ABBREVIATIONS MECHANICAL SHEET INDEX

Transcript of ABBREVIATIONS MECHANICAL SHEET INDEX

ASSOCIATES

RAIN CONDUCTORRETURN AIR GRILLE

RETURN AIR REGISTER

PHYSICAL HANDICAPPEDPRESSURE RELIEF VALVE

OPPOSED BLADE DAMPEROPEN END DUCT

PUMP #1

SUPPLY AIRROOF SUMP

RETURN AIR

OUTSIDE AIR

STORM

VENTURINAL

SAFE WASTE SINK

VENT THRU ROOF

TRANSFER AIR DUCTTEMPERED WATERUNDERGROUNDUNIT HEATER

SERVICE SINK

SUPPLY DIFFUSERSUPPLY REGISTERSANITARY

WASTE

WATER CLOSETWATER HEATER

REDUCED PRESSURE BACKFLOW PREVENTER

VARIABLE VOLUME AIR TERMINAL BOX

T.A.D.

U/GRD.U.H.

T.W.

V.V.B.V.T.R.

W.H.W.C.

W.

UR.V.

O.A.O.B.D.

P.REL.V.P.H.O.E.D.

R.C.R.A.

RG -#

S.A.R.S.RR-#R.P.B.P.

SR-#SD-#

SAN.

S.W.S.

S.S.ST.

P-1

SUPPLY AIR DIFFUSER

SPIN-IN FITTING W/DAMPER

FLEXIBLE DUCT

RETURN AIR GRILLE

H.V.A.C. SYMBOLS

VOLUME DAMPER

VERTICAL FIRE DAMPER

HORIZONTAL FIRE DAMPER

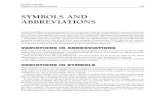

ABBREVIATIONS

CEILING DIFFUSERCUBIC FEET PER MINUTE

ACOUSTICAL LININGBALANCING VALVE

DAMPER

CAST IRONCLEAN OUT

RECTANGULAR TO ROUND TRANSITION

DRINKING FOUNTAINDRINKING WATER SUPPLY

LINEAR SUPPLY AIR DIFFUSER

EXHAUST REGISTER

INDIRECT WASTEINVERT ELEVATION

ELECTRIC WATER COOLER

HUB OUTLET

FLOOR DRAINFIRE DAMPER

DRINKING WATER RETURNEXHAUST FAN

LAVATORY

HOSE BIBB

LINEAR RETURN AIR DIFUSER

C.F.M.

C.O.DPR.

D.W.S.D.W.R.

EWCER-#

H.B.F.DPR.

H.O.

LAV.LD-#LR-#

I.E.I.W.

F.D.

E.F.

D.F.

C.I.

C.D.B.V.A.L.

.

.

.

DAMPER

T THERMOSTAT

FLEXIBLE CONNECTOR

UNION

STRAINER

THERMOMETER

BALANCING VALVE

CHECK VALVE

GATE VALVE

VENT

GAS OR NG

ST

SAN

DOMESTIC HOT WATER RETURN (H.W.R.)

STORM SEWER

SANITARY SEWER-UNDER GROUND

NATURAL GAS

DOMESTIC HOT WATER (H.W.)

DOMESTIC COLD WATER (C.W.)

PLUMBING & PIPING SYMBOLS

NEW CONNECTION

BALL VALVE

SAN SANITARY SEWER-ABOVE GROUND

MOTOR ACTUATORBALL VALVE

SOLENOID VALVE (NORM. CLOSED)

SOLENOID VALVE (NORM. OPEN)

DIFFERENTIAL REGULATOR

BACK PRESSURE REGULATOR

PRESSURE REGULATOR

PNEUMATIC CONTROL VALVE

DAMPER

MODULATING VALVE

VALVE WITH HANDWHEEL

STOP CHECK STRAIGHT VALVE

GLOBE VALVE

VALVE

CHECK VALVE

GAS COCK VALVE

NEEDLE VALVE

PRESSURE GAUGE TO MATCHEXISTING

TURBINE FLOW METER

CURRENT / PNEUMATIC POSITIONER

INSTRUMENT - NON-ACCESSIBLE

ELECTRIC MOTOR / ACTUATOR

SPARK PLUG

FLEX COUPLING (2 FT MIN)

STEAM TRAP

GENERAL MECHANICAL NOTES:1. PRIOR TO SUBMITTING BID, VISIT THE JOB SITE AND BECOME FULLY ACQUAINTED WITH THE EXISTING

CONDITIONS OF THE PROJECT. REVIEW THE GENERAL NOTES, SPECIFICATIONS, AND OTHER DRAWINGSFOR ADDITIONAL REQUIREMENTS WHICH MAY NOT BE SPECIFICALLY CALLED OUT IN THIS PORTION OF THECONSTRUCTION DOCUMENTS. NOTIFY ARCHITECT, ENGINEER, AND/OR OWNER OF CONFLICTS ORDISCREPANCIES PRIOR TO SUBMISSION OF BID.

2. COORDINATE THE INSTALLATION OF THE MECHANICAL SYSTEMS WITH OTHER TRADES TO ENSURE A NEATAND ORDERLY INSULATION. INSTALL PIPING AS TIGHT TO STRUCTURE AS POSSIBLE. COORDINATE WITHOTHER TRADES TO AVOID CONFLICTS. COORDINATE INSTALLATION OF PIPING TO AVOID CONFLICTS WITHELECTRICAL PANELS, LIGHTING FIXTURES, ETC. ANY MODIFICATIONS REQUIRED DUE TO LACK OFCOORDINATION WILL BE THE RESPONSIBILITY OF THE CONTRACTOR AT NO EXTRA COST TO THE OWNER.

3. NEW MECHANICAL PIPING ARE SHOWN AT APPROXIMATE LOCATIONS. FIELD MEASURE FINAL PIPINGLOCATIONS PRIOR TO FABRICATION AND MAKE ADJUSTMENTS AS REQUIRED TO FIT THE PIPING WITHIN THEAVAILABLE SPACE. VERIFY THAT FINAL EQUIPMENT LOCATIONS MEET MANUFACTURER'SRECOMMENDATIONS REGARDING SERVICE CLEARANCE AND PROPER AIRFLOW CLEARANCE AROUNDEQUIPMENT.

4. REFER TO ARCHITECTURAL DRAWINGS FOR RELATED CONSTRUCTION DETAILS AS APPLICABLE TO THEMECHANICAL SYSTEM. VERIFY CHASES AND PENETRATIONS SHOWN ON ARCHITECTURAL DRAWINGS THATARE INTENDED FOR DUCTWORK AND PIPING MEET REQUIREMENTS.

5. INSTALL PIPING PARALLEL TO BUILDING COLUMN LINES UNLESS OTHERWISE SHOWN OR NOTED.

6. OVERHEAD HANGERS AND SUPPORTERS FOR PIPING SHALL BE FASTENED TO BUILDING JOISTS OR BEAMS.DO NOT ATTACH HANGERS AND SUPPORTS TO THE ABOVE FLOOR SLAB OR ROOF EXCEPT WHERECONCRETE INSERTS IN CONCRETE SLABS ARE ALLOWED BY THE SPECIFICATIONS.

7. COORDINATE LOCATION OF SUPPORTERS WITH LOCATION OF EQUIPMENT ACCESS PANELS/DOORS TOENABLE SERVICE OF EQUIPMENT AND/OR FILTER REPLACEMENT.

