A R Recycler $6 COURTESY OF ARGONNE NATIONAL LABORATORY Remanufactured auto parts: ... ties,” said...

Transcript of A R Recycler $6 COURTESY OF ARGONNE NATIONAL LABORATORY Remanufactured auto parts: ... ties,” said...

There’s significant value tobe found from auto shredderresidue (ASR), if a new plasticsrecycling operation in Fond duLac, Wisconsin proves to be themodel for profitable recovery.And, it appears this venture hasthe partners and the technologyto make it happen. EnviroPlasticsGroup, a subsidiary of PlasticsConversion Technologies head-quartered in Spokane, Washing-ton and Plas2Fuel Corporation,based in Kelso, Washington areteaming up to merge dedicatedASR sorting and cleaning with achemical process that recyclesplastics not suitable for resinmarkets into synthetic crude oil.

Raw ASR or shredder“fluff” presents growing prob-lems for landfills because it con-tains contaminants at a timewhen environmental regulationsare getting tighter. The primeconcerns are metals like lead,copper, zinc and cadmium, petro-leum hydrocarbons, volatile andsemi-volatile organic com-pounds.

California, for example, haspending legislation (SB 524) toestablish an auto shredder residueworking group by February, 2010to review and evaluate the prac-tice of using ASR as alternativedaily landfill cover to determine

if it poses a threat to humanhealth and the environment.Meanwhile, Rick Brasch, legisla-tive director of the CaliforniaDepartment of Toxic Substancestold us, “Since the 1980s ASRhas been permitted for alternativedaily cover, but now we arereevaluating the constituents ofASR to determine if the current

operating conditions adequatelyprotect public health and environ-ment.” Brasch went on to say thathis department wants to workwith the industry to see how tobest control the risks and whetherthe current operating conditionsdo that or not.”

Yet, ASR consists of poten-tially valuable commodities –

primarily plastics and non-fer-rous metals. If these materialscan be liberated into clean com-modity streams for the resin andnon-ferrous markets, and if theleftover plastics can be convertedinto fuels, it could be a successfulmodel to profitably recycle ASRand help solve landfill problems.

ecyclerRA R ®

Vol. 12 • Issue 8 August 2009

NewsVoice of Salvage, Waste and Recycling AmericanRecycler.com

$6.00

ecyclerR

08.2

009

900 W. South Boundary, Bldg. 6Perrysburg, OH 43551-5235

CH

AN

GE

SE

RV

ICE

RE

QU

ES

TE

DP

RS

RT

ST

DU

.S.

Posta

ge

PA

IDC

olu

mbia

, M

OP

erm

it N

o.

353

On TopicScrap Metals MarketWatchSalvaging MillionsEvents CalendarBusiness BriefsAdvertiser IndexNew Product Showcase AR ClassifiedsFocus SectionEquipment SpotlightA Closer Look

California C&D recycling center toprovide relief to landfills. Page A5

Remanufactured auto parts: A goodbusiness gets better. Page B1

Oregon House passes new metaltheft legislation. Page A10

Clunkers modifications ease effectson auto recyclers. Page B3

European Commission sends Italyfinal warning over illegal wastelandfills. Page A21

Designing vehicles with recyclingin mind. Page B7

WHAT’S INSIDE1011182022232425B1B4B6

■ Focus Section Cover, Page B1

Value in auto shredder residueby MIKE [email protected]

Seattle reaches newcity record for recycling

Seattle Mayor Greg Nickels announcedthat Seattle set a new city record for recyclingin 2008, with 50 percent of the city’s residen-tial, commercial and self-haul waste beingrecycled instead of going to the landfill. This isup 1.8 percentage points from 2007, and marksthe fifth straight year of increased recycling forthe city of Seattle.

“The credit for this milestone reallybelongs to everyone in Seattle for taking small,

simple steps every day,” said Nickels. “Peoplehave taken recycling to heart. It’s part of ourvalues, and what makes Seattle a great place.”

The city of Seattle’s diversion rate dippedto 38.2 percent in 2003, prompting Nickels topush the city’s goal to divert 60 percent of itswaste through recycling and composting by2012. The recycling rate has climbed steadilyeach year as the city greatly expanded its solid

See SEATTLE, Page 3

See RESIDUE, Page 4

PHOTO COURTESY OF ARGONNE NATIONAL LABORATORY

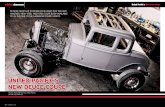

Remanufactured autoparts: A good businessgets better

Bassam Jody, group leader of the energy systems division at the Argonne National Laboratory, displays plastics recovered fromshredder residue by the Argonne Separation process and successfully tested for making auto parts.

The federal government’stimetable for cellulosic ethanolcalls for more than 15,900 percentincrease in production by 2022.

“While envi-ronmentalists arefocusing on cutbacks in green-house emissions,investors need tokeep an eye onthese federallymandated increases,” said AndyObermueller, chief investmentstrategist for Government-DrivenInvesting.

Investors tend to dismissethanol because they think they’veheard the story. They focus oncorn-based ethanol. Obermuellersays that’s a mistake. He advisesinvestors to focus instead on cellu-losic ethanol, an advanced biofuelderived from an organic com-pound found in all plant life.

They need look no furtherthan existing energy law.

“Most investors look forstocks in the Wall Street Journal,”Obermueller said. “I look in theFederal Register.”

Federal lawdemandsmore ethanol –not from corn

—Obermueller

See ETHANOL, Page 3

Tomra Pacific Inc., a unit of Tomraof North America, a provider ofadvanced recycling solutions, opened anew, user-friendly Tomra RecyclingCenter in San Francisco’s Bayshore Cor-ridor.

The recycling center, which openedJuly 18, will serve the city’s largelyunmet demand for consumer recyclingfacilities for the redemption of plastic,glass and aluminum CRV beverage con-tainers.

“Citywide, San Francisco has only15 locations where consumers can recy-cle their beverage containers, down from35 locations just three years ago. For acity with a population of over 800,000,there is large unmet demand for facili-ties,” said Frank Canelo, Tomra Pacific’soperations manager for the Bay Area.“The new Tomra Recycling Centeroffers convenient drive-through service,as well as self-service ‘reverse vending’machines, in a clean, friendly environ-

ment, capable of handling large amountsof container returns quickly and accu-rately.”

The center has the capacity to han-dle 5,000,000 containers on a monthlybasis, which puts it among the largestcenters in San Francisco. Located at 195Bay Shore Boulevard, next to BevMo!,the Tomra Recycling Center will provideconsumers with the opportunity toredeem empty beverage containers sevendays a week.

Consumers will have two ways ofreturning containers to the center:

•Drive-through weighing service –offers a convenient way of processinglarge and small amounts of CRV con-tainers for redemption.

•Self-service reverse vendingmachines – allows consumers to use anautomated machine to count as manyCRV containers as they would like toinsert.

San Francisco has lost many recy-cling centers as a result of several gro-cery stores moving out of the city,resulting in the closure of drop-off cen-ters located on their properties. Zoningrestrictions have made it difficult formodern, new centers to set up.

TOMRA Pacific opens recycling center in San FranciscoAmerican RecyclerPage A2, August 2009

Non-ferrous sorting system

Precision engineeredrecycling solutions

Rotors andwear parts

Scrap baling presses

New Hybrid and

heavy-duty shredders

Scrap shears

Shredder drive

systems

Benefits of our ferrous cleaning system

Texas Shredder

BEST

Mueller Engineering

Lindemann

Ex

pe

ct resu

ltsw

ww

.me

tso.co

m/re

cyclin

g

Texas Shredder engineers have set the standard for ferrous cleaning systems with the largest installed base in North America. Our years of application experience have established us as the leader in ferrous cleaning technology. With this experience, we have developed state-of- the-art magnetic separation systems which maximize your recovery. We have also pioneered the use of “Z-Box” air classifiers for producing the cleanest scrap in the market. As we strive to be the leader in the market, we have designed and installed shredder and downstream emissions collecting systems which will meet or exceed the most demanding permit requirements. Whether you have a new installation or an upgrade of an existing plant, our engineers welcome the challenge to increase your productivity.

Metso Recycling North America

www.metso.com/recycling

Tough times call for precision

engineered solutions

BEST

edderhrxas SeTTe

enefits oB

e the leader ino btxoZ-B“the use of

t magnetic the-arorerthe leader in ffe

installed base in Nedder enhrxas SeTTe

ous clearerof our f

e designed ave ha w,, etkn the marducing the coor pr air classifiers ffo””

ems which maximsttion syaseparith thiW.ygechnoloous cleaning t

ears of appli Our ya..icmerth AorNod fe set the standarvngineers ha

emstaning sy

wnsedder and dond installed shrs w Aet..kap in the marcleanest scr

e also pve haW.yervoecour re ymizedelopve deve haw,,eiencerxps e

e establisheve haiencerxption eacems with thstous cleaning syrerr f

eam treive strwedpioneer

e-of-tstaed us as

gesthe lar

Lindemann

ngineeueller EM

inger

om/r.c.metsowww

cling Nyetso RecM

eour engineers whW.tsemenequirr

tiollecemissions c

cling yecr

aicmerth AorN

ease yo incrome the challenge tlctione a new installavou hahether y

xems which will meet or esting syg

.ytivitducoour pryxisting plaade of an egrn or an up

mereed the most demanding pcx

,tanmit

When it comes to beverage container recycling,San Francisco is a very underserved community.In the last 3 years, the number of recycling centershas dropped to 15 from 35.

