A systematic approach to integral snap-fit attachment design

Transcript of A systematic approach to integral snap-fit attachment design

Research in Engineering Design (1998)10:84-93 © 1998 Springer-Verlag London Limited

Research in

E~gineering eslgn

A Systematic Approach to Integral Snap-Fit At tachment Design

Suat Genc 1, Robert W. Messier Jr. 2 and Gary A. Gabriele 1 ~Department of Mechanical Engineering, Aeronautical[ Engineering & Mechanics; 2Department of Materials Science & Engineering, Rensselaer Polytechnic Institute, Troy, NY, USA

Abstract. Traditional integral snap-fit attachment design focuses almost exclusively on the individual locking features, such as cantilever hooks, bayonet-fingers, compressive hooks and others'. The positioning and orientation of other signifi- cant features on parts, such as those that facilitate or enhance engagement and eliminate unwanted degrees of freedom left by locking features, i.e. locating features and enhancements, are not considered. This paper builds on relatively new methodologies and guidelines for arranging all attachment features on plastic parts comprising snap-fit assembly. Classification of features into categories of locking features, locating features and enhancements of these is used as the basis for discussion. A systematic approach to attachment design is presented.

Keywords: Design methodology; Integral attachment; Snap-fits

1. Introduction

Use of snap-fit integral attachments is ollen a key element in the creation of plastic part designs that are easy to manufacture and assemble. The major goals of Design for Manufacture and Assembly (DFMA) methodologies can be summarized as elimi- nating as many parts as possible and simplifying the assembly of remaining parts to the greatest extent possible. Such methodologies strongly rec- ommend the use of integral attachment features, including snap-fits, in a product. As examples, Chow [1] and Boothroyd et al. [2] recommend integral attachments as substitutes for separate fasteners, particularly for injection molded plastic parts, but, increasingly, for parts made from other materials and by other processes as well. Simplification of assembly without overly complicating detail part

Correspondence and offprint requests to: S. Genc, Department of Mechanical Engineering, Aeronautical Engineering and Mech- anics, Rensselaer Polytechnic Institute, Troy, NY 12180, USA.

design and manufacture is clearly possible using integral attachment methods, but the state-of-the-art or, more properly, the state-of-practice, needs study and development.

To understand the state-of-the-art and state-of- practice in the integral snap-fit attachment design process, the available literature was searched, designers were interviewed, and industry and com- pany design method were reviewed. From this, the design process for placement of snap-fits was found to be more of an art than an engineering science. Most likely, this is so because the issues involved in the placement of integral snap-fit attachments are complex and old rules for traditional fastening are being applied to this new approach, despite not being appropriate.

Snap-fit attachment feature placement is influ- enced by many variables which, until recently, were not recognized or organized in a useful manner. These include real and representative part shapes, installation directions and assembly motions, loading directions and degrees of freedom or constraint, molding direction, and part stiffness and tightness (through tolerance). Little design information or guidance was found in the published literature, or even within trade or company design manuals, to help with these concerns. In fact, most existing snap- fit design guides do not even discuss determining the type and location of snap-fit features as part of the design process [3,4].

Of the half dozen diverse-industry companies sur- veyed, General Motors had the most formalized approach to the assembly of parts. GM considered and considers the integral attachment interface as a system, and uses a so-called 'attachment-level approach' as opposed to the traditional feature-level approach [5-7]. From this foundation, research has continued to attempt to create a formalized attach- ment strategy. On the way to defining that strategy, a systematic approach to integral snap-fit attachment

A Systematic Approach to Integral Snap-Fit Attachment Design

design has been developed. That approach, now complete, is described in this paper.

2. I n t e g r a l S n a p - F i t A t t a c h m e n t F e a t u r e s

For the purpose of this paper, integral snap-fit attachments refer to the specific, detailed features molded into a plastic part to actually provide attach- ment functionality. These features can be further sub-classified based on sub-functions within attach- ment or assembly. This approach is important, since designers often do not know the full range of snap- fit features available to them. Because of this, the best feature for a particular application is often not selected, with the consequence that problems are encountered during product assembly or during ser- vice. The following definitions and classifications were originally presented by Luscher et al. [8], and are summarized here in order to increase understand- ing of the features that can be found on plastic parts. Fundamental definitions can also be found in other papers [9,10].

