Aa

-

Upload

mmxriweb -

Category

Technology

-

view

1.608 -

download

0

Transcript of Aa

Resource Audit

MMX Mineração e Metálicos S.A.

Serra Azul Mines

Brazil

Prepared for:

MMX Mineração e Metálicos S.A. Avenida Prudente de Morais1250

Belo Horizonte, Minas Gerais Brazil

SRK Project Number: 162700.10

Prepared by:

7175 W. Jefferson Avenue, Suite 3000 Lakewood, CO 80235

Effective Date: November 16, 2010

Report Date: January 5, 2011

Author:

Leah Mach, CPG, MSc

MMX Mineração e Metálicos S.A. I Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

Table of Contents

1 INTRODUCTION ........................................................................................................... 1-1 1.2.1 Sources of Information ......................................................................... 1-1 1.3.1 Site Visit................................................................................................ 1-2

2 PROPERTY DESCRIPTION AND LOCATION ........................................................... 2-1

3 GEOLOGICAL SETTING .............................................................................................. 3-1 3.1.1 Regional Structure ................................................................................ 3-1 3.2.1 Local Lithology ..................................................................................... 3-4 3.2.2 Alteration .............................................................................................. 3-4 3.2.3 Structure ................................................................................................ 3-4 3.2.4 Metamorphism ...................................................................................... 3-5

4 MINERALIZATION ....................................................................................................... 4-1

5 DRILLING ....................................................................................................................... 5-1

6 SAMPLING METHOD AND ANALYSIS..................................................................... 6-1 6.1.1 Logging and Sampling .......................................................................... 6-1 6.2.1 Logging and Sampling .......................................................................... 6-2 6.4.1 Sample Preparation ............................................................................... 6-3 6.4.2 Sample Analysis.................................................................................... 6-3 6.5.1 Comparison of Assayed and Calculated Global Grades ....................... 6-4 6.5.2 Stoichiometric Closure.......................................................................... 6-4 6.5.3 Certified Reference Material ................................................................. 6-5

7 DATA VERIFICATION ................................................................................................. 7-1

8 MINERAL RESOURCES ESTIMATE .......................................................................... 8-1

9 RECOMMENDATIONS ................................................................................................. 9-1

10 REFERENCES .............................................................................................................. 10-1

11 GLOSSARY .................................................................................................................. 11-1 11.1.1 Mineral Resources .............................................................................. 11-1 11.1.2 Mineral Reserves ................................................................................ 11-1

List of Tables

Table 1: Drilling at the Serra Azul Mine ..................................................................................... IV

Table 2: Serra Azul Mineral Resource Statement, as of November 16, 2010* ........................... VI

Table 1.3.1: Key SRK Project Personnel .................................................................................... 1-2

Table 2.2.1: Serra Azul Land Tenure .......................................................................................... 2-1

Table 5.1.1: Comparison of Twin RC and Core Drillholes ........................................................ 5-1

Table 5.1.2: Drilling at Serra Azul.............................................................................................. 5-2

Table 6.4.1: Laboratories used for Sample Preparation and Analysis ........................................ 6-2

Table 6.4.1: Bureau Veritas Detection Limits ............................................................................ 6-4

MMX Mineração e Metálicos S.A. II Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

Table 8.1.2: Basic Statistics for Assays ...................................................................................... 8-1

Table 8.2.1: Basic Statistics of Metal Variables by Lithotypes used in Grade Estimation ........ 8-3

Table 8.3.1: Composite Statistics................................................................................................ 8-4

Table 8.4.1: Density of Lithotypes ............................................................................................. 8-5

Table 8.5.1: Variogram Parameters ............................................................................................ 8-6

Table 8.6.1: Block Model Dimensions and Origin ..................................................................... 8-7

Table 8.6.2: Estimation Parameters ............................................................................................ 8-7

Table 8.7.1: Basic Statistics of the Blocks .................................................................................. 8-8

Table 8.8.1: Serra Azul Classification Criteria ........................................................................... 8-9

Table 8.9.1: Serra Azul Mineral Resource Statement, as November 16, 2010* ...................... 8-10

Table 8.10.1: Measured and Indicated Grade and Tonnage by Fe Cutoff. ............................... 8-11

Table 8.10.2: Inferred Grade and Tonnage by Fe Cutoff ......................................................... 8-11

Table 11.2.1: Glossary .............................................................................................................. 11-2

Table 11.2.2: Abbreviations ...................................................................................................... 11-3

List of Figures

Figure 2-1: General Location Map of the Serra Azul Mine ........................................................ 2-2

Figure 3-1: Project Location within the São Francisco Craton ................................................... 3-6

Figure 5-1: Drill Collar Location Map........................................................................................ 5-3

Figure 8-1: Drillhole Location Map with Topography and Mining Concessions .................... 8-13

Figure 8-2: Cross-sections with Geology and Drilling Looking East ....................................... 8-14

Figure 8-3: Oblique View of Cross-sections Showing Change in Bedding Dip ...................... 8-15

Figure 8-4: Omni-Directional and Downhole Variograms for Iron, Friable and Compact Itabirite8-16

Figure 8-5: Cross-sections with Geology, Block Model and Drilling Looking East ................ 8-17

Figure 8-6: Swath Plot Index Map and Iron Swath Plot ........................................................... 8-18

Figure 8-7: Cross-sections with Geology, Block Model Classification and Drilling ............... 8-19

Figure 8-8: Grade Tonnage Curves, Iron .................................................................................. 8-20

MMX Mineração e Metálicos S.A. III Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

Summary

Property Description and Location

The Serra Azul Mine (the Project) is located in the Serra Azul area in the state of Minas Gerais, Brazil near the town of Igarapé, approximately 60km southwest of Belo Horizonte, the capital of Minas Gerais. The Project consists of an operating mine and two beneficiation plants for the production of lump and sinter feed.

Ownership

The Project is controlled by AVG Mineraçao S/A, a subsidiary of MMX Sudeste Mineração Ltda. (MMX Sudeste), a 100% owned subsidiary of MMX Mineração e Metálicos S.A. (MMX).

Geology and Mineralization

The Project lies within the Quadrilátero Ferrífero (Iron Quadrangle). The geology of the Iron Quadrangle has been studied since the 18th century and is one of the most important metallogenic provinces in the world. The lithologies in this area include the Rio das Velhas and Minas Supergroups, which are part of the crystalline basement. This area is known for its banded iron formation (BIF) deposits.

In the Project area, the Serra das Farofas is composed of rocks from the Minas Supergroup that are underlain by the Rio das Velhas Supergroup in a clear discordant contact. The Minas Supergroup is subdivided, from youngest to oldest, into three groups:

Piracicaba Group;

Itabira Group; and

Caraça Group.

Locally, the stratigraphic sequence is inverted, with the most recent quartzitic formations of the Piracicaba Group overlain by the itabirites of the Cauê Formation, Itabira Group, which, in turn, is capped by the oldest phyllites and quartzites of the Caraça Group.

Within the pit area, the geology is dominated by four formations. From oldest to youngest, these are the Batatal, Cauê, Gandarela and Cercadinho Formations. The Batatal Formation has been thrust over the younger Cauê Formation, which has been thrust over the youngest Cercadinho Formation. The deposit is crosscut by a northwest-trending, high-angle brittle fault that appears to be offset by younger northeast trending faults.

The mineralization at the Project consists of metamorphosed BIF subsequently with strong evidence of hydrothermal syngenetic formation with areas of supergene enrichment through lateritic weathering. This results in a variety of different mineralization types. There are seven distinct lithological ore types observed in this area of the Serra do Curral:

Canga;

Friable siliceous itabirite;

Friable rich itabirite;

Compact itabirite;

Friable hematite;

MMX Mineração e Metálicos S.A. IV Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

Compact hematite; and

Friable carbonate itabirite.

Exploration

Like most private iron mine operators in Brazil, AVG, Minerminas and prior operators have not had extensive and detailed exploration programs. There has been minimal exploration drilling prior to MMX’s involvement in the Project. Limited channel samples were collected in the pit area.

Since 2005, 213 holes have been drilled at the Project, totaling 18,857M. The drilling consists of both core and reverse circulation drilling. Table 1 lists the number of drillholes by program and company and the laboratory that was used to analyze the samples.

