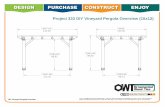

ACT 333 Project

-

Upload

sakibmdshafiuddin -

Category

Documents

-

view

25 -

download

0

description

Transcript of ACT 333 Project

North south University

Course: Managerial Accounting (ACT- 333)

Project

Implication of the mechanics of Managerial Accounting on a product

Product Name: Birds House

Submitted to- Submitted by-

Afrin Rifat (Ani) Group – ABC

Section – 1

LETTEROFTRANSMITTAL

Date: 8th August, 2015

Afrin Rifat

Course Instructor, Introduction to Managerial Accounting

School of Business

North South University,

Bashundhara, Dhaka.

Subject: Seeking permission for submitting the Project report.

Dear Madam:It is our pleasure to submit this report, which is a part of this course: ACT 333 (Managerial Accounting). While accomplishing this project we had to start a manufacturing company from scratch and manufacture our selected product i.e. “Birds House”. In doing so we had to set a price of our product, determine various costs, allocate these costs and prepare budgeted financial statements. Moreover we had to conduct detailed analysis e.g. margin of safety, break-even analysis and sensitivity analysis for given situations. All these activities have corroborated our accounting concepts to a significant extent. In our report we have included all relevant calculations and supporting information. We sincerely hope that this report will fulfill the requirements suggested by you for the course ACT 333.

Sincerely Yours

No Name ID1 Md.MirajHossen 12107440302 Sakib Md. Shafiuddin 13204130303 Tariqul Islam 13204560304 Md. Al Mamun 1311210630

ABSTRACTThis report is aimed to exhibit major accounting practices used by a company for which we had to open a new manufacturing company and manufacture our selected products. In the Introduction of the report reasons behind selecting the product has been described. The next section Birds House “Industry” Birds House about the competitors of the company. This section is followed by “Manufacturing Process” which gives a precise description of how our selected product i.e. Birds House has been manufactured. In the next section, we have showed a calculation of maximum number of units that will be produced in a month for which we have assumed that, we, the members of the group are only available labors. Production cost of the product includes Direct Materials Cost, Indirect Materials Direct Manufacturing Labor Cost, and Indirect Manufacturing Overhead Cost. Based on all relevant and necessary calculations a per House production cost of 373 TK has been calculated. The support cost to manufacture the product includes administrative expenses and selling cost includes transportation, advertising and sales commission. All the costs have been classified in several categories i.e. fixed and variable, direct and indirect, prime and conversion cost. Each of month birds house produce 500 house and capacity of the company produce almost 550 house. In the following sections we have described the costing strategy and pricing strategy that we have applied. While formulating pricing strategy we have also taken into account the prices of the products of competing companies. As per project guideline, we have prepared some forecasted statements i.e. forecasted sales budget, forecasted production budget, Direct Materials usage budget, Direct Manufacturing Labor budget etc. in the section entitled “Forecasting”. While forecasting these, we followed the strategy to keep 15% of the budgeted unit sales as finished goods inventory and 25% of the materials used in production as ending inventory. Based on the forecasted statements we have prepared budgeted income statement and budgeted contribution format income statement. This section is followed by the calculation of Break-even point in both unit sales and in revenue. Moreover with a view to get an idea about riskiness of the product we have calculated margin of safety for our product. Based on all the previous calculations, degree of operating leverage is also calculated. Finally a sensitivity analysis has been conducted for two different situations i.e. 12% increase and 16% decrease in the demand of theproduct.

Table of Contents

Serial No. Content Page no.