Integral attachment features are formed into parts to enable mechanical joining of those parts by: (I) establishing part location, alignment and orientation; (2) eliminating degrees of freedom and/or absorbing the tolerances between these parts; (3) locking the parts into an assembly; and (4) transfemng service loads. The two key attributes of any integral attach- ment feature are that it be integral to a part, and that its primary purpose be to provide some joining or attachment functionality. The term 'feature' emphasizes that such attachments are an integral portion of a part, and are not a separate part (e.g. a fastener).

The special integral attachments referred to as snap-fits accomplish attachment by elastically deforming or deflecting during part assembly, and then recovering to their original undeflected state to lock or trap the mating part. The process of recovery is often accompanied by an audible or tactile 'snap' indicating both the attachment features, and, there- fore, the mating parts are properly engaged.

For sub-classification of integral attachment fea- tures, attachment functionality was defined as one of three primary tasks accomplished by attachment features when two parts are connected. These three primary tasks are: (1) location of the parts relative to each other to remove degrees of freedom and transfer service loads; (2) final locking of the parts together during assembly; and (3) enhancement of

85

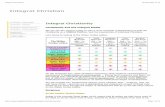

Integral Attachnlent Feature Types [

Fig. 1. Three primary classes of integral attachment features.

the attachment by enhancement features [8]. This first level of classification is shown in Fig. 1.

In this hierarchy, locating features or locators eliminate degrees of freedom between parts, transfer the service loads, and establish the major reference or datum planes or points which locate parts relative to each other. Several locating feature types com- monly found in plastic parts are shown in Fig. 2. Locating features often differ greatly in their top- ology since each is designed for a very specific loading situation. For example, the 'stop' feature only contains motion which is inward and normal to its large surface (in the negative x-direction in Fig. 2). It does not constrain motion in any other direction (y or z) or outwardly normal (positive x) to its large surface. The stop feature is designed to make planar contact with another flat surface or line contact with a curve surface. The 'pin-in-hole' fea- ture, on the other hand, constrains all planar motion normal to its centreline in both x and y directions. A 'pin-in-hole' feature, however, will allow inplane rotation around the pin. The 'wedge-in-slot' feature limits motion to along the slot, i.e. z direction.

Locking features or locks are features used to provide the final attachment between two parts through their elastic deflection and recovery. The locking feature classification represents the most common integral attachment seen in products and they are most closely associated with the term 'snap- fit'. Several common locking features are shown in Fig. 3.

Stop Lug Pin-in-Hole Wedge-in-Slot

Fig. 2. Examples of types of locating features.

86 S. Genc et al.

Cantilever Hook Compressive Hook Bayonet-Finger

Trap BaH & Socket Annular Snap

Fig. 3. Examples of several major types of locking features.

It is proposed that locking features are made up of the following two functional units, a deflection mechanism and a retention mechanism. Examples are shown in Fig. 4 for the cantilever hook feature. These two mechanisms are defined as follows: A deflection mechanism is the portion of a locking feature which accommodates the elastic deflection necessary for assembly insertion. Deflection mech- anisms can be classified by the deflection which occurs (e.g. torsion, bending) and the shape or top- ology of the structure. Deflection mechanisms are commonly called latches. A retention mechanism is the portion of a locking feature which provides the interference necessary to prevent separation. The most common type of retention mechanism is called a catch, and consists of two planar faces, called a retention face and a insertion face, molded into the end of the deflection mechanism.

Enhancement features (or Complaints) [8,12] or enhancements are features or, more precisely, attri- butes of constraining (locating or locking) features that add robustness or user-friendliness to a snap-fit attachment. Enhancements divide into four categor- ies: (1) assembly enablers; (2) disassembly enablers; (3) performance enhancers; and (4) manufacturing enablers [12].

Inse~on Retention Fa~ ~ ~ a c e ,,

Deflection M ~ m Retention Mechanism

1. Assembly Enablers include guides, which ensure smooth engagement and latching of mating parts, and feedbacks, which provide an audible or tactile signal to verify that the attachment has been properly made.

2. Disassembly Enablers include visuals, which pro- vide information about the attachment feature's location, function, operation, or disassembly, and assists, which provide a means for manual deflection of manual locks.