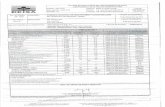

Table 1: Drilling at the Serra Azul Mine

Campaign Number of

Drillholes Type Period

Length

(m)

Number of

Samples Laboratory

FSAVG, FSAVGSB 11 HW Core 2005 440 50 AVG Total AVG 11 2005 440 50 AVGMMX 9 HWL Core 2007 694 88 SGS SEFDSF 26 HQ, HWL 2007-2008 1,459 273 SGS,MMX FSMNM 3 HWL Core 2007-2008 191 34 MMX FDSB, SEFDSB 50 HWL Core 2008 3,190 628 MMX FDSF 6 HWL Core 2008 203 49 MMX RPSF (RC) 19 4 or 5" 2009 2,836 522 SGS FDSA 32 HQ, HN 2010 3,872 448 SGS, Bureau Veritas FDSC 11 HQ 2010 590 * Bureau Veritas RPSA (RC) 46 4.75 or 5" 2010 5,382 551 Bureau Veritas Total MMX 202 2007-2010 18,417 2593

Total 213 2005-2010 18,857 2643

Mineral Resources

MMX prepared the resource estimation for Serra Azul under the direction of Ms Lilian Grabellos, Manager of Resouces and Reserves. Leah Mach, Principal Resource Consultant with SRK, audited the resource.

The drillhole sample database was compiled by MMX and verified by SRK and is determined to be of high quality and suitable for resource estimation. SRK received the drillhole database as four comma separated variable (csv) files consisting of:

Collar: Drillhole ID, easting, northing, elevation, and total depth;

Survey: Depth, azimuth, inclination;

Geology: From, to, lithology and code from drill log, modeled lithology and code from cross-sections; and

Assay: Four files with one file for each of three size fraction groups and one for global, containing from, to, Fe, SiO2, Al2O3, P, Mn and LOI.

Sixty-seven geologic cross-sections were constructed at 100 or 50m intervals depending on the drill spacing. The cross-sections were used to prepare horizontal sections at 10m spacing from

MMX Mineração e Metálicos S.A. V Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

elevation 9550 to 1,365. The block model was coded from the horizontal sections. The lithotypes that were used in grade estimation are Canga (CG), friable itabirite (IF), friable carbonate itabirite (IFCA), and compact itabirite (IC).

MMX composited the samples on 5m intervals starting at the top of the drillhole with breaks at the lithotype solid boundaries. MMX conducted variography studies on the AVG and Minerminas properties separately because of the difference in the dip of the beds between the two properties. The study included directional and downhole variograms as well as omni-directional variograms. The omni-directional variogram was chosen as showing the best fit for the data.

A block model was created that covers the entire AVG/Minerminas mine area. The block model contains variables for:

Fe, SiO2, Al2O3, Mn, P, and LOI – global and for each of the three size fractions;

Lithotype;

Percentage below topography;

Estimation parameters – number of composites, number of drillholes, average distance of composites used in estimation, and distance to closest composite; and

Class – 1=measured, 2=indicated, 3=inferred, 4=potential.

Block grades were estimated by ordinary kriging in three passes. Blocks were classified as Measured, Indicated or Inferred after each estimation pass. Blocks that did not meet the necessary criteria for classification were re-estimated in the next pass. The search ranges were determined by the iron variogram range with the first pass at the variogram range and the second at 150% of the range. The third pass was at 2000m to fill all the blocks in the model and estimate a mineral potential. The estimation was conducted using block and composite lithotype matching.

The resources were classified according to CIM classification as Measured, Indicated, or Inferred based on the pass in which the block was estimated and the number of drillholes used in the estimation. In order to control the depth to which the blocks could be classified, a surface was generated at the base of the drillholes. This surface was lowered 20m and then uused to limit the classification of measured, indicated, and inferred resources.

The Mineral Resources for the Serra Azul Mine as of November 16, 2010, on a wet tonnes basis are presented in Table 2.

MMX Mineração e Metálicos S.A. VI Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

Table 2: Serra Azul Mineral Resource Statement, as of November 16, 2010*

ROCK CLASS

Tonnes

(000's) Fe% SiO2% Al2O3% Mn% P% LOI%

IF

Measured 158,368 51.14 23.36 1.8 0.047 0.049 1.261

Indicated 41,621 48.46 26.99 1.67 0.144 0.048 1.333 Total

M&I 199,989 50.58 24.12 1.77 0.07 0.05 1.28

Inferred 17 40.84 38.02 1.11 0.029 0.033 0.774

IC

Measured 384,164 35.82 14.1 0.62 0.031 0.025 0.372

Indicated 252,657 34.32 49.23 0.7 0.082 0.025 0.519 Total

M&I 636,821 35.22 28.04 0.65 0.05 0.03 0.43

Inferred 3,939 30.57 53.25 0.78 0.341 0.049 1.652

IFCA

Measured 37,491 32.97 44.3 3.64 0.832 0.081 2.799

Indicated 13,608 32.9 44 3.72 0.993 0.083 2.926 Total

M&I 51,099 32.95 44.22 3.66 0.87 0.08 2.83

Inferred 0

CG

Measured 4,447 59.4 5.75 4.05 0.022 0.159 4.634

Indicated 7,170 55.37 8.1 5.69 0.037 0.226 5.801 Total

M&I 11,617 56.91 7.2 5.06 0.03 0.2 5.35

Inferred 5,535 53.01 10.98 6.16 0.045 0.218 5.998

Total

Measured 584,440 39.97 40.37 1.16 0.087 0.036 0.801

Indicated 315,056 36.6 45.13 1.07 0.129 0.035 0.851 Total

M&I 899,496 38.79 42.04 1.13 0.1 0.04 0.82

Inferred 9,492 43.67 28.57 3.92 0.168 0.147 4.185 * Cut-off Grade 12% Fe; tonnes on a wet basis.

Recommendations

Analytical and QA/QC Data

MMX has a laboratory quality assurance/quality control program (QA/QC) in place and monitors the laboratory results from these samples on a regular basis. The QA/QC samples includes standard reference samples developed from Serra Azul material and pulp duplicates.

Resource Estimation

SRK recommends that MMX continue to drill additional holes into the compact itabirite to gain additional samples and analysis and increase confidence in the grades at depth and to increase the indicated resources in this rock type.

MMX Mineração e Metálicos S.A. 1-1 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

1 Introduction SRK Consulting (U.S.), Inc., (SRK) was commissioned by MMX Mineração e Metálicos S.A. (MMX) to audit resources at the Serra Azul Mine. The Project is located in the Serra Azul area in the state of Minas Gerais, Brazil near the town of Igarapé, located approximately 60km southwest of Belo Horizonte, the capital of Minas Gerais. The Project consists of two contiguous open pit mines and two beneficiation plants for the production of lump and sinter feed. The Tico-Tico Mine was acquired by MMX as part of the acquisition of AVG Mineração S.A. (AVG) in December 2007. The Ipê mine was acquired as part of the acquisition of Mineradora Minas Gerais Ltda (Minerminas) in March 2008. The properties are operated by MMX Sudeste Mineração Ltda. (MMX Sudeste), a 100% owned subsidiary of MMX.

This report is prepared using the industry accepted Canadian Institute of Mining, Metallurgy and Petroleum (CIM) “Best Practices and Reporting Guidelines” for disclosing mineral exploration information and CIM Definition Standards for Mineral Resources and Mineral Reserves (December 11, 2005).

Certain definitions used in this executive summary are defined in the body of this Technical report on resources and in the glossary in Section 10.

1.1 Terms of Reference and Purpose of the Report

This audit of Mineral Resources is intended to be used by MMX to further the development of the Project by providing an independent audit of the mineral resource estimates and classification of resources. MMX may also use this Report for any lawful purpose to which it is suited.

1.2 Reliance on Other Experts

SRK’s opinion contained herein is based on information provided to SRK by MMX throughout the course of SRK’s investigations as described in Section 1.2.1, which in turn reflect various technical and economic conditions at the time of writing.

SRK reviewed certain materials pertaining to a limited amount of correspondence, pertinent maps and agreements to assess the validity and ownership of the mining concessions. However, SRK did not conduct an in-depth review of mineral title and ownership; consequently, no opinion will be expressed by SRK on this subject.

SRK is of the opinion that the information concerning the properties presented in this report (within or not produced by SRK) adequately describes the properties in all material respects.

1.2.1 Sources of Information

The underlying technical information upon which this Report is based represents a compilation of work performed by MMX. The studies and additional references for this Technical Report on Resources are listed in Section 10. SRK has reviewed the Project data and incorporated the results thereof, with appropriate comments and adjustments as needed, in the preparation of this Report on Resources.

The author reviewed data provided by MMX including hard copy and digital files located in the Project and MMX’s offices in Brazil. Discussions on the geology and mineralization were conducted with MMX’s technical team. The drillhole assay database was prepared by MMX and verified by SRK.

MMX Mineração e Metálicos S.A. 1-2 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

Leah Mach is a Qualified Person as defined by NI 43-101.