1 Background 5

2 Industry (Handicraft) 6

3 Manufacturing process 7

4 Maximum capacity 8

5 Production cost(direct material, direct manufacturing labor, manufacturing overhead cost )

8

6 Selling and administrative cost 10

7 Cost analysis(fixed/variable, direct/indirect, prime/conversion)

11

8 Full cost 15

9 Simple costing system ( job costing ) 15

10 Allocation of support cost 16

11 Activity-based costing system 18

12 Pricing strategy 19

13 Product line profitability 20

14 Budgets 21

15 Budgeted contribution format income statement 26

16 Budgeted income statement ( traditional format ) 27

17 Break- even point 27

18 Margin of safety 28

19 Degree of operating leverage 28

20 Sensitivity analysis 29

1. Introduction

The product we have decided to manufacture is Birds House. It is basically made from wood, board, grill, water pot, food pot etc. now a days, bird houses are becoming interesting to a lot of people as they are more concern about expressing the hobbies. It is basically considered as a product which is used to keep our birds. But bird house is not only for birds to stay, it can be used as a show-piece too. Recently the popularity of using of birds house has become more and more popular and people find it really interesting to use something that they can make by their own. Though the house is made of wood, board ,girl but it does not seem like that because the manufacturing process of the house is quite tricky. The house looks like a beautiful house and the design of the house is quite unique. Basically we have found the manufacturing process of the house from internet and it's been same modify by all group members. We have uploaded the manufacturing process in the internet and we found it quite enticing and that is why we chose to manufacture the product.

Reasons behind selecting the productThe reason that we have chosen to manufacture the product is that it looks like beautiful house and it is also a low price product , quite easy to manufacture. Nowadays people more conscious about their hobby and happiness, so we do believe it would be a good idea to choose birds house as our product. The market of souvenir is not that much saturated in our country and most of the products available in the market are imported from abroad. That is why we have decided to manufacture birds house as we can provide people something through which they will be able to enjoy country made product. That is why we have decided to manufacture such a product which can contribute to the society as well as provide benefit to the company.

2. Industry Analysis

The product of ours belongs to the birds sale stores and gift shop industry. These two industries are considered as one of the prolific industry in the world as well as in Bangladesh. The demand for among people is quite high as these things are comparably cheap to purchase as well as liked by all class of people who lives if birds. In terms of there is no gender problem as most of the products in these two industries are made for unisex. The products that belong to industries are gift shop, birds stores, furniture shop etc . The market of showpiece items is still growing in Bangladesh and in the near future there is a huge possibility that this market will be the next big thing in the country.

CompetitorsThe competitors that we have in the market are not in great numbers but not also in small number either. The main competitor that we have is the Furniture and small birds stores . This market is dominated by these few stores and they act as a dominant stores in the industry. In every market there are storeitems which we also considered as our competitors. Though the competition seems a bit tougher but we are quite hopeful about the sustainability of our business. The reason of being optimistic about the product is because it is being made by using eco-friendly materials and also the design of the product is alluring. In order to compete with our competitors we will distribute our products among local birds stores and furniture shop to compete with those branded shop rather than taking risk of opening up a new store to run the business.

3. Manufacturing Process

We will have two portions in the manufacturing process. All the work will be done by one person. In the first part we will make the roof and in the second part we will make the walls of the bird house ready. After finishing both portions we will join them and make a beautiful bird house . manufacturing process is given below –

1. First we have to draw the roof top design in the board with a pencil . then we will cut those boards using the saw according to the design.

2. After that we have to add the boards together by using pin and glue. We will use hammer for joining the different parts. Our roof is ready

3. Now we have to make our bird house walls. For that we will first cut wood sticks and then make a frame . we can use glue and pin to make our frame.

4. At this time we need to attach grills with the wooden frame.

5. After that we will join our roof and walls together using a hammer and pins. So our basic bird house is completely made.

6. Now we have to add some value to our house. As it is a bird house we will add a water pot for the birds to drink water and a food pot in order to feed them.

7. At last we can make our bird house more beautiful and glassy if we polish it with a leaker burnish. this particular step is not compulsory but this step can be taken as an option.

4. Maximum Productivity

According to the project rule we have to consider our group members as our labor. In our group we have four members and each of them agreed to work eight hours per day. Also the labors are willing to work extra two hours each day if they are being paid fifty percent more than their original wage per hour. To make profit, we need to produce a good amount of birds house and for that reason we agreed to the proposal. The number of days the labors will work is twenty six days and every Friday will be a day off for them. Below is the table that illustrates the maximum number of units we will be able to produce.

Calculation for maximum number of units:Number of Labors= 4

Total working hours for each labor per day= 10 hours (8 hours+2 hours)

Total working hours by all the labors per day= (10 Hours×4)= 40 hours

Number of labors

Total working hours for each labor per day

Total working hours by all the labor each day

Number of working days

Total number of working hours each month

Number of hours to produce each house

Maximum Number of houses can be produce each month

4 10 hours =10*4=40

26 =26*40=1040

2 =1040/2=520

Number of working day= 26 days

Total number of working hours each month=(26 Hours×40)=1040 hours

Number of hours to produce each unit of product=2 hours ( Basically it takes two hours to manufacture one product by each labor .

