Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

-

Upload

jaime-vesga-cohen -

Category

Documents

-

view

221 -

download

0

Transcript of Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

-

7/26/2019 Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

1/12

Adsorption of uranium(VI) by grapefruit peel in a fixed-bedcolumn: experiments and prediction of breakthrough curves

Weihua Zou Lei Zhao Lu Zhu

Received: 23 April 2012 / Published online: 25 July 2012

Akademiai Kiado, Budapest, Hungary 2012

Abstract Adsorbent, natural grapefruit peel (GFP) exhi-

bit good efficacy to adsorb a highly toxic radioactive heavymetal, uranium(VI). Through the fixed-bed column tech-

nique adsorption characteristics of uranium(VI) is observed

at different flow rate, bed depth, influent uranium(VI)

concentration and particle size of adsorbent. The results

showed that adsorption reached saturation faster with

increasing the flow rate and influent uranium(VI) concen-

tration while it was the advantage of column adsorption

with the increase in the GFP bed. The data were fitted to

the Thomas model, the Yan model, the Clark model and the

mass transfer model by nonlinear regressive analysis.

When the flow rate was 8.0 mL min-1 and the influent

concentration of uranium(VI) was 90 mg L-1, the maxi-

mum adsorption quantity reached 104.1 mg g-1 according

to the Thomas model. The bed depth service time model

was applied to predict the service times with other flow rate

and initial concentration. The theoretical breakthrough

curve was compared with experimental breakthrough curve

profile in the dynamic process. The results showed that the

Yan model was better for the description of breakthrough

curves at the experimental conditions than the Thomas and

the Clark models. The saturated column was regenerated

by 0.05 mol L-1 hydrogen chloride solution and GFP

could be reused in uranium(VI) removal.

Keywords Column adsorption Grapefruit peel

Uranium(VI) Dynamic model

Introduction

Uranium is one of the most important heavy metals because

of its strategic importance in the energy field. Thus, exces-

sive quantities of uranium have entered into environment

due to activities of nuclear industry. The toxic nature of the

radionuclides, even at trace levels, has been a public health

problem for many years [1, 2]. Thus, the removal of uranium

from wastewater is of great importance [3].

Adsorption technology is one of the effective methods

used to remove heavy metals from aqueous solutions and

agricultural wastes or by-products are considered to be the

most potential low-cost adsorbents for wastewater treatment

[47]. Up to now, different types of biomass have been uti-

lized for adsorption of uranium(VI). They include rice straw,

olive cake, wood powder and wheat straw, etc. [710].

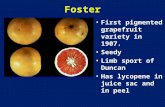

Grapefruit peel (GFP) is one of the valuable agriculture

biomass wastes, principally consisting of cellulose, pectin,

hemicellulose, lignin, chlorophyll pigments and other low

molecular weight hydro-carbons [11]. It is also found to

contain abundant carboxyl and hydroxyl functional groups,

thusmakingit a potential adsorbent materialfor severalmetals

through ion exchange and/or complexation mechanism. The

pattern of adsorption of ions onto GFP was attributable to the

active groups and bonds present on them [12]. These groups

may function as proton donors, hence deprotonated hydroxyl

and carboxyl groups may be involved in coordination with

positive ions. UO22? ions are positively charged and will

undergo attraction on approaching the anionic GFP structure.

On this basis, it is expected that an UO22? ion will have a

strong sorption affinity by GFP. Since GFP is a cheap,

W. Zou (&) L. ZhaoSchool of Chemical Engineering and Energy, Zhengzhou

University, 100# of Kexue Road, Zhengzhou 450001,

Peoples Republic of China

e-mail: [email protected]

L. Zhu

Department of Chemistry, Zhengzhou University, 100# of Kexue

Road, Zhengzhou 450001, Peoples Republic of China

1 3

J Radioanal Nucl Chem (2013) 295:717727

DOI 10.1007/s10967-012-1950-4

http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?- -

7/26/2019 Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

2/12

renewable, biodegradable and readily available material often

considered as waste [11, 12], its advantage over synthetic

materials such as polymers is enormous and contributes to the

actual trend of green chemistry.

In the previous paper, we have reported the adsorptive

removal of uranium(VI) by an GFP adsorbent in batch

method [12]. The adsorption characteristic obtained from

batch experiments is useful in providing fundamentalinformation about the effectiveness of the uranium(VI)/

GFP system. Batch adsorption provides certain preliminary

information such as pH for maximum adsorption, maxi-

mum initial uranium(VI) concentration, and approximate

time for adsorption of uranium(VI) ions as well as the

adsorption capacity of the adsorbent. All these information

are useful for fixed-bed studies.

Batch adsorption experiments are used easily in the

laboratory for the treatment of small volume of effluents,

but less convenient to use on industrial scale, where large

volumes of wastewater are continuously generated [13]. In

fixed-bed, the adsorbate is continuously in contact with agiven quantity of fresh adsorbent, thus providing the

required concentration gradients between adsorbent and

adsorbate for adsorption. During the flow of the wastewater

through the percolator, the wastewater is purified by

physicochemical processes. The design and theory of fixed-

bed adsorption systems focuses on establishing the shape of

the breakthrough curve and its velocity through the bed.

The performance of packed beds is described through the

concept of the breakthrough curve [13].