The Solid Waste Authority of Cen-tral Ohio’s (SWACO) Green EnergyCenter has received the “InnovationAward of Excellence” from The SolidWaste Association of North America(SWANA).

The Green Energy Center turnslandfill methane from decomposingtrash into vehicle fuel (Compressed Nat-ural Gas). The Center also is designed topower itself via a 250 kw micro-turbinewhich uses the clean natural gas gener-ated by the process.

Earlier this year, The Green EnergyCenter was honored as a “project of theyear” by the EPA’s Landfill MethaneOutreach Program. It also received a2009 Clean Air Award from the MidOhio Regional Planning Commission.

The completed phase one ofSWACO’s has the capacity to produce250,000 gasoline gallon equivalents(GGE) of compressed natural gas (CNG)annually using just 8 percent of themethane from SWACO’s FranklinCounty landfill. Phase two, when com-pleted, will have the annual capacity of5-to-7-million gasoline gallon equiva-lents.

SWACO GreenEnergy Centerwins award

American Recycler August 2009, Page A3

Waste Management of Oregonchristened an expansive and ultra-greenrecycling center that will dramaticallyincrease recycling and reduce landfillwaste across Washington County.

The recycling center will acceptconstruction and demolition castoffsthat, in the past, have ended up in land-fills. It will collect, sort and reclaimthese materials – concrete, asphalt,wood, and metals – for use in new ways.

The 65,000-square-foot facility iscentral to Waste Management’s efforts tohelp local and regional governmentsachieve aggressive new sustainabilitygoals.

This process will result in importantenergy savings and greenhouse gasreductions as more materials are re-pur-posed.

Waste Management’s new recyclingcenter will also deliver significantenergy savings and environmental bene-fits resulting from its innovative and sus-tainable features.

Designed and constructed to meetrigorous sustainability standards knownas LEED (Leadership in Energy andEnvironmental Design), the center looks

and operates differently than traditionalrecycling centers.

Most distinctive is the massivetranslucent roof that allows for naturallighting and reduces energy consump-tion. The roof includes a system to har-vest rainwater and store it for later useon site. There is also a powerful ventila-tion system that circulates fresh airthrough the facility every 10 minutes.

The new facility is a $10 millioninvestment for Waste Management. Theproject involved 100 construction jobsand has resulted in 20 permanent jobs.

The new facility is near Hillsboro,where Waste Management also operatesa landfill and manages more than 100acres of certified wildlife habitat andwetlands. The site is home to 100 birdspecies and mammals, including greatblue heron, deer, beaver, and rabbits.

The landfill is permitted to acceptprimarily construction and demolitiondebris. It does not accept householdgarbage or hazardous waste.

The new recycling center openedfor commercial and residential use onJuly 1.

Waste Management of Oregonopens ultra-green location

waste programs, taking steps such as offer-ing food and yard waste collection to allbusinesses and residents, and free recy-cling for small businesses, as well as pro-hibiting recyclables in the garbage.

In 2008, Seattle’s single-family resi-dents diverted 65.4 percent of their wastethrough recycling and composting, upfrom 64.8 percent in 2007. Multifamilyresidents recycled 28.3 of their waste, upfrom 27.6 the previous year. Commercialrecycling climbed 2.2 percentage points,to 54.7 percent in 2008. And 18.4 percentof waste dropped off at the city’s two recy-cling and disposal stations was diverted torecycling or compost in 2008. The figuresare based on an annual waste audit con-ducted by Seattle Public Utilities. Withincreased recycling and less solid wastegenerated last year, Seattle reduced theamount of garbage shipped to a landfill inArlington, Oregon, by 40,000 tons.

Seattle’s recycling rate is expected tocontinue increasing, in part because thecity launched new residential services inMarch, including:

•More paper, plastic and metal can berecycled, including all rigid plastic foodcontainers, plastic plant pots, large lids,

and aluminum foil and foil trays, as wellas plastic and paper cups.

•All recycling goes into one recyclingcart – no more separating glass bottles andjars.

•Weekly food and yard waste collec-tion. All food scraps, including meat, fishand dairy, can go in food and yard wastecarts.

•Electronics, used motor oil and bulkyitems can now be collected using specialservices.

Upgrades to Seattle’s recycling facil-ity now allow more recyclables to be madeinto new, useful products. Food and yardwaste is delivered to a high-tech facilitywhere an advanced process breaks downharmful bacteria and chemicals, and turnsthe waste into compost for local parks andgardens.

The national recycling average is 32.1percent. While each city calculates itsdiversion rates differently, Seattle, SanFrancisco and Portland are among theleaders in municipal recycling. Seattle’srate includes recycling set out for collec-tion by businesses and residents, materialshauled to the city’s recycling and disposalstations and on-site composting. Someother cities include private recycling ofconstruction, demolition and hazardousmaterials.

Seattle■Continued from Page 1

As an example, Obermueller cites the2007 Energy Security and IndependenceAct. It calls for 100 million gallons of cellu-losic ethanol in 2010 and 16 billion gallonsby 2022, an over 15,900 percent increase.

Obermueller thinks companies thatown significant cellulosic ethanol technol-ogy will see similar gains in their stockprices. There aren’t many.

“Lots of companies have a stake intraditional corn-based ethanol,” Ober-

mueller said. “But there’s only one pure-play in cellulose and that’s Verenium.”The company developed the enzymes thatcan turn cellulose into ethanol.

In 1995, Verenium was granted alicense to commercialize cellulosicethanol technology that had been devel-oped at the University of Florida and otheracademic institutions. It’s been hard atwork ever since, spending millions of dol-lars to hone the process. It also has builttwo demonstration-scale plants in theUnited States and a third in Japan.

Ethanol■Continued from Page 1

EPA awards Georgia DCAfor recycling hub program

The United States EnvironmentalProtection Agency (EPA) awarded theGeorgia Department of CommunityAffairs (DCA) Office of EnvironmentalManagement the “2009 Resource Con-servation Challenge National Achieve-ment Award.” The award recognizesDCA’s innovative statewide recyclinginfrastructure initiative, known as theGeorgia Regional Recycling TransferHub Program.

DCA was selected and applaudedfor its Recycling Hub infrastructure thatis facilitating cost-effective single-stream recycling collection in rural partsof the state.

“EPA nominated DCA for this pres-tigious award for two reasons. The Hubconcept is the first of its kind in thenation, with the ability to be replicatednationwide. Second, the very conceptallows for ‘economies of scale’ to pro-vide cost-effective access to recyclingfor all citizens, whether they live in anurban or rural community,” said actingregional administrator Stanley A.Meiburg.

Implementation of the regionalHubs offers residential recycling collec-tion to communities in which no previ-ous recycling programs existed, addingeven greater convenience for residents

and further decreasing the amount ofvaluable materials wasted every day inGeorgia.

“Approximately 170 Georgia citieswill now have access to central recyclingcollection facilities. These facilities willprovide much-needed infrastructure tocollect and transport recyclable materi-als, making local programs more cost-effective and ultimately moresustainable,” added Randy Hartmann,director of the Office of EnvironmentalManagement for DCA, who was onhand to accept the award. “Efficient col-lection, sorting, processing and shippingof recyclables within the state keep pro-grams viable and keep materials inGeorgia, and these materials go directlyback to Georgia’s industries.”

The award also recognizes DCA’sfocus on partnerships as a fundamentalcomponent of the Hub program. Privatepartnerships with the Curbside ValuePartnership (CVP), Pratt Industries andSP Recycling support DCA’s efforts toincrease participation in residential curb-side recycling programs and to measurethe growth of the Hub program.

For links and additional informationabout Georgia’s recycling efforts,

view this article onwww.AmericanRecycler.com.

We’ve

Moved!

This is official notice

of our new address!

Please record the new

address on the reverse

side as well as our new

telephone numbers.

To ensure you continue receiving your copy ofAmerican Recycler, please notify us as soon asyou have your forwarding information available.

Send changes to Circulation, American Recycler, 900 W South Boundary, Bldg 6, Perrysburg, OH 43551 orvisit AmericanRecycler.com.

Moving soon?

American RecyclerPage A4, August 2009

American Recycler is published 12 times per year, postage paid at Colum-bia, Missouri.