Maximum number of units can be produced each month= (1040 Hours÷2 Hours) =520 units

5. Production Cost Determination

The production cost of our selected product i.e. birds house includes Direct Materials cost, Direct Manufacturing Labor cost, and Manufacturing Overhead cost. We are expecting to produce 500 units of products.

Direct Material Cost:

For producing 500 house of birds house in a month,

1) wood Cost = (Tk.75/house ×500house) = Tk.37500

2) Cost for board = (Tk.100/house ×500houses) = Tk.50,000

3) girl cost = (Tk.60/house ×500house) TK = Tk.30000

4) water pot cost=(Tk.5/house*500 house) Tk.=2500

Direct material Units needed Cost per unit of direct material

Total cost per unit of bird house

1.Wood stick 1.5 piece 50 Tk.752. Board 4 square feet Tk.25 Tk.1003.Grill 4 piece Tk.15 Tk.604.Water pot 1 piece Tk.5 TK.55.Food pot 1 piece Tk.5 Tk.56.Tray 1 piece Tk.15 TK.15

Total TK.260

5) tray cost=(Tk.15/house*500 house) Tk=7500

6) food pot=( Tk.5/house*500 house) Tk=2500

Total Direct Material Cost:

= (37500+50000+30000+2500+7500+2500)=130000tk

Direct Manufacturing Labor (DML) Cost:

Direct manufacturing labor cost

Cost per direct labor hour Direct labor hour needed per unit

Total direct manufacturing labor cost per unit

50 tk 2 hours 100 tk

Manufacturing overhead cost :

These are the costs that cannot be traced directly to a specific product. Manufacturing overhead costs include indirect material, indirect manufacturing labor and all other factory related costs we incur to produce our product. So manufacturing overhead costs of our product is given below-

Costs (monthly)Indirect material :1. Glue gum2. Pin3. Pencil

1000 tk100 tk

40 tkIndirect manufacturing labor :1. supervisorOther costs :1. rent (factory)2. utilities ( factory)3. depreciation of hammer *4. depreciation of saw *

2500 tk

2500 tk500 tk100 tk111 tk

.’. Total manufacturing overhead cost 6851 tk

* Though we don’t need any heavy machinery for our production process, we will need some small equipment in order to manufacture the goods such as hammer and saw. Since

we have only 4 labors available, that’s why 4 hammer and saw will be required. We have decided to purchase 4 hammer at the cost of 600 tk per hammer and 4 saw at the cost of 1000 tk per saw. we will use these guns for 3 years. However the cost of the depreciation is allocated below in monthly basis –

4 hammers x 600 tk = 3600 tk

monthly depreciation =3600/(3x12)

= 100 tk

4 saw x 1000 tk = 4000 tk

Monthly deprcialton = 4000/(3x12)

= 111 tk

6. Support Cost and Selling Cost Determination

These are the selling and administrative costs incurred to operate the business as well as to sell the product. Like all other companies , our business has also some support and selling costs –

selling and administrative costs Total

1. Rent (showroom)2. Utilities (showroom)3. Sales man’s salary4. Accountant5. Convince6. Logistic coordinator7. Miscellaneous8. Depreciation of office furniture *

2500 tk500 tk

2500 tk3000 tk1000 tk1000 tk500 tk

83 tk

.’. total selling and administration cost 1183 tk

* For the purpose of running the business successfully, we will need some fixed assets such as office furniture. We have decided that we will buy furniture at the total cost of 10000 and these assets will be consumed over 10 years. So monthly depreciation for these furniture are calculated below –

Monthly depreciation = 10000/(10x12)

= 83 tk

7. Cost Analysis

In order to make our house, we have incurred a lot costs. These are different according to the types. Some are fixed cost, some are variable. We have incurred some direct cost as well as some indirect cost. However the costs of our product are analyzed and classified below in different types –

Fixed and variable costs

Fixed costs are those costs which are permanent for a certain period of time and do not change with the volume. On the other hand, variable costs are the costs that varies when activity or volume changes.

