specific tank related damage mechanisms are:

• Internal and external corrosion of roofs, floors and shells• Weld and weld heat affected zone integrity• Structural deficiencies (Settlement Surveys, Out of Roundness, Strapping)

Advanced techniques used to determine the above damage mechanisms are:

aCOuSTiC EmiSSiON TaNkPaC™MISTRAS utilizes a proprietary methodology for evaluating the condition of tank floors using Acoustic Emission (AE) while the tank is in service. An overall condition assessment is performed and individual areas of concern are noted to pinpoint follow up areas to inspect during a subsequent Out of Service inspection.

TaLRuT™: uLTRaSONiC TaNk aNNuLaR LONG RaNGE iNSPECTiONUtilizing our proprietary LSI™ system, we are able to generate semi-quantitative data regarding the tank floor integrity adjacent to the shell to floor weld. This inspection technique encompasses approximately 10” into the tank floor from the exterior of the tank using an ultrasonic technique and a proprietary algorithm. The annular area of the tank is critical to the support structure, and safe operation of the tank.

Time-of-flighT-DiffracTion (TofD)Ultrasonic TOFD is a rapid survey tool used to evaluate the shell and/or roof weld and weld heat affected zone looking for original fabrication type defects, or in service corrosion occurring in the heat affected zone. Follow up phased array inspec-tion may be required in any area that exhibits potential damage discovered through the TOFD inspection.

auTOmaTED uLTRaSONiC LSi™The ultrasonic LSI is a rapid erosion/corrosion scanning tool used for ultrasonic “drops” down the tank shell or the roof. The device is magneti-cally attached to the tank and operated remotely. The amount and quality of data is far superior to ultrasonic thickness readings, in that actual trend-ing can be visualized as in the case of liquid to air interface corrosion. In the case of roof readings, the ability to attach the scanner enhances the safety of the project, as there is no need to access the roof by inspection personnel.

TaNkS 2

TaLRuT™TankPaC™ LSi™

•Avoidopeningtanksandeliminatecostsassociatedwithcleaningandwastedisposal.

•IncreaseprobabilityofdetectingcorrosionusingLSI™highspeedcorrosionmapping

•Enhancesafetyusingremotecrawlersonroofs.

For more details and specifications, please visit us on the web at mistrasgroup.co.uk or call +44 (0) 1954 231612

Vessel service leads to the following issues:

• Internal and External Erosion/Corrosion• Cracking• Weld and weld heat affected zone issues• Metallurgical damage

Advanced techniques used to determine the above damage mechanisms are:

aE mONPaC PLuS™ iNSPECTiONMonPAC Plus™ is a technology package developed by MISTRAS that allows owners to inspect a pres-sure vessel to determine the relative condition of the asset while the asset is still in service. Poten-tial anomalies are detected and located for use in follow up inspections. The use of MonPAC™ Plus greatly reduces the need to further perform costly out of service inspections of vessels that show no signs of degradation.

ROPE aCCESSCertified rope access technicians work in difficult or inaccessible areas efficiently without the need for scaffolding, cranes, or mobile work platforms. Using rope access for inspection and maintenance activities generates significant cost-savings for as-set owners, especially where traditional access methods comprise a major portion of the overall project budget.

auTOmaTED uLTRaSONiC LSi™See Page 5, Piping, for more information.

PuLSED EDDy CuRRENT (PEC)PEC technology is an inspection technique for measuring the thickness of steel objects without direct contact to the steel surface. The electro-magnetic test uses a pancake probe to identify general corrosion through insulation or concrete surfaces by introducing an electric current into the transmitter coil, magnetizing the steel and measuring wall thickness. PEC is ideal for survey-ing large sections of piping or pressure vessels to detect areas that have been affected by moisture trapped under insulation causing corrosion of the asset being inspected. Use PEC when other NDT techniques may be limited due to the larger diameters encountered when inspecting insulated vessels.

PHaSED aRRaySee Page 5-6, Piping, for more information.

UlTrasonic P-scanDifferent forms of cracking such as fatigue, creep, HIC, SOHIC and various forms of embrittlement, may occur depending on the process in which the equipment is operating. These begin as mi-croscopic damage and can occur along the grain boundaries of the parent material or the weld heat affected zones. The P-Scan is used to ac-curately detect and size these mechanisms in its early stages of damage formation, while creating three dimensional views of the weld that enables the operator to better visualize its position.

