Abstract New Design Testing - TAMU College of EngineeringTo verify that the new design was more...

Transcript of Abstract New Design Testing - TAMU College of EngineeringTo verify that the new design was more...

Jacob Arend, Leon Guan, Matthew Monroe, Taylor Rupp, D’Anne Wilder, David Yu, Juan Gilardo Texas A&M University

Abstract

Method

New Design

Block Diagram

System Sketch

Testing

This project entailed enhancing the design of a “Small-scale

Concentrating Solar Thermal System” to heat water with maximum efficiency.

To verify that the new design was more efficient due to minimizing elements

of heat loss, a test was conducted to find the heat transfer of the copper heat

pipe (used in the original design) to an aluminum cylindrical block. A

stagnation test was then performed to test the efficiency of the new design,

which proved to be 19.057% efficient. The new design appeared to be more

efficient, but has much room to be further improved to reach maximum

efficiency.

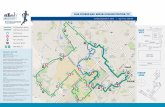

Evacuated Tube

Water

Tank

Fresnel Lens

Sunlight

Flow Meter

The new design has water entering the evacuated tube through a

copper pipe (at the top inlet) and exiting the system through an output pipe

(at the right outlet) after being heated. The design provides more efficient

heat transfer by decreasing free convection and increasing forced

convection. This is done by having the water flow directly through the

evacuated tube. In addition, by eliminating the copper heat pipe, the

design reduces the radiation resistance and overall loss of the system.

Stagnation Test (No Water Flow)

12

13

14

15

16

17

18

19

20

21

22

11

/11

/201

3 1

4:2

4

11

/11

/201

3 1

4:2

6

11

/11

/201

3 1

4:2

7

11

/11

/201

3 1

4:2

8

11

/11

/201

3 1

4:3

0

11

/11

/201

3 1

4:3

1

11

/11

/201

3 1

4:3

2

11

/11

/201

3 1

4:3

4

11

/11

/201

3 1

4:3

5

11

/11

/201

3 1

4:3

6

11

/11

/201

3 1

4:3

8

11

/11

/201

3 1

4:3

9

11

/11

/201

3 1

4:4

0

11

/11

/201

3 1

4:4

2

11

/11

/201

3 1

4:4

3

11

/11

/201

3 1

4:4

4

11

/11

/201

3 1

4:4

6

11

/11

/201

3 1

4:4

7

11

/11

/201

3 1

4:4

8

11

/11

/201

3 1

4:5

0

11

/11

/201

3 1

4:5

1

11

/11

/201

3 1

4:5

2

11

/11

/201

3 1

4:5

4

Temperature Change

Temperature Change

Linear (Temperature Change)

Dynamic Test (With Water Flow)

0

200

400

600

800

1000

1200

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

11/1

1/2

01

3…

Irradiance

Irradiance

𝐸𝑠𝑡𝑜𝑟𝑒𝑑 = 𝑚𝑐∆𝑇

= (200 𝑔) 4.186𝐽

𝑔 ∗ ° 𝐶(5° 𝐶)

= 4186 𝐽

𝐴𝑒 = 𝜋𝑟𝑙 = 0.01178 𝑚2

𝐸𝑖𝑛 = 𝐴𝑒𝐼 𝑑𝑡 = 21456 𝐽𝑡

0

𝜂 =𝐸𝑠𝑡𝑜𝑟𝑒𝑑𝐸𝑖𝑛

= 19.507 %

This monitoring system allows us to store information about

different factors that determine what is going on at any time at the

Concentrator. The system monitors temperature at different important

locations; it also reads input solar irradiance from a pyranometer and

flow of current of the water system. All of this information is displayed

at all times on a LCD screen attached to the Arduino controller and

ready to be extracted through the SD card plugged to the monitoring

system. All of the information is dated and recorded on a text file

indicating the readings from each sensor.

Initial Design

To maximize heat transfer of the water,

several aspects needed to be tested to

improve the original design. Originally,

the design had a copper heat pipe

inserted from the center of the

evacuated tube to a water header,

which the water ran through, to transfer

the heat as shown below in Figure 1.

This design was rejected because too

much heat would be lost due to free

convection and conduction, so a new

design was implemented.

Due to many problems,

the dynamic test could

not be properly

performed. Before any

data could be recorded,

the evacuated tube burst

due to the water being

too cool for the quickly

heated glass under the

fresnel lens.