ABC s of a Multi Project Control System

Transcript of ABC s of a Multi Project Control System

-

8/6/2019 ABC s of a Multi Project Control System

1/8

A-lDick Sharad, Member AACESupervisor - Project ControlNuclear Field Services Division

INTRODUCTION

Sargent & Lundy Engineers55 East Monroe StreetChicago, Il l inois 60603

ABCS OF A MULTIPROJECT CONTROL SYSTEM

throughout the project control processwithin practical, manageable limits.The requirements of cost and schedule controlin the case of a multi-million dollar industrialproject are enormous; to manage a major engineer-ing and construction program involv ing severalprojects is a real challenge for the owner as wellas the architect-engineer/construction manager.A sys tems approach facilitates meeting thischallenge generally in one of two ways: Eitherby integrating existing stand-alone sys tems involv-ing estimating and cost control, planning andscheduling, and production and productiv ity; orby developing a new integrated management systemwith modular design of subsystems for variousaspects of project control.This paper will discuss basic principles ofthe design and implementation of a project manage-ment sys tem in a multi-project environment. The

discussion is generic and educational, ratherthan a presentation of any particular sys tem.

PROJECT CONTROLCriteria

In the case of any large industrial project,cost and schedule control ought to receive thesame high level of management attention as theengineering, procurement and construction workitse lf. The project control criteria for projectmanagement are based on:1. Manageability - To keep management

abreast of the exact project status ,and to assist superv isory personnelin the planning and execution ofproject work, it is ensured that thenecessary extent of compatibility ismaintained in the detail with whichplans and schedules, estimating andcost accounting, and progress monitor-ing and status reporting are done.This facilita tes making timely deci-sions to keep the project in linewith specified objectives of targetdates and budgets.

The level of detail is maintained

2. Dependability - Detail and summary planningis done basically by the responsiblemembers of the project team. Each dis-cipline supervisor details his own workplan; the planning engineer coordinatesand integrates work plans of variousdisciplines. An adequate common database is developed and kept up-to-dateto be utilized for integrating cost,schedule, production, productiv ity, andaccounting.This participative approach yieldsdependable project reporting.

3. Computer Applicability - The computerapplications to the control processare established by the manageabilityand dependability criteria. The com-puter systems employed are meant toprovide the practical tool for thecontrol purposes with the capabilityof producing detailed and summaryreports on an as-required basis. Thereports are distributed at the appropriatelevel of management. The computeroutputs are supplemented by manually pre-pared analyses/critiques/interpreta-tionsirecommendations.A balanced use of computerization andanalytical review sustains the interestof the project personnel in makingfull use of what the computer systemscan offer.

Profile of a Typical Project Control SystemBefore considering the multi-project Situation,

it may be worthwhile to look at the profile Of atypica l project control system. The exhibit "Func-tional Criteria for Controln points out the majoraspects of project control. The project controltechnique applied to a specific project will con-sist of employing three main systems:

. A realistic scheduling sys tem.. A dependable cost/estimating sys tem.. A select ive progress measurement sys tem.

-

8/6/2019 ABC s of a Multi Project Control System

2/8

FUNCTIONAL CRITERIA FOR CONTROL e. Stand-Alone or Interconnected Net-works - The sys tem is capable ofsimultaneous processing of:- A multiple of totall y inde-pendent networks.- A multiple of totall y inde-pendent groups o f intercon-nected component networks.- A combination of the abovetwo sets of networks.PLAN & SCHEDULE

1. Scheduling System - A versatile schedul-ing system is generally an activ ity net-work based sys tem with several desirablefeatures:a.

b.

C.

d.

Integrated Modular Design - Depend-ing on the speci fic application, theuser may activa te those modules whichhe needs to control his tasks. Thebasic modules required for the input,analysis and report. The sys tem mayhave any of a variety of forms o fmodules, such as:- Input Processor (including filegenerating and storage procedure).- Time Analysis Processor.