SUBSCRIPTIONS: Call 877-777-0737 or visit www.AmericanRecycler.com. US 1 year $48; 2 years $72.

© COPYRIGHT 2009 by American Recycler. All rights are strictly reserved and reproduction in whole or in part is prohibited without prior written permis-sion from the publisher.

Submission of articles, artwork and all photography must be accompanied by a self-addressed stamped envelope if a return of materials is wanted. Byline contributors’ views should not be construed as representing the opinion of the publisher.

American Recycler reserves the right to edit any and all material submitted for publication. All Letters to the Editor must be signed and include a telephone number for verification. The editor of this publication does not accept responsibility for statements made by advertisers herein.

PRINTED ON RECYCLED PAPER

Publisher and Editor

ESTHER G. [email protected]@AmericanRecycler.com

Production and Layout

MARY E. [email protected]

Editorial Focus Section Editor, Production and Layout

DAVID FOURNIER, [email protected]

Marketing Representatives

MARY M. [email protected] E. [email protected]

Circulation Manager

DONNA L. [email protected]

Writers and Contributors

MIKE [email protected] R. [email protected] [email protected] FOURNIER, [email protected] [email protected] [email protected] [email protected]

Production Offices

900 W South Boundary, Bldg 6Perrysburg, OH 43551-5235877-777-0737 fax 419-931-0740www.AmericanRecycler.com

877-777-0737 Fax 419-931-0740

The partners in the Fond du Lac proj-ect envision a network of scalable ASRrecycling plants close to auto shreddingoperations to access feedstock and mini-mize transportation costs. If successful,these plants could save shredders on truck-ing costs and tipping fees and create aboom in ASR recycling.

No one seems to have an accuratemeasure of ASR volume generated byroughly 250 United States auto shreddingoperations. “As far as we know there are250 to 270 auto shredders in the UnitedStates and a total of about 650 to 700worldwide,” said Rusty Manning, directorof new equipment sales for RiversideEngineering, an auto shredder manufac-turer. Industry experts agree that the num-ber of vehicles being shredded today isdramatically down due to the economy andthe drop in metal prices.

A study released in April by the PaulScherer Institute in Switzerland calculatedthe composition of ASR at 60 percent plas-tics, 15 percent minerals (glasses andsand), 10 percent textiles, leather andwood; 10 percent paint dust and rust, and 5percent residual metals. If these figures arecorrect, there is approximately three mil-lion tons of plastic feedstock annuallywaiting to be monetized. Of course, ASRcomposition varies from shredder to shred-der depending on the types of vehiclesingested, but with the right technologyASR holds the promise of yielding con-stant flows of non-ferrous metals and plas-tics. Profitably liberating these largepotential streams is the Holy Grail formany entrepreneurs.

EnviroPlastics Group plans to buildlarge-scale, plastic recycling operationsnear automotive shredder locations nation-wide, the first being a 84,000 sq. ft. facilityin Fond du Lac’s Southwest IndustrialPark, on a 12.2 acre site. Now in the designphase, the company expects to breakground in October. The site is close to oneof its strategic partners, Sadoff & RudoyIndustries, which has an auto shredder inFond du Lac. Sadoff & Rudoy is a majorMidwest processor of scrap metal with six

operations in Wisconsin and one inNebraska.

In addition, EnviroPlastics hopes todraw ASR feedstock from others in theregion since their plants are designed tohandle 100,000 tons of ASR per year. Theplant will take raw ASR as it comes out ofthe shredder. It goes through ferrous andnon-ferrous separation and plastics areresized into one-half inch pieces. “On theconservative side we will recover about 25percent out of the ASR. From that, approx-imately 40 percent will go to oil produc-tion and the balance to the resin market,”said Gary De Laurentiis, founder and COOof EnviroPlastics.

The Fond du Lac plant will houseboth EnviroPlastics proprietary sorting andcleaning technology as well as thePlas2Fuels’ chemical process that convertsmixed waste plastics into synthetic crudeoil and other petrochemical products.

Plas2Fuel has proven the efficacy ofits technology at its demonstration plant inOregon that was recently approved for fullscale production by the Oregon Depart-ment of Environmental Quality. Whileoperating at 25 percent capacity during thedemo phase, the plant produced 10,000gallons of synthetic crude oil per monthfrom waste agricultural plastics such asnursery pots, barrels and silage bags. Thiscrude oil is sold to a nearby refinery whereit is made into ultra low sulfur diesel, gaso-line, jet fuel and other petrochemicals.“We looked at three different chemicalprocesses, but Plas2Fuel was the only onethat had a plant up and running and is actu-ally selling oil,” said De Laurentiis.

“Most oil coming out of the groundcontains sediment and water, so perhapsonly 87 percent of the barrel is useable forhigh value products, the rest is sludge,”said Brent Bostwick, Plas2Fuels’ vicepresident of business development. “Ourproduct has virtually zero sludge or sulfur,so the entire barrel is useable for highvalue products.”

Now that Plas2Fuel is reaching fullcapacity in Oregon, Bostwick stated thatwhen all costs of manufacturing areaccounted, the company produces syn-thetic crude from mixed plastics for $42 abarrel. With crude oil prices approaching$70 a barrel and predicted to go higher,that is an extremely healthy profit outlook.

Plas2Fuel’s chemistry would not bepractical for ASR without EnviroPlastics’proprietary micro-segregation system andtheir patent pending cleaning process thatwas developed over the past year at a pilotplant in Pittsburgh. “The automated sepa-ration component is not rocket science, butthe cleaning component is critical,” DeLaurentiis emphasized. This technologyremoves contaminants from plastics usinga single step process that employs a com-bination of two liquefied gases under pres-sure. “As far as we know, we are the firstprocess that is actually able to capture allof the contaminants for proper disposal,”De Laurentiis added.

Shredder residue is separated into twostreams, plastics and waste. The mechani-cal separation process was developed withEnviroPlastics’ strategic partner and share-holder, Central Manufacturing. “The sepa-ration technology exists. We just had to becreative and mix and match it to ourneeds,” said De Laurentiis.

Once cleaned, the plastic is separatedinto three streams (PP/PE, ABS/HIPS and

mixed plastics) using ‘sink float’ technol-ogy. The separated streams are sentthrough a metal detector and packaged forsale, or sent bulk to make oil.

“Autos contain anywhere from 350 to500 pounds of plastic per car, so we hadworked with a large auto shredder in thePacific Northwest and found that in itspresent form it is too dirty and commingledto extract an economically viable hydrocar-bon stream. While we were searching for away to get at that plastic we becameacquainted with EnviroPlastics and theirtechnology. Their technology is incredible– very impressive,” said Bostwick. “Ourprocess is indiscriminate. We take plastictypes one through seven (PETE, HDPE, V,LDPE, PP, PS and other). We don’t care ifit is dirty,” said Bostwick of Plas2Fuel.

Plas2Fuel’s process is relatively sim-ple. Forced air, heated by a natural gasburner, is used to indirectly heat the feed-stock. The material is isolated from oxygenin a vacuum environment. Through ther-molysis and chromatography various com-pounds found in mixed waste plastics areseparated. Gases created during thermoly-sis are sent back into the process to mini-mize energy consumption and are alsoused to heat storage tanks and run an oil-water separation process. The vessels arewell insulated to retain heat. The processessentially “cracks” the plastic into syn-thetic crude oil.

“For every one BTU of energy used inthe process we yield almost eight BTUs ofenergy,” said Bostwick. Depending on thecomposition of the feedstock, it takesapproximately eight pounds of plastic tomake one gallon of synthetic crude.

Once the system is up to temperatureit runs 24/7 in what Plas2Fuel calls a con-tinuous batch process. It is actually severalvessels running separate batches on a stag-gered schedule so there is continuous pro-duction. With a four vessel configuration attheir Oregon plant, Plas2Fuel can process10 tons of waste plastic per day. An inter-esting aspect of this process is that the indi-vidual vessel is relative small andPlas2Fuel says that the equipment is easyto operate with minimum training. Becauseof the small size, the number of vessels canbe scaled to the volume of the feedstocks.This may allow small plants to be locatedat or near shredders, thus avoiding trans-portation costs.

“There are hundreds of millions ofpounds of ASR going to landfills everyyear and it has to be stopped. Finally, ourtechnology is able to handle virtually anyplastic feedstock,” said Bostwick.

Liberating value from ASR is a chal-lenge, one that is being addressed by anumber of entrepreneurial companies usingvarious chemical processes, low speed sec-ondary shredders for size reduction, eddycurrent separation to recover non-ferrousand mechanical processed with finer gran-ularity to separate marketable commodi-ties. Landfill prohibitions appear to be onthe horizon and the shredding industry isnervous.