Total Costs(monthly)

Costs per unit

Fixed costs

1. Supervisor2. Rent-

Factory Showroom

3. Utilities- Factory Showroom

4. Depreciation of hammer5. Depreciation of saw6. Sales man’s salary7. Accountant8. Convince9. Logistic coordinator10. Miscellaneous11. Depreciation of office furniture

2500tk

2500tk2500tk

500tk500tk100tk111 tk2500tk3000tk1000tk1000tk500tk83tk

5

55

11

0.20.22

56221

0.17

.’. total fixed costs16794tk 34tk

Cost per unit Total cost

Variable cost

1. Wood stick 75 37500

2. Board 100 50000

3. Grill 60 30000

4.Water pot 5 2500

5.Food pot 5 2500

6.Tray 15 7500

7. Direct manufacturing labor 100 50000

8.Pin 0.2 100

9. Pencil 0.08 40

10. Glue 2 1000

Total 362 181140

* pin , pencil and glue are indirect material. So it is not possible to feasibly trace them to the product. We cannot determine exactly how much glue or pin is used for production. That’s why we have estimated an amount that will be needed per month. Since we can produce maximum 500 units in a month, therefore we have determined these costs per unit through dividing the costs by the units. The calculations are as follows-

Glue cost per unit = 1000/500 = 2

pencil cost per unit =40/500 = 0.08

pin cost per unit = 100/500 = 0.2

Direct and indirect costs

Direct cost is a cost that can be easily and conveniently traced to a specified cost objects. On the other hand indirect costs are opposite. These costs are presented in a table below-

Cost per unit Total cost

Direct cost

1. Wood stick 75 37500

2. Board 100 50000

3. Grill 60 30000

4.Water pot 5 2500

5.Food pot 5 2500

6.Tray 15 7500

7. Direct manufacturing labor 100 50000

8.Convince 2 1000

Total 362 181000

Indirect costs

1. Supervisor2. Rent-

Factory Showroom

3. Utilities- Factory Showroom

4. Depreciation of hammer5. Depreciation of saw6. Sales man’s salary7. Accountant8. Conveyance9. Logistic coordinator

5

55

11

0.20.22

5622

2500tk

2500tk2500tk

500tk500tk100tk111 tk2500tk3000tk1000tk1000tk

10. Miscellaneous11. Depreciation of office furniture12. Pencil13. glue

10.170.08

20.2

500tk83tk

401000100

.’. total fixed costs36tk 17934tk

Prime /conversion costs

Prime Costs are all direct manufacturing cost which is the combination of direct material and direct manufacturing labour costs. in contrast conversion costs are all manufacturing costs other than direct material costs.Prime and conversion costs of our product are –

Prime cost=(Direct manufacturing labor cost+ Direct material cost)

=Tk. (50000+130000)

= Tk. 180000

Conversion Cost==(Direct manufacturing labor cost+ Manufacturing overhead cost)

= Tk. (50000+6851)

=Tk. 56851

8. Full Cost Determination

Full cost is normally the sum of all variable and fixed costs in all business functions of the value chain ( R&D, design, production, marketing, distribution, and customer service). Determining full cost is very important because based on this cost, most of the businesses set their product price. Full cost is calculated below –

Full cost per unit = variable cost per unit + fixed cost per unit

= 362+34

= 396

Total full cost = total variable cost + total fixed cost

=181140+16794

=197934

9. JOB COSTING SYSTEM

There are many different types of systems to determine the manufacturing cost of a product. Among these systems, job costing system is the most common system. It is also called simple costing system. For our product , unit manufacturing cost is calculated under this simple costing system –

Allocation Base

Our allocation base is Direct Labor Hour

Direct Labor Hour = per day 8 hour × 4 person ×26days

¿832 Direct Labor Hour

Manufacturing overhead cost ¿ 6851tk

Manufacturing overhead cost¿manufacturingoverhead cost

Direct Labor Hour

¿6851 tk

832hours

¿8.23 tk per hours

Product costs using the simple costing system

Per unit cost (taka) Total cost (taka)