3. Performance Enhancers include: (1) limiters, which protect sensitive locks, provide local strength, and/or improve lock performance (i.e. locking integrity); (2) compliance, in the form of the feature's design or attribute of its design to allow manufacturing tolerances to be taken up and provide and maintain a tight fit to prevent vibration or rattle without violating constraint requirements; and (3) dual attachments, in which features provide a back-up or secondary means of attachment should the primary locking feature(s) fail. Examples of assembly enablers, disassembly enablers, and performance enhancers are shown in Fig. 5.

4. Manufacturing Enablers are not physical devices, rather design philosophies that enhance snap-fit performance. There are two such philosophies: (1) preferred design practices, which follow rec- ommended and preferred practices of the design of plastic parts; and (2) process-friendly design, in which specific practices enable easy mold adjustments. Examples of each are shown in Fig. 6.

3. Designing Parts with Integral Attachment Features: Integral Attachment Design

Designing parts with integral attachment features occurs at two fundamental levels: attachment-level design, and feature-level design. Attachment-level design deals with higher level issues, and focuses on interacting surfaces, assembly motions, and selec- tion and placement of attachment features, while feature-level design deals with detailed issues such as sizes and tolerances of features. These two levels in integral attachment design correspond to concep- tual design and detail design, respectively [13]. Since in a formalized design process (e.g. Pugh's method [13]), identification of design specifications, such as constraints and objectives, is a design activity, this step needs to be handled prior to the

Fig. 4. Deflection and retention mechanisms on a locking feature, or a latch and a catch.

A Systematic Approach to Integral Snap-Fit Attachment Design 87

Assembly En~#.L¢~

/ \

Pin Tapered Pin Cone

Limiters

(a)

Di~;assembly Enablers

Wedge Lug Lift then Slide Lift lhcn Twist Lift and Pull

P~formance Enablers Assists

(c)

Fig. 5. Examples of enhancement features, (a) Assembly enablers, (b) disassembly enablers, and (c) performance enhancers.

Stop

adjusted in the stop contact

area

: Wail Metal-Safe Lug

Fig. 6. Manufacturing enabler philosophies for design enhance- ment.

attachment-level in integral attachment. Figure 7 shows how integral attachment design fits into the overall design process.

The first task of integral snap-fit attachment design (i.e. development of an attachment concept, during attachment-level design) has as its goal the formation of an effective attachment concept for the parts to be joined. To create an attachment concept, a designer considers overall part geometry, service loads to be carried between the parts, limitations on assembly direction, joint strength, and tolerance. Based on these, the designer must specify: (1) inter- face geometry or part geometry involved in the attachment process; (2) an assembly procedure to bring the parts together; and (3) attachment feature information such as position, orientation and type, etc. (see Fig. 8). This entire level of design, how- ever, is often overlooked in terms of product design or is approached in a very ad hoc manner.

The second level, called feature-level design, has as its goal the specification of the geometry of all the individual features in the attachment concept.

Market

f

L Design Spccilicatic.~_____.._._..~

] Consideration of: Gross part geometry

1 ~ o b ~ t i ~ [ "~ Design constraints

:1= • < Specification of:

Interface geometry Assembly procedure Feature inforraation

Specification of; Dimensions " Tolerances

For features I_ 4

It Sell

Fig. 7. Integral attachment design within the overall design pro- cess.

Figure 8 shows information flow in integral attach- ment design. Each integral snap-fit attachment fea- ture is designed to support load(s) in specific direction(s), absorb a certain amount of variability (i.e. provide tightness), and provide a certain struc- tural stiffness. On the basis of these considerations,

88 S. Genc et al.

Design Specifications

i ,.~ Concerns &

Assembly

',~ Objectives

:e

Attachment-Level Feature-Level (Conceptual Design) (Detail Design)

r ._ caC e

e~, Attachment ~ )

~:king Locating Feature ~ ~ De~ai| sizing ' Feantre ' of the features

Fig. 8. Information flow in the integral attachment design process.

the integral snap-fit attachment features' dimensions and tolerances must be calculated. As currently prac- ticed, feature design has many limitations. These include, but are not limited to: (l) imprecise analyti- cal or numerical methods for predicting behavior; (2) insufficient materials property data for use in analysis; and (3) tedium, i.e. the need for design and analysis of every feature every time (as opposite to selection of standard fasteners). At the feature level, design guidelines and mathematical or empiri- cal models are available, and readers are urged to refer to studies by Mobay [3], Lewis et al [14,15] and Knapp et al [16,17] for each approach, respect- ively.