“All the shredders are waiting for us tobuild our first plant to prove the concept.The ideal situation is for us to site thisequipment right at the shredder and con-tinue to further process the material. Wecan help mitigate the pressure on shred-ders from the legislative side and reducethe volume going to landfill,” said De Lau-rentiis.

Auto residue■Continued from Page 1

Editor:Your article was good on the Cash

for Clunkers bill.I help my son at Zeb’s Auto Sal-

vage in North Central Wisconsin.I assure people it will hurt. People

around here buy used parts for theirold cars and some can’t afford the $10or $20 part they need.

Who on earth is this going tohelp? If you couldn’t get used partsaround the yard, they would have towalk!

I have a ‘99 Buick and hope andpray every day it holds together at147,000 miles.

Thank you for your article. Toobad the Senate and Congress can’t orwon’t see it.

—Bev Kasperek, Tigerton, Wisconsin

A Letter tothe Editor

American Recycler August 2009, Page A5

Index will drive higher quality, lower costsand measure sustainability of products

Wal-Mart plans to develop a world-wide sustainable product index during ameeting with 1,500 of its suppliers,associates and sustainability leaders atits home office. The index will establisha single source of data for evaluating thesustainability of products.

“Customers want products that aremore efficient, that last longer and per-form better,” said Mike Duke, Wal-Mart’s president and CEO. “Andincreasingly they want information aboutthe entire lifecycle of a product so theycan feel good about buying it. They wantto know that the materials in the productare safe, that it was made well and that itwas produced in a responsible way.

The company will introduce the ini-tiative in three phases, beginning with asurvey of its more than 100,000 suppliersaround the world. The survey includes 15questions that will serve as a tool for Wal-mart’s suppliers to evaluate their own sus-tainability efforts. The questions will focuson four areas: energy and climate, materialefficiency, natural resources and peopleand community.

“The survey will include simple butpowerful questions covering familiar ter-ritory, such as the location of our suppli-ers’ factories, along with new areas likewater use and solid waste,” said JohnFleming, chief merchandising officer,Wal-mart U.S. “The questions aren’tcomplicated but we’ve never before sys-tematically asked for this kind of infor-mation. The survey is a key first steptoward establishing real transparency inour supply chain.”

Fleming also said the company willask its top tier United States suppliers tocomplete the survey by October 1. Out-side the United States, the company willdevelop timelines on a country-by-country basis for suppliers to completethe survey.

As a second step, the company ishelping create a consortium of universi-ties that will collaborate with suppliers,retailers, NGOs and government todevelop a global database of informationon the lifecycle of products – from rawmaterials to disposal. Wal-mart has pro-vided the initial funding for the Sustain-ability Index Consortium, and invited allretailers and suppliers to contribute.

The company will also partner withone or more leading technology compa-nies to create an open platform that willpower the index.

“It is not our goal to create or ownthis index,” said Duke. “We want to spurthe development of a common databasethat will allow the consortium to collectand analyze the knowledge of the globalsupply chain. We think this shareddatabase will generate opportunities tobe more innovative and to improve thesustainability of products andprocesses.”

The final step in developing theindex will be to translate the productinformation into a simple rating forconsumers about the sustainability ofproducts. This will provide customerswith the transparency into the qualityand history of products that they don’thave today.

For links to the survey questions, photosand a fact sheet, view this article on

www.AmericanRecycler.com.

Retailer to encourageuse of eco-friendlymanufacturing

A mother worried when it was gettingawfully late and her daughter, Debbie,wasn't yet home. Not knowing anyfriend's phone numbers, she looked onDebbie's computer and saw a list of e-mail addresses.

She sent a note to each one asking ifthey knew where her daughter was.Within twenty minutes, she received 16replies all saying that she shouldn’tworry, that Debbie was spending thenight at their house and had simply for-gotten to call.

New California C&Drecycling center toprovide relief to landfills

Business and community environ-mental leaders joined executives fromWaste Management (WM) to unveil aConstruction and Demolition (C&D)Processing and Recycling Center thatwill generate new green jobs in ElCajon. Using the latest in eco-technol-ogy, the facility will recover andprocess up to 130,000 tons of com-mercial construction waste, as well astraditional recyclables, annually.

The C&D Processing and Recycling Center was built in response to growingconsumer and government interest in green programs to both reduce the amount ofbuilding materials waste going to landfills and to encourage reuse, recycling andrecovery. C&D accounts for more than 22 percent of the overall waste stream in Cal-ifornia, 35 percent of the waste at Miramar Landfill, and it is estimated at more than100,000 tons annually for the unincorporated areas of the county and over 1 milliontons countywide.

From sheet rock and concrete to wood and metal, the $7 million, state-of-the-artsorting line, custom built for WM by Lubo, separates C&D recyclable items fromthe waste stream collected at commercial building sites or home remodeling proj-ects. The line also has state-of-the-art TiTech optical sorting capabilities for the pro-cessing of dry recyclables such as aluminum cans, glass and newspapers fromcommercial trash loads. Fully staffed, the line could employ up to 30 people andprocess up to 30-35 tons per hour of C&D materials and approximately 25 tons perhour of dry recyclables.

The materials processed through the sort line can be sold for use in a number ofdifferent ways. Sheet rock may be transformed into soil amendment for farmingapplications while scrap metal can be recycled to make other steel products. Woodcan be processed into landscape cover or used to generate green power.

PHOTO COURTESY OF GALINA DREYZINA

Waste Management’s new sorting line can process upto 35 tons of C&D material per hour.

American RecyclerPage A6, August 2009

www.sasforks.com Phone: 920-845-2198

West: [email protected] East: [email protected]

Now available for wheel loaders 22,000#’s and up. Turn to page B4 to read more about engine pullers.

FORKSSASe n g i n e e r e d t o u g h

Solo creates compostablesugarcane products

Solo Cup Company introduced Bare by Solo com-postable plates made with sugarcane.

The new plates offer an environmentally preferableway to serve meals, using renewable materials that canalso reduce the amount of waste sent to landfills.

Solo also is rolling out a Bare compostable cup madewith a bio-based plastic that comes from renewable plantssuch as corn. The new Bare plates and cups are compostablein commercial composting facilities.

Bare is the first full line of eco-forward single-useproducts for serving food and beverages made with recycled, recyclable, com-postable or renewable materials.

The sugarcane plates are strong and soak-through resistant and are available indinner, lunch and dessert sizes. The bio-based plastic cup is available in a 14-ouncesize that fits smaller hands and grown-ups alike. The new products expand the Bareline for consumers that already includes plates made with plant-based renewableresources and cups made with 20-percent recycled plastic.

The Bare sugarcane plates and compostable cup are certified compostable bythe Biodegradable Products Institute (BPI) when composted in a commercial com-posting facility. If composted, the products do not contribute to landfill waste. Com-mercial composting programs that accommodate single-use foodservice productsvary by area and may not be available in your community. To determine the avail-ability and policies of commercial composting facilities in your community, checkwith your local municipality.

RecycleBank launches recyclingprogram in Westland, Michigan

Westland, Michigan, Mayor WilliamR. Wild successfully ushered Recycle-Bank, the rewards-for-recycling program,to over 26,000 households in Westland.

Westland looks to save a considerableamount of money through diverting recy-clables away from the waste stream andinto a profitable recycling market.

In June, single-family householdswere provided with 96-gallon wheeled

recycling carts that feature an ID tag,which match the cart to the householdaccount number. Republic Services trucks,retrofitted with special technology, trackrecycling activity. Once the pick-up routeis complete, the total weight of the amountof material the community recycled isdivided among participating householdsand then converted into RecycleBankPoints.

American Recycler August 2009, Page A7

Ask Us About Our Special Rubber Processing and

Carpet Grinders!

WE HAVE WHAT YOU NEED

Mitts & MerrillQuali ty Since 1854

• Rubber — Cured• Rubber — Uncured• Plastics/Purgings/Pipe Reclaim• Textiles• Organics• C&D and MSW• Paper• Carpet

ShreddersWire ChoppersHog Mill GrindersOpen Rotor GranulatorsClosed Rotor Granulators

888-733-8248

J RDANREDUCTION SOLUTIONS

www.JordanReductionSolutions.com

eds/Pipe Reclaim

Jordan Reduction Solutions has strongly supportedthe American workforce for over 150 years and willcontinue to manufacture 100% in the U.S.

Total printing-writing papershipments down in June

According to the American Forest& Paper Association’s (AF&PA) June2009 Printing-Writing Paper Report,total printing-writing paper shipmentsdecreased 19.6 percent in June com-pared to June 2008. For the year to date,shipments were down 22.7 percent.United States purchases (shipments plusimports less exports) of printing-writingpapers dropped 21.8 percent in June ver-sus year-ago June and declined 24.1 per-cent for the year to date. Totalprinting-writing paper inventory levelsdecreased 22,600 tons, or 1.1 percent,from May, as uncoated paper inventorydeclines more than offset coated papersinventory increases.