8. SEAL PENETRATIONS THROUGH THE BUILDING COMPONENTS IN ACCORDANCE WITH THE CONTRACTSPECIFICATIONS. FIREPROOF PENETRATIONS THROUGH FIRE RATED COMPONENTS IN ACCORDANCE WITHU.L. REQUIREMENTS.

9. CONTRACTOR SHALL CEASE WORK AND IMMEDIATELY NOTIFY THE OWNER SHOULD ANY HAZARDOUSMATERIALS BE ENCOUNTERED DURING THE PERFORMANCE OF THE WORK.

10. REFER TO SPECIFICATIONS FOR PIPING INSTALLATION REQUIREMENTS.

DRAIN TRAP

MECHANICAL SHEET INDEX

MECHANICAL LEGEND, SYMBOLS AND SHEET INDEXM.000

SHEET No. DESCRIPTION

M.100

NOT ALL SYMBOLS ARE USED ON THIS PROJECT

M.102 FIRST FLOOR PLAN - DOMESTIC WATER PLUMBING

M.200 FIRST FLOOR PLAN - HVAC

M.201 SECOND FLOOR PLAN - HVAC

M.300 ROOF PLAN - MECHANICAL

SECOND FLOOR PLAN - SANITARY/ VENT PLUMBINGM.101

M.103 SECOND FLOOR PLAN - DOMESTIC WATER PLUMBING

FIRST FLOOR PLAN - SANITARY/ VENT PLUMBING

M.400 MECHANICAL SCHEDULES

M.401 MECHANICAL DETAILS

M.500 MECHANICAL SPECIFICATIONS

ASSOCIATES

PLUMBING NOTES:1. THIS DRAWING IS DIAGRAMMATIC AND SHOULD BE USED TO

DETERMINE THE DESIGN INTENT. THE CONTRACTOR IS RESPONSIBLEFOR THE COMPLETE SET OF WORK AS INDICATED AND SHALL FIELDVERIFY ALL WORK, COORDINATE ALL DRAWINGS / NEW WORK ANDSHALL NOTIFY ARCHITECT IMMEDIATELY OF ANY DISCREPANCIES INTHE DOCUMENTS BEFORE PROCEEDING. FAILURE TO DO SO WILLRESULT IN THE CONTRACTOR TAKING FULL RESPONSIBILITY ANDLIABILITY FOR SAID DISCREPANCIES.

2. COORDINATE PROPER SHUTDOWN OF EXISTING CW SYSTEM WITH THEEND USER PRIOR TO CONNECTION OF NEW SYSTEM.

3. ALL LABOR, VALVES, TRAPS, TAILPIECES, PRESSURE-REDUCINGVALVES, AND FITTINGS REQUIRED FOR FINAL CONNECTION OFEQUIPMENT TO COMPLY WITH ALL CODES, INCLUDING INTERWIRINGCONNECTIONS TO BE FURNISHED BY MECHANICAL CONTRACTORUNLESS OTHERWISE INDICATED.

4. PLUMBING CONTRACTOR TO DO ALL ROUGH-INS AND MAKE ALL FINALCONNECTIONS TO EQUIPMENT.

5. PLUMBING CONTRACTOR TO FURNISH ALL TRIM, ACCESSORIES,VALVES, PRESSURE REGULATORS, P-TRAPS, GREASE TRAPS,BACKFLOW PREVENTION SYSTEM DEVICES ETC.

6. PLUMBING CONTRACTOR TO EXTEND ALL INDIRECT WASTE LINESFROM EQUIPMENT TO NEAREST FLOOR DRAIN / FLOOR SINK ASREQUIRED.

7. COORDINATE FIXTURE, DRAIN, FLOOR SINK & GAS LAYOUT W/ FOODSERVICE CONTRACTOR.

ASSOCIATES

PLUMBING NOTES:1. THIS DRAWING IS DIAGRAMMATIC AND SHOULD BE USED TO

DETERMINE THE DESIGN INTENT. THE CONTRACTOR IS RESPONSIBLEFOR THE COMPLETE SET OF WORK AS INDICATED AND SHALL FIELDVERIFY ALL WORK, COORDINATE ALL DRAWINGS / NEW WORK ANDSHALL NOTIFY ARCHITECT IMMEDIATELY OF ANY DISCREPANCIES INTHE DOCUMENTS BEFORE PROCEEDING. FAILURE TO DO SO WILLRESULT IN THE CONTRACTOR TAKING FULL RESPONSIBILITY ANDLIABILITY FOR SAID DISCREPANCIES.

2. COORDINATE PROPER SHUTDOWN OF EXISTING CW SYSTEM WITH THEEND USER PRIOR TO CONNECTION OF NEW SYSTEM.

3. ALL LABOR, VALVES, TRAPS, TAILPIECES, PRESSURE-REDUCINGVALVES, AND FITTINGS REQUIRED FOR FINAL CONNECTION OFEQUIPMENT TO COMPLY WITH ALL CODES, INCLUDING INTERWIRINGCONNECTIONS TO BE FURNISHED BY MECHANICAL CONTRACTORUNLESS OTHERWISE INDICATED.

4. PLUMBING CONTRACTOR TO DO ALL ROUGH-INS AND MAKE ALL FINALCONNECTIONS TO EQUIPMENT.

5. PLUMBING CONTRACTOR TO FURNISH ALL TRIM, ACCESSORIES,VALVES, PRESSURE REGULATORS, P-TRAPS, GREASE TRAPS,BACKFLOW PREVENTION SYSTEM DEVICES ETC.

6. PLUMBING CONTRACTOR TO EXTEND ALL INDIRECT WASTE LINESFROM EQUIPMENT TO NEAREST FLOOR DRAIN / FLOOR SINK ASREQUIRED.

7. COORDINATE FIXTURE, DRAIN, FLOOR SINK & GAS LAYOUT W/ FOODSERVICE CONTRACTOR.

ASSOCIATES

PLUMBING NOTES:1. THIS DRAWING IS DIAGRAMMATIC AND SHOULD BE USED TO

DETERMINE THE DESIGN INTENT. THE CONTRACTOR IS RESPONSIBLEFOR THE COMPLETE SET OF WORK AS INDICATED AND SHALL FIELDVERIFY ALL WORK, COORDINATE ALL DRAWINGS / NEW WORK ANDSHALL NOTIFY ARCHITECT IMMEDIATELY OF ANY DISCREPANCIES INTHE DOCUMENTS BEFORE PROCEEDING. FAILURE TO DO SO WILLRESULT IN THE CONTRACTOR TAKING FULL RESPONSIBILITY ANDLIABILITY FOR SAID DISCREPANCIES.

2. COORDINATE PROPER SHUTDOWN OF EXISTING CW SYSTEM WITH THEEND USER PRIOR TO CONNECTION OF NEW SYSTEM.

3. ALL LABOR, VALVES, TRAPS, TAILPIECES, PRESSURE-REDUCINGVALVES, AND FITTINGS REQUIRED FOR FINAL CONNECTION OFEQUIPMENT TO COMPLY WITH ALL CODES, INCLUDING INTERWIRINGCONNECTIONS TO BE FURNISHED BY MECHANICAL CONTRACTORUNLESS OTHERWISE INDICATED.

4. PLUMBING CONTRACTOR TO DO ALL ROUGH-INS AND MAKE ALL FINALCONNECTIONS TO EQUIPMENT.

5. PLUMBING CONTRACTOR TO FURNISH ALL TRIM, ACCESSORIES,VALVES, PRESSURE REGULATORS, P-TRAPS, GREASE TRAPS,BACKFLOW PREVENTION SYSTEM DEVICES ETC.