1.3 Qualifications of Consultants (SRK)

The SRK Group is comprised of over 900 staff, offering expertise in a wide range of resource engineering disciplines. The SRK Group’s independence is ensured by the fact that it holds no equity in any project and that its ownership rests solely with its staff. This permits SRK to provide its clients with conflict-free and objective recommendations on crucial judgment issues. SRK has a demonstrated record of accomplishment in undertaking independent assessments of Mineral Resources and Mineral Reserves, project evaluations and audits, technical reports and independent feasibility evaluations to bankable standards on behalf of exploration and mining companies and financial institutions worldwide. The SRK Group has also worked with a large number of major international mining companies and their projects, providing mining industry consultancy service inputs.

This report has been prepared based on a technical and economic review by a team of consultants sourced principally from the SRK Group’s Denver, US office. These consultants are specialists in the fields of geology exploration, mineral resource and mineral reserve estimation and classification, open pit mining, mineral processing and mineral economics.

Neither SRK nor any of its employees and associates employed in the preparation of this report has any beneficial interest in MMX or in the assets of MMX. SRK will be paid a fee for this work in accordance with normal professional consulting practice.

The individuals who have provided input to this Report, who are listed below, have extensive experience in the mining industry and are members in good standing of appropriate professional institutions. Ms. Leah Mach is a Qualified Person under Canadian Instrument NI 43-101 guidelines.

Table 1.3.1: Key SRK Project Personnel

Name Responsibility

Leah Mach Geology, Resources, Project Manager Neal Rigby Reviewer

1.3.1 Site Visit

Leah Mach, Qualified Persons for this report, made site visits to the Property on June 27 and October 7, 2007, February 13, 2009 and June 30, 2010. The site visits consisted of reviewing the drill core and logging procedures, visiting the open pit and observing the operations and product types, visiting the beneficiation plant, and touring the property to see the tailings facility and waste dumps.

1.4 Units of Measure

Metric units are used throughout this report, except where otherwise stated.

1.5 Effective Date

The effective date of this Audit of Resources is November 16, 2010. The resource estimation includes drilling through November 10, 2010. The topography is current as of November 16, 2010.

MMX Mineração e Metálicos S.A. 2-1 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

2 Property Description and Location 2.1 Property Location

The Project is located approximately 60km southwest of Belo Horizonte, and approximately 560km northwest of Rio de Janeiro in Minas Gerais State, Brazil (Figures 2-1 and 2-2). The Project consists of three contiguous licenses in the Serra Azul Mountain Range, located near the city of Igarapé in the southwest part of the Quadrilátero Ferrífero (Iron Quadrangle). The Project also includes six exploration claims surrounding the licenses. The licenses lie between 20°07’30”S and 20°06’30S and between 44°17’W and 44°19’W (Figure 2-3). The Project lies within the municipalities of Brumadinho, Igarapé, Itatiaiuçu, Mateus Leme and São Joaquim de Bicas.

2.2 Mineral Titles

MMX holds the mineral rights through leases and ownership. Table 2.2.1 presents the mining and exploration licenses and requests for exploration licenses controlled by MMX in the Serra Azul area. The holder of the three mining licenses is Companhía de Mineração Serra da Farofa (CEFAR) and MMX has lease agreements with CEFAR for each one. Brazilian Mining Law allows holders of Exploration or Mining Licenses to totally or partially assign or transfer these claims to a third party, with DNPM’s approval. The three mining licenses cover 509.71ha, the exploration licenses cover 4,331ha and areas requested for exploration cover 6,393.38ha.

Table 2.2.1: Serra Azul Land Tenure

Claim Holder Location* Mineral(s)

Area

(ha) Permit

Validity

Term

801.908/68 Cia. de Mineração Serra da Farofa - CEFAR

Igarapé, Brumadinho and São Joaquim de Bicas

Iron 351.64 Mining Not

Applicable

805.374/71 Cia. de Mineração Serra da Farofa - CEFAR

Brumadinho and Igarapé Iron 83.37 Mining Not

Applicable

5.182/58 Cia. de Mineração Serra da Farofa - CEFAR

Brumadinho Iron 74.70 Mining Not

Applicable

833.379/2004 AVG Igarapé,Itatiaiuçu,Mateus Leme Iron 1,035.00 Exploration

License September

2012

832.182/2006 AVG Itatiaiuçu,Mateus Leme Iron 1,400.00 Exploration

License May 2013

830.632/2006 AVG Brumadinho, Igarapé Iron 1,896.00 Exploration

License July 2013

830.633/2006 AVG Brumadinho, Igarapé, Itatiaiuçu Iron 1,881.25 Exploration

Request

831.243/2006 AVG Mateus Leme Iron 960.00 Exploration

Request

832.183/2006 AVG Brumadinho, S. Joaquim de Bicas

Iron 1,912.50 Exploration

Request

830.826/2010 AVG Brumadinho, S. Joaquim de Bicas

Iron 7.97 Exploration

Request

831.713/2010 AVG Brumadinho Iron 12.01 Exploration

Request

832.607/2010 AVG Brumadinho Iron 261.47 Exploration

Request

834.356/2020 AVG Brumadinho, S. Joaquim de Bicas

Iron 1,358.18 Exploration

Request

*City or District

SRK Job No.: 162700.10

File Name: Figure 2-1.doc Date: 12/20/10 Approved: LEM Figure: 2-1

Serra Azul Mine, Brazil

Source: MMX Mineração e Metálicos S.A

General Location Map of the

Serra Azul Project Mine

SERRA AZUL MINE

SRK Job No.: 162700.10

File Name: Figure 2-2.doc Date 12/20/10 Approved: LEM Figure: 2-2

Serra Azul Mine, Brazil

Source: MMX Mineração e Metálicos S.A

Site Location Map of the Serra Azul Mine

SRK Job No.: 162700.10

File Name: Figure 2-3.doc Date: 12/20/10 Approved: LEM Figure: 2-3

Serra Azul Mine, Brazil

Source: MMX Mineração e Metálicos S.A

Mineral Licenses Serra Azul Mine

832182/2006

Exploration License

Mining License

Request for Exploration

Municipal Limits

MMX Mineração e Metálicos S.A. 3-1 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

3 Geological Setting 3.1 Regional Geology

The Project area is situated in the western portion of the Iron Quadrangle near Belo Horizonte, Minas Gerais, in the Serra do Curral homocline. Mineralization is hosted by the Minas Supergroup which is dominated by supracrustal metasedimentary and metavolcanic rocks. Intrusive rocks are rarely found in the area but where present, are basic sills and dikes up to 1m wide. Regional metamorphism reached the greenschist facies during multiple episodes of deformation.

3.1.1 Regional Structure

The Project area lies within the São Francisco Craton tectonic province of South America shown in Figure 3-1. The Project is located in the extreme west of the Serra do Curral homocline and in the north/northwest limit of the Iron Quadrangle. This region has a complex tectonic-metamorphic history and is part of the basement of the southern portion of the São Francisco Craton. The São Francisco Craton (Almeida et al 1981) tectonic province was not affected by the Brazilian deformation but is bordered by Brazilian fold belts that developed during orogenesis culminating in the formation of Gondwana approximately 650 Ma. The basement of the craton was subjected to the Jequié/Rio das Velhas and Transamazonic tectonic-metamorphic events that preceded the Brazilian deformation. There are various evolutionary models proposed for the Iron Quadrangle region, and this area is still extensively studied.

Among the large-scale structures in the Iron Quadrangle are the:

Serra do Curral homocline;

Serra da Moeda syncline; and

Dom Bosco Syncline.

The Serra do Curral homocline is located in the north and has a NE-SW strike and dips SE. Serra Moeda is located in the west part of the Iron Quadrangle and is the west limb of a syncline which has an N-S axis and dips to the south. The Dom Bosco syncline is in the south and has an E-W axis and is connected to the Serra Moeda syncline on the west side. There is also the Falha do Engenho zone of trans-current shearing, the Mariana anticline to the southeast and the Santa Rita syncline to the east. According to Dorr (1969), the Santa Rita syncline corresponds to the major and most complex folding of the region. Finally, the Gandarela isoclinal syncline is located to the northeast with SE dipping limbs and the Fundão-Cambotas fault system that extends for almost the entire length of the east border. Figure 3-2 shows the homocline, synclines and anticlines in the region.

Serra do Curral Homocline

There have been five different interpretations for the formation of the Serra do Curral homocline as listed below:

The homocline is a section of the Serra dos Três Irmãos region (Eichler, 1964);

The homocline is the south limb of the Piedade syncline (Dorr, 1969);

Pires (1979) interpreted the homocline as related to an anticline;

MMX Mineração e Metálicos S.A. 3-2 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

Alkmim and Marshak (1998) interpret the structure as the inverted flank of a regional anticline; and

Oliveira et al. (2005) interpret the homocline as the overturned limb of a recumbent allochthonous megafold, referred to as the Curral Nappe.