First half 2009 uncoated free sheet(UFS) shipments were lower than firsthalf 2008. UFS shipments were down15.6 percent compared to June 2008, to815,500 tons. While the June decrease isthe largest in the past four months, June2008 shipments were the second highestrecorded in 2008 – the highest was Janu-ary 2008. For the first half of 2009, UFSshipments were 15.2 percent below lastyear. U.S. purchases of UFS were alsodown, declining 16.1 percent when com-pared to June 2008. UFS inventoriesdecreased 4.8 percent compared to lastmonth, a decline of 51,800 tons.

Coated free sheet (CFS) shipmentsdeclined sharply for the sixth consecu-

tive month. CFS shipments dropped by27.5 percent compared to June 2008, to280,900 tons. For the year to date, ship-ments of CFS were down 29.0 percent.United States purchases of CFSdecreased even more, down 33.8 percentcompared to last June and were off 32.1percent for the year to date. CFS inven-tories increased 5.3 percent compared toMay, an increase of 32,600 tons.

Declines in coated mechanical(CM) shipments slows but still in dou-ble-digits. CM shipments fell 16.6 per-cent when compared to June 2008,settling in at 280,700 tons. Year to dateshipments of CM were down 32.7 per-cent compared to last year. United Statespurchases of CM were down 20.2 per-cent compared to June 2008, and for theyear to date were down 33.6 percent.CM inventories increased 2.4 percent, or6,900 tons, from last month.

Uncoated mechanical (UM) ship-ments declined by more than 20 percentcompared to 2008 for all six months of2009. UM shipments decreased 28.8percent when compared to June 2008, to142,400 tons, and for the year to datewere down 27.6 percent. United Statespurchases of UM were down 24.5 per-cent when compared to June 2008 andwere down 25.0 percent for the year todate. UM inventories decreased 10.2percent, or 10,400 tons, from May.

San Francisco passes toughrecycling, composting law

The San Francisco Board of Super-visors has passed a mandatory compost-ing law that is believed to be the strictestsuch ordinance in the nation. Residentswill be required to have three color-coded trash bins, for trash, recycling,and compost. Residents and businessesthat fail to recycle or compost the appro-priate waste could be fined. San Fran-cisco, which boasts a recycling rate of72 percent, has aggressively pursuedgreen initiatives such as banning plasticbags at supermarkets. The city eventu-ally wants to eliminate all waste going tolandfills by 2020.

Robert Reed, a spokesman forRecology (formerly Norcal Waste), saidthat waste collectors will not pickthrough anyone’s garbage. Rather, ifworkers notice recyclables from binsbeing emptied, they will leave “a lovenote” alerting the customer of non-com-pliance.

A moratorium on imposing fineswill end in 2010, after which repeatoffenders like individuals and smallbusinesses generating less than a cubicyard of refuse a week face fines of up to

$100. Businesses that don’t provide theproper containers face a $500 fine.

A comprehensive study conductedby the Department of the Environmentfound that 36 percent of what San Fran-cisco sends to landfills is compostable,primarily food scraps, and 31 percent isrecyclable — which is mostly paper.There are facilities in the City and sur-rounding areas that reuse, recycle, com-post or otherwise process and marketmost materials discarded in San Fran-cisco, saving this material from landfilland creating green-collar jobs.

San Francisco Mayor Newsom saida primary goal of the mandatory recy-cling ordinance, which was cosponsoredby Supervisors Ross Mirkarimi andChris Daly, is to get recycling and com-posting happening in buildings where itis not currently provided.

Newsom said that if all of the recy-clable and compostable materials cur-rently going to landfills were capturedby our programs, San Francisco’s recy-cling rate would soar from 70 percent to90 percent.

NEWS YOU TAKE WITH YOU, NO MATTER WHERE YOU GO877-777-0737

AR

SUBSCRIBETODAY

Greenstar opens largestrecycling facility in Texas

Houston-based Greenstar NorthAmerica, the largest municipal recyclerin Texas, announced that it has officiallyopened the largest recycling facility inTexas. The new plant is among thelargest, most automated single streamfacilities in North America. It has thecapacity to process 20,000 tons permonth at its 180,000 square foot facilitylocated on nine acres in San Antonio.

Greenstar has experienced a dra-matic rise in recycling rates across itsTexas markets, particularly in San Anto-nio. San Antonio rates have increased ashigh as 200 percent over the previouscollection approach in some areas. Thesharp increase is a direct result of thecity implementing a single stream col-lection system as well as convertingtheir existing 18-gallon collection sys-tem to 95 gallon carts. Single streamprocessing lets participants put recy-clables conveniently into one bin, allow-

ing for more efficient collection of mate-rials and a decrease in labor.

While Texas has not traditionallybeen known for its recycling programs,Greenstar sees that perception shifting inthe near future. Greenstar selected Texasas its North American headquarters rec-ognizing there is significant amount ofpotential on the commercial and munici-pal side for growth in recycling. Green-star’s level of investment has beensignificant: it invested over $300 millionin its United States recycling businessover the last two years, of which $50million has been invested in Texas and intotal, over this same period, its parentcompany, NTR, invested over $700 mil-lion in its United States environmentalbusinesses.

The facility employs approximately100 people and accepts single streammaterials from other recycling programsacross the Central and South Texas region.

New California law will providefree mercury thermostat recycling

A new California law designed toprotect public health and reducetaxpayer costs through the collectionof mercury thermostats is now effective.The Mercury Thermostat CollectionAct of 2008 (AB 2347, Ruskin)increases the number of thermostat col-lection locations and makes recyclingmore convenient.

The law requires heating and airconditioning wholesalers with physical

locations in California to collectthermostats from the public and contrac-tors. Retailers are also encouraged toparticipate.

Co-sponsored by the CaliforniaProduct Stewardship Council (CPSC)and Sierra Club California, AB 2347 isCalifornia’s first full producer responsi-bility legislation and makes Californiaonly the third state to pass such a law inan effort to protect public health.

American RecyclerPage A8, August 2009

Highest Prices, Friendly Service, Prompt Payments!

Heartland Aluminum, Inc.www.heartlandaluminum.com

[email protected] / FAX: (260)375-4651

WE BUY SCRAP ALUMINUM WHEELS

Serving the Secondary Aluminum Needs of the Automotive Industries.

Call Tiffany for a price quote:

888-834-2673

The United States EnvironmentalProtection Agency (EPA) welcomedShaw Industries, Inc., a carpet manufac-turer and floor covering provider, as itsnewest WasteWise partner. WasteWisepartners are organizations that voluntar-ily set goals to reduce municipal solidwaste. Partners include businesses, insti-tutions, and other organizations repre-senting 50 industrial sectors committedto cutting costs and conserving naturalresources. EPA provides WasteWisepartners with technical assistance andhelps promote the achievement of itspartners.

Shaw is a recycler of post-con-sumer carpet, and the comprehensive

Shaw Green Edge Recycling programreclaims and recycles carpet nation-wide. At the company’s EvergreenRecycling Facility in Augusta, Georgia,post-consumer carpet is recovered andthen remanufactured.

The by-product of the recyclingprocess is also recovered for ultimatereuse as post-consumer recycled contentin carpet backing. Shaw also manufac-tures a line of wood flooring from post-industrial recycled wood that uses 50percent less harvested wood than com-parable engineered wood flooring. Car-pet scraps, along with all wastegenerated from laminate manufacturingat Shaw’s facility in Ringgold, Georgia,

is diverted from landfills and used togenerate fuel. An innovative waste-to-energy technology converts carpet andwood waste to steam energy throughgasification.

Shaw is joining EPA’s WasteWiseprogram as it is launching a project tobetter track its efforts in reducing theamount of post-industrial waste pro-duced in all of its carpet, rug, hardwoodand laminate manufacturing facilities.The total post-industrial waste producedwill be compared to the amount of fin-ished production, and Shaw intents tosignificantly reduce that percentageover the next three years and beyond.

Shaw joins EPA WasteWise Program

California law will provide freemercury thermostat recycling

A new California law designed toprotect public health and reduce taxpayercosts through the collection of mercurythermostats is now effective. The MercuryThermostat Collection Act of 2008 (AB2347, Ruskin) increases the number ofcollection locations and makes recyclingmore convenient. The law requires heatingand air conditioning wholesalers withlocations in California to collect thermo-stats. Retailers are also encouraged to par-ticipate.

Co-sponsored by the California Prod-uct Stewardship Council (CPSC) andSierra Club California, AB 2347 is Cali-fornia’s first full producer responsibilitylegislation and makes California only the

third state to pass such a law in an effort toprotect public health.