- Resource Allocation and AnalysisProcessor.- Cost Analysis Processor.- Network Drafting Processor.- Report Processor.Flexibilit y to Use Partial/TotalCapability - The sys tem provides severaloptions of selecting the processormodules, as well as obtaining desiredset of sorts/reports within a module.Comprehensive diagnostic proceduresare built into the sys tem to correctinput errors and to guide the user.CPM or PERT Option - Single durationestimates (Critical Path Method) orthree duration - optimistic, normal,pessimistic - estimates (Program Evalua-tion and Review Technique) are acceptedfor the network activ ities.Arrow or Precedence Diagramming Method(ADM/PDM) - The sys tem can processnetworks whether they have activi tieson the arrow (ADM) or on the node (PDM).

PDM has certain inherant advantagesfor construction logic network structure,but ADM, being simpler, is more commonly used.

Interconnections of component networksmay optionally be removed at run time,whereby the component networks may beanalyzed as stand-alone networks.This feature is particularly usefulfor construction/project managementwork where interdependencies ofvarious contracts may be requiredto be evaluated for impact of workprogress of one contract on others;and variations in individual contractperformance may be prevented frominfluencing schedules already com-mitted.f. Resource Allocation and Cost Control -By establishing a compatible relation-ship between network activi ties andthe code of construction or projectactiv ity accounts, the schedulingsys tem presents an excellent tool tointegrate the cost/estimating andmonitoring aspects of project con-trol. The system has the capabilityto process the allocation of estimatedand available resources by activ ityin conjunction with the cost module.A cross-referencing method is employedin cases where more than one codenumbering sys tem is required for out-put reporting.

g. Network Drafting - The sys tem can beinstructed to draw logic network,histograms of resource-loading,cumulative curves, and bar chartschedules for any selected length o fproject period.h. Input and Output - The sys tem acceptsa variety of input data:- Calendar related, such as: Pro-ject period, unit of time (hour,

day, week, or month), holidays/weekends.- Activ ity related, such as:Activ ity on node/arrow, activ ityidentification/duration/description,any imposed start/finish dates,progress/update information.- Processing related, such as: Time/resources/cost as applicable,optional output/reports required,network drafting as required.- Resource related, such as: Re-source category , quantity requiredand units, associated activityreference, availability.- Cost related, such as: Costbreakdown structure/code ofaccounts, resource unit costs,estimates.

-

8/6/2019 ABC s of a Multi Project Control System

3/8

- Progress related, such as: Start/completion of activi ties, per-cent complete, projection forremaining work.

The system provides a variety of out--put data:- Structure listing of pre-decessors and successors.- Time listing of computed star t/finish dates and floa ts, withoptional sorts with variabletime spans.- Gantt Diagram reflecting datesand floats.- Criticality listing showingcritical paths in a decreasinghierarchical order.- Resource distribution by selectedtime units, cumulative sub-totals and totals.

- Estimate, forecast and actualcost data.- Actual/projected starts andfinishes, histogram/resourcedistribution, percent complete.- Network plots with variablescale.

2. Cost/Estimating System - The cost/est imat-,ing system may consist of two componentsystems: A cost estimating system and acost monitoring system.a. Cost Estimating System - Four basictypes of cost estimates may be pro-duced by the program: Initial, budget,preliminary, and detailed estimates.These estimates follow a chronologicalsequence, and progressively containmore precise information as projectdetails continue to become available.The project estimating system is de-signed to assist the client and theproject manager in the decision makingprocess related to financial andproject planning. The project scheduleis utilized to furnish information intwo primary areas: Physical require-ments of design drawings, materialsand equipment, and time requirementsfor erection and construction labor.The data gathered is useful in cal-culating the escalation/inflationcosts and in developing the cash flow.The estimate program calculatesmaterial and labor costs , total man-hours utilizing input data for quan-tities, unit costs, manhours perunit of work, and manhour rates. Acontingency amount, listed undereach major account, is usually pro-vided in all estimates. Summary ofdetailed cost estimate is providedwith subtotals and grand total ofestimated project cost, indirectcost, escalation cost, etc.Computer-plotted cash flow projec-tions for short and long-term reportsare prepared to reflec t interruption