Direct material (260*500) 260 130000

Direct manufacturing labor(100*500) 100 50000Total Direct cost 360 180000Manufacturing Overhead(8.23tk*500) 8.23 4115Total cost 368 184115

10. ALLOCATION OF SUPPORT COST

we have determined that there will be 2 support departments in our business to assist operation department. These departments are maintenance and procurement departments. Moreover from the manufacturing process we can identify that we have 2 operation departments. These are production and joining department( here roof will be made and joined with the walls ). Here the cost of each department is shown underneath –

Support department Operation departmentMaintenance procurement production Joining

1. Rent (showroom)2. Utilities3. Accountant4. Miscellaneous5. Convince6. coordinator7. Direct material *8. Direct manufacturing

labor *9. Manufacturing overhead

*

.’. total

25005003000500

10001000

8000037500

5151

5000012500

17006500 2000 122651 64200

We have 3 approaches to allocated the support cost to operating department. These are direct, step-down and reciprocal method. But here we will use direct method because this is easy to use.

Now the support costs will be allocated to the operation department –

Support department Operation department TotalMaintenance

procurement production joining

Cost incurred before allocation

6500 2000 122651 64200 195351

Allocation of Maintained cost (6500*66%,34%)

(6500) 4290 2210

Allocation of Procurement cost (2000*66%, 34%)

(2000) 1320 680

Total cost after allocation 0 0 128261 67090 195351

Production department : 122651/ (122651+64200) = 0.66 or 66%

Joining department : 64200/(122651+64200) = 0.34 or 34%

11. ACTIVITY BASED COSTING SYSTEM

Activity based costing is another system of determining the unit manufacturing cost. But this type of costing is not alike simple costing system. Here several activities are established and there are several allocation rates. Here we have found 2 activities to allocate all indirect costs. So the indirect costs under each activity is shown below –

Identifying the indirect costs associated with each cost allocation base

Production Administration Total

Salaries (supervisor, accountant, salesman)

2500tk 5500tk 8000tk

Rent (factory and showroom rent)

2500 2500 5000

Utility 500 500 1000Depreciation 211 83 183Miscellaneous 500 500Logistic coordinator 1000 1000.’. total 66711tk 9083tk 15683tk

*production Cost will increase with the level of production. If we increase the production level we will need more man power and space to support.

*The demand for administrative resources increases with direct manufacturing labor hours.

Activity cost rates indirect cost pool

No. Activity Cost Hierarchy category

Total Budgeted indirect Cost

Budgeted Quantity

Allocation base

Budgeted indirect cost rate (taka)

1 production Output unit level

6711 500 units Number of unit

13.42

2 Administration

Facility sustaining

9083 832hrs. Direct labor hrs.

10.92

Product cost using activity based costing

Per Unit(taka) Total(taka)Direct CostsDirect material (260*500) 260 130000

Direct manufacturing labor(60*576) 100 50000

Total Direct cost 360 180000Indirect Costs of Activitiesproduction (13.42*500) 13.42 6711Administration (10.92*2hrs*500) 21.84 10920Total 395 197631

12. PRISING STRATEGY

Selecting a proper pricing strategy is very important. It helps a business to survive in the market by providing accurate price based on the market perception, customer demand and competitors etc. Out of two pricing approaches we have determined to use cost plus pricing approach to calculate our product price. The reason behind choosing this strategy is that our business is on handicraft goods. So we are staying in a perfectly competitive market where we don’t have much power to the choice of setting the price by ourselves. But while pricing, we also have to be careful because too high price may reduce the demand. However we have decided that the mark up rate of our product will be 25 percent of full cost. Here the price is determined by using this approach below-

Selling price = full cost + mark up

= 396 + (396x0.25)

= 49

13. PRODUCT LINE PROFITABILITY

Operating income product line profitability report under Simple Costing

Bird houseRevenue (495*500) 247500(-)cost of goods manufactured (368*500) 184000Gross profit 63500(-)Selling and administration 9500Total operating income 54000

Profit margin ratio=operating income

revenue

=54000

247500

=.2182 or 21.82%

Operating income for product under ABC Costing

Royal Hand FanRevenue (495*500) 247500(-)cost of goods manufactured (395*500) 197500Total operating income 50000

Profit margin ratio=operating income

revenue

=50000

247500¿

¿

=.2002 or 20.20%

14. BUDGETS

the maximum number of units we can produce in a month is limited. So we cannot supply more than the production even if the demand is more.