6. PLUMBING CONTRACTOR TO EXTEND ALL INDIRECT WASTE LINESFROM EQUIPMENT TO NEAREST FLOOR DRAIN / FLOOR SINK ASREQUIRED.

7. COORDINATE FIXTURE, DRAIN, FLOOR SINK & GAS LAYOUT W/ FOODSERVICE CONTRACTOR.

ASSOCIATES

PLUMBING NOTES:1. THIS DRAWING IS DIAGRAMMATIC AND SHOULD BE USED TO

DETERMINE THE DESIGN INTENT. THE CONTRACTOR IS RESPONSIBLEFOR THE COMPLETE SET OF WORK AS INDICATED AND SHALL FIELDVERIFY ALL WORK, COORDINATE ALL DRAWINGS / NEW WORK ANDSHALL NOTIFY ARCHITECT IMMEDIATELY OF ANY DISCREPANCIES INTHE DOCUMENTS BEFORE PROCEEDING. FAILURE TO DO SO WILLRESULT IN THE CONTRACTOR TAKING FULL RESPONSIBILITY ANDLIABILITY FOR SAID DISCREPANCIES.

2. COORDINATE PROPER SHUTDOWN OF EXISTING CW SYSTEM WITH THEEND USER PRIOR TO CONNECTION OF NEW SYSTEM.

3. ALL LABOR, VALVES, TRAPS, TAILPIECES, PRESSURE-REDUCINGVALVES, AND FITTINGS REQUIRED FOR FINAL CONNECTION OFEQUIPMENT TO COMPLY WITH ALL CODES, INCLUDING INTERWIRINGCONNECTIONS TO BE FURNISHED BY MECHANICAL CONTRACTORUNLESS OTHERWISE INDICATED.

4. PLUMBING CONTRACTOR TO DO ALL ROUGH-INS AND MAKE ALL FINALCONNECTIONS TO EQUIPMENT.

5. PLUMBING CONTRACTOR TO FURNISH ALL TRIM, ACCESSORIES,VALVES, PRESSURE REGULATORS, P-TRAPS, GREASE TRAPS,BACKFLOW PREVENTION SYSTEM DEVICES ETC.

6. PLUMBING CONTRACTOR TO EXTEND ALL INDIRECT WASTE LINESFROM EQUIPMENT TO NEAREST FLOOR DRAIN / FLOOR SINK ASREQUIRED.

7. COORDINATE FIXTURE, DRAIN, FLOOR SINK & GAS LAYOUT W/ FOODSERVICE CONTRACTOR.

S-3300 CFM

S-3300 CFM

S-3300 CFM

S-3300 CFM

S-3250 CFM

S-3250 CFM

S-3300 CFM

S-3300 CFM

S-3175 CFM

R-1

R-1

S-3200 CFM

S-3200 CFM

S-3200 CFM

S-3200 CFM

S-3200 CFM R-1

R-1

E-1125 CFM

E-1100 CFM

E-175 CFM

S-4125 CFM

S-450 CFM

S-3250 CFM

30x14 OPEN ENDRETURN AIR DUCT

30x16 S.A. DUCTUP TO HVAC30x18 R.A. DUCTUP TO HVAC

T

TO HVAC

S-3300 CFM

S-3300 CFM

S-3300 CFM

S-3300 CFM

S-3250 CFM

S-3250 CFM

S-3300 CFM

S-3300 CFM

S-3175 CFM

R-1

R-1

S-3200 CFM

S-3200 CFM

S-3200 CFM

S-3200 CFM

S-3200 CFM

R-1

R-1

E-1125 CFM

E-1100 CFM

E-175 CFM

S-4125 CFM

S-450 CFM

S-3250 CFM

30x16 OPEN ENDRETURN AIR DUCT

20x14 S.A. DUCTUP TO HVAC

30x18 R.A. DUCTUP TO HVAC

T

TO HVAC

30x16

20x1024x16

14x10

24x16

12x8

30x16 24x16

24x16

14x10

20x10

12x8

S-3200 CFM

S-4125 CFM

S-3200 CFM

S-3200 CFM

S-3200 CFM

S-2100 CFM

S-2100 CFM

10x8

10x6

E-1125 CFM

E-1100 CFM

8x6 EXHAUST DUCTUP TO EF ON ROOF

10x8 S.A.DUCT UP

ECUH-25 KW

ECUH-15 KW

T

T

TR-1TR-1

TR-1

EWUH-13 KW

EWUH-23 KW

TO HVAC

TO HVAC

GAS METER & SERVICE BYLOCAL COMPANY ( CFH),VERIFY IN FIELD EXACTSIZES & LOCATION

2" GAS LINE (1520CFH) UP TO ROOF

18x8 S.A.DUCT UP

14x8

ASSOCIATES

HVAC NOTES:1. ALL NEW MECHANICAL EQUIPMENT SHOWN ON THE MECHANICAL PLANS SHALL

BE PROVIDED BY THE MECHANICAL CONTRACTOR UNLESS OTHERWISE NOTED.

2. COORDINATE THE EXACT MOUNTING SIZE AND FRAME TYPE OF DIFFUSERS,REGISTERS, AND GRILLES WITH THE SUPPLIER TO MEET THE CEILING, WALL,AND DUCT INSTALLATION REQUIREMENTS.

3. ADJUST LOCATION OF CEILING DIFFUSERS, REGISTERS, AND GRILLES ASREQUIRED TO ACCOMMODATE FINAL CEILING GRID AND LIGHTING LOCATIONS.

4. PROVIDE A PREFABRICATED RECTANGULAR/ROUND BRANCH DUCT TAKEOFFFITTING WITH MANUAL BALANCING DAMPER AND LOCKING QUADRANT FORBRANCH DUCT CONNECTIONS AND TAKE-OFFS TO INDIVIDUAL DIFFUSERS,REGISTERS AND GRILLES.

5. BRANCH DUCTWORK TO AIR OUTLETS SHALL BE SAME SIZE AS OUTLET NECKSIZE UNLESS OTHERWISE NOTED.

6. REFER TO SPECIFICATIONS FOR DUCTWORK AND PIPING INSULATIONREQUIREMENTS. DUCT SIZES ON MECHANICAL PLANS INDICATE CLEAR INSIDEAIRFLOW DIMENSIONS.

7. FLEXIBLE DUCTWORK SHALL NOT EXCEED 5'-0" IN LENGTH AND SHALL BEINSTALLED AND SUPPORTED TO AVOID SHARP BENDS AND SAGGING. REFER TOSPECIFICATIONS FOR ADDITIONAL REQUIREMENTS.