or delays in schedules as well aspossible impact of any design or workscope change on construction.b. Cost Monitoring System - The basisfor the project cost monitoringsys tem rests in the schedulingsys tem, since the two complementeach other in terms of the level ofdetail at which the planning is doneand the work measurement is made.The system basically assists themanagement/supervisory personnel in keeping track of resource expendi-tures on project activi ties associatedwith the account codes, and evaluat-ing current or potential overrunsvis-a-vis schedule delays. Follow-ing are the highlights/benefits ofsuch a system:- Translate design/scope changesas reflected in constructioninto financial facts .- Relate project progress tocosts incurred.- Establish cost centers foraccountability.

- Evaluate alternate or cor-rective courses of action.c. Summary of Outputs - The outputs ofa good cost/estimating system may besummarized as follows:

- Project estimates - Initial,Budget, Preliminary, Detail.- Cash Flows - Monthly/YearlyReports, Histograms and/or"S" Curves.- Detail Cost Reports - Committedand Actual Costs , By Account,Purchase Order, Contract, and/orWork Package.- Financial Reports - MonthlySummary Reports for Entire Pro-ject, Individual Contract orWork Packages, Committed v s.Budgeted and Budgeted vs . Actualcosts.

3. Progress Monitoring System - For an effec-tive project control program, a progressmonitoring and status reporting sys temshould be operational in conjunction withthe cost and schedule systems. The pro-gress monitoring system may provide acombination of computerized and manuallyprepared analysis reports. In eff ect , itmay have two modules, namely, PhysicalMeasurement System and Progress Report-ing System.The progress monitoring mechanism hasthe following aspects to it:a. Schedule Related - The managementreporting of progress against theschedule is affected by thecriticality analysis report pre-pared each month to reflect cri-tical problems causing a delay or

having the potential of causingdelays. Detailed computer print-outs resulting from periodical re-visions/updates are made availableto the supervisors for their res-3

-

8/6/2019 ABC s of a Multi Project Control System

4/8

pective areas, systems and dis-cipline responsibility.b. Cost Related - The cost/estimatingsystems provide various summaryand detail reports that are com-prised of expenditures by projectaccount, manpower/material fore-

casts and cash flow projections.c. Accomplishments Related - To com-pare the resource expenditures withphysica l accomplishments, informa-tion reports are developed to in-clude percent completions of installedquantities and manhours, variancesof actuals from estimates, and pro-duction in relation to the producti-vit y. Accomplishments in variousproject areas, such as: Design,engineering, procurement, construc-tion, and start-up, are established,and by using appropriate weightings,they are combined to determineoverall project status.d. Narrative Synopsis/Project Reports -Since computer printouts have atendency to overwhelm the manager/supervisor with too much information,and often in a coded fashion, a nar-rative synopsis is prepared for themonth's highlights and included inthe Monthly Progress Reports. In-puts from contractors are collectedand incorporated in the projectreports.

DESIGN OF A MULTI-PROJECT CONTROL SYSTEM (MPCS)Perhaps the best approach to explain the designof a multi-project control sys tem, as in the caseof any information system, might be to take a

hypothetical case to demonstrate how a preliminaryspecification for the sys tem could be developedfor management review.Preliminary Specification for a MPCS

The sys tem specification outlined below brie flyrelates to multi-project construction programs forpower generating stations in the utility industry .General Purpose

To develop a unique degree of managementsophistication as part of corporate businessstrategy to increase the company's share of powerplant construction market in the utilit y industry .Specific Objectives

1. To provide a practical management infor-mation tool for better monitoring andcontrolling of individual projects bycomparing performance with similar pro-jects, and by maintaining a balancedsupply of resources.2. To develop a reliable data bank whereby

precise historical information couldbecome available for guidance in pre-paring new business proposals, as wellas planning upcoming projects.