So we have predicted that the demand will be more or less same or close to our production. Therefore we are expecting to sale approximately 500 units in every month. Now based on the forecast, some important budgets are prepared below in the tables –

Schedule 1: Revenue Budget

For the month ending august 31, 2015

Product Units Selling price Total revenue

Bird house 500 495 247500

Schedule 1: Production budget

For the month ending august 31, 2015

Bird house

Budgeted sales in units(+) desired ending inventory ( 500units x 10% )

.’. Total requirement

(-) beginning inventory

500

50

550

0

.’. total units to be produced 550

Schedule 3A:Direct material usage budget

For the year ending august 31, 2015

wood board grill Waterpot

Foodpot

tray total

Physical unit budget

Direct material needed per unit

.’. direct material to be used in production(550x1.5,4,1)

1.5 4 4 1 1 1

825 2200 2200 550 550 550

Cost budget

Cost per unit of direct material

.’. cost of direct material to be used in production

50 25 15 5 5 15

14300041250 55000 33000 2750 2750 8250

Schedule 3B:Direct material purchase budget

For the year ending august 31, 2015

wood board grill Waterpot

Foodpot

tray total

Physical unit budget

direct material to be used in production(+) desired ending inventory (20%)

Total requirement

(-) beginning inventory

.’. direct material to be purchased in unit

825

165

2200

440

2200

440

550

110

550

110

550

110

990 2640 2640 660 660 660

990 2640 2640 660 660 660

Cost budgetCost per unit of direct material

.’. cost of direct material to be purchased

50 25 15 5 5 15

17160049500 66000 39600 3300 3300 9900

Schedule 4: Direct manufacturing labor budget

For the year ending august 31, 2015

Product Output units Hour per unit

Total hour Rate per hour

Total cost

Bird house 550 2 1100 50 55000

Schedule 5: Manufacturing overhead budget

For the year ending December 31, 2015

TotalVariable costs

1. Glue ( 550x2)2. pin (550x0.2)3. Pencil 550x0.08)

.’. total variable costs

110011044

1254

Fixed costs

1. Supervisor2. Rent3. Utilities4. Depreciation of hammer and saw

.’. total fixed costs

.’. total manufacturing overhead costs

25002500500211

5711

6965

Bird house cost per unit-

Direct material1.Wood 752.Board 1003.Grill 604.Water pot 55. Food pot 56.Tray 15

Direct manufacturing labor 100Manufacturing overhead

1. Pin 0.22. Pencil 0.083. Glue 24. Supervisor ( 2500/550) 4.555. Rent (2500/550) 4.556. Utilities (500/550) 0.917. Depreciation (211/550) 0.38 __________

.’. Unit manufacturing cost 373

Schedule 6: Ending inventory budget

For the year ending December 31, 2015

TotalDirect material inventory

1. Wood 165*502. Board 440*253. Grill 440*154. Water pot 110*5

8250110006600550

5. Food pot 110*56. tray 110*15

.’. total direct material inventory

Finished goods inventory

Bird house (50x373)

.’. total ending inventory

5501650

35200

18650

53850

Schedule 7: Cost of goods sold budget

For the year ending December 31, 2015

TotalBeginning inventory

(+) cost of goods manufactured Direct material cost Direct manufacturing labor cost Manufacturing overhead cost

.’. total goods available for sale

(-) ending finished goods inventory

.’. cost of goods sold

143000550006965

0

204965

(18650)

186315

Budgeted Contribution Format income statement

For the year ending December 31, 2015

Per unit Total

Selling price (500 units) 495 247500

(-) variable cost

.’. contribution margin

(-) Fixed cost1. Supervisor2. Rent-

Factory Showroom

3. Utilities- Factory Showroom

4. Depreciation of hammer and saw5. Sales man’s salary6. Accountant7. Convince8. Logistic coordinator9. Miscellaneous10. Depreciation of office furniture

.’. total fixed costs

.’. Net operating income

(362) (181000)

133 66500

5

55

11

0.4256221

0.17

2500

25002500

500500211250030001000100050083

(33.59) (16794)