Time of flighT DiffracTion (TofD)TOFD is utilized as a quick survey tool of welds and weld heat affected zones in pressure vessels looking for the presence of welding fabrication defects or screening for cracking. It is an excellent tool for providing accurate through-wall depths of existing cracks.

VESSELS3

TOFD

•Eliminatevesselsfromturnaroundsusingriskbasedinspection(RBI)methodologyandglobalinspection.

•IdentifyandsizedefectscausedbyuniquedamagemechanismslikeHighTemperatureHydrogenAttack,StressCorrosionCracking,andmore.

•Perform“On-Line”Monitoringofsuspectassetstoensurecontinuedsafeoperation.

Guided Wave Collar

For more details and specifications, please visit us on the web at mistrasgroup.co.uk or call +44 (0) 1954 231612

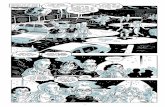

A variety of tube inspection techniques are used for bundle inspections. The choice of technique depends on the tube material type. MISTRAS technicians are cross trained on IRIS, Remote Field Eddy Current, Near Field Eddy Current and stand-ard Eddy Current techniques and use the same operating system to achieve these results. This “Cross Training” allows us to minimize the amount of technicians we need to deploy to your project, ultimately saving inspection dollars.

Heat Exchangers and Condensers are subject to various issues related to the tube bundles such as:

• Internal and External Pitting and Corrosion and Erosion• Cracking (SCC, Fatigue, Thermal, Vibration)• Mechanical damage (Inlet Erosion, Baffle Fretting, Freeze Bulges, Tool Gouges)

A variety of advanced techniques are used for bundle inspections, such as:

remoTe fielD TesTing (rfT)Carbon steel tube bundles are inspected using RFT. The RFT technique utilizes the same platform as our standard ET inspections which does not require tubes to be as clean as other techniques. Our professional inspectors are cross trained to provide both ET and RFT while on site.

near fielD TesTing (nfT)NFT is used for inspecting fin fan (air coolers) designed tube bundles. Also available in our standard ET equipment platform, NFT is a very reliable technique to determine ID anomalies - such as inlet erosion, corrosion, and pitting - that normally occur during service in this previously difficult to inspect tube design.

inTernal roTary insPecTion sysTem (iris)IRIS uses ultrasonic technology with a rotating transducer to deliver quantifiable data on the ID or OD damage to tubes. Primarily used as a prove up tool, IRIS requires tubes to be cleaner than oth-er tube inspection techniques and scan speeds to be slightly slower. Also available in our ET equip-ment platform, all IRIS tube data is presented in a C-Scan and B-Scan profile & archived for playback.

eDDy cUrrenT (eT)ET is the predominant inspection technique for the alloy tubes. ET does not require the tubes to be as clean as some other techniques and is relatively fast compared to more quantitative techniques like IRIS. MISTRAS’ tube inspection specialists utilize the latest ET technology along with an electronic reporting format that allows for quick analysis and generation of tube sheet drawings and results in an easy to read template.

4HEaT EXCHaNGERS & CONDENSERS

NFT Sample Damage 3D reporting

3-D rePorTingMISTRAS tube inspection reports are revolution-ary in their ability to provide defect data down the length of the tube. The tube data allows owners the increased ability to determine the root cause of tube degradation and potentially allows them to avoid the problem in the future through operat-ing procedural changes or change in tube material choice during bundle repair. All tube inspection data is left on site in order to speed the process of getting the exchanger into production as quickly as possible. Tube inspection specialists review all on-site data & provide the final report to the client within 72 hours of the completion of the project.

For more details and specifications, please visit us on the web at mistrasgroup.co.uk or call +44 (0) 1954 231612

The goal of piping system inspection is to increase the reliability of the system by increasing the mean run time to failure. In order to achieve this, an owner must utilize the proper inspec-tion technique based on the associated damage mechanism. Utilizing point to point ultrasonic thickness readings is relatively useless if the owner is concerned about localized corrosion. Propri-etary techniques such as a Touch Point Corrosion ultrasonic methodology and On-line monitoring of suspect lines are available through MISTRAS.