The aim of the present work is to explore the possibility

of utilizing GFP for the adsorptive removal of uranium(VI)

from wastewater in fixed-bed columns. The effect of such

factors such as the flow rate, influent concentration, bed

depth and particle size of adsorbent on uranium(VI)

adsorption by GFP bed column was investigated, respec-

tively. The dynamic process of adsorption was modeled by

Thomas model, Yan model, Clark model, bed depth service

time (BDST) model and mass transfer model. Error anal-

ysis was carried out to test the adequacy and the accuracy

of the model equations. Regeneration studies were also

carried on the adsorbent.

Models

The Thomas model

The expression by Thomas for an adsorption column is

given below [14]:

Ct

C0

1

1expkThq0x=QkThC0t 1

where, Ct is the effluent uranium(VI) concentration

(mg L-1), C0 is the influent uranium(VI) concentration

(mg L-1), kTh is the Thomas rate constant (mL min-1

mg-1),q0is the maximum uranium(VI) uptake per g of the

adsorbent (mg g-1), x is the amount of adsorbent in the

column (g), Q, the flow rate (mL min-1). The value of

Ct/C0is the ratio of effluent and influent each uranium(VI)

concentrations. The value of t is breakthrough time (min,

t= Veff/Q, Veffis the volume of effluent solution).

The values ofkTh and q0 can be determined from a plotof Ct/C0 against t for a given flow rate using nonlinear

regression analysis as the values of Ct/C0 is within

0.050.90.

The Yan model

The Yan model [15] is also used to describe the column

adsorption data. Use of this model can minimize the error

resulting from the use of the Thomas model, especially at

lower or higher time periods of the breakthrough curve.

The expression is given as:Ct

C01

1

1 Qtba

2

where a and b are the constants of the Yan model,

respectively. From value of b, the value of q0 can be

estimated using following equation [15]:

q0bC0

x 3

The Clark model

Clark [16] defined a new simulation of breakthroughcurves. The model developed by Clark was based on the

use of a mass transfer concept in combination with the

Freundlich isotherm [16]:

Ct

C0

1

1Aert

1=n14

From a plot of Ct/C0 against t at a given bed height and

flow rate using nonlinear regressive analysis, the values of

A and rcan be obtained.

The bed depth/service time analysis (BDST) model

BDST is a simple model for predicting the relationship

between bed depth, Z (cm), and service time, t (min), in

terms of process concentrations and adsorption parame-

ters. BDST model is based on the assumption that the

rate of adsorption is controlled by the surface reaction

between adsorbate and the unused capacity of the

adsorbent [17].

The values of breakthrough time obtained for various

bed heights used in this study were introduced into the

718 W. Zou et al.

1 3

http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?- -

7/26/2019 Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

3/12

BDST model. A linear relationship between bed depth and

service time given by Eq. (5)[17]:

t N0

C0FZ

1

KaC0ln

C0

Ct1

5

A plot of t vs. Z, should yield a straight line where N0(mg L-1) andKa (L mg

-1 min-1), the adsorption capacity

and rate constant, respectively, can be evaluated.A simplified form of the BDST Model is:

t aZ b 6

where

a N0

C0F 7

b 1

KaC0ln

C0

Ct1

8

The slope constant for a different flow rate can be directly

calculated by Eq. (8)[17]:

a0 aF

F0 a

Q

Q0 9

where a and F (cm min-1) is the old slope and influent

linear velocity and a 0 and F0 (cm min-1) is the new slope

and influent linear velocity, respectively. As the column

used in experiment has the same diameter, the ratio of

original (F) and the new influent linear velocity (F0) and

original flow rate (Q) and the new flow rate (Q0) is equal. It

was assumed that the value of b does not change signifi-

cantly by change in flow rates.

For other influent concentrations, the desired equation is

given by a new slope, and a new intercept given by fol-

lowing expression:

a0 aC0

C0010

b0 C0ln

C00

C0t

1

C00ln C0

Ct1

b 11

whereb0,b are the new and old intercept, respectively; C00and C0 are the new and old influent concentration,

respectively. C0t is the effluent concentration at influent

concentration C00 and Ct is the effluent concentration atinfluent concentration C0.

The mass transfer model

The data obtained from the batch adsorption isotherm can

be used to predict the theoretical breakthrough curve,

which can be well compared with the experimental

curve. The detailed calculations for the generation of the

experimental breakthrough curve from the equilibrium data

obtained from batch studies are as follows [18,19]:

(1) An experimental equilibrium curve is drawn assum-

ing various values ofCe(the value is equal to Ct) and

calculating the corresponding values of qe using the

best fit isotherm model obtained from the batch

results.(2) An operating line is drawn, which was passing

through the original and end points obtained by

experimental equilibrium curve. The significance of

this operating line is that the data of the continuously

batch reactor and the data of the fixed-bed reactor are

identical at these two points, first at the initiation and

other at the exhaustion of the reaction.