4. An Attachment-Level Design Approach or Methodology

The focal points of attachment-level design, as stated earlier, are issues such as: (1) the geometry of parts (or interface geometry) that can be brought together with an appropriate assembly direction and motion; (2) selection of an assembly procedure (i.e, instal- lation direction and assembly motion) associated with geometry of parts to be attached; and (3) attachment feature information (i.e. the number, location, orientation, type and general style or form). The following approach proposes a formalized pro- cedure to identify these three issues. Designing parts at the attachment-level includes the following steps: (1) identification of parts (or classification of parts); (2) consideration of allowable (or permissible) com- binations of parts; (3) stipulation or selection of installation direction and assembly motion; (4) selec- tion of features; (5) constraining parts; and (6) evalu- ating alternative design options. These steps are shown in Fig. 9 and will be described in detail in the following subsections.

~ ' - ~ D e s i g n S p e c i f i c a f i o n s ~

Consideration of: Gross part geometry Design objectives Design constraints

Part Classification

~ _ Can Combi~ons ~ _ A s s e m b l y Procedure

~ . ~ _ . _ ~ _ Feature Selection ~ _ ~

Part Conswaining

Concept Evaluation L_ " l - - _2

Specification of: Interface geometry Assembly procure Feature information

Detail Design

Fig. 9. Attachment-level design steps.

4.1. Identification of Part Geometry: Part Classification

Identification of the geometry of each part to be attached into an assembly comprises the first step in the process of integral attachment design. The procedure listed below assumes that all or some portion of a product consisting of multiple compo- nents uses integral attachment features to accomplish mechanical attachment. For such attachment, the term part geometry refers to the sub-assembly or to some portion of the product. Selection of an appro- priate assembly procedure for the parts, and selection

A Systemat ic Approach to Integral Snap-Fi t A t t achmen t Des ign 89

and placement of attachment features are the design activities of integral attachment. Variation in assembly procedure and attachment features to be selected mostly depend on interacting surfaces or interface geometD' of parts in the assembly. There- fore, part geometry needs to be identified at the beginning of the design process. Most of the time, designers are allowed to modify the interface geometry of the parts if the result is worthy or they may change feature placement surfaces or portions without any geometric modification. Either case results in a different attachment geometry, once representative shapes of the parts are considered [10,11]. Identification of the geometry of parts should include the steps listed below.

Step 1. Selecting the Arrangements of Parts in the Assembly The arrangement of parts in the final assembly plays a very important role to both the attachment strategy and final product performance. The surfaces of parts comprising the assembly interact with each other differently depending on their final arrangement. Attachment features are, in general, placed on the interacting surfaces of the parts. Since interacting surfaces comprise the essential geometry involved in attachment, designers may try different arrange- ments of parts and may use different assembly motions to generate several totally or subtly different design options. Figure 10(a) gives an example show- ing an arrangement of parts in the assembly. For different applications, the designer can come up with alternative part arrangements.

Step 2. Obtaining Alternative Geometry to be Used in Attachment Having selected one or more possible arrangements

of parts in the final assembly lets the designer consider portions or volumes of parts to be used in attachment through either direct surface interaction or by feature placement. Feature placement surfaces or volumes or portions of those surfaces and vol- umes constitute the representative shapes of the parts [10,11]. During the alternative attachment geometry generation process, the designer may refer to Genc's classification to see possible geometry options to be used in attachment, i.e, representative shapes, that can be obtained by either geometric modifications or changing feature placement surfaces and volumes [10,11].

In the example in Fig. 10(b), alternative represen- tative shapes are obtained for both parts. According to Genc's classification scheme, either surface or solid shapes for Part 1 can be obtained by changing the attachment surfaces. For Part 2, two alternative representative shapes, surface and cavity, can be obtained. Cavity shape for Part 2 is generated by modifying the geometry at the interface. Thick lines in Fig. 10(b) show attachment surfaces.

4.2. Identification of Possible Part Combinations

Identifying the portion of parts actually used in attachment leads to the representative shapes of the parts. In the previous step, alternative representative shapes that can be generated for the parts were identified. The next task is to find which combi- nations can actually be brought to create an assembly. It is thus obvious that some shapes can be mated and some cannot. A matrix of possible attachment combination of representative shapes can be used to identify allowable combinations [1t].