3. To better utilize existing data processingsystems with minimum additional effort .System Scope

1. The multi-project control sys tem may drawdata, in a manual or automated mode, fromexisting (this is an assumption) systems,such as:a. Scheduling System (SS).b. Cost Estimating System (CES).c. Cost Monitoring System (CMS).d. Physical Measurement System (PMS).e. Progress Reporting System (PRS).

2. The sys tem, though primarily intended toserve management needs at the top level,may have the capability to generatedetailed reports for backup and referencepurposes. The amount of detail may beextended and segregated to any levelconsidered desirable or practicable.

3. The system may generate tabulated and/or graphical reports to cover basicallycomparative information assimilated insome manner as follows:a. Projects sorted and grouped bysimilarity.- Type and size (Fossil/Nuclear,PWR/BWR/HTGR, 600/800/1200MW Range).- Chronological sequence (Year1971-72-73....76, and/orYears 1960-65, 65-70, 70-75).- Major equipment and supplier(T-G/NSSS, GE/GE/Westinghouse).- Type of contract for services.- Other.b. Comparison of main features or keywork items (Total, by area, ect.).

- Excavat ion, concrete, steel,piping, cable.- Direct labor, indirects.- Total costs/fees and billingformulas/revenues/profits/cash flows/cost per KW.- Indicator ratios, e.g.,direct labor to indirects,direct labor to total labor.- Field force at peak construc-tion.- Home office services (mandays),sub-grouped for design andengineering - Total/By disci-pline, project/constructionmanagement, related services,overa-l project.- Other.

4. The overall scope of a multi-project controlsystem ordinarily envelops estimating andbudgeting, scheduling and resource alloca-tion, cost accounting and control, monitor-ing and reporting. The exhib its, "ATypical Multi-Project Control System" and"An Overview of Multi-Project ControlSystem", delineate the interaction of theseaspects of the system in a graphical man-ner. The exhibit "Multi-Project ControlSystem Processll provides a visual aid inunderstanding how input from project

-

8/6/2019 ABC s of a Multi Project Control System

5/8

scope with design/estimating/constructioninformation on each project is processedthrough scheduling, cost and resourcemodules - on a project-by-project basis,and for selective inter-project compari-son. Once a central data base is established,output reports can be produced in numerousconvenient ways by shuffling and rearrang-ing the data.

Methodology1. Data processing runs on various indivi-dual systems (scheduling, etc.) are

made for each project at the homeoff ice computer installation on amonthly basis. This makes it possible toharness selected items of informationfrom such data flowing in from all jobsites, with the help of "interface pro-grams". Such an interface system willaccomplish integration of subsystems(like scheduling and cost estimating/monitoring), and also allow inter-project processing.2. Each time a SS-CES-CMS interface run

for a project is made, with an appro-priate connector program, key projectdata can be filtered out, sorted andstored on a MPCS file. Similar datacollection can be made from PMS andPRS interface runs and added on tothe master MPCS file. This file keepsbuilding up until all major projectsare processed on individual bases byother systems.In effec t, the outputs from these systemsfor individual projects will providethe necessary selective input for multi-project processing.Once the update run cycle for allparticipating projects is completed, theoutput generating phase of the MPCS canbe entered into and reports produced asprescribed.

3. The real trick in facilitating extrac-tion of relevant information out of eachconstituent system of the MPCS is themanner in which various linking codesare constructed to identi fy type, size,vendor, resources, and similar items asapplicable for each sys tem in relationto the MPCS.4. The methodology described so far is alsoadaptable to nuclear projects (especiallyforce account contracts), where thefield computer system may be installedfor convenient automated exchange ofschedule and cost/production related data.

5

-

8/6/2019 ABC s of a Multi Project Control System

6/8

For full-size foss il and other limitedscope projects, however, provisions maybe made for manual input to cover pertinentdata to fulf ill MPCS requirements.Manual input provision for new entries,and for overriding earlier entries, iscustomarily built into an well designedsystem. It may be useful in case ofnuclear projects also, during pre-con-struction stages when a field basedautomated sys tem may not have been putinto operation.