“We want contractors and the pub-lic to know that this new law is in effectto protect the public from mercury expo-sure,” says Heidi Sanborn, CPSC execu-tive director. “Having the producers fundand manage the collection systemreduces public costs to manage the prod-uct at the end-of-life and is in line withthe overall framework for an ExtendedProducer Responsibly (EPR) systemadopted by the California IntegratedWaste Management Board in 2008.”

Information about free thermostatrecycling in California can be found atwww.calpsc.org/products/thermostats.html.

American Red Cross charged withbio-hazardous waste dumping

The Teamsters Union filed a com-plaint with the Environmental Investiga-tions Division of the City of St. Louischarging American Red Cross withdumping biomedical waste into the regu-lar trash stream.

The complaint was filed after redbiohazard bags were found in opengarbage dumpsters outside of the RedCross Blood Services Division Head-quarters in St. Louis filled with trashheaded for landfills.

“We have an obligation to makesure our employers are responsible stew-ards of the environment and are notengaging in practices that violate healthor environmental regulations,” saidJames P. Hoffa, Teamsters general presi-dent. “We believe that the American RedCross also has a responsibility to thecommunity to ensure that it is not endan-gering the public’s health or violatingthe letter or spirit of state or federal envi-ronmental laws.

Teamsters file charges against American Red Cross

Waste Management Recycle Amer-ica, a wholly-owned subsidiary of WasteManagement, announced a partnershipwith iGo, a provider of portable powersolutions, to increase domestic electron-ics recycling and reduce landfill waste.Through this partnership, WM RecycleAmerica, the nation’s largest residentialrecycler, will provide environmentallycertified recycling services for iGo elec-tronic waste.

Through the “iGo Recycles” con-sumer electronics and charger recyclingprogram, iGo customers can mail backtheir used products, which WM RecycleAmerica will process to recover valuablecomponents for reuse.

WM Recycle America, an ISO Cer-tified partner, recycles this material inconjunction with the Basel Action Net-work (BAN) Electronics Recycler’sPledge of True Stewardship. In accor-dance with this program, WM RecycleAmerica processes all hazardous materi-als domestically, protects workers’health and tracks e-waste throughout therecycling chain.

Recycle Americapartners with iGo

Veolia ES Solid Waste, Inc. hasappointed Jim Long to the position ofpresident and CEO of that organization.He replaces former CEO RichardBurke, who was recently promoted topresident and CEO of Veolia Environ-mental Services North America Corp.(VESNA).

Long was president and CEO ofATC Transportation, which was sold toVeolia Transportation North America in2005. He also served in various financeand operational leadership roles duringhis 13 years with Waste Management inEurope and the United States.

As CEO of VESNA, Burke now hasoversight for all of the company’s oper-ating divisions in North America,encompassing solid waste collection andrecycling, hazardous waste processingand disposal, industrial and marine serv-ices, and waste-to-energy operations.

Veolia namesnew CEO to solidwaste division

Science Applications InternationalCorporation announced that it has signeda definitive agreement to acquire R.W.Beck Group, Inc., a provider of businessand technical consulting services inengineering, energy and infrastructure.R.W. Beck is headquartered in Seattle,Washington.

Founded in 1942, R. W. Beck’s 550technically-based business consultants –including engineers, economists, ana-lysts and other professionals – developsustainable solutions specific to cus-tomers’ engineering, economic, plan-ning, operational and organizationalchallenges. R.W. Beck’s customersinclude utility organizations, govern-ment entities, financial institutions andother commercial customers.

The definitive agreement includesSAIC’s acquisition of Beck DisasterRecovery (BDR), Inc. R. W. Beck is themajority owner of BDR. The companyprovides all hazards mitigation, pre-paredness/planning, response, recoveryand reconstruction services; continuityand emergency operations planning; riskmanagement and mitigation; and train-ing services to local and state govern-ment agencies nationwide.

R.W. Beck will join SAIC’s Infra-structure, Logistics and Product Solu-tions Group led by group president JoeCraver. The Group, one of four at SAIC,provides technical and engineering solu-tions for a variety of customers and mis-sion areas including all hazardspreparedness and logistics; energy man-agement services; and environmentalsupport. R.W. Beck’s core consultingand engineering organization will jointhe Group’s Energy, Environment, andInfrastructure business unit led by J.T.Grumski to combine synergies in envi-ronmental services. BDR will join theHomeland Protection and Preparednessbusiness unit led by John Ferriter.

The acquisition is expected to closeat the beginning of August 2009, subjectto R. W. Beck shareholder approval andcustomary closing conditions, includingexpiration or early termination of thewaiting period.

SAIC to acquireR.W. Beck, Inc.

American Recycler August 2009, Page A9

Crushed Car Carriers

734.740.7722www.wbwsales.com

WBW Sales, Inc.FOB Detroit, Michigan

METALS

Scrap metals industry representativetestifies before senate subcommittee

Mark Lewon, vice president ofoperations for Utah Metal Works of SaltLake City, testified before the UnitedStates Senate Judiciary Committee’sSubcommittee on Crime and Drugs,voicing support for the scrap recyclingindustry’s cooperative/collaborativeapproach to combating the problem ofmetal theft.

“Rather than simply restating statelaws that have been enacted over thepast few years and which have notproven effective, we support efforts tocraft national legislation that builds onsuccessful strategies including coopera-tion and communication amongst allstakeholders,” Lewon stated. “Ulti-mately focusing efforts on preventingthe crime will better serve victims andcommunities.”

Lewon, also speaking on behalf ofthe 1550 members of the Institute ofScrap Recycling Industries, Inc. (ISRI),continued by stating, “ISRI members areseriously committed to reducing metaltheft. In 2006, ISRI developed Recom-

mended Best Management Practices,which guide our members on how toidentify stolen property, document theirpurchases, validate identity, install cam-eras in the scrap yard, and catch thieves.In cooperation with law enforcement,ISRI has pioneered the use of collabora-tive coalitions of victims, law enforce-ment, prosecutors, and recyclers toprevent the crime or to catch a thief. Notechnique works better than this one. Iwork closely with a coalition in SaltLake City and County. Crime is downand we catch and prosecute thieves.”

“ISRI members recognize their keyrole in addressing metal theft. After all,we are the experts in scrap metal recy-

cling. There are no easy solutions. Whatour expertise has taught us, however, isthat the best way to approach the crimeof metal theft is through communicationbetween recyclers, law enforcement, vic-tims and prosecutors. Much more than ametal theft statute, that’s what it takes.”

“Metal theft will not stop simply bybanning the customary use of cash. Fur-ther regulating us doesn’t stop a thiefwho will find an underground way tomove his contraband. As much as wewould like to believe it so, simply enact-ing new laws won’t cause resource-strapped law enforcement agencies tosuddenly make metal theft a priority.Nor will it cause prosecutors to go afterthieves. Nor will it stop thieves fromcrossing state lines unless you include apreemption provision in a bill that takesaway their incentive to do so.”

“The scrap recycling industry looksforward to developing a national solu-tion to this problem with all the stake-holders.”

Additional regulationswon’t stop a thief who

will find an undergroundway to move his

contraband.

"Middle age is the time in life when, after pulling in your stomach, you look as if you ought to pull in your stomach."

RRECYCLING ECYCLING SERVICESERVICES

INTERNATIONALNTERNATIONAL 518-424-1168

fax 518-233-0006www.RecyclingFurnaces.com

• Full EPA compliance guaranteed.

• Built for years of continued service.

• New technology burner and control systems.

• Permit assistance available.

• Large hearth opening for automotive scrap.

Hi Efficiency Hi Efficiency Sweat FurnaceSweat Furnace

US Furnace’s MAX-4000US Furnace’s MAX-4000

Customers report that charges of 50% recovery material are producing 1,250 to 1,500 lbs. metal out per hour at a cost of

$0.03 per pound for fuel.

Get themost efficientsweat furnaceon the market!

The Oregon House of Representa-tives unanimously passed legislation tocombat metal theft, completing a three-year process and a bipartisan effort tostem the growth in metal theft. SB 570imposes new fines and penalties onmetal thieves and improves the ability ofthe state’s law enforcement communityto monitor transactions.

State Rep. Brent Barton (D-Clacka-mas) and State Rep. Andy Olson (R-

Albany) were the House participants in abicameral work group that came up withthe final agreement.

“Metal theft affects both rural andurban communities and fuels the methepidemic in Oregon,” said Barton.

SB 570 contains several main com-ponents that will end the ease withwhich metal thieves are able to tradestolen products for cash, including:

•Clarifying the duties of scrapmetal businesses to notify law enforce-ment if they believe that the metal prop-erty they purchased or received isstolen.

•Requiring scrap metal businessesto collect and retain for one year a metalproperty record from individuals andcompanies that engage in the selling ofmetal products.

•Creating misdemeanor crime forunlawfully altering metal property, forexample obliterating a serial number.