(3) According to Weber, the rate of transfer of solute

from solution over a differential depth of column, dh,

is given by Eq. (12):

vdC K0a CC dh 12

where v is the wastewater flow rate, K0a the overall mass

transfer coefficient, which includes the resistances offered

by film diffusion andpore diffusion and C* is the equilibrium

concentration of solute in solution corresponding to an

adsorbed concentration, qe.Theterm(C- C*) is the driving

force for adsorption and is equal to the distance between the

operating line and equilibrium curve at any given value of

qe. Integrating Eq. (12) and solving for the height of the

adsorption zone:

hZ v

K0a

Z CECB

dC

CC 13

For any value of h less than hZ, corresponding to a

concentration C between CB and CE, E q . (13) can be

written as:

h v

K0a

Z CCB

dC

CC 14

Dividing Eqs. (14) by(13) results in Eq. (15)

h

hZ

RCCB

dC= CC

RCE

CBdC= CC

V VBVE VB

15

where VB and VE are total volume of water treated till

breakthrough and up to exhaust point, respectively, and V

is the volume of water treated within VE for effluent

concentration C within CE. Dividing the values ofRCCB

dC= CC by the valueRCE

CBdC= CC the term

(V- VB)/(VE - VB) was evaluated.

(4) Now the plot of Ct/C0 versus (V- VB)/(VE - VB)

represents the theoretical breakthrough curve.

Adsorption of uranium(VI) by GFP in a fixed-bed column 719

1 3

http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?- -

7/26/2019 Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

4/12

Error analysis

As different formulate used to calculate R2 values would

affect the accuracy more significantly during the linear

regressive analysis, the nonlinear regressive analysis can be

a better option in avoiding such errors [14, 20]. So the

parameters of different kinetic models were obtained using

nonlinear analysis according to least square of errors.In order to confirm which model was better, error

analysis was performed. Relative mathematical formula of

SS is:

SS

PCt=C0c Ct=C0e

2

N 16

where (Ct/C0)c is the ratio of effluent and influent ura-

nium(VI) concentrations obtained from calculation accord-

ing to dynamic models, and (Ct/C0)e is the ratio of effluent

and influent uranium(VI) concentrations obtained from

experiment, respectively; N is the number of the experi-

mental point. In order to confirm the best fit isotherm forthe adsorption system, it is necessary to analyze the data

using SS, combined the values of determined coefficient

(R2).

Experimental

Materials

Reagents

All chemicals and reagents used for the study were analyticalgrades, and all aqueous solutions were prepared in distilled

water. The stock solution of 1,000 mg L-1 uranium(VI) was

prepared by dissolving accurately weighted amount of

UO2(NO3)26H2O, while working solutions were obtainedby diluting the stock solution. The initial pH of the working

solution wasadjusted by addition of HCl andNaOH solution.

Arsenazo III solution was prepared by dissolving0.5 g of the

reagent in 1,000 mL of distilled water.

A simple and sensitive spectrophotometric method based

on coloured complexes with arsenazo III in an aqueous

medium was used for the determination of the uranium(VI)

ion concentration [21]. The concentration of uranium(VI)ions in solution was determined spectrophotometrically by

absorbance measurements at kmax = 588 nm using a Shi-

madzu Brand UV-3000 spectrophotometer.

Adsorbent preparation

Grapefruit peels was selected and washed with water sev-

eral times to remove ash and other contaminants. Then it

was washed with double distilled water and was dried at

70 C inside a convection oven for 24 h. The dried GFPs

was crushed and sieved to obtain a particle size range of

1620, 2040 and 4060 mesh for future use.

Methods of adsorption studies

Column adsorption was operated in 1.10 cm diameter glass

column (weighted mass of GFP packed in column) at298 K. The uranium(VI) solution was pumped from the

container to the fixed-bed with a peristaltic pump at a

specified flow rate. The pH of uranium(VI) solution was

adjusted to 5.0 by addition of 0.1 mol L-1 HNO3 or

0.1 mol L-1 NaOH solution, respectively. No other solu-

tions were provided for additional ionic strength. Samples

of the effluent were collected at regular intervals and the

effluent concentrations were analyzed for the uranium(VI)

content. Upon column exhaustion, the adsorbed ura-

nium(VI) from GFP were eluted by using 0.05 mol L-1

HCl solution. Usually, breakthrough and exhaustion were

defined as the phenomenon when effluent concentrationswere about 5 and 90 %, respectively.

Result and discussion

Influence of operating conditions on column sorption

of uranium(VI)

The effect of bed depth on breakthrough curve

The breakthrough curves of the ratio between effluent and

influent concentration (Ct/Co) versus time for various bed

depth of 6.4, 9.6 and 12.6 cm (2.09, 2.99 and 3.84 g) at a

constant flow rate of 8 mL min-1 and uranium(VI) initial

concentration of 90 mg L-1 are shown in Fig.1. FromFig.1,

as the breakthrough time and exhaustion time increased with

the bed depth. The bed depth (adsorbent mass) increased,

uranium(VI) had more time to contact with GFP and this

resulted in higher removal efficiency of uranium(VI)ions in

column. So the higher bed column resulted in a decreasein the

effluent concentration at the same service time. The slope of

breakthrough curve decreased with increasing bed depth,

which resulted in a broadened mass transfer zone. High

adsorptioncapacity was observed at thehighest beddepth due

to an increase in the surface of adsorbent, which provided

more binding sites for the adsorption [22, 23]. The adsorption

capacities are listed in Table1.