8. IN EXPOSED AREA (NO CEILING). PROVIDE PREFABRICATED SPIRAL ROUND DUCTOF SIZES AS SHOWN ON DWG UNLESS OTHERWISE NOTED.

E-175 CFM

S-450 CFM

E-175 CFM

S-450 CFM

S-2100 CFM10"Ø NKS-2100 CFM10"Ø NK

30x16 S.A. DUCTUP TO HVAC

30x18 R.A. DUCTUP TO HVAC

30x16 S.A. DUCTUP TO HVAC

30x18 R.A. DUCTUP TO HVAC

12x8 EXHAUST DUCTUP TO EF ON ROOF

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-350 CFM

S-2200 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

S-1715 CFM

HVAC-125 TON10000 CFMON ROOF

HVAC-225 TON10000 CFMON ROOF

E-175 CFM

6x4

8x6 EXHAUST DUCTUP TO EF ON ROOF

24"Ø

30"Ø

30"Ø

54x20 OPEN ENDRETURN AIR DUCT

24"Ø

30"Ø

24"Ø

54x20 R.A. DUCTUP TO HVAC54x20 R.A. DUCT

UP TO HVAC

54x20 OPEN ENDRETURN AIR DUCT

OPEN ENDRETURN AIR DUCT50x20 S.A. DUCT

UP TO HVAC50x20 S.A. DUCTUP TO HVAC

8"Ø

8"Ø

TR-1

EWUH-33 KW

EWUH-43 KW

HVAC-310 TON4000 CFMON ROOF

HVAC-410 TON4000 CFMON ROOF

18x8 S.A.DUCT DN

10x8 S.A.DUCT DN

ASSOCIATES

HVAC NOTES:1. ALL NEW MECHANICAL EQUIPMENT SHOWN ON THE MECHANICAL PLANS SHALL

BE PROVIDED BY THE MECHANICAL CONTRACTOR UNLESS OTHERWISE NOTED.

2. COORDINATE THE EXACT MOUNTING SIZE AND FRAME TYPE OF DIFFUSERS,REGISTERS, AND GRILLES WITH THE SUPPLIER TO MEET THE CEILING, WALL,AND DUCT INSTALLATION REQUIREMENTS.

3. ADJUST LOCATION OF CEILING DIFFUSERS, REGISTERS, AND GRILLES ASREQUIRED TO ACCOMMODATE FINAL CEILING GRID AND LIGHTING LOCATIONS.

4. PROVIDE A PREFABRICATED RECTANGULAR/ROUND BRANCH DUCT TAKEOFFFITTING WITH MANUAL BALANCING DAMPER AND LOCKING QUADRANT FORBRANCH DUCT CONNECTIONS AND TAKE-OFFS TO INDIVIDUAL DIFFUSERS,REGISTERS AND GRILLES.

5. BRANCH DUCTWORK TO AIR OUTLETS SHALL BE SAME SIZE AS OUTLET NECKSIZE UNLESS OTHERWISE NOTED.

6. REFER TO SPECIFICATIONS FOR DUCTWORK AND PIPING INSULATIONREQUIREMENTS. DUCT SIZES ON MECHANICAL PLANS INDICATE CLEAR INSIDEAIRFLOW DIMENSIONS.

7. FLEXIBLE DUCTWORK SHALL NOT EXCEED 5'-0" IN LENGTH AND SHALL BEINSTALLED AND SUPPORTED TO AVOID SHARP BENDS AND SAGGING. REFER TOSPECIFICATIONS FOR ADDITIONAL REQUIREMENTS.

8. IN EXPOSED AREA (NO CEILING). PROVIDE PREFABRICATED SPIRAL ROUND DUCTOF SIZES AS SHOWN ON DWG UNLESS OTHERWISE NOTED.

EF-1750 CFMON ROOF

EF-2300 CFMON ROOF

GA

SG

AS

GA

SG

AS

GA

S

3" GAS LINE (5,159 CFH) BASED ONINITIAL SUPPLY PRESSURE OF 11.0 "WCOR GREATER, VERIFY WITH UTILITYCOMPANY & COORDINATE AS REQUIRED

GA

SG

AS

GA

SG

AS

GAS METER & SERVICE BY LOCALCOMPANY (5,159 CFH), VERIFY INFIELD EXACT SIZES & LOCATION

GA

SG

AS

GA

SG

AS

GA

S

GAS

GASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGASGAS

GA

SG

AS

GA

SG

AS

GA

SG

AS

GA

SG

AS

2" GAS LINE (1520CFH) UP TO ROOF

SHUT-OFFVALVE

SHUT-OFFVALVE

SHUT-OFFVALVE

SHUT-OFFVALVE

GAS GAS GAS GAS

GA

SG

AS

GA

SG

AS

GA

SG

AS

GA

S

1" GAS ONROOF

1" GAS ONROOF

1" GAS ONROOF

1" GAS ONROOF

HVAC-125 TON10000 CFM400 CFH

HVAC-225 TON10000 CFM400 CFH

HVAC-310 TON4000 CFM250 CFH

HVAC-410 TON4000 CFM250 CFH

1 1/4" GAS ONROOF

3/4" GASON ROOF

1" GASON ROOF

2" GAS ON ROOF

3/4" GAS TO WATER HEATER,FOR CONTINUATION REFERTO SHEET M.101

6" SECONDARYSTORM LINE

STORM NOZZLE,COORDINATE EXACTLOCATION W/ARCHITECT

6" MAIN STORM LINE

6" ST DN TO UNDERGROUND.REFER TO SANITARY & VENTPLUMBING PLAN ON SHEET M.100

6"SRS

6" SECONDARYSTORM LINESTORM NOZZLE,COORDINATE EXACTLOCATION W/ARCHITECT

6"RS

4"SRS 4"RS

6" ST DN TO UNDERGROUND.REFER TO SANITARY & VENTPLUMBING PLAN ON SHEET M.100

4"SRS 4"RS 4"SRS 4"RS3"SRS 3"RS 3"SRS3"RS

6" MAIN STORM LINE

4" MAIN STORM LINE 4" ST DN TO UNDERGROUND.REFER TO SANITARY & VENTPLUMBING PLAN ON SHEET M.100

3" MAIN STORM LINE

4" MAIN STORM LINE

3" MAIN STORM LINE

4" ST DN TO UNDERGROUND.REFER TO SANITARY & VENTPLUMBING PLAN ON SHEET M.100

4" SECONDARYSTORM LINE

3" SECONDARYSTORM LINE

4" SECONDARYSTORM LINE

4" SECONDARYSTORM LINE

3" SECONDARYSTORM LINE

STORM NOZZLE,COORDINATE EXACTLOCATION W/ARCHITECT

STORM NOZZLE,COORDINATE EXACTLOCATION W/ARCHITECT STORM NOZZLE,

COORDINATE EXACTLOCATION W/ARCHITECT

STORM NOZZLE,COORDINATE EXACTLOCATION W/ARCHITECT

STORM NOZZLE,COORDINATE EXACTLOCATION W/ARCHITECT

4" MAIN STORM LINE

6"RS 6"SRS

2" GAS LINE UP

2 1/2" GAS LINE UNDERGROUND TOEMERGENCY GENERATOR (3,420 CFH),COORDINATE WITH LOCAL GAS COMPANY,CIVIL & ELECTRICAL DRAWINGS

ASSOCIATES

MECHANICAL ROOF NOTES:1. ALL NEW MECHANICAL EQUIPMENT SHOWN ON THE

MECHANICAL PLANS SHALL BE PROVIDED BY THEMECHANICAL CONTRACTOR UNLESS OTHERWISENOTED.

2. REFER TO SPECIFICATIONS FOR DUCTWORK ANDPIPING INSULATION REQUIREMENTS.

ASSOCIATES

ELECTRIC WALL UNIT HEATER SCHEDULETAG

BASIS OFDESIGN

MODEL LOCATION TYPECAPACITY(WATTS)

ELECTRICALVOLT/PH/HZ

NOTES /ACCESSORIES

EWUH-1 Q-MARK LFK 404F STAIRS WALL 3000 208 / 1 /60WALL MOUNTED ACCESSORIES,

TEHRMAL OVERHEAT PROTECTOR,BUILTIN POWER DISCONNECT SWITCH,

UNIT MOUNTED THERMOSTAT.