•Requiring that payment for scrapmetal is given no sooner than three busi-ness days after sale and delivered by amailed check to the seller’s streetaddress.

The bill is now being reviewed bythe Senate.

American RecyclerPage A10, August 2009

U.S. IMPORTS OF FINISHED STEEL MILL PRODUCTS BY COUNTRY OF ORIGIN (Thousands of Net Tons)

CHINASOUTH KOREAJAPANTAIWANINDIANETHERLANDSTURKEYGERMANYAll OthersTOTAL

MAY2009148118613328262622

5411,002

APR200910071843479352650

6451,123

MAY200828920211852

123226

811,1552,047

2008Annual

4,8212,3051,614

6621,102

474827

1,12213,02925,956

% Change 2009Annual vs. 2008

-42.7%-23.5%-25.7%-21.2%-24.7%-51.8%-6.8%

-43.7%-33.6%-33.1%

President Barak Obama signed into law the Cash forClunkers legislation (Title XIII - Consumer Assistance toRecycle and Save Program) on June 24. The new regulationsare to be published by the Department of Transportation onJuly 24, which will officially launch the program.

The limited program (the program is set to expire this fall) will provide $1 bil-lion in grants for automobile purchases by consumers.

To learn how the legislation and regulations will affect automobile sales andmanufacturing, the auto recycling industry and the overall economy, AmericanRecycler queried Charles Territo, the Alliance of Automobile Manufacturers’ seniordirector of communications for his take on this economic stimulus package.

ON TOPIC Q & Aby Irwin Rapoport

Territo: Automakers are hopeful that the Cashfor Clunkers (CARS) program can provide amuch need boost in auto sales and dealershipfoot traffic. Automakers believe a wellcraftedfleet modernization program will provide twobeneficial effects – helping to stimulate autosales during the current economic/credit crisisand replacing older, less fuel-efficient vehicleswith cleaner, safer, more fuel-efficient ones.A fleet modernization program can deliver ben-efits to consumers, the environment and theeconomy.

What is this importance of this legislationand its accompanying regulations?

Territo: This legislation has the potential toadd as many as 250,000 vehicles to the autorecycling industry. The law stipulates that onlythe engine must be scrapped and renderedinoperable. All other vehicle parts can bereused.

How will the legislation and regulationsaffect the auto recycling industry?

Alliance of AutomobileManufacturers sharescurrent industry view

Vehicles today are 75 percent cleaner forsmog forming emissions than vehicles just fiveyears ago. The program is designed to encour-age consumers to trade in their older, less effi-cient vehicles for cleaner, safer and more fuel-efficient new vehicles. Ultimately, oil savingsand emissions reductions will happen only ifbuyers can use this program to buy vehiclesthat meet their needs.

How is the legislation expected to reducegreen house gas emissions? How impor-tant is it for the environment to removeolder cars from service?

Territo: Companies are in the process of com-piling information about eligible vehicles. Thenumber of vehicles a company has will play alarge part in how the program will stimulatetheir sales. The CARS program is open to allmanufacturers and new automobile dealers.Around the world, consumers are already ben-efiting from similar programs, and the resultingeconomic stimulus has been significant. InJanuary, Germany implemented a fleet mod-ernization program. At the end of the firstmonth of the program, sales in Germany wereup 21 percent over 2008. Corresponding salesin the United States were down 41 percent forthe same period. Fleet modernization pro-grams have been adopted in China, U.K.,Brazil, Spain, Austria, France, Italy, Portugal,Romania and Slovakia, and are under consid-eration in several others.

How will the legislation stimulate autosales, especially by GM, Chrysler andFord?

Territo: It is estimated that there are roughly77 million vehicles eligible for trade-in underthe terms of the CARS program. If 1 in every300 eligible vehicles is traded in, this programwill be an overwhelming success.

How do you think the public will react tothe legislation and do you think peoplewill make the connection between theneed to stimulate the auto industry andhelp to reduce GHG?

Territo: The auto recycling industry can workwith local auto dealers and help coordinate thescrappage efforts for vehicles traded in as partof the CARS program.

What can the auto recycling industry doto help make the law and regulations asuccess?

X-Met 3000T XRF

$12,500

METAL ALLOYANALYZER

2 Lithium batteriesPDF (part of gun, but removable)Lithium battery and PDF charger10 Kapton window filmsUser manual and training manualsPurchased new in 2004.

—Charles Territo

Territo: Continued investment in advancedtechnologies, retooling and research anddevelopment of battery technology. Since con-sumers are often reluctant to pay higherupfront costs, policymakers can acceleratesales of fuel-efficient autos through consumerincentives like tax credits and auto loan inter-est tax deductibility.

In terms of future legislation and govern-ment support, what do you foresee isrequired to help restore the health ofAmerican automobile manufacturers andthe environment?

3 out of 4 people will read this headline,but only 1 of 4 continue reading.

Information like this impacts theeffectiveness of your advertising dollars.

Creativity and Experience in Ad DesignAre Offered Free to Advertisersin American Recycler.

AR

877-777-0737

METALS

Steel imports declineBased on preliminary Census

Bureau data, the American Iron andSteel Institute (AISI) reported that theUnited States imported a total of1,020,000 net tons (NT) of steel in May2009, including 1,002,000 NT of fin-ished steel (down 17 percent and 11 per-cent, respectively, vs. April final data).Total and finished steel imports on anannualized basis are down 42 percentand 33 percent, respectively, vs. 2008.Annualized total imports of steel in 2009would be 18.6 million NT. Finished steelimport market share was an estimated 22percent in May and year-to-date (YTD)through five months is an estimated 29percent.

Key products with increases in May2009 compared to April include Rein-forcing Bar (up 44 percent), Oil Country

Goods (up 23 percent) and Plates-in-Coils (up 21 percent). For YTD 2009 vs.the same period last year, OCTG imports(led by China) are up 30 percent.

In May, the largest volume of fin-ished imports from offshore was fromChina (148,000 NT, up 49 percent fromApril). The May tonnage from Chinawas 15 percent of all finished importsand, based on YTD data, finished steelimports from China in 2009 would annu-alize at 2.8 million NT. Other major off-shore suppliers in May were SouthKorea (118,000 NT, up 66 percent fromApril), Japan (61,000, down 27 percent)and Taiwan (33,000 NT, down 3 per-cent). For YTD 2009 vs. the same periodlast year, finished imports are up signifi-cantly for a number of countries –including China (up by 23 percent).

Oregon House passesnew metal theft legislation

The trouble with hitting the jackpot ona slot machine is that it takes so long toput the money back.

American Recycler August 2009, Page A11

Scrap Metals

MarketWatch

DISCLAIMER: American Recycler (AR) collects pricing and other information from experienced buyers, sellers and facilitators of scrap metal transactionsthroughout the industry. All figures are believed to be reliable and represent approximate pricing based on information obtained by AR (if applicable) prior topublication. Factors such as grades, quality, volumes and other considerations will invariably affect actual transaction prices. Figures shown may not be con-sistent with pricing for commodities associated with a futures market. While the objective is to provide credible information, there is always a chance forhuman error or unforeseen circumstances leading to error or omission. As such, AR is not responsible for the accuracy or completeness of the informationprovided, or for outcomes arising from use of this information. American Recycler disclaims any liability to any person or entity for loss or damage resultingfrom errors or omissions, including those resulting from negligence of AR, its employees, agents or other representatives.

1 2

3 5

4

Commodity Zone 1 Zone 2 Zone 3 Zone 4 Zone 5#1 Bushelings per gross ton $160.00 $168.00 $175.00 $183.00 $298.00#1 Bundles per gross ton 160.00 168.00 175.00 183.00 293.00Plate and Structural per gross ton 198.00 162.00 165.00 172.00 260.00#1 & 2 Mixed Steel per gross ton 194.00 150.00 210.00 190.00 245.00Shredder Bundles (t in) per gross ton 168.00 172.00 180.00 145.00 185.00Crushed Auto Bodies per gross ton 168.00 172.00 180.00 145.00 189.00Steel Turnings per pound 61.00 52.00 90.00 95.00 140.00#1 Copper per pound 2.23 1.90 1.90 2.00 2.11#2 Copper per pound 2.05 1.79 1.83 1.87 2.02Aluminum Cans per pound .45 .44 .45 .45 .49Auto Radiators per pound 1.31 1.30 1.35 1.40 1.50Aluminum Core Radiators per pound .46 .40 .41 .39 .80Heater Cores per pound .95 1.00 1.00 1.02 .98Stainless Steel per pound .58 .58 .58 .60 .69All prices are expressed in USD. Printed as a reader service only.

METALSNucor reports secondquarter and first half results

Nucor Corporation announced aconsolidated net loss of $133.3 million,or $0.43 per diluted share, for the secondquarter of 2009, compared to a net lossof $189.6 million, or $0.60 per dilutedshare, in the first quarter of 2009, animprovement of 30 percent. The resultscompare to net income of $580.8 mil-lion, or $1.94 per diluted share, in thesecond quarter of 2008.