The effect of flow rate on breakthrough curve

The effect of flow rate on the adsorption of uranium(VI)

ions in the GFP column was investigated by changing the

flow rate from 5.8 to 10.3 mL min-1 at the bed depth of

720 W. Zou et al.

1 3

http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?- -

7/26/2019 Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

5/12

9.6 cm. The initial uranium(VI) concentration was holdconstant at 90 mg L-1. As seen in Fig. 2, the adsorption

arrived saturation faster with increasing flow rate. Break-

through time reaching saturation was increased signifi-

cantly with a decreased in the flow rate. The tendency

accorded with other research [18,24]. When at a low rate

of inlet uranium(VI) had more time to contact with GFP

that resulted in higher removal of uranium(VI) ions in

column. The variation in the slope of the breakthrough

curve and adsorption capacity may be explained on the

basis of mass transfer fundamentals. At higher flow rate,

the rate of mass transfer gets increases, i.e. the amount of

uranium(VI) adsorbed onto unit bed height (mass transfer

zone) gets increased with increasing flow rate leading to

faster saturation at higher flow rate [24]. At a higher flow

rate, the adsorption capacity was lower due to insufficient

residence time of the solute in the column and diffusion of

the solute into the pores of the adsorbent, and therefore, the

solute left the column before equilibrium occurred.

The effect of initial concentration on breakthrough curve

Initial uranium(VI) concentration of 60, 90 and 120

mg L-1 were used to study the column studies at flow rate

of 8 mL min-1 and Z= 9.6 cm. The change in the initial

uranium(VI) concentration had a significant effect on

breakthrough curve (Fig.3). It is illustrated that the

breakthrough time slightly decreased with increasing initialuranium(VI) concentration. At lower influent uranium(VI)

concentrations, breakthrough curves were dispersed and

breakthrough occurred slower. As influent concentration

increased, sharper breakthrough curves were obtained. This

can be explained by the fact that a lower concentration

gradient caused a slower transport due to a decrease in the

diffusion coefficient or mass transfer coefficient. The larger

the influent concentration, the steeper is the slope of

breakthrough curve and smaller is the breakthrough time.

These results demonstrate that the change of concentration

gradient affects the saturation rate and breakthrough time,

or in other words, the diffusion process is concentrationdependent [17]. The adsorption capacity was expected to

increase with increasing the influent concentration because

a high concentration difference provides a high driving

force for the adsorption process.

The effect of particle size of GFP on breakthrough curve

The adsorption process of GFP was performed at various

particle sizes. Figure4 showed the results of the experi-

ments carried out at a flow rate of 8.0 mL min-1 for dif-

ferent particle sizes ranged from 1620 mesh to 4060 mesh.

The initial uranium(VI) concentration was 90 mg L-1.

It was observed from Fig.4 that the column with a

larger adsorbent particle size had an earlier breakthrough,

and the slope of the breakthrough curve increased with a

decrease in particle sizes. The equilibrium adsorption

capacity (qe(exp)) increased significantly. The results may

be due to the fact that the adsorption is a surface

0 300 600 900 1200

0.0

0.2

0.4

0.6

0.8

1.0

6.4 cm

9.6 cm

12.6 cm

Thomas model fitted curve

Yan model fitted curve

Clark model fitted curve

Ct

/C

0

t/min

Fig. 1 Comparison of the experimental and predicted breakthrough

curves obtained at different bed depth according to the Thomas, the

Yan model and the Clark model

Table 1 Thomas parameters at different conditions

C0 (mg L-1) Q (mL min-1) Zcm Particle size (mesh) qe(exp) (mg g

-1) q0 (mg g-1) kTh (mL mg

-1 min-1) R2 SS

90 8.0 6.4 2040 108.4 95.5 3.5 0.082 0.006 0.9671 0.002390 8.0 9.6 2040 111.0 104.1 1.9 0.061 0.003 0.9856 0.0012

90 8.0 12.6 2040 133.1 116.3 1.8 0.055 0.003 0.9814 0.0019

120 8.0 9.6 2040 122.0 111.3 2.4 0.054 0.003 0.9866 0.0012

60 8.0 9.6 2040 101.1 88.2 1.6 0.076 0.003 0.9804 0.0018

90 5.8 9.6 2040 136.2 124.7 1.6 0.044 0.002 0.9860 0.0013

90 10.3 9.6 2040 103.9 91.7 2.8 0.088 0.006 0.9764 0.0020

90 8.0 9.6 4060 127.6 121.9 1.2 0.093 0.004 0.9927 0.0008

90 8.0 9.6 1620 95.1 85.1 2.4 0.060 0.003 0.9733 0.0019

Adsorption of uranium(VI) by GFP in a fixed-bed column 721

1 3

http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?- -

7/26/2019 Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

6/12

phenomenon and the extent of adsorption is expected to be

proportional to the specific surface. So effective surface

area increase as particle size decreases and as a conse-

quence, the saturation adsorption per unit mass of adsor-

bent increases.

Evaluation of breakthrough curves

In order to describe the fixed-bed column behavior and to

scale it up for industrial applications, five models, Thomas,

Yan, Clark, mass transfer and BDST were used to fit the

experimental data in the column.

Application of the Thomas model

The column data were fitted to the Thomas model to

determine the Thomas rate constant (kTh) and maximum

solid-phase concentration (q0). The determined coefficients

and relative constants were obtained using non-linearregression analysis according to Eq. (1) and the results are

listed in Table1. The values of SS (less than 0.0023) at

various conditions are also listed in Table1. From Table1,

it is seen that values of determined coefficients (R2) range

from 0.9671 to 0.9927. From Table1, as the influent

concentration increased, the value ofq0 increased but the

value ofkTh decrease. The reason is that the driving force

for adsorption is the concentration difference between

uranium(VI) ions on the adsorbent and uranium(VI) ions in

the solution [14]. Thus, the high driving force due to the

higher uranium(VI) concentration resulted in better column

performance. The bed capacity q0 decreased while the

value ofkTh increased with the flow rate increasing. With

the bed volume increasing, the value of q0 decreased. As

the particle size of GFP increases, the value ofq0 and kThdecreases. So higher flow rate and lower influent concen-

tration have a disadvantage for the adsorption of ura-

nium(VI) on the GFP column.