In addition to damage mechanisms, accessibil-ity to the piping becomes a determining factor in the choice of inspection tools. For instance, for piping systems at height, MISTRAS utilizes rope access technicians to aid in the inspection. These individuals are capable of performing any inspec-tion from ropes that we perform from the ground including Guided Wave, Erosion Corrosion scan-ning, PEC Tool or Pocket UT®.

A variety of potential damage mechanisms need to be considered when inspecting piping, such as:

Advanced techniques used to determine the above damage mechanisms are:

auTOmaTED uLTRaSONiC LSi™Our LSI system performs ultrasonic surveys at 25 inches per second, allowing us to inspect large ar-eas of piping very quickly. Our UTIA software al-lows the operator enhanced flexibility to analyze the data for optimum visual correlation with the A-B and C-Scans. Stitching multiple scans together allows an overview of the entire piping system.

PHaSED aRRayPhased array is a versatile tool that electroni-cally produces multiple wave modes and angles electronically in nanoseconds. This is an excellent choice for detecting cracking caused by a host of other damage mechanisms and is highly beneficial in providing accurate sizing data for use in Fitness for Service calculations. Phased Array may also be used to perform final acceptance of code qual-ity welding per ASME code requirement in lieu of radiography. This application results in substantial savings to the owners by eliminating the restrict-ed areas required when performing radiography.

GuiDED uLTRaSONiC LONG RaNGEGuided wave technology utilizes torsional and longitudinal waves to inspect large sections of piping from one location. Guided wave is used as a screening tool, in most cases, on insulated piping as well as buried piping, wharf and jetty piping, offshore piping in splash zones and in tra-ditionally inaccessible areas. It is also used as part of a PMI Retrofit program to locate piping welds between attachments.

PiPiNG5

• External Erosion Corrosion • Internal Erosion Corrosion • Cracking • Mechanical Damage

• Metallurgical Issues • Weld Quality• Leaking Valves

Guided Wave Weldstar

•Increaseprobabilityofdetectionutilizingcomprehensiveglobalinspectionmethods

•Applyappropriateultrasonictechniquestovariouscrackingmechanisms

•Performonlinemonitoringtoensuresafeoperationofat-riskpiping

Touch Point Corrosion

For more details and specifications, please visit us on the web at mistrasgroup.co.uk or call +44 (0) 1954 231612

Guided wave can detect both internal and external corrosion or other significant defects and locate them along the pipe. MISTRAS uses the latest guided wave technology called the G3 or the third generation system which supplies better accuracy than previous technology. In addition, Permanent-ly Installed Sensors (PIMS) can be installed in vari-ous locations, including buried piping applications, to monitor areas that are suspect without having to dig trenches for subsequent inspections.

UlTrasonic P-scanWhether looking for a more thorough tool to evaluate the quality of a weld, or for environ-mentally assisted cracking such as fatigue, stress corrosion cracking and others, the P-Scan system is more than capable of imaging these flaws in a way to better evaluate, characterize and size them.

COmPuTED RTComputed Radiography is especially effective when used with profile radiographic techniques when looking for quantitative & qualitative data for pip-ing. This technique enables evaluation of large sec-tions of piping to determine erosion/corrosion rates in this section vs. the relatively small areas obtained using point to point ultrasonic thickness exams. In addition, computed radiography may be used dur-ing ASME or other code welding processes in lieu of traditional radiography. The combination of com-puted radiography and a Selenium 65 radiographic source enables a dramatic reduction of radiation in boundary areas. This reduction allows welders to work in close proximity to the inspection area.

acoUsTic emission (ae)Leaking valves are a common problem with results showing that 5 to 10 percent of the valves in Oil and Gas plants leak. More importantly, it was determined that just 1 to 2 percent of the valves accounted for approximately 70 percent of the losses. Valve leak detection works by detect-ing the “noise” produced as the medium passes through the valve as “turbulent” flow. Turbulent flow creates a signal with frequency components well over 100 KHz. This allows the use of high fre-quency acoustic emission sensors with frequencies above the vibration and background noise level of the plant. This characteristic makes reliable detection and quantification of leaks possible. In addition to being able to determine if a valve is leaking, our proprietary algorithms allow us to “quantify” the amount of the leak.