Figure 3-3 shows schematic sections showing each author’s interpretation, which are discussed in detail below.

Dorr (1969). The first interpretation was proposed by Eichler (1964) and is shown in Figure 3-3 schematic section (a). Eichler (1964) interprets the homocline as a section of the Serra dos Três Irmãos region that has been brought in through thrust faults that trend to the north.

According to Simmons (1968), the Serra do Curral homocline is the south limb of the Piedade syncline, as suggested by Dorr (1969). This is shown in schematic section (b) in Figure 3-3. This structure is well characterized at the NE limit of the Serra do Curral (Serra da Piedade), where the two limbs of the syncline are recognized, a fact that leads Simmons (1968) to believe that the homocline represents one of the limbs of this megastructure. The Serra do Curral homocline, dipping to the SE, is characterized by secondary folding with axial planes oblique to the direction of the mountain ridge. Also recognized were small reverse faults, direction parallel to the syncline with displacement to the SE and normal faults of high angle that cut the megastructure.

Pires (1979) was the first author to propose that the regional folding is related to an anticline. Through work that was done at the junction of the Serra do Curral homocline with the Moeda syncline, Pires (1979) proposes schematic section (c) shown in Figure 3-3. In this section, Pires (1979) shows an anticline, whose inverse limb (the north limb) would represent the Serra do Curral homocline. This structure is limited at the base by the Falha Curral, a thrust fault and the schists to the north, which are part of the Rio das Velhas Supergroup.

Romano (1989) determined the petrographic and textural characteristics of the metavolcanic rocks of the regions of Mateus Leme to Esmeraldas and of Pará de Minas to the Pitangui. According to the author, such rocks represent the continuity of the Rio das Velhas Supergroup in the Occidental Serra do Curral. In this region, Romano (1989) identified thrust faults sectioning the Rio das Velhas Supergroup, among various other deformational features. The structures are attributed to two phases of regional deformation (Dn and D1). The first deformation affected only the Rio das Velhas Supergroup and the second that extended to the Minas Supergroup in the west portion of the Serra do Curral homocline. The second regional deformation was of a progressive compressional character.

In the contact between the Sabará Group and the Belo Horizonte Metamorphic Complex, in the region of Ibirité, southwest of the city of Belo Horizonte, Marshak et al. (1992) and Jordt-Evangelista et al. (1992), identified a zone of normal shearing and characterized three zones of contact metamorphism. They are, from NW to SE the zones of cordierite-sillimanite, of staurolite-andalusite-cordierite and of biotite. This situation exemplifies the metamorphic aureoles that occur in the contact zones of the supercrustal rocks with the basement metamorphic complexes, in response to the formation of domes and synclines.

Endo and Machado (1997) interpret the Serra do Curral homocline as part of a syncline, characterized by the absence of a northern rim, or limb, at the western limit of the structure. Endo and Machado (1997) observed that on the southern rim/limb the rocks of the Minas

MMX Mineração e Metálicos S.A. 3-3 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

Supergroup are in normal stratigraphic sequence with inclinations that vary from moderate to high while on the northern rim/limb the stratigraphic sequence is inverted. According to Endo and Machado (1997), the Zone of Normal Shearing (the Moeda-Bonfim zone) in contact between the Bonfim Metamorphic Complex and the supracrustal rocks along the Serra da Moeda, extends to the Serra do Curral homocline. Here, the zone of normal shearing it is identified by the Souza Nochese Zone of Shearing. Thus, the principal structural features are:

Sub-orthogonal between the synforms Moeda and Curral;

Breaking and absence of north rim/limb of the syncline;

Normal ductile shearing between the metasediments and the Bonfim Complex; and

Stratigraphic inversions in the south rim/limb of the synform.

Based on these structures, Endo and Machado (1997) propose eight events of deformation for the region: four in the Neo-Archean and four in the Proterozoic, all of co-axial character.

Alkmim & Marshak (1998) observed parasitic asymmetric folding and mesoscopic faults trending to the NW at the western limit of the Serra do Curral homocline. This observation led to the interpretation that the Serra do Curral homocline may be the inverted flank of a regional anticline with polarity to the NW. According to Alkmim & Marshak (1996), at the Curral-Moeda junction, the Curral anticline is refolded the Moeda syncline. The development of the mega-anticline would be related to a compressive event, during the Transamazonic period and older than the extension that resulted in doming and syncline formation. Alkmim and Marshak’s (1998) interpretation is shown in Figure 3-3 section (d).

Finally, the relations proposed by Oliveira et al. (2005) for the region of Itatiaiuçu, is shown in Figure 3-3 section (e). According to the Oliveira et al. (2005), the schistocity observed in the rocks of the Minas Supergroup and Rio das Velhas in the entire Serra do Curral region, is the same that predominates in the sedimentary layering and schistocity in the mesoscopic folds with overturned limbs. According to the authors, the Serra do Curral homocline is the overturned limb of a allochthonous recumbent megafold, trending to the north-northeast, and referred to by Oliveira et al (2005) as the Curral Nappe.

3.2 Local Geology

In the Project area, the Serra das Farofas is composed of rocks from the Minas Supergroup that are underlain by the Rio das Velhas Supergroup in an unconformity. The Minas Supergroup is subdivided, from youngest to oldest, into three groups:

Piracicaba Group;

Itabira Group; and

Caraça Group.

Locally, the stratigraphic sequence is inverted, with the most recent quartzitic formations of the Piracicaba Group overlain by the itabirites of the Cauê Formation, part of the Itabira Group, which, in turn, is capped by the oldest phyllites and quartzites of the Caraça Group. This stratigraphic inversion, as discussed in Section 5.1.1, characterizes the mountain ridge and is most likely the rim of a recumbent fold.

MMX Mineração e Metálicos S.A. 3-4 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

3.2.1 Local Lithology

The Caraça Group is subdivided into the Moeda (lower) and Batatal (upper) Formations. The Moeda Formation is composed, principally, of coarse quartzites, metaconglomerates, and phyllites. According to Renger et al. (1994), the Moeda Formation has a maximum age of 2.65Ga, and was deposited in a fluvial environment. Over time, this depositional environment evolved into a marine-platform identified as the Batatal Formation. The Batatal Formation is composed, predominantly, of phyllites and graphitic phyllites. Its maximum age of deposition is 2.5Ga (Renger et. al. 1994) and the Batatal Formation has a gradational contact with the Itabira Group.

The Itabira Group is essentially composed of chemical sediments, a characteristic that separates it from the Caraça Group. It is of great economic importance, as it hosts world class deposits of iron and manganese, associated with gold and bauxite. It is divided, from base to top, into the Cauê and Gandarela Formations. The Cauê Formation is composed of itabirites, dolomitic itabirites, amphibolitic itabirites, carbonate itabirites and lenses of marl and phyllites. Due to their resistance to weathering, the itabirites form the principal ridges of the region with extensive escarpments, such as the Serra do Curral. The Cauê Formation represents the principal target of research work. Since the Gandarela Formation does not occur in the area researched, is the Cauê Formation is in direct contact with the Piracicaba Group.

The Piracicaba Group is divided, from base to top, into the Cercadinho, Fecho do Funil, Taboões and Barreiro Formations. The Cercadinho Formation is the only one of this group that is identified in the Project area, being composed of quartzites and graphitic phyllites, of light grey coloring that occurs in the north part of the area. According to Renger et al. (1994), this group represents a new period of tectonic movement in the Minas Basin, initiated around 2.4Ga.

The rocks show a general E-W direction with dips varying between 45º and 50º to the south with some local variations occasioned by secondary asymmetric folding and by transverse faulting of the structure.

3.2.2 Alteration

Alteration in the area is described as intense silicification of compact itabirite resulting from hydrothermal activity.

3.2.3 Structure

The dominant structure in the project area is an antiform overturned to the north. The upper limb has been completely eroded, leaving only the inverted lower limb.

As a result of the numerous deformational episodes, bedding is rarely observed and then only in the quartzite and phyllite of the Cercadinho Formation. However, the principal foliation, Sn is well developed in all of the local lithologies. The Sn foliation dips approximately 30º to 40°S in the northern part of the project and increases to about 70°S in the southern part of the area. This suggests that the Project is located on the inverted limb of an isoclinal anticline with vergence to the north. Small scale, asymmetric folds with amplitudes from centimeter to meter scale are observed at the Project where cataclasite has also been observed. These folds are typically tight with E-W axes. Intense folding is seen in the BIF, often obliterating the primary structures.

The contacts between formations show tectonic textures and are interpreted to be thrust faults. Normal faults are also observed in the project area.