] , Final Assembly , Part Geometry Options i I , Parts to be Attached Arrangement ~ ~ tn Attachment i

i

, ~ ~ / ~ ~ ~ . . . . . . . . . . . . ~ Surfaces '

i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , ! i (a) (b)

Fig. 10. Obta in ing alternative a t tachment geomet ry or a r rangement for parts to be attached.

90 S. Genc et aL

To illustrate the procedure, the case study shown in the previous sub-section will be used. By using a matrix of possible or allowable combinations [11] and using alternative representative shapes generated in Fig. l l(a), the three possible combinations are identified as (1) surface-surface, (2) solid-surface, and (3) cavity-solid combinations (Fig. l l(b)).

4.3. Stipulation or Selection of Installation Direction and Assembly Motion

Having identified part geometry at the attachment interface, an appropriate assembly procedure needs to be selected to bring parts into their final position during engagement. The designer can inspect each part combination and identify applicable installation directions to bring the parts into proximity and assembly motions to accomplish final engagement or locking. Figure 1 l(c) shows applicable installation directions and assembly motions for surface-surface part combination. For this combination, the z trans- lation direction can be used as the installation direc- tion (not others due to the walls of the part) to bring parts into proximity, and push, slide, tip, and spin assembly motions can be used for final locking. Possible assembly motions for part pairs making up an assembly depend mostly on the gross part geometry and, secondly, on size. Because certain geometry does not allow certain assembly motions, the geometry of the entire part, although not involved in the attachment process, can constrain

assembly motion selection. In the example in Fig. 1 l(c), due to the walls of the enclosure not being actively used in the attachment, but which, neverthe- less, limit access from certain directions, a slide assembly motion cannot be applied. Preference for an assembly motion selection may also depend on other issues such as ease of assembly, restrictions in access, requirements of automated equipment (e.g. robots), etc.

4.4. Selection of Locking Features

At the attachment-level of the design process, sel- ecting an installation direction and an assembly motion for parts based on their geometry is, in general, followed by the feature selection and place- ment process. Feature selection comprises an important step in the overall design, affecting per- formance, ease of assembly, and ease of manufac- ture. Features to be selected change from application to application due to changes in design objectives and constraints. Since there are many feature types and forms, designing a part for effective and efficient integral attachment requires a formal, sys- tematic feature selection process.

Besides preventing separation after assembly (at least accidentally), integral attachment features are used to constrain mating parts in an assembly in directions left unconstrained when the parts are initially brought together. Either locating or locking features, or a combination of the two, can be used

Possible A;~embty Procedures

Possiblefor PartsRepresentatiVein the AssemblyShapes Possible Combination of Parts .

Surface-Surface ~ - / / " Slide

, ..................... ~ - . . / Convex Solid-Surface \ ,,,, \

(a) (b)

Spin

l~slaltation Direction

z 'l x

Fig. 11. Possible combina t ions and assembly procedures for parts in an example .

A Systematic Approach to Integral Snap-Fit Attachment Design 91

to achieve this constraint. As will be seen later, locating features are inherently rigid features and do not differ fundamentally from one another from form to form. Unlike locating features, locking fea- tures have quite different characteristics and proper- ties from form to form. Some, besides providing their obvious locking function, also provide rigidity, but many do not; they simply accomplish locking. Locking features are, in general, the weakest portion of part assemblies. So, they are to be used only to constrain part motion opposite the installation direc- tion. Other unconstrained directions should be con- strained by locating features. Therefore, selecting a particular locking feature requires more care that selecting a particular locating feature.

A proper feature selection process requires know- ing all the weaknesses and superior characteristics of possible locking feature forms, preferences or restrictions of the assembly process, and issues of structural integrity for the assembly in service. In this manner, studies by Genc et al. [18,19] present important issues in locking feature selection, and a formalized locking feature selection methodology. Locking feature selection methodology presented by Genc et al. [19] uses geometric and assembly procedure information as design inputs and identifies alternative locking feature options for an application. In the same methodology, a way of evaluating alter- native locking features based on design objectives is also presented. Therefore, by using the locking

feature selection methodology, one can identify alternative locking features, and then, begin con- sidering fully constraining parts. This step is presented next. Figure 12(a) shows alternative lock- ing features, i.e. compressive hook, cantilever hook, and trap locking feature, identified by using locking feature selection methodology for a part combination and assembly procedure.