EWUH-2

EWUH-3

EWUH-4

120V/1Ø, DISCONNECT SWITCH

NATURAL GAS

EXPANSION TANK

DOMESTIC WATER HEATER SCHEDULE

POWER VENTED

P & T RELIEF TO FD

FLOOR MOUNTED

C

A

B

F

E

D

& MODEL No.MANUFACTURER

WH-1

TAG LOCATION

CAPACITIES

RECOVERY

NOTES AND ACCESSORIES DESIGNATION

STORAGE TD °F ØFLUE NOTES/ACCESSORIESGAS

INPUT CFH

WH-2

CFH

GAS LOAD SCHEDULETOTAL INPUT

NATURAL

EQUIPMENT

250

TOTAL 5,159 CFH

HVAC-3

400HVAC-1

400HVAC-2

HVAC-4 250

WATER HEATER - 1 199

WATER HEATER - 2 120

WATER HEATER - 3 120

WH-3

BTH-120A.O. SMITH SEE 60 173 80 4" A B C D E F120DRAWINGS

BTH-120A.O. SMITH SEE 60 173 80 4" A B C D E F120DRAWINGS

BTH-199A.O. SMITH SEE 100 223 100 4" A B C D E F199

DRAWINGS

GREASE TRAP SCHEDULE

SIZE OUTLETSIZE (IN)

FLOW RATE(GPM)

CAPACITYWATER (GPM)

CAPACITYGREASE (LBS)

MANUFACTURERMODEL #TAG

GT ZURNZ1170

600 3 25 21 50

SUS - SUSPENDED

B

A INTEGRAL THERMOSTAT

BUILT-IN DISCONNECT

NOTES AND ACCESSORIES DESIGNATION

SW - SURFACE WALLRW - RECESSED WALL

ECUH-1

MOUNTING KEY

CABINET UNIT HEATER SCHEDULEELECTRICAL DATA

KW INPUTLOCATIONTAG

MANUFACTURER

& MODEL No.MOUNTING CFM

AMPSMBH NOTES/ACCESSORIES

VOLT

VESTIBULEMARKEL6300 SERIES

350 --17.05 5.0 208/1 A B

C REMOTE THERMOSTAT

D HANGING KIT

RC - RECESSED CEILING

RCECUH-2

EMERGENCY GAS GENERATOR 3,420

ASSOCIATES

DAMPER BACKDRAFT

PRIMER COAT AND PAINT EXTERIOR GAS PIPE.GRAVEL IF ANY. INSTALL GAS PIPE TO ALLOW FOR EXPANSION AND CONTRACTION.1-1/2"=9', 1-1/4"=8', 1"=7', 3/4"=6'. PLACE BASE SHEETS ON ROOFING BEFORESUPPORT SPACING FOR PIPE SIZE: 5"=16', 4"=14', 3"=12', 2-1/2"=11', 2"=10'

NYLON ROLLER

MIRO MODEL 3-R

HVAC UNIT

INSULATION OVERDUCTWORK

FLEX. CONN.

ROOFING MEMBRANE

RAIL ON UNIT CURB PROVIDE ISOLATION

COUNTER FLASHING

AIRSUPPLY

2" BLANKET WRAP

CONT. CANT STRIP

FILL CURB SPACE BETWEENHVAC AND ROOF WITHBATT INSULATION

CURB (BY UNIT MANUFACTURER)

OPENING IN TOP

RETURNAIR CEILING

OF MAIN

GASKET

OUTDOOR AIR INTAKE HOOD

VENT REGULATORTO ATMOSPHERE IF

UNION (SHOWN) ORFLANGED CONNECTIONPLUG

COCKS

REQUIRED

MAXIMUM

6'-0"

GAS-FIREDEQUIPMENT

OR HAND SINKTO LAVH. & C.W.

PIPINGSUPPLY

SINK)(LOCATE VALVE UNDERSET @ 110°F MAXIMUMAPOLLO ASSE 1070, 34D SERIESMIXING VALVE

(2) 90 DEG. ELBOWS. ELBOWSTO BE MADE WITH MINIMUMRADIUS OF 1 1/2 R/D.

MAXIMUM OF 5ft. LONGFLEXIBLE DUCTWORK WITH

WITH DAMPERSPIN IN FITTING

S.A. DUCT

AIR TERMINAL UNIT

BELOW FLOOR SLAB WITHOUT JOINTS.SLOPE TOWARD FLOOR DRAIN TRAP.PROVIDE ELASTOMERIC INSULATIONFROM TRAP TO ABOVE FLOOR SLAB.

PROVIDE COUPLING

TYPE "K" SOFT COPPER TUBE

CONCRETE FLOOR

FLOOR DRAIN

PRIMER CONNECTIONP-TRAP WITH TRAP

PRIMER.

WATER DAILY) IN CEILING MAKE BRANCH TO

MORE THAN ONE TRAP IS SERVED BY A

DOMESTIC COLD WATER LINE (THAT FLOWS

TRAP PRIMER OFF TOP OF THIS PIPE.

PROVIDE DISTRIBUTION UNITS WHERE

CEILING

VENT

IF 3"V NOT USED

3"x2" BUSHINGS OR3"x2-1/2" BUSHINGS

ROOF BOOT/FLASHING

AIRCOMBUSTION

MAINTAIN 36"MIN.CLEARENCE ABOVEHIGHEST ANTICIPATEDSNOW LEVEL. MAXOF 24" ABOVE ROOF

ROOF

VENT

UNION

HOT WATER

FLOOR

THERMOSTAT & PILOT

HEATER

(TYP.)

DIRT LEG-FULL SIZE(CAPPED)

GAS COCK

PIPE TO FLOORRELIEF VALVE

DRAIN

FLOOR DRAIN

6" MIN.

G

EXPANSION TANK

PVC INTAKE &EXHAUST

GAS MAIN

(BY SITE UTILITESWATER SERVICE

6"

CONTRACTORS)CONC. SUPPORT

BYPASS

BE INSTALLED PER LOCAL CITYREQUIREMENTS

METER AND BACKFLOW PREVENTER TO

M

F.D.

NOTE

METERWATER

PREVENTERBACKFLOW

BFP CW

CW

HW

CP-1HWR

SPKR SYSTEM (ZONE-2)

SPKR SYSTEM (ZONE-1)

CHECK VA.

WATER ALARM GONGALARM CHECK VA.

BALL CHECK & DRIP

(TYPICAL EACH ZONE)

ARCH. TRADESSPLASH BLOCK BY

2" ANGLE

2" DRAIN

OS & Y VA.

VALVE

WALL

CONNECTIONSIAMESE

OUTSIDE

ALARM BELL(TYP.)

PRESSURE GAUGE

DRAIN VALVE

FINISHED FLOOR

RETARD CHAMBER

FLOW SWITCH

TO FIRST FLOOR

TO FIRST FLOOR

(BY SITE UTILITIESCONTRACTOR)

PROVIDE REDUCED PRESSURE BACKFLOWPREVENTER IF REQUIRED BY APPLICABLE

DETECTOR CHECK

WATER SERVICE

PIPE SUPPORTS

DRAIN VALVES

6"

NOTES:1.

CODES.

4"

3/4" HW & CWDRAINBOARD

FLOW CONTROL (TYP)TAIL PIECE INSTALL.

GREASE TRAP

3"

2" WASTE& V DN

2"

2" VENT UP

2" VENT UP& DOWN

2"AIR GAP

(TYP)

FLOOR SINK W/SEDIMENT BUCKET

3" TO SAN.