The predicted curves at various experimental conditions

according to the Thomas model are shown in Figs.1,2,3

and4, respectively. It was clear from the figures that there

was a good agreement between the experimental points and

predicted normalized concentration. The Thomas model is

suitable for adsorption processes where the external and

internal diffusions will not be the limiting step [14].

Application of the Yan model

The Yan model constants (aand b) and the values ofq0are

listed in Table 2 using nonlinear regressive analysis. From

Table2, they were fitted higher determined coefficients

(R2) ranging from 0.9902 to 0.9993 and lower values of SS

(less than 9.59 10-3). From Table2, as the bed depth

increased, the value of a, b and q0 increased. While with

the flow rate increasing, the value ofa,b and q0decreased.

The bed capacity q0 increased while the value of a and

b decreased with the influent concentration increasing. As

the particle size of GFP increases, the value ofq0decreases

but the values ofa and b decreased. The all values ofq0in

Table2are smaller than those in Table1.

The comparison of the experimental points and pre-dicted curves according to the Yan model are also shown in

Figs.1, 2, 3, and 4 at different experimental conditions.

The experimental breakthrough curves were significantly

close to those predicted by the Yan model. So the corre-

lation between the experimental and predicted values using

the Yan model conformed significantly.

0 300 600 900 1200 1500

0.0

0.2

0.4

0.6

0.8

1.0

10.3 mL min-1

8.3 mL min-1

5.8 mL min-1

Thomas model fitted curve

Yan model fitted curve

Clark model fitted curve

Ct

/C

0

t/min

Fig. 2 Comparison of the experimental and predicted breakthrough

curves obtained at different flow rate according to the Thomas, the

Yan model and the Clark model

0 300 600 900 1200

0.0

0.2

0.4

0.6

0.8

1.0

120 mg L

-1

90 mg L-1

60 mg L-1

Thomas model fitted curve

Yan model fitted curve

Clark model fitted curve

Ct

/C

0

t/min

Fig. 3 Comparison of the experimental and predicted breakthrough

curves obtained at different concentration according to the Thomas,

the Yan model and the Clark model

722 W. Zou et al.

1 3

http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?- -

7/26/2019 Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

7/12

The amount of uranium(VI) adsorbed on the GFP col-umn was approximately 104.1 and 94.1 mg g-1 at the

initial uranium(VI) concentration of 90 mg L-1, flow rate

of 8 mL min-1 and bed depth of 9.6 cm, which calculated

according to the Thomas and the Yan model, respectively.

The maximum adsorption capacity (qm) of GFP was also

investigated in a batch experiment with a variable initial

uranium(VI) concentration. Using the Langmuir model, the

qm was calculated to be 140.8 mg g-1 adsorbent. This

means that the capacity of column system in this study was

lower than that of batch system. In the batch process, the

adsorption reached equilibrium in 90 min [12], while the

time of these column studies was less than 10 min.

Therefore, the studied flow rate might not provide suffi-

cient contact time for uranium(VI) to distribute throughout

all surface area of the adsorbent. It is also difficult to

control the column conditions in order to obtain the maxi-

mum loading of uranium(VI), because the flow distur-

bances, channeling effects, and clogging are easily occurred

in the column. Therefore, the batch system may provide

better interaction between uranium(VI) and adsorbent than

the column system.

Application of the Clark model

In our previous study [12], the Freundlich constants of

1/n were obtained in a batch experiment. The value of1/n (0.336) calculated according to Freundlich model at

298 K was used to calculate the parameters in the Clark

model. The values of A and r in the Clark model were

determined using Eq. (4) by nonlinear regression analysis

and are shown in Table 3. As seen in Table3, as both flow

rate and influent dye concentration increased, the values of

r increased. However, the values of r decreased when the

bed depth and particle size of adsorbent increased. Plotting

Ct/C0 against taccording to Eq. (4) also gave the break-

through curves predicted by the Clark model (also shown

in Figs. 1, 2, 3, and4). From the experimental results and

data regression, the model proposed by the Clark modelprovided good correlation on the effects of bed depth,

influent uranium(VI) concentration, flow rate and particle

size of adsorbent.

Comparison of the Thomas, the Yan and the Clark

models

Among the Thomas, the Yan and the Clark models, the

values of R2 from the Yan model and the Thomas model

are higher than that of the Clark model. The value of error

(SS) for the Yan was lowest for a given experimental

condition, while it was the largest for the Clark model. At

all conditions examined, the predicted breakthrough curves

from the Yan model showed reasonably better agreement

with the experimental curves than the Thomas and Clark

models. At the lower and high time of breakthrough curves,

the fitted curves of the Clark model were far from exper-

imental points. Thus, it was concluded that the Yan model

0 200 400 600 800 1000

0.0

0.2

0.4

0.6

0.8

1.0

40-60 mesh

20-40 mesh

16-20 mesh

Thomas model fitted curve

Yan model fitted curve

Clark model fitted curve

Ct

/C

0

t/min

Fig. 4 Comparison of the experimental and predicted breakthrough

curves obtained at different particle size of adsorbent according to the

Thomas, the Yan model and the Clark model

Table 2 Yan parameters at different conditions

C0 (mg L-1) Q (mL min-1) Zcm Particle size

(mesh)