4.5. Constraining Parts (or Constraining Remaining DOFs)

Parts are first constrained naturally by their geometry, then they are constrained by locking fea- tures selected in the previous step. After locking feature selection and placement, remaining uncon- strained directions (DOFs) need to be constrained by locating features. Constraint features might be single or multiple, and can be continuous or discon- tinuous along the edge, depending on the design requirements. The simplest type of contact element (i.e. a point contact) should initially be used to constrain the surfaces of parts in the unconstrained directions for the sake of simplicity. All locking features, and some forms of locating features such as bosses, pins, cones, and stops, provide a point contact if their sizes are relatively small compared to the sizes of the whole parts. After this is done, a basis design emerges from the fully constrained

}

i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i ' A Concept to be Constrained Alternative Locking Features I

Compressive Hook,

/

Can~lever Hook .

i : \ 'r~ / , \

i '

(a)

ARernafive Attachment Concepls ~ i (generated by changing the basis design) ',

7---'- . . . . . . . ~ ................ ~? i{ Features # . ~ - . {I '

Constraining Pans: B.is Design i, / / ~ ' : ' f~" - " ~ :"\ II } {

, - vmi {} / " , . . [ j / ii '

"\ i F e a t u r e ~ r ~ ! i ; !

. . . . . '., i . -> ....... ~- .... t~atmg{? ~ ~ / " i t.ocmng ~ Feature i

Fig. 12. Obtaining alternative attachment concepts.

92 s. Genc et al.

parts. The basis design is the fully constrained design with the minimum number of features, and the simplest type of geometric constraint for a given assembly motion and engagement form. The basis design of the parts is taken as the starting point for creating alternative designs. Figure t2(b) shows a basis design using alternative locking features and locating features.

In the next stages of the design process, other types of constraint elements with different numbers, locations, and orientations need to be considered since they might be prefelTed to enhance the attach- ment based on design objectives such as structural performance, ease of assembly or ease of manufac- ture. By so doing, as many design options as poss- ible should be created. In Fig. 12(b), two alternative attachment concepts are also shown. These alterna- tive concepts are generated using different number of locking features and different type of locating features to enhance the design for loading cases in in-plane and out-of-plane directions, respectively.

4.6. Evaluation of Alternatives

The final step in attachment-level design involves evaluating the alternatives of possible design options. Here, 'evaluating' means initially quan- tifying each alternative design and then optimizing it. The problem is, quantifying it and optimizing it on what basis? Research has already concluded that there are three, often competing, measures: (1) struc- tural performance; (2) ease of assembly; and (3) ease of manufacture of the individual parts compris- ing the assembly. For example, optimum perform- ance may require full constraint in all three orthog- onal directions, as well as constraint against all possible induced moments (of which there are six ... in opposite directions around each of three orthogonal axes). To achieve this may greatly com- plicate the design of individual parts and may also complicate the process of assembly. Thus, perform- ance comes at the cost of more complicated (and expensive) manufacture and assembly. As often as not, optimization means meeting multiple goals involving combinations of any two or all three of performance, ease of assembly, and ease of manu- facture. Since there is no quantitative optimization tool to evaluate these alternative designs, qualitative approaches can be utilized to find the best (design(s)). In this regard, Pugh's and Pahl and Beitz's Methods [13,20] employing weighting coef- ficients for multiple objectives can be used.

5. Concluding Remarks

Design employing integral attachments in the form of snap-fit features have historically focused almost exclusively on detailed design of individual locking features such as cantilever hooks, bayonet-fingers, compressive hooks, traps, etc. Higher level issues relating to how mating and base parts should best be brought together, what type of assembly/attachment interface is most appropriate, and what types of features should be employed in what locations, what orientations, and what numbers, for the most part, have not been considered. Research suggests this higher attachment-level design is critically important; so important that a systematic approach to integral attachment design using snap-fits has been developed and presented here. This is a key step in the development of an overall strategy for integral attachment design long-term.