FINISHED FLOOR

(TYP)

LEVER DRAIN.

DEPTH AS REQUIRED

1" AIR GAP FLOOR

INDIRECT WASTE FROMEQUIPMENT

ASSOCIATES

PROVIDE CLEANOUTS AS REQUIRED BY LOCAL CODES. THE FINISH OF COVER PLATES, TOPAND TOP FRAME ACCESS COVERS SHALL BE NICKEL BRONZE, UNLESS OTHERWISE SCHEDULED.

PLUMBING CONTRACTOR SHALL BE RESPONSIBLE FOR CLEAN OUTS AND PROPER VENTING OF PLUMBING

PLUMBING CONTRACTOR SHALL FURNISH AND INSTALL ALL EQUIPMENT, BACK FLOW PREVENTERS, VALVES,UNIONS, BY-PASS PIPING AND ALL REQUIRED ACCESSORIES, BY LOCAL AUTHORITIES HAVING JURISDICTION,TO MAKE A COMPLETE AND OPERATING SYSTEM. COMPLY WITH APPLICABLE PLUMBING CODES FOR ALL INSTALLATION.

PROVIDE FOR EXPANSION, PROPER HANGERS AND SUPPORTS FOR ALL PIPING. PROVIDE NECESSARY VALVES,

WATER SERVICE LINES TO PLUMBING FIXTURES SHALL BE TYPE "L" COPPER FOR UNDERGROUND AND TYPE

CONTRACTOR SHALL PROVIDE PIPES PENETRATE EXTERIOR WALL AND WEATHER PROOF AS REQUIRES.

PLUMBING WORK SHALL COMPLY WITH STATE PLUMBING CODE AND ALL OTHER AUTHORITY HAVING

MECHANICAL CONTRACTOR SHALL PAY FOR REQUIRED PERMITS, INSPECTIONS AND TAP-IN FEES.

UNIONS, DIRTY TRAPS AS REQUIRED FOR EACH PIECE OF EQUIPMENT AND FIXTURES.

SANITARY PIPING SHALL SLOPE 1/8"PER FOOT IN DIRECTION OF FLOW.

CONTRACTOR SHALL FLUSH SANITIZE ALL PIPING PER CODE REQUIREMENT.

DRAIN PIPING: TYPE "L" COPPER WITH FPC OR PF INSULATION.

INDICATED, CONFORMING TO ASTM B88 WITH EITHER WROUGHT COPPER OR CAST BRASSDOMESTIC WATER PIPING: PROVIDE COPPER TUBING, TYPE L HARD DRAWN OF SIZES AS

CONFORMING TO CISPI 501 WITH CISPI 310 COUPLING JOINTS AND OF SIZES AS INDICATED.SANITARY WASTE AND VENT PIPING: PROVIDE CAST IRON HUBLESS PIPE AND FITTINGS

PROVIDE ECCENTRIC REDUCERS FOR CHANGES IN WASTE PIPE LINES.

ADAPTERS FOR CONNECTION TO THREADED VALVES AND FITTINGS SHALL BE

SOLDER SHALL CONFORM WITH ASTM B88 TIN LEAD-FREE SOLDER.

GAS PIPING WITH DRIPLEG AND SHUT OFF GAS VALVE, COMPLY WITH MANUFACTURERSMALLEABLE IRON FITTING IN ACCORDANCE WITH ANSI B165 CLASS 150. CONNECTACCORDANCE WITH "NFPA 54" AND "ASTM A55" PROVIDE SCREWED GALVANIZEDNATURAL GAS PIPING: STD WEIGHT BLACK STEEL, FABRICATED AND INSTALLED IN

CLOSE WHEN FAN STOPS.

ACCEPTABLE MANUFACTURERS: COOK, GREENHECK AND ACME.

PROVIDE PIPING SYSTEMS LAID OUT AND INSTALLED IN ACCORDANCE WITH LATEST

GAS PIPING WHERE INDICATED, INCLUDE ALL HANGERS, SUPPORTS ETC... REQUIREDGENERAL: FURNISH AND INSTALL WATER, SANITARY, DRAIN, VENT, AND NATURAL

1. ACCEPTABLE MANUFACTURERS: LOCKINVAR AND O.A. SMITH.

LATEST "PRESSURE VESSEL CODES". UNITS SHALL BE PLUMBED AND WIRED PERASSEMBLED. UNIT SHALL BE "UL" LISTED AND LABELED AND COMPLY WITH THE FURNISH AND INSTALL GAS WATER HEATER THAT IS FACTORY TESTED AND

NATIONAL PLUMBING CODE OR INTERNATIONAL PLUMBING CODE.

STANDARDS AND "NFPA 70" NATIONAL ELECTRICAL CODE.AND LABLED. MOTOR AND ELECTRICAL ACCESSORIES SHALL COMPLY WITH NEMAFANS SHALL COMPLY WITH "UL" 705 "POWER VENTILATORS" AND SHALL BE LISTED

PIPING / PLUMBING

FOR A COMPLETE INSTALLATION.

A.

B.

MANUFACTURERS WRITTEN INSTRUCTIONS.

WATER HEATER

A.

4.

3.

THE WORK INCLUDED IN THE CONTRACT SHALL CONSIST OF FURNISHING,INSTALLING, LASTING AND GUARANTEEING OF THE FOLLOWING WORK:

AND BACK DRAFT DAMPER MOUNTED IN CURB BASE, FACTORY SET TO PROVIDE THE FOLLOWING ACCESSORIES: DISCONNECT SWITCH, BIRD SCREEN

COORDINATE LOCATION AND DIMENSIONS. PROVIDE WALL LOUVER WHEREPROVIDE HANGING VIBRATION ISOLATORS AND NESSESSARY ACCESSORIES.

FABRICATED AND ASSEMBLED WITH CAPACITY AS SCHEDULED.FURNISH AND INSTALL CENTRIFUGAL AND CABINET EXAUST FAN THAT IS FACTORY

ACCEPTABLE MANUFACTURERS: TRANE, LENNOX, CARRIER OR EQUAL.

PLUMB AND LEVEL FIRMLY ANCHORED IN INDICATED LOCATION.INSTALL UNIT IN ACCORDANCE WITH MANUFACTURERS INSTRUCTIONS

AGA SAFTY STD, AND ASHRAE 15 "SAFETY CODE FOR MECHANICALHVAC UNITS SHALL BEAR "UL" LABEL. UNIT SHALL COMPLY WITH

AND TEMPERATURE CONTROL, FILTERS AND DAMPERS.CONSISTING OF: BLOWER, EVAPORATOR COIL, ECONOMIZER, REFRIGERANTHVAC UNITS SHALL BE FACTORY ASSEMBLED AND TESTED.

TESTS, ADJUSTMENTS AND BALANCING OF ALL SYSTEMS.

HOT AND COLD WATER PIPING AND INSULATION.LOW PRESSURE DUCT WORK AND INSULATION.

IN A PROFESSIONAL MANNER AND SHALL MEET ALL THE

SAFETY AND HEALTH CODES, NFPA, STATE CODES AND ALL OTHER APPLICABLEREQUIREMENTS OF THE STATE BUILDING CODE, CITY BUILDING CODE,

COMPLETE AND OPERATING SYSTEM. ALL WORK SHALL BE INSTALLEDNOT SPECIFICALLY MENTIONED, BUT NECESSARY TO PROVIDE AAND AIR CONDITIONING SYSTEM. INCLUDE ANY LABOR AND MATERIALDETAILS NECESSARY TO PROVIDE A COMPLETE HEATING, VENTILATINGFURNISH ALL LABOR, MATERIAL, TOOLS INCIDENTALS AND

CODES AND REGULATIONS.