5. The MPCS may be programmed to utilizethe interface system to compare dura-tions and timing for various designstages, such as: Completion of generalarrangement drawings, or excavation andfoundation drawings required for startof construction.6. The scheduling system may be upgraded

to process resource allocation ofselected resource categories (salariedprofessional staf f, major constructionequipment like cranes, etc.) so that aschedule review/adjustment can be madefor like resources competing over a fewprojects on a priority basis.Management Reports

There is practically no limit to the number ofways in which a management report out of an in-formation system can be structured. It stretcheswith the imagination of the sys tems designer aslimited only by speci fic decision making needsexperienced by management. A versatile high-capa-cit y computer installation (like B6700, IBM 370,UNIVAC 1106) with a plotter is capable of creat-ing a meaningful variety of outputs.

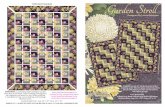

In line with what has been discussed so far,one important report may look like the exhibit,"Cost/Schedule Management Summary". Whichever waythe layout is preferred, it can enlist all projectsor groups of compatible similarity , and furnishthe latest selected updated information regardingmilestone attainment, manpower situation, cost per-formance, and the like.

The exhibit, "Multi-Project Resource Planning"presents a graphical display or a plot o f resourcesplanned against time in months or years . It maystrikingly point out how Project A followed byProjects B and C, as currently planned, willdemand resources of an identical nature. These re-sources may involve designers, engineers, fieldsupervisors/labor, dollars or materials of con-struction.

The exhibit, "Manpower Requirements" may beof particular interest to Project Management whohas the responsibility of committing professionalstaf f to all projects and of continuously review-ing estimates and forecasts against actual usage.A monthly report extending into the next quarter'smanpower picture, for example, could be of signi-ficant VdUt? to a manager of projects whileexamining home off ice services in design andengineering.

MULTI-PROJECT CONTROL SYSTEMCOST/SCHEDULE MANAGEMENT SUMMARY

ITYPICAL NUCLEAR POWER PLANTS PRMjRAM,

2. MILESTONESSELECT A-E SCHEO.:

ACT.SELECT NSSS SCHED.:

ACT. :FILE PSAR SCHEO.:

ACT. :FILE ER SCHEO.:

ACT. :RECWE LWA SCHED..

ACT. :RECEIV E CONST. PERMIT SCHED:

ACT..3. MANPOWER ,oml MDS)

ENOtNEERING TOTALSTO OATE:

CONSTRUCTION TOTAL:TO DATE.

RELATE0 SERWCES TOTAL:TO DATE:

4. COSTS ,ow sslORIGINAL ESTIMATE:CURRENT FORECAST.COMMITTMENTS TO LIATE:COST PER KW:

MULTI-PROJECT RESOUR CE PLANNING

DISCUSSIONIf there is a formal project control system

already operational in a project services organi-zation, the maintenance and operation of the MPCSmay not necessitate any significant addition ofmanpower. The responsibility for its upkeep, andpossible enhancement with increasing experience/needs, will naturally be with projects management.With the in-house computer sophistication alreadybeing utilized, and with the accompanying expertiseand varied personnel talent, an A-E or C-M organi-zation can successfully accomplish the developmentand implementation of a multi-project controlsystem. The assistance of an outside managementconsultant quite often provides the necessaryobjectivi ty and management commitment to expeditesuch systems enhancement effort s. The heavy in-house involvement ensures that the management

6

-

8/6/2019 ABC s of a Multi Project Control System

7/8

MULTI-PROJECT CONTROL SYSTEMMANPOWER REQUIREMENTS

ENGINEERS/DESIGNERS

ECAN1CALlCLENWI1LLECTlllCALNSTRUMENTATION:OST ENOlNCENSLANNINO ENOlNEENSIsrIMATONS:ONSTRUCTION ENOINEERS

--1 i

finall y receives a remarkable operating tool withminimal modification to current informationsystems, and the least additional inputs or pro-cedural requirements. Then, of course, there isthe choice of adopting a "canned" system packagefrom an outside supplier, and modifying thatsystem and/or the in-house existing systems tomake them mutually compatible.