MMX Mineração e Metálicos S.A. 3-5 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

3.2.4 Metamorphism

The metamorphism identified in the Project area is related to continental collision during the Transamazonian Orogeny. Metamorphic grade in the Iron Quadrangle increases from west to east as described by Dorr (1969). The rocks of the western and central portions reached greenschist facies whereas those in the east reached the almandine-amphibolite facies. In the Serra do Curral, metamorphism of greenschist facies predominates.

Itabirite is a highly deformed rock with a composition derived by tectonic and metamorphic processes. Small preserved nuclei of magnetite in the interior of hematite crystals suggest that the greater part of these rocks were oxidized by hydrothermal solutions during the deformational processes. The most common minerals in BIF, other than quartz, are siderite, ankerite, ferroan dolomite, magnetite, martite and, locally, chlorite. Martite is a product of altered magnetite and ankerite and is often a secondary mineral.

3.3 Project Geology

Within the pit area, the geology is dominated by four formations. From oldest to youngest, these are the Batatal, Cauê, Gandarela and Cercadinho Formations. The pit geology is shown in Figure 3-4, and Figure 3-5 shows north-south cross-sections 573050 and 574250 through the mine area. The Batatal Formation has been thrust over the younger Cauê Formation, which has been thrust over the youngest Cercadinho Formation. The deposit is crosscut by a northwest-trending, high-angle brittle fault that appears to be offset by younger northeast trending faults.

The dominant structural features consist of Sn foliation, fracture planes and minor fold axes. Foliation is the most conspicuous planar element within the pit and is preferentially developed in the enriched itabirite. The Sn foliation strikes NW-SE and dips both NE and SW suggesting the presence of a larger fold. Parasitic fold axes typically trend 150º to 200º.

Well-defined fracture planes are found in both the friable itabirite and compact itabirite. It is typically more prominent in the compact itabirite. The fracture planes have two predominant orientations. One strikes NW and dips NE the other strikes NNE and dips SE. These fabrics often host breccia zones with areas of significantly enriched iron.

SRK Job No.: 162700.10

File Name: Figure 3-1 Date: 12/20/10 Approved: LEM Figure: 3-1

Serra Azul Mine Brazil

Source: Marshak & Alkmim 1989 and

Alkmim & Marshak 1998

Project Location within the

São Francisco Craton

Três Marias Formation São Francisco Supergroup

Other units of São Francisco Supergroup Espinhaço Supergroup Piracicaba and Sabará Groups

Itabira Group Caraça Group

Rio das Velhas Supergroup Basement Normal Fault

Thrust Fault Foliation

Bedding

Metamorphic Aureole

Serra Azul Mine

SRK Job No.: 162700.10

File Name: Figure 3-2.doc Date: 12/20/10 Approved: DKB Figure: 3-2

Serra Azul Mine Brazil

Source: Modified from Alkmim & Noce

2006 after Dorr (1969) and Romano (1989)

Location of Large Structures in the

Serra Azul Mine Area

Serra Azul

Mine Area

SRK Job No.: 162700.10

File Name: Figure 3-3.doc Date: 12/20/10 Approved: LEM Figure: 3-3

Sources: a) Schematic section proposed by Eichler (1964) in the region of the Serra dos Três Irmãos; b) Section proposed by Dorr (1969), section NW-SE in the Quadrilátero Ferrífero; c) Section proposed by Pires (1979) for the region of junction of the Serra do Curral with the Moeda syncline; d) Section proposed by Alkmim & Marshak (1998) for the region west of the homocline of the Serra do Curral; e) Schematic section proposed by Endo et al (2005) for the region of Itatiaiuçu (Section Itatiaiuçu). (Fm. Formation, Gr. Group, Sgp. Supergroup, ST Topographic Surface).

Serra Azul Mine Brazil

Geological Sections Proposed for the Region of the

Serra do Curral

SRK Job No.: 162700.10

File Name: Figure 3-4.doc Date: 12/20/10 Approved: LEM Figure: 3-4

Serra Azul Mine Brazil

Source: MMX Mineração e Metálicos S.A

Geological Map of the Serra Azul Mine Area

COMPACT AMPHIPLITIC ITABIRITE

SRK Job No.: 162700.10

File Name: Figure 3-5.doc Date: 12/20/10 Approved: LEM Figure: 3-5

Cross-section 573050 North-South

Cross-section 574250 North-South

Serra Azul Mine

Brazil

Source: MMX Mineração e Metálicos S.A

North-south Cross-sections through the Serra Mine in the

Minerminas Area

MMX Mineração e Metálicos S.A. 4-1 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

4 Mineralization 4.1 Mineralized Zones

The mineralization at the Project consists of metamorphosed BIF with strong evidence of hydrothermal syngenetic formation with areas of supergene enrichment from subsequent lateritic weathering. This results in a variety of different mineralization types. There are seven distinct mineralization types at the Project:

Canga;

Friable siliceous itabirite;

Friable rich itabirite;

Compact itabirite;

Friable hematite;

Compact hematite; and

Friable carbonate itabirite.

Canga is the product of chemical weathering of all the types of friable ore. It generally has more elevated grades of aluminum, phosphorous, and greater loss on ignition (LOI). It occurs in three stratigraphic locations: at the top of the BIF, in the base of the southern Serra das Farofas and over the schists of the Batatal Formation. In the Batatal Formation, canga is formed in the iron ore colluvium. In some areas, it has elevated iron grades, due to the nature of the source rock. The presence of visible hematite clasts is common and goethite and limonite commonly occur with secondary minerals, increasing the hardness.

The friable itabirite is confined to the proximities of compact itabirite or of zones of silicification. The principal characteristics of this type of ore are the grades of silica that vary from 6% to 10% and in granulometry that is above 19mm. The bands are composed of friable hematite intercalated with bands of recrystallized quartz.

Compact itabirites occurs at the base of the friable itabirites and as small elongated bodies preferentially oriented WNW/ESE within the friable itabirite. These last are protoliths of proto-ore that remain after intense weathering and/or hydrothermal alteration along certain preferential directions such as the axis of folds.

The friable carbonate itabirite is characterized by intercalations of clay bands alternating with bands of friable and compact hematite. The bands of clay are generally light rose colored but locally may be white in color. Where these bands are white, kaolinite is often present. The texture is banded, with bands up to 40 to 50cm in width. Where kaolinite is common in the clay-rich bands, internal breccia texture are observed. The clay bands of clay also contain isolated crystals of euhedral quartz and specularite, both of which are coarse to very coarse in grain size. The euhedral quartz and the specularite are the product of secondary alteration, growing over the original texture of these rocks. The hematite bands are fine and even occur as films intercalated with clay minerals. Friable hematite also occurs disseminated within the clay bands.

MMX Mineração e Metálicos S.A. 4-2 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

4.2 Relevant Geological Controls

The mineralization at the Serra Azul Mine shows strong evidence for both structural and lithological controls. There is also evidence for hydrothermal origin for the iron formation, with later supergene modification that probably caused major enrichment in addition to “softening” of the ore. The hypogene phase is associated with D1 folding during which, hydrothermal fluids ascended to the surface as a result of decompression. This would also permit meteoric fluids to descend along the normal faults causing mixing resulting in oxidizing conditions and the formation of magnetite and carbonates, as described by Rosière et al. (2008). In this model, Fe-rich hydrothermal dolomite could be formed during the tight folding. Later, oxidization of the Fe-rich dolomite caused leaching of Mg, Ca and CO2, resulting in the formation of hematite. Subsequent weathering resulted in supergene enrichment and “softening” of the ore. These same normal faults would be the preferred routes for the meteoric fluids to circulate to deeper parts of the system. At the Project, this faulting could be represented by the high-angle brittle faults observed in the pit.

The genesis of the friable carbonate itabirite with hypogene characteristics, could be controlled by D1 folding, that channelized mineralizing hydrothermal fluids parallel to the layering or compositional banding. Higher-grade ore is concentrated in these folded areas. In the locations where the fluid/rock ratio was higher, bands of compact hematite were generated, possibly by leaching or complete substitution of the pre-existent carbonates. Nearby, where the fluid/rock ratio was less, the leaching/substitution of the carbonates was not complete, some carbonate remained that, subsequently leached during supergene alteration, generating the contaminated friable ore. This high-grade ore is generally porous and almost always contains remnants of weathered carbonate, observed as the orange to ochre colored interstitial material.

Another observation at the Serra Azul Mine, primarily at AVG, is the close relationship between breccias and/or veined areas with the high-grade friable ore and the rich itabirite. It has been observed that in areas with the greatest amount of breccias with carbonate veins and veinlets, it is likely that friable ore or rich itabirite will be present. This is also characteristic of areas only affected by carbonate veins and veinlets. The carbonate veins can be parallel as shown in Figure 7-2 or may crosscut itabirite banding. Portions of compact itabirite are common in the middle of friable ore.