a b (mL) q0 (mg g-1) R2 SS

90 8.0 6.4 2040 1.96 0.06 1938.5 32.2 83.5 1.4 0.9950 0.00043

90 8.0 9.6 2040 2.25 0.08 3126.9 51.9 94.1 1.6 0.9902 0.00080

90 8.0 12.6 2040 2.95 0.03 4644.9 15.3 108.9 0.4 0.9993 0.00005

120 8.0 9.6 2040 2.11 0.10 2477.9 53.3 99.4 2.1 0.9895 0.00095

60 8.0 9.6 2040 2.33 0.05 3990.1 37.4 80.1 0.8 0.9960 0.00037

90 5.8 9.6 2040 2.64 0.04 3846.6 23.4 115.8 0.7 0.9974 0.00040

90 10.3 9.6 2040 2.16 0.06 2701.3 38.8 81.3 1.2 0.9962 0.00039

90 8.0 9.6 4060 4.09 0.06 3909.4 14.6 117.7 0.4 0.9991 0.00011

90 8.0 9.6 1620 1.84 0.06 2460.1 43.6 74.0 1.3 0.9917 0.00058

Adsorption of uranium(VI) by GFP in a fixed-bed column 723

1 3

http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?- -

7/26/2019 Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

8/12

was better to predict the uranium(VI)/GFP column

adsorption than the Thomas and Clark model. Several

researchers studied the metal removal by adsorption in the

column mode, and found that that the column kinetics

could be described more adequately by the Yan model than

by the Thomas model [15, 25, 26]. Our study on ura-

nium(VI) removal in column adsorption had similar results.

Application of the BDST model

The adsorption capacity (N0) and rate constant (Ka) canbe obtained through the BDST model. From the lines of

t- Z at values of Ct/C0 (0.20, 0.55 and 0.75) (shown in

Fig.5), the related constants of BDST according to the

slopes and intercepts of lines are listed in Table4,

respectively. From Table4, as the value ofCt/C0increased,

the adsorption capacity of the bed per unit bed volume,N0,

increased. From the values ofR

2

, the validity of the BDSTmodel for the present system is demonstrated. The BDST

model constants can be helpful to scale-up the process for

other flow rates and concentration without further experi-

mental runs.

The BDST equation obtained at a flow rate of

8.0 mL min-1 and influent concentration 90 mg L-1 was

used to predict the adsorbent performance at other flow rates

(5.8 mL min-1) and influent concentration (120 mg L-1),

respectively. The predicted time (tcal) and experimental time

(texp) are shown in Table 5. The percent values of error (E)

between theory (tcal) and experiment (texp) were also listed in

Table5. From Table5, values ofE were lower and goodprediction has been found for the case of changed feed

concentration and flow rate at Ct/C0 = 0.20, 0.55 and 0.75

Thus, model and the constants evaluated can be used to

design columns over a range of feasible flow rates and

concentrations at Ct/C0 = 0.20 0.55, 0.75, respectively.

These results indicate that the equation can be used to predict

adsorption performance at other operation conditions for

adsorption of uranium(VI) onto GFP column.

Mass transfer model based on batch isotherm studies

to the experimental data

According to mass transfer model, the date obtained from

the batch isotherm studies can be used to predict the

6 8 10 12 14

0

200

400

600

800

1000

Ct/C

0=0.20

Ct/C

0=0.55

Ct/C

0=0.75

t/min

Z/cm

Fig. 5 Iso-removal lines for breakthroughs of 0.20, 0.55 and 0.75,

respectively, for different bed depths

Table 3 Clark parameters at different conditions

C0 (mg L-1) Q (mL min-1) Zcm Particle size (mesh) A r9 103 R2 SS

90 8.0 6.4 2040 46.0 14.4 9.63 0.93 0.9488 0.0044

90 8.0 9.6 2040 71.8 15.9 7.16 0.44 0.9721 0.0024

90 8.0 12.6 2040 193.9 58.9 6.58 0.44 0.9640 0.0044

120 8.0 9.6 2040 63.3 15.5 8.56 0.62 0.9720 0.0025

60 8.0 9.6 2040 85.7 20.6 5.95 0.38 0.9637 0.0044

90 5.8 9.6 2040 139.7 31.1 5.25 0.28 0.9707 0.0026

90 10.3 9.6 2040 73.1 24.2 10.52 0.96 0.9591 0.0037

90 8.0 9.6 4060 1066.3 436.1 11.41 0.76 0.9812 0.0022

90 8.0 9.6 1620 36.3 8.38 6.91 0.52 0.9563 0.0031

Table 4 Calculated constants of the BDST model for the adsorption of uranium(VI) onto GFP

Ct/C0 a (min cm-1) b (min) Ka (L mg

-1 min-1) 9 104 N0 9 103 (mg L-1) R SD

0.20 40.2 7.3 159.8 71.7 0.964 3.04 0.55 0.9840 31.864

0.55 56.5 1.7 78.5 17.2 -0.284 4.27 0.13 0.9995 7.937

0.75 67.8 1.5 11.1 15.1 -11.0 5.13 0.11 0.9997 6.715

724 W. Zou et al.

1 3

http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?- -

7/26/2019 Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

9/12

theoretical breakthrough curve, which can be compared

with the experimental breakthrough curve. Evaluating the

result from fitting the batch experimental data to the

Langmuir, Freundlich, RedlichPeterson and KobleCor-rigan isotherm [12], it was showed that KobleCorrigan

isotherm (R2 = 0.9887) provided a best fitness compared

to others (Langmuir 0.9839, Freundlich 0.8938, Redlich

Peterson 0.9884). So the KobleCorrigan isotherm was

used to generate the theoretical breakthrough curve. Fig-

ure6 showed the theoretical breakthrough curves com-

pared with the experimental breakthrough curves which

relevant to 5.4, 9.6 and 12.6 cm bed depth, respectively.