Most organizations require a resource usageprojection and utilization monitoring device -particularly, for instance, when they have multipleproject assignments concurrently made to some oftheir professional staf f individually and toservice functions as groups. Supervisors responsiblefor controlling operations on several projectswelcome one report - or a set of reports - tocover all their activi ties, rather than having topiece together separate reports developed onindividual projects. Generally, an extensionof the payrool system provides the basicmechanism to identify manpower utilization forvarious cost centers, by projects, by organiza-tional units, by personnel classification, skills,etc. A convenient project charge numberingscheme may also provide a breakdown by tasks ormajor activities within each project. Themulti-project system concept essentially draws onthis to isolate, assemble and summarize suchdetails for comparison among similar projects,as well as for enabling the corporate managementto obtain a total company-wide picture, in termsof operating cash requirements and anticipatedrevenues, and in terms of ongoing manpower plan-ning requirements. The multi-project scenario

7

presents an excellent tool for possible companyexpansion and long-range planning.There are several scheduling systems availablein the market today - some from computer manufac-turers, some from firms specializing in computerservices, and in project management softwarepackages. Systems that deal with the multi-projectenvironment do generally carry out resource alloca-tion functions. PMI's "Computer Software Survey1975" provides good basic information on some ofthese systems. Notable among them are ManagementScheduling and Control System (MSCS) of McDonnellDouglas Automation Company; Multi-Project Manage-ment System (MPM) of Florida Power Corporation -available through General Electric Mark III remotebatch/time sharing service; PROJECT/2 of ProjectSoftware & Development, Inc.; PERT 6 of DynamicSolutions Inc.; PROMIS of Burroughs Corporation;and Project Management System (PMS) of R. J. HansenAssociates, Inc. Not included in the survey aretwo major computer suppliers' systems, namely,Project Management System IV (PMS IV) of IBM andOPTIMA llOO/PMS of UNIVAC.It is doubtful if any ready-made system packagecould be easily assimilated into the in-house

sophistication already being utilized for variouspurposes like payroll, scheduling, cost/estimating,etc. The efforts involved in changing forms,procedures, and perhaps the organizational struc-ture, could be enormous. It is diffi cult togeneralize and recommend any one approach; eachcase has to be studied on its own merit. Thisdiscussion is aimed at bringing as many relevent

-

8/6/2019 ABC s of a Multi Project Control System

8/8

factors into focus as possible.Another benefit resulting from the MPCS approachis the consistency or uniformity which has to beestablished in the scheduling, cost estimating, andreporting techniques for all projects. For example:Act ivit y networks must be structured at an accpetedlevel of detail, be of the same kind (arrow diagram-ming or precedence diagramming, CPM or PERT, samecalendars in terms of units of time, holidays, etc.).

The resource categories/identification codes, thereporting cycle and turn-around time, reportingformats, and similar aspects of project control be-come better defined and refined, and ultimatelymore acceptable to the user. Of course, certainprojects by their very nature may need specialtailoring of what the control sys tem can be fed andbe asked to produce. Flexibility to handle suchexceptions has to be provided for, and if notpracticable, such projects can be exempted from themulti-project family since they may not be

quite comparable to other projects anyway.It must be emphasized again that in spite ofthe computer's capabilities to provide ready in-formation, its output must be analyzed andexplained adequately in some selective narrativeform for proper perspective, evaluation, andnecessary action.

REFERENCES1. D. Sharad, "A Systems Approach to Long-Range Planning", 1976 TRANSACTIONS,American Association of Cost Engineers,Boston, MA, July , 1976, pages 301-310.2. "Computer Software Survey1975", Projelt Management Inst itute,Technology Committee, Drexel Hill, PA,1975, Pages 81, 97, 109, 114, 143, and 164.