Acknowledgements

This work was performed as a project to study, charac- terize, optimize, and standardize a strategy for integral attachment. It is part of an industrially-sponsored Integral Fastening Program (IFP) being conducted at Rensselaer Polytechnic Institute. Sponsers included: Digital Equipment Corporation, Fisher-Price/Mattel, General Motors Corpor- ation, Thomson Consumer Electronics, and United Techno- logies Corporation--Automotive Division.

References

1. Chow WW-L. Cost Reduction in Product Design. Van Nostrand Reinhold, New York, 1978

2. Boothroyd G, Dewhurst P, Knight W. Product Design for Manufacture and Assembly. Dekker, New York, NY, 1994

3. Mobay. Snap-fit joints in plastics - a design manual. Miles Plastics and Rubber Division, Pittsburgh, PA, 1990

4. Chow WW-L. Snap-fit design. Mechanical Engineer- ing July 1997; 99(7): 35-41

5. Bonenberger PR. Stretching the limits of DFM. Machine Design September 12 1994: 67-70.

6. Bonenberger PR. A new design methodology for inte- gral attachments. ANTEC '95 Conference of the Society of Plastic Engineers, Boston, MA, May 7-11 1995, pp. 3766-3770

7. Bonenberger PR. Becoming capable in snap-fits, GM's attachment level methodology supports DFM/DFA. Proceedings of the Boothroyd-Dewhurst International Forum on DFMA, I996

8. Luscher AF, Gabriele GA, Bonenberger PR, Messler RW, Jr. A classification scheme for integral attachment features. ANTEC '95 Conference of the Society of

A Systematic Approach to Integral Snap-Fit Attachment Design 93

Plastic Engineers, Boston, MA, May 7-11 1995, pp. 3783-3787

9. Messler RW, Jr, Genc S, Gabriele GA. Integral attach- ment using snap-fit features: a key to assembly, Part 1 - introduction to integral attachment using snap-fit features. J. of Assembly Automation 1997; 17(2): 143-155

10. Genc S, Messier RW Jr, Gabriele GA. Enumerating possible design options for integral attachment using a hierarchical classification scheme. ASME Trans. J. Mechanical Design 1997; 119(2): 178-184

11. Genc S, Messler RW, Jr, Gabriele GA. A hierarchical classification scheme to define and order the design space for integral snap-fit assembly. Research in Engineering Design, 1998 (to appear)

12. Bonenberger PR. The role of enhancement features in high quality integral attachments. ANTEC '95 Confer- ence of the Society of Plastic Engineers, Boston, MA, May 7-11 1995, pp 3788-3792

13. Pugh S. Creating Innovative Products Using Total Design: The Living Legacy of Stuart Pugh. Clausing, D, Andrade, R, Eds., Addison-Wesley, Reading, MA, 1996

14. Lewis DQ, Knapp KN, Gabriele GA. An investigation of the comprehensive hook integral attachment feature. ANTEC '97 Conference of the Society of Plastic Engineers, Toronto, Canada, April 27-May 2 1997

15. Lewis DQ, Wang L, Gabriele GA. An investigation of the bayonet-and-finger integral attachment feature. ANTEC '97 Conference of the Society of Plastic Engineers, Toronto, Canada, April 27-May 2 1997

16. Knapp KN, Lee D, Messler RW, Jr, Lushcer AF, Aksit MF, Gabriele GA. A combined analytic-experimental approach to the in-plane cantilever hook fastener per- formance. ANTEC '97 Conference of the Society of Plastic Engineers, Boston, MA, May 7-11 1995, pp. t 978-1982

17. Knapp KN, Gabriele GA, Lee D. Stress-strain response of polymers for predicting the behaviour of integral fasteners. ANTEC '97 Conference of the Society of Plastic Engineers, Toronto, Canada, April 27-May 2 1997

18. Genc S, Messler RW, Jr, Gabriete GA. Selection issues for injection molded integral snap-fit assembles. Journal of Injection Molding Technology 1997; t(4).

19. Genc S, Messler RW, Jr, Gabriele Ga. Methodology for locking feature selection in integral snap-fit assembly. Proceedings of the ASME 1997 Design Automation Conference (DAC), Sacramento, CA, Sep- tember 14-17 1997

20. Pahl G, Beitz W. Engineering Design: A Systematic Approach. Wallace, K,, ed. (translated by Blessing L, Bauert F, Wallace K), Springer-Verlag, London, 1996