The contacts between friable and compact ores may be sharp or transitional. Where there are carbonate veins/veinlets there is a tendency for the intensity of friability to be greater than the areas without carbonate veining.

Iron remobilization most likely occurred as an association with hydrothermal fluids, resulting in the formation of concordant and discordant hematite veins. These veins are often breccia zones filled by hematite. Some of the remobilized material is composed of magnetite. The process of quartz remobilization was very intense in some areas, resulting in breccia formation and silicification of the itabirite. Quartz remobilization often results in high compactness to the itabirite (hard itabirite). In places, the orientation of these silicified zones appears, to be controlled by the hinges of D1 folds, where it is parallel to the banding. However, in other areas the pattern is rather complex.

MMX Mineração e Metálicos S.A. 5-1 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

5 Drilling 5.1 Type and Extent of Drilling

Core drilling in the Project area by MMX was performed by Vórtice Sondagens e Serviços de Mineração, Ltda. (Vórtice) and Geológica e Sondagens Ltda. (Geosol), both based in Belo Horizonte. MMX also conducted reverse circulation (RC) drilling with contractor, Geosol Geosedna Perfurações and Especiais S.A. (Geosedna), also based in Belo Horizonte.

A total of 18,858m have been drilled at the Project in 149 core holes and 64 RC holes. Holes were drilled on a slightly irregular 100m x 100m grid.

Core

All core holes are HQ or HW sized core (77.8mm), and were drilled using a conventional drill rig. Sixty-one holes are vertical and the remaining holes were drilled at inclinations between -60° and -77° to the north. The hole depth varies from 11m to 268m with an average of 72m.

RC Drilling

The RC holes were drilled with a hammer or tricone depending on the hardness of the rock. The diameter of the hole drilled by hammer is 5in and the diameter of the hole drilled by tricone is 4in. All holes were drilled at an inclination of 70° to the north. The average depth of the holes is 125m, with a minimum of 35m and a maximum of 280m.

The technique of RC drilling was new to the AVG/Minerminas project in 2009. In order to assess the results of RC drilling, two twin holes were drilled for comparison. Table 5.1.1 presents the twin drillholes and the results for the matching intervals. RPSF15 and SEFDSF08 are not true twins as one is vertical and the other angled at -70 to the north, however, the results for the friable and compact itabirite are quite similar. The holes were collared on the fines stockpile, so the initial interval would not necessarily be expected to be similar. The twins, FSAVGB05 and RPSF16, show similar grades in the canga, but the RC hole has higher grades in the friable itabirite.

Table 5.1.1: Comparison of Twin RC and Core Drillholes

Drilled Vertical

Drillhole Orientation From To Interval Thickness Lith Fe SiO2 Al2O3 P Mn LOI

RPSF15 Vertical 0.0 12.0 12.0 12.0 FS 49.10 24.95 2.43 0.072 0.01 2.42 17.0 51.0 34.0 34.0 IF,IC 50.87 26.11 0.47 0.014 0.01 0.27

SEFDSF08 North,-70 0.0 11.3 11.3 10.6 FS 44.40 31.70 1.60 0.052 0.01 1.38 16.9 52.6 35.7 33.5 IF,IC 52.02 24.20 0.52 0.011 0.02 0.17

FSAVGSB05 Vertical 0.0 8.2 8.2 8.2 CG 63.79 2.42 2.57 0.057 0.03 3.51 12.7 39.9 27.2 27.1 IF,IC 47.91 29.67 0.56 0.014 0.02 1.06

RPSF16 Vertical 0.0 5.0 5.0 5.0 CG 60.20 12.00 1.47 0.020 0.01 0.86 12.0 37.0 25.0 25.0 IF 56.84 16.72 1.02 0.012 0.01 0.71

SRK also reviewed the drillholes in cross-section and did not detect a noticeable difference in grades between the RC and core holes.

Table 5.1.2 lists the number of drillholes by program and company.

MMX Mineração e Metálicos S.A. 5-2 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

Table 5.1.2: Drilling at Serra Azul

Campaign Number of

Drillholes Type Period

Length

(m)

Number of

Samples Laboratory

FSAVG, FSAVGSB 11 HW Core 2005 440 50 AVG Total AVG 11 2005 440 50 AVGMMX 9 HWL Core 2007 694 88 SGS SEFDSF 26 HQ, HWL 2007-2008 1,459 273 SGS,MMX FSMNM 3 HWL Core 2007-2008 191 34 MMX FDSB, SEFDSB 50 HWL Core 2008 3,190 628 MMX FDSF 6 HWL Core 2008 203 49 MMX RPSF (RC) 19 4 or 5" 2009 2,836 522 SGS FDSA 32 HQ, HN 2010 3,872 448 SGS, Bureau Veritas FDSC 11 HQ 2010 590 * Bureau Veritas RPSA (RC) 46 4.75 or 5" 2010 5,382 551 Bureau Veritas Total MMX 202 2007-2010 18,417 2593

Total 213 2005-2010 18,857 2643

*Assays not received at time of estimation

5.2 Procedures

The drillhole locations are first determined by the supervising geologist. Drill access is provided by clearing trails and drill pads with the use of a dozer. For inclined holes, a line is drawn between two stakes in the azimuth direction and the drill rig is aligned with it. The inclination of the drill rig is set by a MMX technician using the inclinometer of a Brunton compass. Upon completion of the drillhole, the final collar location is then surveyed by Prisma Produtos e Serviços Ltda. ME (Prisma) using a Topcon Total Station, 239W, 3003W or 3005W. Prisma then generates a Microsoft Excel spreadsheet and/or a certified report in PDF format.

The drilling at the Project has focused on the pit area. In general, the drillholes are on north-south section lines spaced at 100m. The drillholes on section line are about 100m apart. Drilling is limited by pit walls and areas of active mining, so the 100m by 100m is not completely filled. The drillholes were not drilled to a uniform elevation, consequently, the drillhole spacing is wider with depth below the surface. Core recovery is typically in excess of 90%. Figure 5-1 is a plan map showing the location of drillholes.

5.3 Results

The compact and friable itabirites have varying hardness, which may result in different drill recoveries and possible loss of material in friable zones. Core recovery averages more than 90% for all zones and RC recovery was generally greater than 70%. SRK did not observe problems with loss of material in friable intervals. A comparison of twin RC and core holes and visual examination of RC holes by cross-section did not detect a bias between the two drilling methods. MMX is using industry best practices for exploration drilling programs at the Project.

SRK Job No.: 162700.10

File Name: Figure 5-1.doc Date: 12/20/10 Approved: DKB Figure: 5-1

Serra Azul Mine Brazil

Drill Collar Location Map

MMX Mineração e Metálicos S.A. 6-1 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

6 Sampling Method and Analysis 6.1 Core Drilling

At the drill rig, the drill core is placed in wooden boxes, and washed of all foreign material. A technician delivers the boxes to the logging area where they are placed either in the sun or under a roof until they are completely air-dried. The drill core is photographed before and after sampling to record geological descriptions and sampling intervals. Geologic logging and identification of sample intervals are carried out by the project geologist. This process identifies the different litho types, geological contacts, zones of fault or fracture, ferruginous zones and internal waste.

MMX personnel supervise all sample security. The drill core is collected from drill sites, logged and sampled under the direction and control of MMX. SRK is of the opinion that there has been no tampering with the samples.

6.1.1 Logging and Sampling

The HW-sized drill core is first photographed, and then logged by a geologist onto a standardized paper form. Data from the geological log is entered into an acQuire database, the geological database management system developed by acQuire Technology Solutions Pty Ltd. During core logging, the geologist marks the beginning and end of each sample interval on the box. Sample breaks are at changes in lithology and friability with some consideration placed on visual estimations of Fe percentage. Sampling is conducted only within the ferruginous zones. Sample intervals have a minimum length of 1m and a maximum length of 5m. The preferred sample interval ranges between 3m and 5m (80% of samples). Zones of internal waste within mineralized intervals are sampled and material outside the ferruginous zone is not sampled.

Samples are collected by a trained sampler under the supervision of a technician or a geologist following a sampling plan produced by acQuire. The sampling plan contains the identification of primary and check samples according to MMX's QA/QC policy (see Section 11.4). The core is split lengthwise using a diamond core saw in the competent zones and a specially designed scoop in the highly weathered zones. The sample is placed in a plastic bag with a sample tag. The plastic sample bag is further marked in two places on the outside with the sample identification. The sample bags are then sealed and sent to the laboratory for physical and chemical analysis. The remaining core is archived for future reference.