In the first half of 2009, Nucorreported a consolidated net loss of$323.0 million, or $1.03 per dilutedshare, compared with net earnings of$990.5 million, or $3.36 per dilutedshare, in the first half of last year.

In the second quarter of 2009,Nucor’s consolidated net sales decreased7 percent to $2.48 billion compared with$2.65 billion in the first quarter of 2009and decreased 65 percent compared with$7.09 billion in the second quarter of2008. Average sales price per tondecreased 16 percent from the first quar-ter of 2009 and decreased 34 percentfrom the second quarter of 2008. Totaltons shipped to outside customers were4,116,000 tons in the second quarter of2009, an increase of 11 percent over thefirst quarter of 2009 and a decrease of 47percent from the second quarter of 2008.

In the first half of 2009, Nucor’sconsolidated net sales decreased 57 per-

cent to $5.13 billion, compared with$12.06 billion in last year’s first half.Average sales price per ton decreased 23percent while total tons shipped to out-side customers decreased 45 percentfrom the first half of 2008.

The average scrap and scrap substi-tute cost per ton used in the secondquarter of 2009 was $312, a decrease of6 percent compared with $333 in thefirst quarter of 2009 and a decrease of32 percent from $456 in the secondquarter of 2008. The average scrap andscrap substitute cost per ton used in thefirst half of 2009 was $322, a decreaseof 19 percent from $396 in the first halfof 2008.

At The David J. Joseph Company,total volumes in the second quarter(both scrap processing and brokerage)were approximately 50 percent of theprior year; however, in both cases, thevolumes improved each month of thequarter and show a strong start to thethird quarter.

In June, Nucor’s board of directorsdeclared a cash dividend of $0.35 pershare payable on August 11, 2009 tostockholders of record on June 30,2009. This dividend is Nucor’s one-hun-dred forty-fifth consecutive quarterlycash dividend.

Gerdau Ameristeel closesmill; suspends production

Gerdau Ameristeel Corporation issuspending production at its Sayreville,New Jersey steel mill and closing itsrolling mill in neighboring PerthAmboy, New Jersey due to lowerdemand for its products resulting fromthe downturn in the economy. The com-pany said these actions are expected tooccur gradually over the next severalmonths. The company indicated that itwould restart operations at the Sayre-ville facility when business conditionswarrant.

The company is also entering intodiscussions with the United Steel Work-ers regarding the potential closure of theCompany’s steel mill located in SandSprings, Oklahoma.

Service to customers will be unin-terrupted and will be provided by pro-duction from Gerdau Ameristeel’sextensive network of steel mills in theUnited States and Canada. The Sayre-ville facility will continue to carry a fullrange of products in inventory availablefor shipment or customer pickup untilproduction resumes.

Mario Longhi, President and CEOof Gerdau Ameristeel commented, “This

was a very difficult decision that cameafter careful analysis and review of themarketplace, our production capabilities,and the most cost effective alternativesto meet the current and future needs ofour customers throughout North Amer-ica during this unprecedented economicdownturn. These actions follow a seriesof steps the company has taken over thelast nine months to reduce its costs. Weunderstand the impact that these deci-sions will have on the lives of ouremployees and our communities, butunfortunately market conditions man-dated that these actions be taken at thistime. The company will make everyeffort to help displaced employeesthrough this time of transition.”

In connection with these actions,depending on the outcome of the SandSprings discussions, the Companyexpects to incur an after tax charge fromapproximately $80 million to $140 mil-lion related to these closures. Of theseamounts, between approximately $15million to $30 million are expected to becash costs for severance and facility clo-sure expenses.

April steel shipments downThe American Iron and Steel Insti-

tute reported that for the month of April2009, United States steel mills shipped4,042,000 net tons, a 57.0 percentdecrease from the 9,403,000 net tonsshipped in April 2008 and a 2.3 percentdecrease from the 4,138,000 net tonsshipped in the previous month, March2009.

A year-to-year comparison of year-to-date shipments shows the followingchanges within major market classifica-tions: service centers and distributors,down 56.2 percent; automotive, down55.4 percent; construction and contrac-tors’ products, down 55.0 percent; andoil and gas, down 54.9 percent.

Severstal Wheeling agrees to sellPennsylvania sheet rolling facility

Severstal Wheeling, Inc., a businessunit of Severstal North America, Inc.,has signed a letter of intent to sell itsAllenport, Pennsylvania sheet rollingplant to North American Trading Com-pany, LLC (NATCO).

The plant includes a pickle line, tan-dem mill, box anneal facility and tempermill, all critical to the final forming andconditioning of light flat rolled steel prod-ucts. Cold mill sheet is used by a widerange of consuming industries includingautomotive, appliance and construction.

The facility operated until May 2008when it was temporarily idled due toduplicative facilities elsewhere in SeverstalNorth America and Severstal Wheeling.

Under new ownership, the mill isexpected to produce stainless-clad sheetsteel, the core of NATCO’s business, forappliance, automotive and culinary uses.

The letter of intent calls for SeverstalNorth America to sell all equipment andplant property of about 400 acres toNATCO. The prospective buyer is cur-rently performing due diligence and dis-cussing operating plans with the UnitedSteel Workers to staff the facility with for-mer Severstal Wheeling employees. Pend-ing the execution of a purchase agreementbetween Severstal North America andNATCO, Severstal North America antici-pates completing the sale of Allenport toNATCO in August 2009.

Government Liquidation operates an exclusive sales contract for the DefenseReutilization and Marketing Service to sell scrap material to the public.

All sales of scrap are conducted via our online auction platform through Internet Auctions and Sealed Bid Events. For a list of upcoming scrap auction

events visit our website or contact us at: 480. 367. 1300

800-328-3613 | 320-274-3594 | Fax 320-274-3859EZCrusher.com | [email protected]

R. M . J O H N S O

N

R. M . J O H N S O

N

R. M . J O H N S O

N

• • • • • • •• • • • • • •

R. M. Johnsonhas your

Silver Lining.

Take advantage of the lowernew steel prices by buying your

new equipment now!There’s never been a better time.

You can write off 100% of the costwrite off 100% of the cost of a new

E-Z Crusher or E-Z Baler using this year’s

$250,000 Section 179* equipment expense

deduction. Added with the extended full two

year warranty, the time to buy

could not be better.

When calling, ask your sales person When calling, ask your sales person

to tell you about the new high-speed automated chambered baler!to tell you about the new high-speed automated chambered baler!

Sort your material while finishing a bale, load or unload a truck

while finishing a bale. Increase your production as market demands

increase. This time, be ready and have the equipment for market

demands!

R.M. Johnson Company R.M. Johnson Company

is looking for older is looking for older

trade-in units.trade-in units.

*Seek the advice of your tax preparer for full Section 179 details.

Steel prices got you down?

1994 CAT 375LC

Rebuilt motor, ready to go. $239,000

1999 FUCHS RHL 340

Grapple, no gen-set. Good condition. $179,000

Only 1,300 hours. HUGE savings. $260,000

2007 AL-JON 400XL METAL BALERAL-JON MODEL 20 CAR CRUSHER

Runs very well, has waste oil system. Processcars very cheaply. $29,500

With forks and bucket. 2,000 hours. $115,000

2006 CASE 621D KOEHRING 6644-7 with SHEAR

Equipped with LaBounty MSD70 Shear. $95,000

2006 MAC QS AUTO CRUSHER REPO

Very nice condition. Only 1,900 hours. SPECIAL DEAL, CALL! 800-823-9688Perrysburg, OH

Visit DADECapital.com for acomplete list of current equipment

and more photos.

2004/2008 CAT 325 with SHEAR

With MSD 2500 shear. Only 4,800/600 hours. $295,000 Under 250 hours! Excellent condition. $375,000

2008 SIERRA RB6000JEFFREY 62 x 90 METAL SHREDDER

800 h.p. electric motor with an Eriez model ESC-36 eddy current separation system. $495,000

The Enviro-RackAuto Fluid Removal & Dismantling Station

Toll-free 877-247-6629Fax 478-252-9030Wadley, Georgia

Iron Ax, Inc.Website: www.ironax.comE-mail: [email protected]

We offer all steel tanks along with a grated catwalk for operator safety. Underneath the catwalk is a 249 gallon catch pan and also a 360 gallon tank to catch any spills. No other system on the market comes close to the Enviro Rack. Meet EPA and State level regulations

concerning fluid removal. The Enviro Rack is totally air operated. There are no gasoline or electric motors that could create a spark. The

Enviro Rack is a safe system. Complete fluid removal in less than 5 minutes.

The Enviro Rack is theFIRST AND ONLY

self-contained fluid removalsystem on the market.