99.4 49706

Budgeted income statement

For the year ending December 31, 2015

From schedule Total

Revenue(-) COGSGross profitOperating costs

1. Rent (showroom)2. Utilities (showroom)3. Sales man’s salary4. Accountant5. Convince6. Logistic coordinator7. Miscellaneous8. Depreciation of office

furniture

17

25005002500300010001000500

83

247500(186315)

61185

(11083)

.’. total operating costs

.’. net operating income 50102

17. Break-even point

Break-even is very much important because through this analysis we can determine how many units we have to sell to cover the cost and make profit. Here the break-even point of our product both in units and in revenue is shown below-

Break-even point in units = total fixed costs/ contribution margin = total fixed cost / (selling price per unit-variable cost per unit) = 16794 / 133 = 127 units we have t sell to meet the break-even point.

Break-even point in revenue = 127* 495 = 62865

MARGIN OF SAFETY

Margin of safety is an aspect of sensitivity analysis. It is the amount by which budgeted revenues exceed breakeven revenues. The margin of safety answers the “what if” question such as if budgeted revenues are above breakeven and drop, how far can they fall below budget before the breakeven point is reached.

Margin of safety ( in revenues) = budgeted revenues – breakeven revenues = 247500 – 62865 = 184635Margin of safety ( in units) = budgeted sales(units) – breakeven sales(units) = 500-127 = 373unitsBy observing the analysis, we have noticed that our business is safe by the revenue of 62865 tk. So we will not incur any loss even if our sale falls by this amount. But if the actual revenue falls more than the margin of safety, then we will incur lose.

19. OPERATING LEVERAGE

It is a vital analysis that is needed in every organization. So the operating leverage is calculated below –

Operating leverage = contribution margin / operating income = 66500/49706 = 1.34 timesThe result indicates that, when sales are 500 units, a percentage change in sales and contribution margin will result in 1.34 times that percentage change in operating income.

20. SENSITIVITY ANALYSIS

Sensitivity analysis is a “what if “technique that managers use to examine how an outcome will change if the original predicted data are not achieved or if an underlying assumption changes.

For example if the demand of the product increases by 12%,. then the new increased sales volume will be –

( 500+500x12% ) = 560 units. So based on this new volume, we can find out our profitability condition –

Contribution format income statement For the month ending May 31, 2015

Per unit Total

Selling price (560 units)(-) variable cost

.’. contribution margin

(-) Fixed cost1. Supervisor2. Rent-

Factory Showroom

3. Utilities- Factory Showroom

4. Depreciation of hammer and saw5. Sales man’s salary6. Accountant7. Convince

495(362)

277200(202700)

133 74480

4.5

4.54.5

0.90.90.384.55.361.79

2500

25002500

500500211250030001000

8. Logistic coordinator9. Miscellaneous10. Depreciation of office furniture

.’. total fixed costs

.’. Net operating income

1.790.90.15

100050083

(30.17) (16794)

103 57686

if the demand for our product decreases by 16%, then the new reduced sales volume will be –

( 500-500x16%) = 420 units. Now based on the new volume, operating profit or cost will be –

Contribution format income statement For the month ending May 31, 2015

Per unit Total

Selling price (420 units)(-) variable cost

.’. contribution margin

(-) Fixed cost1. Supervisor2. Rent-

Factory Showroom

3. Utilities- Factory Showroom

4. Depreciation of hammer and saw5. Sales man’s salary6. Accountant7. Convince8. Logistic coordinator9. Miscellaneous10. Depreciation of office furniture

495(362)

207900 (152040)

133 55860

5.9

5.95.9

1.191.190.55.95.212.382.381.190.19

2500

25002500

500500211250030001000100050083

.’. total fixed costs

.’. Net operating income

(39.98) (16794)

93 39066

![Paged Coffee Act Cap. 333 - No. 9 of 2001 Act Chapter 333... · 2017-08-03 · [Rev. 2012] CAP. 333 Coffee 5 [Issue 1] CHAPTER 333 COFFEE ACT [Date of assent: 31st December, 2001.[Date](https://static.fdocuments.us/doc/165x107/5f4bb6de5051954d701ceae0/paged-coffee-act-cap-333-no-9-of-2001-act-chapter-333-2017-08-03-rev.jpg)