aDVaNCED uLTRaSONiC BaCkSCaTTER TechniQUe (aUBT)Certain low alloy carbon steel material operat-ing at temperatures and hydrogen partial pres-sures above the Nelson Curve, can be suspect to decarburization as well as microfissuring and macrocracking, which can result in catastrophic consequences. With the use of proven ultrasonic technologies evaluating frequency dependence, velocities, and several other factors, we are able to help determine which pieces have been affected by High Temperature Hydrogen Attack (HTHA). PuLSED EDDy CuRRENT (PEC)See Page 3, Vessels, for more information.

6

Phased array P-Scan & Computed RT Valve Testing and monitoring

•Savemillionsofdollarsinlostproductioncost

•Qualitativeandquantitativemeasurementcapabilities

For more details and specifications, please visit us on the web at mistrasgroup.co.uk or call +44 (0) 1954 231612

Predictive Maintenance (PdM) and Proactive Maintenance (ProAM) technologies are utilized on the following assets:

Rotating Equipment• Motors• Pumps• Compressors• Gearboxes• Turbines• Fans

Electrical Equipment• Transformers• Motor Control Centers• Switch Gear

Fixed Equipment• Steam Traps• Compressed Air lines

A variety of potential damage mechanisms need to be considered when applying PdM/ProAM technologies such as:

• Bearing Damage• Gear Damage• Coupling type and condition• Lubrication - Lack of and Contamination• Alignment of coupled shafts• Balance or rotors• Leaks • Electrical Discharge

Advanced techniques used to detect the various issues listed above are:

ViBRaTiON aNaLySiSVibration Analysis technology can be applied to all rotating equipment on site. Utilizing this technolo-gy can provide the site with immediate insight into the health of the rotating components. It can be used to isolate the location of damage to rotating components, as well as help determine the

severity of damage. All of the potential damage mechanisms listed above and more can be identi-fied, trended and potentially eliminated by effec-tively implemented PdM programs using vibration analysis. Vibration is applied to equipment in service so there is no impact to production. MISTRAS Services can also provide this technol-ogy in hazardous environments by the use of Intrinsically Safe (IS) equipment.

OiL aNaLySiSLube oil is critical to the health of any rotating piece of equipment. Understanding the condi-tion of the lubrication (oil/grease) in rotating equipment allows operations and maintenance to effectively plan lubrication PMs. Due to sample size equipment, isolation and shut down are not required. MISTRAS uses independent lab analysis and correlates the data with other PdM technolo-gies in a unified database. Applying multiple tech-nologies provides our customers the confidence with secondary and tertiary confirmation.

airBorne UlTrasonics (aU)Airborne Ultrasonics is used in several applica-tions to monitor bearings, electrical discharge, air leaks and effective management of lube oil programs. Some assets are inaccessible to vibra-tion probes, however airborne ultrasonics can be applied effectively. Airborne Ultrasonics, used in combination with Thermography scans, has provided additional accuracy and safety to electri-cal system inspections. PdM programs have saved hundreds of thousands of dollars annually by us-ing UT to find steam and compressed air leaks.

infrareD insPecTion (ir)Thermography, initially considered an electrical inspection technique, can be applied to rotating and fixed assets as well. Used in electrical inspec-tion, it can identify differences in temperatures of connections, fuses, transformers, switchgear, etc.

ROTaTiNG EquiPmENT7

•Maximizereliabilityandavailabilityofrotatingassets

•Prewarrantyexpirationinspection

•Facilityroutinepreventionmaintenance

For more details and specifications, please visit us on the web at mistrasgroup.co.uk or call +44 (0) 1954 231612

Combining IR and AU is essential to any compre-hensive PdM program, and applying AU provides additional levels of safety during electrical inspec-tions. Electrical discharge, also known as carona, can only be detected using AU, and the effects of carona can be found with visual and IR inspection.

moTor cUrrenT signaTUre analysis (mcsa)Our periodic MCSA program detects motor faults such as broken/cracked bars, as well as problems with the high resistance joints on any AC induction motor. Our advanced approach helps to identify the probability and severity of these faults, while trending values to allow ample time for scheduling repairs.

acoUsTic emission (ae)Acoustic Emission is the term used when defects in metals, plastics and other materials rapidly release energy when subjected to mechanical loading. The energy propagates in the form of high frequency stress waves and these types of oscilla-tions are picked up by AE sensors on the surface of the specimen and converted to electrical signals, so-called bursts. The AE analysis is the charac-terization of the bursts according to intensity and frequency content. Analyzing bursts from several sensors at well placed positions on the asset al-lows for determination of the location of the AE source(s) on the asset.