1.

POWER VENTILATORS

APPLICABLE.

REFIGERATION".

2.

A.

1.

3.

2.

CAPACITY AS INDICATED ON SCHEDULE.

HVAC UNITS.

AIR DEVICES / ACCESSORIES.POWER VENTILATORS.

WATER HEATERS.SANITARY PIPING.

7.

A.

HVAC UNIT

8.

1.

4.

6. 5.

2. 3.

B.

SPECIFICATIONS

GENERAL

A.

PLUMBING FIXTURE SCHEDULE:

"M" COPPER FOR ABOVE FLOOR OR PEX IF APPROVED BY LOCAL AHJ.

CLEANOUTS:

O.

M.

N.

L.

IN ACCORDANCE WITH THE LATEST PLUMBING CODE.

RECESSED SOLDER JOINT FITTINGS.

G.JURISDICTION.

K.

J.

H.

I.

CAST BRASS. 1.

2.

F.

PIPING / PLUMBING CONT'D

INSTRUCTIONS.

E.

D.

C.

ALL AUTOMATIC TEMPERATURE CONTROLS SHALL BE ADJUSTED AND SET FOR PROPER

SHEAVES, BELTS AND DAMPERS AND ALSO THE ADDITION OF DAMPERS AS REQUIRED FOR THE CONTRACTOR SHALL BE RESPONSIBLE FOR MAKING ALL REQUIRED CHANGES IN THE

SHALL COMPLY WITH THE LATEST STANDARDS OF THE ASSOCIATED AIR BALANCE COUNCILBALANCE AIR QUALITIES TO WITHIN 5% AND LOCK VOLUME REGULATORS. AIR BALANCING

BE SUBMITTED TO ARCHITECT FOR APPROVAL PRIOR TO RELEASE OF FINAL PAYMENT.

CORRECT BALANCE.

OPERATION.

OR THE NATIONAL ENVIROMENTAL BALANCING BUREAU.

D.

C.

B. -+

INCLUDING THE PAYMENT OF ALL COSTS OF SUCH TESTS. AIR BALANCE REPORT SHALLTEST AND ADJUSTMENTS OF ALL SPECIFIED SHALL BE MADE BY THIS CONTRACTOR,

BLANKET "UL" LABELED REINFORCED VAPOR BARRIER JACKET, 0.3 K FACTOR AT 75 F.SUPPLY DUCTS: FDB-FIBERGLASS DUCT BLANKET, FOIL FACED FIBERGLASS DUCT WRAP

WATER PIPING: GLASS FIBER COVERING 0.26K FACTOR @ 75 F, SINGLE CYLINDRICAL

ADHESIVE, SEALERS, JACKETS ETC... FOR A COMPLETE INSTALLATION. EXPOSED ROUNDGENERAL: PROVIDE PIPE AND DUCT INSULATION AS DESCRIBED BELOW. INCLUDE ALL

FURNISH AND INSTALL ALL AIR DEVICES ( DIFFUSERS, GRILLES) AS SCHEDULED. ACCEPTABLE

FLEXIBLE DUCT CONNECTIONS WITH PANDUIT ADJUSTABLE DIAMETER RYLON CLAMPS.GENFLEX MODEL #SM-2DE CONICAL FITTING AT NEW RUN OUTS FROM MAIN. SECURE ALLFURNISH AND INSTALL FLEXIBLE ROUND DUCTS TO AIR DEVICES GENFLEX TYPE SLR FAN

NOT EXCEEDING FOUR (4') FEET SPACING. GAGES FOR ROUND AND RECTANGULAR LOW SUPPORTED AND ANCHORED TO THE BUILDING CONSTRUCTION WITH DOUBLE-STRAP HANGERSAND AIR CONDITIONING SYSTEM" PUBLISHED BY "SMACNA". DUCTS SHALL BE SECURELY

ALL SHEET METAL WORK SHALL BE FABRICATED AND INSTALLED IN ACCORDANCE WITH

FURNISH AND INSTALL GALVANIZED DUCTWORK AND ACCESSORIES AS INDICATED ON

THE LATEST EDITION OF THE " DUCT MANUAL AND SHEET METAL CONSTRUCTION FOR VENTILATING

PRESSURE SHALL BE PER SMACNA 0-2 INCHES STATIC PRESSURE CLASS

TEST AND ADJUSTMENTS:

INSULATION

1. LOW PRESSURE DUCT WORK: 1 1/2 INCH

DUCTWORK IS NOT TO BE INSULATED.

CONSTRUCTION.

MANUFACTURERS: TITUS, CRANE AND KRUGER.

DRAWING.

SHEET METAL AND ACCESSORIES

A.

C.

B.

A.

D.

C.

B.

A.

FD

o

3"

FIXTURE CONNECTIONS SHALL BE IN ACCORDANCE WITH THE FOLLOWING TABLE:

WATER CLOSETS (FLUSH TANK)

LAVATORY

FIXTURE

1-1/2"

4"

WASTESOIL OR

1-1/2"

VENT TRAP

1/2"

WATER HOT

o

3/4"

1/2"

WATER COLD

LOCATION: TOILETS AND WHERE INDICATED. MODEL NO. Z-415 ADJUSTABLE.STRAINER, FINISHES AND REMARKS: 5" DIAMETER TYPE "B" STRAINER NICKEL BRONZE WITH INTEGRAL

FD-1 GENERAL FLOOR DRAIN:

SEEPAGE PAN, CLAMPING COLLARS, EXTENSION SLEEVES OR FRAMES.

FLOOR DRAIN SCHEDULE:

1-1/2"

MOP SINK 3" 1-1/2" 3/4" 3/4"3"

FAUCETS SHALL BE SYMMONS, CHICAGO OR SPEAKMAN.TOILET SEATS SHALL BE OPEN FRONT OLSONITE, CHURCH, CENTOCO OR BENEKE.FLUSH VALVE SHALL BE SLOAN OR ZURN.FIXTURE SUPPORTS SHALL BE ZURN. J.R. SMITH, JOSAM OR WADE.

FIXTURES SHALL BE AMERICAN STANDARD, KOHLER OR CRANE. AMERICAN STANDARD MODEL NUMBERS ARE USED TO ESTABLISH A STANDARD.

KITCHEN SINK 1-1/2" 1-1/2" 1/2" 1/2"1-1/2"

ELECTRIC WATER COOLER 1-1/2" 1-1/2" 1/2"1-1/2"

PLUMBING SPECIALTIES:PLUMBING SPECIALTIES SHALL BE JOSAM, J.R. SMITH, WADE, MIFAB, SIOUX CHIEF OR ZURN.

CLEANOUTS: THREADED BRASS PLUGS WITH ZURN Z-1460-9 STAINLESS STEEL COVER IN WALLS AND Z-1400-2NICKEL BRONZE SCORIATED COVER IN FLOORS.

FLOOR DRAINS: CONTRACTOR HAS THE OPTION OF USING TRAP PRIMERS OR TRAP SEAL DEVICES AS FOLLOWS:

TRAP SEALS SHALL BE PROVIDED FOR ALL FLOOR DRAINS, FLOOR SINKS AND OTHERS TO PREVENT TRAPEVAPORATION. SEALS SHALL BE EQUAL TO SURESEAL, SIZED TO MATCH THE DRAIN TRAP.