The two curves followed the same trend with small dif-

ferences. Therefore, KobleCorrigan isotherm constants

found from the batch experimental data can be used to

predict the breakthrough in fixed-bed system for ura-nium(VI) adsorption onto GFP.

Desorption of uranium(VI) and regeneration of GFP

To make the process more effective and economically

feasible, sorbent regeneration and uranium(VI) recovery

must be evaluated. A simple test was carried out to see

whether the columns could be chemically regenerated. The

exhausted fixed-bed column was regenerated by passing

0.01 mol L-1 HCl, 0.05 mol L-1 HCl and 0.05 mol L-1

NaHCO3 solution with a flow rate of 2 mL min-1 down-

wards through the bed, respectively. In a previous paper,batch studies showed that a 0.05 mol L-1 HCl solution

allows desorption of uranium(VI) and regeneration of GFP

[12]. This can be correlated to the fact that in acid solutions

the electrostatic interaction between GFP and uranium(VI)

becomes much weaker and the adsorbed uranium(VI) ions

leaves the adsorption sites of GFP. Figure 7 illustrated the

elution curve of uranium(VI) from GFP with three

desorbing agents. The elution curves obtained in all cases

exhibit a similar trend. The concentration of the effluent

uranium(VI) is very high at the beginning of the desorption

process, and then drops quickly to a very low level. The

maximum concentrations of uranium(VI) are 11,230 mg L-1

Table 5 Predicted breakthrough time based on the BDST constants

for a new flow rate or new influent concentration (Z= 9.6 cm)

Ct/C0 a0 b0 tcal (min) texp (min) E(%)

b

Q0 = 5.8 mL min-1, C0 = 90 mg L-1

0.20 55.4 159.8 372 380 5.3

0.55 77.9 78.5 669 750 10.8

0.75 93.5 11.1 887 1,000 11.3Q = 8.0 mL min-1, C00 = 120 mg L

-1

0.20 30.2 119.9 170 150 13.3

0.55 42.4 58.9 348 360 3.3

0.75 50.9 8.3 480 520 7.7

b E tetcte

100 % -0.2 0.0 0.2 0.4 0.6 0.8 1.0 1.2

0.0

0.2

0.4

0.6

0.8

1.0

Ct

/C

0

(V-VB)/(V

E-V

B)

experimental breakthrough curve

theoretical breakthrough curve

Z= 5.4 cm

-0.2 0.0 0.2 0.4 0.6 0.8 1.0 1.2

0.0

0.2

0.4

0.6

0.8

1.0

Z= 9.6 cm

Ct

/C

0

(V-VB)/(V

E-V

B)

experimental breakthrough curve

theoretical breakthrough curve

-0.2 0.0 0.2 0.4 0.6 0.8 1.0 1.2

0.0

0.2

0.4

0.6

0.8

1.0

Ct

/C

0

(V-VB)/(V

E-V

B)

experimental breakthrough curve

theoretical breakthrough curve

Z= 12.6 cm

Fig. 6 Measured and predicted breakthrough curve according to the

mass transfer model (Z= 6.4, 9.6 and 12.6 cm; Q = 8 mL min-1;

C0 = 90 mg L-1)

Adsorption of uranium(VI) by GFP in a fixed-bed column 725

1 3

http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?-http://-/?- -

7/26/2019 Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

10/12

for 0.05 mol L-1 HCl, 8,538 mg L-1 for 0.01 mol L-1 HCl,

and 6,509 mg L-1 for 0.05 mol L-1 NaHCO3. The solution

of 0.05 mol L-1

HCl was the most effective desorbing agentamong the eluting agents, so it was selected as the desorbing

agent.

This cycle of adsorptiondesorption was repeated three

times to evaluate the efficacy of the regenerated GFP to re-

adsorb more uranium(VI) It was found that the regenerated

GFP column could be utilized for three cycles until com-

pletely exhausted. The result showed that more than 80 %

of adsorbed uranium(VI) could be recovered back in

solution by a solution using 0.05 mol L-1 HCl. The

wastage percent of GFP was less than 10 % after three

biosorptiondesorption cycles. Hence, it was proved that

the regeneration and reuse of GFP was an economical andefficient method for removal of uranium(VI) from water.