LaSER aLiGNmENTPrecision laser alignment of coupled machinery is critical to maximizing the performance and avail-ability of machine trains. Misaligned machines are more likely to experience seal and bearing failures and can result in reduced product quality and ultimately production shutdowns. Misalignment is most frequently detected during routine vibration data collection.

DyNamiC ROTOR BaLaNCEDynamic balancing extends your equipment’s life by eliminating vibration that destroys mechanical components. MISTRAS can balance rotors in their own bearings on site, utilizing portable equip-ment. Precision On-site balancing drastically re-duces downtime and repair costs, while increasing your productivity. Our staff brings extensive balancing experience to your plant for virtually every type, shape and size of rotor.

8

ThermographyVibration analysis

For more details and specifications, please visit us on the web at mistrasgroup.co.uk or call +44 (0) 1954 231612

Our Value Added Services Packages are encompassed in our Asset Integrity Management (AIMS) methodology. The AIMS ap-proach combines traditional NDT with Advanced NDT, Engineering analysis and our robust PCMS® software package, to yield cost effective solutions to current issues with regards to fixed and rotat-ing equipment in the Oil and Gas industry. Most plants utilize traditional inspection techniques to inspect the assets that are covered in the plant’s mechanical integrity program to prioritize their fixed assets based on time and interval based programs, with the data residing in an Inspection Data Management System (IDMS). In our case, the data is housed in our Plant Condition Monitoring Software (PCMS®).

Advanced techniques are utilized as stand alone technology, part of a technology solution to com-bine engineered pre-project planning with Risk Based Inspection (RBI) techniques (also available in PCMS®) or a combination of multiple advanced techniques with more definitive quantitative inspection techniques used to “prove up” our holistic approach(es).

Most of these technologies are implemented while the asset is still in service, thereby eliminating or greatly reducing the cleaning, environmental remediation and disposal costs required to inspect the asset while it is out of service. This also reduces the unanticipated discovery and associ-ated inspection and repair cost when the assets are opened. In all cases, MISTRAS personnel can

not only provide the inspection technology that is appropriate based on anticipated damage mecha-nism, but also house the data within PCMS® and evaluate the data by performing code approved engineering calculations that yield accurate remaining useful life, and run, repair or replace-ment decisions.

An additional benefit of using MISTRAS is our abil-ity to provide on-line health monitoring on high risk critical assets to allow plant operators to con-tinue to operate an asset that exhibits high risk of potential failure until the plant can implement a cost effective alternative plan, such as the repair or replacement of the asset in question.

CaSE STuDy: EXTERNaL CORROSiON OF aBOVE GROuND PROCESS PiPiNGExternal corrosion in above ground piping can oc-cur due to a variety of issues including corrosion under insulation, Touch Point Corrosion (TPC) or Point of Contact corrosion. MISTRAS provides a holistic program to address these two concerns as well as addressing other concerns such as Retro Positive Material Identification to determine if the proper weld filler material was used during piping construction (a common failure in the Oil and Gas industry).

As illustrated in our Asset Integrity Management approach our external corrosion program follows a regimented, consistent method that prescribes the proper technologies to identify potential dam-

ValUe aDDeD serVices Packages (VasP)9

Permanently installed monitor (PimS) LSi Results

For more details and specifications, please visit us on the web at mistrasgroup.co.uk or call +44 (0) 1954 231612

age as well as provide operating decisions to the plant owners regarding the ability to run, repair or replace the asset. Our standardized corro-sion program utilizes external visual inspections, performed by an API 570 inspector, to verify piping isometrics or correct any “field” deviations from the isometric drawings. In addition, the inspec-tor identifies potential problem areas. Corrosion monitoring locations (CML’s) are assigned based on API 570 criteria along with good engineer-ing practice. Next, thickness measurements are obtained using a combination of ultrasonic thickness readings, ultrasonic corrosion surveys or traditional/computed profile radiography. All measurements are then populated into our PCMS® database.