6.2 RC Drilling

The RC drilling is conducted dry, without injecting water. The sample was discharged from the center tube return through a hose to a cyclone. The entire sample was collected over 1m intervals in plastic bags. The bags were marked with the drillhole number and from and to meterage. The bags were weighed by Geosedna personnel and the weights recorded on a form for MMX. A small sample was collected for logging and stored in wooden boxes with 30 compartments and a hinged cover.

MMX personnel supervise all sample security. The samples were collected from drill sites, logged and sampled under the direction and control of MMX. SRK is of the opinion that there has been no tampering with the samples.

MMX Mineração e Metálicos S.A. 6-2 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

6.2.1 Logging and Sampling

The RC chips are logged by the geologist at the core facility and data from the geological log is entered into an acQuire database. The 1m samples are grouped into 5m intervals with breaks at lithological changes and the sample intervals are entered on a sampling form.

Samples are sent to a commercial laboratory in Belo Horizonte where they are composited into the sample intervals indicated by the geologist. The compositing procedure is described in Section 11.

6.3 Factors Impacting Accuracy of Results

The compact and friable itabirites have varying hardness and will have varying drill recoveries. The varying hardness of the mineralized material forces the sampler to use two techniques for core sample collection, which can make it difficult to collect a representative sample. MMX uses a saw for compact material and a trowel for friable material, which is industry standard. Because MMX uses lithological controls for sample intervals that are based on friability versus compactness, the different material hardness does not present a problem. In addition, the core recovery is good to excellent, averaging over 90%. RC drilling may also encounter problems at changes in rock hardness or void spaces. SRK saw no evidence that there is a sampling problem or sample bias introduced at the Project due to varying hardness.

MMX is conducting the sampling according to industry best practices for iron deposits.

6.4 Sample Preparation and Analysis

Before MMX acquired the property, sample preparation and analysis were performed at the AVG laboratory on the AVG property. During the initial exploration phase and in 2009, MMX used SGS Geosol Laboratórios, Ltda. (SGS) located in Belo Horizonte. For part of 2008, MMX used the laboratory at Mine 63 operated by its subsidiary, MMX-Corumbá Mineração Ltda. (MMX-Corumbá). In 2010, MMX used SGS and the Bureau Veritas laboratory in Belo Horizonte. The following sections describe the sample preparation, analysis and Laboratory QA/QC for the samples sent to the Bureau Veritas laboratory. Previous reports by SRK have documented the same information for previous drill campaigns. Table 6.4.1 presents the number of samples sent to each laboratory for the various drill campaigns.

Table 6.4.1: Laboratories used for Sample Preparation and Analysis

Company Year Laboratory Number Samples

AVG 2005 AVG 50

MMX

2007 SGS 88

2007-2008 SGS,MMX 307

2008 MMX 677

2009 SGS 522

2010 SGS 181

2010 BV 850

Total 1825

MMX Mineração e Metálicos S.A. 6-3 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

6.4.1 Sample Preparation

Samples arriving at Bureau Veritas from MMX vary in size and material. The sample is initially checked for sample identification and preservation conditions upon receipt. The core sample preparation process consists of:

Drying in a kiln at 105ºC until the sample is completely dry;

Crushing the whole sample until 95% of the sample passes through a 2mm sieve;

Reducing the volume by homogenization and quartering in a rotary splitter to reduce sample to 300 to 600 g.

Pulverizing the split until 95% passes a 150 mesh sieve;

Quartering in a rotary splitter to a sampling weighing between 25 and 50g for analysis;

Archiving the remaining coarse reject and pulp; and

Record screening tests performed during sample crushing and grinding.

The RC samples are received at the laboratory as the 1m samples originally collected at the drill. The sampling intervals, as noted by the geologist, are sent to the lab with the sample batch. The sample preparation consists of the following steps:

Drying in a kiln at 105ºC until the sample is completely dry;

Jaw crushing until 100% of the sample passes through a 6.3mm sieve;

Compositing samples according to the sample interval plan; and

Splitting in a riffle splitter and dividing the sample into two halves, one for analysis and one retained for additional metallurgical or other testwork.

6.4.2 Sample Analysis

At the Bureau Veritas laboratory, all samples are analyzed using the XRF technique. The typical sample size is 2g and is analyzed for percentage of Fe, Al2O3, SiO2, P, Mn, TiO2, CaO, MgO, K2O, Na2O and LOI.

The steps in the analytic procedure for LOI consist of:

Drying the sample in an oven at around 110ºC for at least one hour;

Weighing the empty container (CV);

Placing 1.5 to 2g of the dried sample in the container and weighing again (C+A);

Placing the container with the sample in a previously heated oven and waiting until the temperature reaches 1000±50ºC and letting it calcine for more than 1 hour; and

Removing the container from the oven, resting it on the refractory plate until it loses incandescence, and then put it in a closed dryer until the container and sample cool.

Weighing and record the final weight. LOI is calculated using the following formula:

100)()(

)()(% x

CVAC

WeightFinalACFW

MMX Mineração e Metálicos S.A. 6-4 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

The detection limits are shown in Table 6.4.1.

Table 6.4.1: Bureau Veritas Detection Limits

Analysis Lower Detection Limit

Fe2O3 0.01% SiO2 0.10% Al2O3 0.10% P2O5 0.01% MnO 0.01% TiO2 0.01% CaO 0.01% MgO 0.10% Na2O 0.10% K2O 0.01%

6.5 MMX Quality Controls and Quality Assurance

MMX has the following QA/QC program in place for its drilling programs:

The insertion of Certified Reference material samples (CRM’s);

Blind duplicates;

Assayed versus calculated global grade comparisons; and

Stoichiometric (chemical) closure calculations.

MMX has used acQuire at its properties as a database management tool since December 2007. AcQuire includes QA/QC protocols within the sample numbering procedure. In the sampling plan, the system inserts two different standards and one pulp duplicate for each 20 samples at random positions. The standard batch size is 40 samples, with 34 primary samples, 2 pulp duplicates and 4 company standards. For each 50 samples, one coarse duplicate is also inserted into the batch at a random position, reducing the primary samples to 33. If the batch is less than 20, the system assures that at least two different standards and one pulp duplicate sample will be inserted in each batch.

6.5.1 Comparison of Assayed and Calculated Global Grades

MMX calculates a global grade of iron and other elements by determining a weighted average based on analysis of different sample of different grain size.

6.5.2 Stoichiometric Closure

MMX calculates stoichiometric closure for analysis at Bureau Veritas from Fe2O3, SiO2, Al2O3, P2O5, MnO, TiO2, CaO, MgO, K2O, Na2O and LOI. This is basically a mass balance calculations and stoichiometric closure is calculated by MMX using the following equation:

S.C.=1.4298*(Fe-0.7773*FeO)+SiO2+Al2O3+2.2915*P+1.2912*Mn+TiO2+CaO+MgO+Na2O+K2O+(LOI+0.1114*FeO)+FeO

Stoichiometric closure is considered acceptable if it falls between 98% and 102%.

MMX Mineração e Metálicos S.A. 6-5 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

6.5.3 Certified Reference Material

MMX has developed its own CRM’s from material at the Serra Azul Mine with the assistance of Agoratek International and SGS. The three CRM’s are:

SAH – Serra Azul Hematite;

SACL – Serra Azul Canga Laterite; and

SAIC – Serra Azul Compact Itabirite (still in preparation).

MMX sent 20 of each samples to SGS in Belo Horizonte, Perth and Ontario, ALS Chemex in Lima and Perth, Intertek, Genalysis, Bureau Veritas, Ultratrace, Amdel and ACTLabs for analysis of Fe, P, SiO2, Al2O3, CaO, TiO2, MgO, K2O, Na2O, FeO and Mn. MMX then performed various statistical tests on the results to arrive at the accepted mean and standard deciation for each element or oxide.

6.6 Interpretation

The samples from Serra Azul are submitted with QA/QC samples, including standards and duplicate samples with standard samples appropriate to the Project. MMX has developed new standards from Serra Azul material. These samples have been sent to several laboratories in a round robin to produce analyses used to calculate an expected mean and standard deviation.

QA/QC sample failures are handled appropriately and are reviewed and investigated to determine the reason for the error. The sampling preparation and analyses follow industry guidelines and the results from the QA/QC samples indicate that the analyses are suitable for a resource database.

MMX Mineração e Metálicos S.A. 7-1 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

7 Data Verification 7.1 Quality Control Measures and Procedures

MMX directly imports data received from the laboratories into its database. SRK has compared assay certificates of 20% of the database and found no errors. The laboratory QA/QC measures are described in the proceeding section.