From the results of desorption and regeneration using

HCl solution, ion exchange was an important mechanism

of uranium(VI) adsorption onto GFP [12, 27]. Because

there was negative charge of hydroxyl group (-OH) and

carboxyl group (-COO-) on the surface of GFP, but

uranium(VI) existed in solution were positive. This sug-

gests that the one mechanism for the adsorption behavior

of uranium(VI) onto GFP be electrostatic interactions

between surface carboxylic groups of adsorbent and

cationic form of uranium(VI). In addition, GFP can

adsorb cation through ion exchange, or complexation, orby a combination of both processes. In a cation

exchange mechanism, H? will be released from the -OH

and -COOH bonds from GFP, meanwhile cationic ura-

nium(VI) will be adsorbed onto the active sites of the

adsorbent. The possible reactions are showed blow:

2GFPOH UO22 ! GFPO2UO2 2H

17

2GFPCOOH UO22 ! GFPCOO2UO2 2H 18

Conclusion

On the basis of the experimental results of this investiga-

tion, the following conclusions can be drawn:

(1) This study showed that GFP was an effective

adsorbent for removal of uranium(VI) from aqueous

solution.

(2) The adsorption of uranium(VI) was strongly depen-

dent on bed depth, the initial uranium(VI) concentra-

tion, the flow rate and particle size of GFP.

(3) At all experimental condition, the whole break-

through process can be described by Thomas, Yan

and Clark model. The Yan model is better used to

predict the breakthrough curves than the Thomas and

Clark model.

(4) The mass transfer model could provide a good

agreement between the experimental breakthrough

curve and theoretical breakthrough curve.

(5) Uranium(VI) ions were easily desorbed from GFP

column using 0.05 mol L-1 HCl solution and the

GFP column can be reused to remove uranium(VI)

from aqueous efficiently.

Acknowledgments This work was supported by the Education

Department of Henan Province in China (No. 2010A610003) and

Henan Science and Technology Department in China (No.

122300410163).

References

1. Bozkurt SS, Cavas L, Merdivan M, Molu ZB (2011) J Radioanal

Nucl Chem 288:867

2. Humelnicu D, Popovici E, Dvininov E, Mital C (2009)

J Radioanal Nucl Chem 279:131

3. Kadous A, Didi MA, Villemin D (2010) J Radioanal Nucl Chem

284:431

4. Mellah A, Chegrouche S, Barkat M (2006) J Colloid Interface Sci

296:434

5. Morsy AMA, Hussein AEM (2011) J Radioanal Nucl Chem

288:3416. Mahramanlioglu M, Bicer IO, Misirli T, Kilislioglu A (2007)

J Radioanal Nucl Chem 273:621

7. Bishay AF (2010) J Radioanal Nucl Chem 286:81

8. Konstantinou M, Pashalidis I (2007) J Radioanal Nucl Chem

273:549

9. Bagherifam S, Lakzian A, Ahmedi SJ, Rahimi MF, Halajnia A

(2010) J Radioanal Nucl Chem 283:289

10. Bursali EA, Merdivan M, Yurdakoc M (2010) J Radioanal Nucl

Chem 283:471

11. Saeeda M, Sharif M, Iqbala M (2010) J Hazard Mater 179:564

0 40 80 120 160 200

0

2000

4000

6000

8000

10000

12000

C

/(mgL-1)

t/min

0.05 mol L-1

HCl

0.01 mol L-1 HCl

0.05 mol L-1

NaHCO3

Fig. 7 Desorption curves of uranium(VI) through a packed bed of

GFP

726 W. Zou et al.

1 3

http://-/?-http://-/?-http://-/?-http://-/?- -

7/26/2019 Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

11/12

12. Zou WH, Zhao L, Zhu L (2012) J Radioanal Nucl Chem

292:1303

13. Unuabonah EI, Olu-Owolabi BI, Fasuyi EI, Adebowale KO

(2010) J Hazard Mater 179:415

14. Aksu Z, Gonen F (2004) Process Biochem 39:599

15. Yan G, Viraraghavan T, Chen M (2001) Adsorpt Sci Technol

19:25

16. Clark RM (1987) Environ Sci Technol 21:573

17. Goel J, Kadirvelu K, Rajagopal C, Garg VK (2005) J Hazard

Mater 125:211

18. Kundu S, Gupta AK (2005) J Colloid Interface Sci 290:52

19. Maji SK, Pal A, Pal T, Adak A (2007) Sep Purif Technol 56:284

20. Han RP, Wang Y, Zou WH, Wang YF, Shi J (2007) J Hazard

Mater 145:331

21. Misaelides P, Godelitsas A, Filippidis A, Charistos D, Anousi I

(1995) Sci Total Environ 173/174:237

22. Ahmad AA, Hameed BH (2010) J Hazard Mater 175:298

23. Vijayaraghavan K, Jegan J, Palanivelu K, Velan M (2004)

J Hazard Mater 113B:223

24. Han RP, Zou LN, Zhao X, Xu YF, Li YF, Li YL, Wang Y (2009)

Chem Eng J 149:123

25. Vijayaraghavan K, Prabu D (2006) J Hazard Mater 137:558

26. Lodeiro P, Herrero R, Sastre de Vicente ME (2006) J Hazard

Mater 137:244

27. Han RP, Zhang JH, Zou WH, Xiao HJ, Shi J, Liu HM (2006)

J Hazard Mater 133:262

Adsorption of uranium(VI) by GFP in a fixed-bed column 727

1 3

-

7/26/2019 Absorption of Uranium(VI) by Grapefruit Peel in a Fixed-bed Column

12/12

Copyright of Journal of Radioanalytical & Nuclear Chemistry is the property of Springer Science & Business

Media B.V. and its content may not be copied or emailed to multiple sites or posted to a listserv without the

copyright holder's express written permission. However, users may print, download, or email articles for

individual use.