In the case of Corrosion under Insulation, Touch Point Corrosion or other more sophisticated pro-grams, the following steps are performed:• Identify piping systems of interest• Walk down piping systems while reviewing,

verifying and editing all P&ID and Isometric drawings normally performed by an API 570 visual inspector

• Enter drawings into PCMS®• Globally inspect the piping systems using Guid-

ed Ultrasonic Long Range inspection. Indicate where potential damage is occurring and if part of a PMI retrofit program, transcribe weld line details to updated P&ID’s and ISO’s. If GUL is being used for Touch Point Corrosion concerns, indicate those TPC’s that exhibit potential dam-age and note on drawings.

• Follow up qualitative or semi-qualitative in-spections. For TPC concerns, utilize MISTRAS’ proprietary Pocket UT® system for touch point corrosion. Results are expressed in percent-age wall loss within a range. For weld defects related to PMI concerns, utilize phased array and/or P-Scan ultrasonic technology. For vari-ous process induced anomalies (HIC, SOHIC etc.) utilize a combination of Time of Flight Diffrac-tion and P-Scan.

• Indicate amount of pipe wall loss, location of damage and extent of damage using LSI™/Pocket UT® C-Scan mapping

• Evaluate extent of damage using Fitness for Service calculations. FFS results will indicate future operational decisions such as repair, replace or run and monitor

• On-line monitoring using Acoustic Emission, Vibration, Strain Gauging or other On-line techniques using MISTRAS’ Sensor Highway II™ system tied into the plant’s control room or remotely monitored from MISTRAS corporate office

• Upload all data into PCMS®• Reinspect using standard API calculations

imbedded in PCMS® software or utilize API 580 based RBI calculations for reinspection data also imbedded in PCMS®

10

Finite Element analysis risk Based inspection Rope access

•Eliminatescaffoldingcost

•Refinersaved$945,000ina3monthperiodavoidingscaffolding

•UsePCMS®RBItoprioritizeappropriateNDTinspectiontechniques.

One Source forAssetProtectionSolutions

Scan this 2D Code with your smartphone’s barcode reader for more O&G information.

Copyright © 2016 MISTRAS Group, Inc. All Rights Reserved. Specifications and features subject to change without notice.#410B-15100-01

UNITED KINGDOM HEAD OFFICE

OTHER LOCATIONS

MISTRAS CAMBRIDGE

Norman Way Industrial Estate

Over, Cambridge, CB24 5QE

United Kingdom

TEL: +44 (0) 1954 231612

FAX: +44 (0) 1954 231102

E-MAIL: [email protected]

WEB: mistrasgroup.co.uk

MISTRAS HARTLEpOOL108 Graythorp Industrial EstateHartlepool, Cleveland, TS25 2DF, UKTEL: +44 (0) 1429 233323E-MAIL: [email protected]

MISTRAS BRIDGEND17 Village Farm Industrial EstatePyle, Bridgend, CF33 6BL, UKTEL: +44 (0) 1656 740232E-MAIL: [email protected]

MISTRAS ABERDEENHowe Moss CrescentKirkhill Industrial EstateDyce, Aberdeen, AB21 0GN, UKTEL: +44 (0) 1224 725277E-MAIL: [email protected]

MISTRAS ROTHERHAMUnit 21 Aspen CourtBessemer WayRotherham, South Yorkshire, S60 1FB, UKTEL: +44 (0) 1709 377443E-MAIL: [email protected]

![yarriambiack.vic.gov.au · Web view2020-02-09 · RFT for: [insert RFT title] RFT Reference No. [insert] Part 4 Page | 9 . RFT for: Supply & Delivery Used/Demo Tractor . RFT Reference](https://static.fdocuments.us/doc/165x107/5e8ea29539577a3486056189/web-view-2020-02-09-rft-for-insert-rft-title-rft-reference-no-insert-part.jpg)