MMX is monitoring core recovery and is eliminating intervals with low recovery from the resource estimation database.

MMX personnel check topographic updates to be sure that data is correct and check drillhole collars against topography.

7.2 Limitations

The limitations to the QA/QC program are described in the preceding section.

SRK considers the data to be suitably verified and fit for resource estimation.

MMX Mineração e Metálicos S.A. 8-1 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

8 Mineral Resources Estimate This section provides details in terms of key assumptions, parameters and methods used to estimate the mineral resources together with SRK’s opinion as to their merits and possible limitations. The resource estimation for the Serra Azul Mine was prepared by Mr. Elvis Vargas under the direction of Ms Lilian Grabellos, Manager of Resources and Reserves. MMX uses Mintec’s MineSight software for resource estimation and mine planning. Leah Mach, Principal Resource Consultant with SRK, audited the resource.

8.1 Drillhole Database

The drillhole sample database was compiled by MMX and verified by SRK and is determined to be of high quality and suitable for resource estimation. The database consists of assays for 214 holes drilled by AVG, Minerminas, and MMX. The average depth is 88m and the total meterage is 18,858m. About a third of the holes are vertical and the remainder were drilled at approximately -70° to the north.

SRK received the drillhole database as five comma separated variable (csv) files consisting of:

Collar: Drillhole ID, easting, northing, elevation, and total depth;

Survey: Depth, azimuth, inclination;

Recovery: Advance from, to, length, recovered length, recovery percentage;

Geology: From, to, lithology and code from drill log, modeled lithology and code from cross-sections; and

Assay: From, to, Fe, SiO2, Al2O3, P, Mn, LOI, TiO2, CaO, MgO, and FeO.

Table 8.1.2 contains basic statistics for the assay interval and metal variables of all analyzed samples.

Table 8.1.2: Basic Statistics for Assays

Variable Number Minimum Maximum Average

1st

Quartile Median

3rd

Quartile

Standard

Deviation

Coefficient

of

Variation

Interval 2669 0.85 16.20 4.40 3.55 4.80 5.00 1.65 0.31Fe 2669 2.86 68.20 40.55 32.67 38.70 49.85 12.80 .032SiO2 2669 0.70 94.78 38.00 24.04 42.05 50.79 18.59 0.49Al2O3 2669 0.02 29.32 1.92 0.31 0.94 2.52 2.76 1.44P 2669 0.003 1.420 0.050 0.016 0.032 0.063 0.065 1.296Mn 2650 0.002 21.53 0.16 0.001 0.01 0.03 0.86 5.41LOI 2448 -1.95 13.95 1.34 0.10 0.57 1.86 1.91 1.43

MMX Mineração e Metálicos S.A. 8-2 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

8.2 Geology

Sixty-seven geologic cross-sections were constructed at intervals of 100 or 50m depending on the drill spacing. Figure 8-1 is a drillhole location map with mining concessions and topography as of September 2010. The following lithotypes were modeled in the cross-sections:

Stock pile;

Canga;

Friable Itabirite;

Friable Hematite;

Friable Carbonate Itabirite;

Compact Itabirite;

Compact Hematite;

Intrusive;

Quartzite;

Phyllite;

Breccia; and

Quartz Vein.

Figure 8-2 shows typical cross-sections through AVG and Minerminas.

The cross-sections were used to prepare horizontal sections at 10m spacing from elevation 955 to 1,365. The geology was coded into the block model based on the horizontal sections.

Grades were estimated for lithotypes Canga (CG), Friable Itabirite (IF), Friable Carbonate Itabirite (IFCA), and Compact Itabirite (IC). Table 8.2.1 presents basic statistics for these lithotypes.

MMX Mineração e Metálicos S.A. 8-3 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

Table 8.2.1: Basic Statistics of Metal Variables by Lithotypes used in Grade Estimation

Lithotype Statistic Fe SiO2 Al2O3 P Mn LOI

CG

Average 55.90 8.48 5.40 0.154 0.02 5.59 Minimum 26.32 0.70 0.64 0.020 0.00 0.18 Maximum 66.40 59.97 22.81 0.760 0.19 13.08 Median 59.54 5.20 3.36 0.124 0.02 4.60 St. Dev 9.92 10.40 5032 0.123 0.03 3.17 Count 119 119 119 119 117 115

IF

Average 49.35 25.76 1.84 0.058 0.04 1.46 Minimum 13.85 0.70 0.04 0.005 0.00 0.00 Maximum 68.25 74.86 14.98 1.420 2.29 12.81 Median 49.50 26.23 1.34 0.040 0.01 0.97 St. Dev 10.32 15.59 1.83 0.085 0.12 1.68 Count 1513 1513 1513 1513 1497 1345

IC

Average 34.96 48.02 0.89 0.034 0.05 0.66 Minimum 2.86 3.18 0.02 0.002 0.00 0.00 Maximum 66.00 94.78 21.33 0.318 7.10 12.66 Median 35.12 48.11 0.41 0.024 0.01 0.30 St. Dev 7.85 11.08 1.42 0.030 0.26 1.05 Count 2651 2651 2651 2651 2649 1755

IFCA

Average 31.42 47.16 3.41 0.087 0.80 2.61 Minimum 6.53 4.40 0.07 0.005 0.00 0.04 Maximum 58.68 89.41 15.57 0.324 21.53 9.95 Median 30.13 48.03 2.87 0.075 0.24 2.20 St. Dev 10.07 14.48 2.24 0.053 1.94 1.75 Count 560 560 560 560 560 556

All

Average 39.56 40 1.59 0.051 0.13 138 Minimum 2.86 0.70 0.02 0.002 0.00 0.00 Maximum 68.25 94.78 22.81 1.420 21.53 13.08 Median 37.75 43.45 0.81 0.035 0.01 0.69 St. Dev 11.70 17.29 2.11 0.063 0.73 1.82 Count 4843 4822 4822 4822 4802 3738

8.3 Compositing

The average length of the samples used in grade estimation is 2.23m with a range from 0.02 to 15m. MMX composited the samples on 5m intervals starting at the top of the drillhole with breaks at the lithotype solid boundaries. The variables that were composited include Fe, SiO2, Al2O3, P and Mn. Resulting composites with lengths less than 2.5m at the base of a lithotype change were added to the previous composite, and samples greater than or equal to 2.5 were maintained as such. Table 8.3.1 presents basic statistics of the composites used in grade estimation.

MMX Mineração e Metálicos S.A. 8-4 Serra Azul Mines Resource Audit

SRK Consulting (U.S.), Inc. January 5, 2011 SerraAzulResource Audit_LMB_003.docx

Table 8.3.1: Composite Statistics

Lithotype Statistic Fe SiO2 Al2O3 P Mn LOI

CG

Average 57.47 7.05 4.79 1.167 0.02 5.23 Minimum 26.32 0.74 0.91 0.020 0.00 0.18 Maximum 66.40 59.97 18.77 0.460 0.19 12.66 Median 59.20 3.58 3.50 0.125 1.02 4.88 St. Dev 7.37 9.52 3.48 0.131 0.03 2.52 Count 84 84 84 84 82 82

IF

Average 50.87 23.60 1.85 1.052 0.04 1.32 Minimum 13.85 0.74 0.05 0.005 0.00 0.00 Maximum 68.20 74.86 14.80 1.223 1.37 12.81 Median 51.49 22.40 1.30 0.034 0.01 0.98 St. Dev 10.23 15.12 1.79 0.079 0.11 1.37 Count 811 811 811 811 800 749

IC

Average 35.31 47.91 0.74 0.028 0.04 0.51 Minimum 4.34 3.18 0.02 0.002 0.00 0.00 Maximum 63.36 91.13 14.58 0.318 5.16 12.66 Median 35.41 48.14 0.34 0.020 0.01 0.20 St. Dev .20 10.20 1.13 0.027 0.24 0.89 Count 1068 1068 1068 1068 1066 763

IFCA

Average 33.20 44.19 3.59 0.086 0.78 2.66 Minimum 8.26 7.88 0.13 0.005 0.00 0.04 Maximum 57.10 85.16 13.80 0.270 15.50 9.36 Median 33.18 45.12 2.98 0.075 0.17 2.30 St. Dev 9.25 13.71 2.45 0.051 1.83 1.87 Count 286 286 286 286 286 283

All

Average 41.46 37.19 1.65 1.049 0.14 1.36 Minimum 4.34 0.74 0.02 0.002 0.00 0.00 Maximum 68.20 91.13 18.77 1.223 15.50 12.81 Median 38.83 41.96 0.84 0.030 0.01 0.69 St. Dev 11.97 17.87 2.05 0.066 0.72 1.75 Count 2249 2249 2249 2249 2234 1877

8.4 Density