TRAP PRIMERS SHALL BE MIFAB, SMITH OR ZURN Z-1022 "SANI-GARD", ALL BRONZE BODY WITH INTERNALVACUUM BREAKER, ANTI-BACK-SIPHON DESIGN, NON-LIMING OPERATING ASSEMBLY, REPLACEABLE VALVE SEAT,GASKETED BRONZE COVER, CHROME PLATED FINISH. LOCATE TRAP PRIMER VALVES ON THE NEARESTDOMESTIC COLD WATER MAIN SERVING THE SPACE AND PIPE TO FLOOR DRAIN TRAP PRIMER CONNECTION.PROVIDE HEAT TRAPS IN BOTH HOT AND COLD WATER PIPE RISERS AT WATER HEATERS UNLESS TRAPS AREINTEGRAL WITH THE HEATERS.

URINAL 2" 1-1/2" 3/4"2"

SYSTEM SHALL BE SIZED PER NFPA STANDARDS, BUILDING CONSTRUCTION AND OCCUPANCY

AND BE IN ACCORDANCE WITH THE OWNER'S (LANDLORD'S) CRITERIA AND INSURING AGENCY.

THE CONTRACTOR SHALL HYDRAULICALLY DESIGN THE PIPE SIZING.

CONTRACTOR SHALL BE LICENSED IN THE STATE OF MICHIGAN FOR THE DESIGN AND

INSTALLATION OF FIRE PROTECTION SYSTEMS.

CONTRACTOR SHALL PREPARE SHOP DRAWINGS OF THE COMPLETE INSTALLATION AND SUBMIT

FOR APPROVAL TO THE LOCAL FIRE MARSHAL AND TO THE OWNER'S INSURING AGENCY.

PIPING SHALL BE SCHEDULE 40, BLACK STEEL PIPE WITH SPRINKLER PATTERN CAST-IRON

SCREWED AND SCREWED FLANGE FITTINGS, 175 PSI S.W.P. UL APPROVED. CONTRACTOR SHALL

HAVE OPTION TO USE APPROVED LESSER WALL THICKNESS PIPE AND ROLL GROOVE TYPE

COUPLINGS EQUAL TO VICTAULIC OR TOTAL LOCK.

PROVIDE SLEEVES FOR ALL PIPING PASSING THROUGH WALLS.

PROVIDE AND INSTALL ALL HANGERS OF APPROVED TYPE. INSTALLATION SHALL CONFORM TO

NFPA STANDARD NO. 13.

PROVIDE AND INSTALL UL LISTED VALVES.

SPRINKLER HEADS SHALL BE "QUICK RESPONSE" TYPE AS MANUFACTURED BY GRINNELL,

CENTRAL, STAR, VIKING OR AUTOMATIC SPRINKLER CORP. OF AMERICA. SEMI-RECESSED

PENDANT STYLE WITH CHROME FINISH BODY AND ESCUTCHEON IN AREAS WITH LAY-IN

CEILINGS, WHITE FLUSH CONCEALED TYPE IN GYPSUM BOARD CEILINGS AND STANDARD BRASS

UPRIGHT STYLE IN EXPOSED AREAS. STANDARD 165 DEGREE RATING UNLESS SPECIFIED OR

REQUIRED FOR HIGHER TEMPERATURE AREAS.

PROVIDE WIRE CAGE GUARDS ON HEADS WHERE REQUIRED.

PROVIDE TWO (2) SPARE HEADS OF EACH TYPE USED, COMPLETE WITH NECESSARY TOOLS AND

STORAGE CABINET, PROPERLY MARKED, SECURED TO WALL IN SPRINKLER RISER ROOM OR

OTHER LOCATION AS SELECTED BY THE ARCHITECT.

WATER FLOW SWITCHES

PROVIDE WATER FLOW SWITCHES AS REQUIRED BY DESIGN WITH CONTACTS AND WITH AN

ADJUSTABLE TIME DELAY MECHANISM BETWEEN THE PADDLE OPERATED STEM AND THE ALARM

INITIATING CONTACT TO ABSORB BRIEF WATER MOVEMENTS DUE TO THE WIDE RANGE OF

WATER PRESSURE OR NUMEROUS SURGES.

WATER FLOW SWITCHES SHALL BE 24 VOLT, SINGLE PHASE, SHALL BE AN APPROVED TYPE,

CONFORMING TO THE RULES AND REGULATIONS OF ALL THE APPLICABLE LOCAL CODES OR

ANY OTHER CODES HAVING JURISDICTION.

CONTRACTOR SHALL WIRE THE WATER FLOW SWITCHES TO ALARM BELLS, OR HORNS AND

STROBES, INSIDE AND OUTSIDE, AND TO SUPERVISORY PANEL.

FLUSH OUT AND TEST SYSTEMS PER NFPA REGULATIONS.

DESIGN BASIS SHALL BE ORDINARY HAZARD. ALL WORK RELATED TO THE SPRINKLER SYSTEM

SHALL BE IN ACCORDANCE WITH THE FIRE INSURANCE UNDERWRITERS REQUIREMENTS AND

THE REQUIREMENTS OF N.F.P.A., AND LOCAL FIRE MARSHAL. BEFORE STARTING ANY WORK ON

THE SPRINKLER SYSTEM, THE CONTRACTOR SHALL SUBMIT A COMPLETE SET OF ENGINEERED

REPRODUCIBLE SPRINKLER PLANS BEARING THE APPROVAL OF THE FIRE INSURANCE

UNDERWRITER, THE ARCHITECT AND THE LOCAL FIRE MARSHAL.

SPRINKLER SYSTEM SHALL BE TESTED AT A WATER PRESSURE OF 200 PSIG FOR A PERIOD OF

TWO (2) HOURS AND SHALL HAVE ALL FACILITIES FOR PROPER DRAINAGE AND ANY NECESSARY

TEST VALVES, ORIFICES, OR EQUIPMENT REQUIRED BY AUTHORITIES HAVING JURISDICTION.

UPON COMPLETION OF THE SYSTEM AND ON POSSESSION OF PREMISES, THE CONTRACTOR

SHALL SUBMIT A WRITTEN CERTIFICATE TO THE OWNER FROM THE UNDERWRITER STATING

THAT THE SYSTEM WAS INSPECTED AND APPROVED.

COORDINATE AND ADVISE THE ELECTRICAL CONTRACTOR OF ELECTRICAL REQUIREMENTS FOR

ALARMS, FLOW SWITCHES, TAMPER SWITCHES, GONGS, ETC. ALL ELECTRICAL WORK REQUIRED

MUST BE INCLUDED IN THE BASE BID.

FIRE PROTECTION SPECIFICATIONS GENERAL

![Index 2015 [ringingworld.co.uk] · 2016-01-24 · Index 2015 Introductory Notes acronyms and abbreviations: ... (let) is used to indicate a letter. Alphabetical Index 12-bell ringing:](https://static.fdocuments.us/doc/165x107/5f49a3e4b1fb230d2e6834e8/index-2015-2016-01-24-index-2015-introductory-notes-acronyms-and-abbreviations.jpg)

![Index [ ] · PDF file3 index copper alloy mechanical connectors kpa line](https://static.fdocuments.us/doc/165x107/5ab6b6ef7f8b9a2f438df333/index-index-copper-alloy-mechanical-connectors-kpa-line-.jpg)