A Novel Flow Sensor for a Smart Shunt...

Transcript of A Novel Flow Sensor for a Smart Shunt...

A Novel Flow Sensor for a Smart Shunt System

Mengdi Bao1, Garrett Soler1, Devina Jaiswal1, Hitten P. Zaveri2, Ryan A. Grant3, Michael L. DiLuna3 and Kazunori Hoshino1

1Department of Biomedical Engineering, University of Connecticut, Storrs, CT 06269, USA 2Department of Neurology, Yale University School of Medicine, New Haven, CT 06510, USA

3Department of Neurosurgery, Yale University School of Medicine, New Haven, CT 06510, USA

Abstract—We describe a microfluidic device for testing the flow rate within a cerebrospinal fluid (CSF) shunt system. The CSF shunt system is a medical device to treat hydrocephalus, in which abnormal accumulation of cerebrospinal fluid occurs in the brain. However, high rates of shunt failure materialize due to shunt malfunction and obstruction. The novel microdevice presented here is used to determine the shunt performance by measuring CSF flow rate. Through experimentation, a relationship is demonstrated between sensor output and fluid flow rate, and a system of external sensor analysis is established.

Keywords—Cerebrospinal fluid (CSF) shunt system, hydrocephalus, flow sensor

I. INTRODUCTION Cerebrospinal fluid (CSF) is a body fluid contained in the brain ventricles and the cranial and spinal subarachnoid spaces [1]. It is renewed about four times every 24 hours. Arterial pulse waves largely decide CSF flow dynamics and pressure from sites of secretion to sites of absorption [2]. Additionally, CSF circulation is effected by the subject’s posture, respiratory waves, jugular venous pressure and physical effort [3]. Recent research shows that CSF plays an essential role in regulating neuronal function and maintaining homeostasis of the interstitial fluid in the brain [1].

Hydrocephalus is a neurological condition classified by the abnormal accumulation of cerebrospinal fluid (CSF) in the brain [4]. It occurs due to a mismatch between CSF production and its absorption within the brain. It is generally caused by low turnover rate of CSF and/or other neurological diseases. Posting CSF shunt system by medical procedure is the most common treatment for hydrocephalus [5]. The shunt system drains excess cerebrospinal fluid from the ventricles of the brain to the peritoneal cavity or into the right atrium [6]. The system contains three major components: an in-flow catheter that drains excess fluid from the ventricles of the brain, a valve that regulates the flow of fluid, and an outflow catheter that receives the fluid to the peritoneal cavity or the right atrium. The CSF flow rate through a shunt varies in individual cases within a range of 0.6 ml/hr up to 116 ml/hr [7].

Shunt failure is fairly common among patients. The most common reasons resulting in shunt failure are due to infection, shunt obstruction, and over drainage [8]. A study conducted on 1,719 hydrocephalic patients asserts the following reasons for shunt failure: (1) Occurrence of shunt malfunction (81%). (2) A high probability of shunt obstruction (56.1%) and fracture or disconnection of the tubings (13.6%). (3) A high

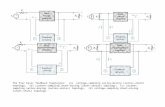

prevalence of proximal occlusion with ventricular catheter [9]. Because of the likelihood of failure, improvements to this treatment modality are clearly required. The concept behind smart shunt technology is to provide a feedback system in which measured conditions and data provide parameters with which to examine shunt efficiency, any hardware malfunction or damage, and to optimize shunt functionality to meet the needs of the individual patient. This precision medicine approach to hydrocephalus could be a key facet in treatment catering to the appropriate levels of CSF buildup for a specific patient. The microdevice proposed in this paper is used to detect the shunt system performance by testing the compartmental flow rate. The device consists of a two-piece compartment and a flow sensor which is situated inside the compartmental cavity, as shown in Fig.1. Using a laser beam focused on the sensor through an opening on the compartment, the internal flow rate is measured by varying fluid flow rate and recording angle deviation. The reflected light, used to record angle variations, is captured by a microscopic camera positioned above. In this way, the microdevice enables monitoring of shunt performance without the need to broach the sealed compartment.

Fig.1 Photograph of the experimental setup

II. METHODS A. Flow sensor fabrication

As shown in Fig.2, the main part of the sensor design is a rectangular part in the center of the device. SU-8 negative photoresist polymer was first patterned on an aluminum substrate to fabricate sensors using photolithography. A 1:1 mixture of SU-8 2005 and SU-8 thinner was used to form a 2µm-thick cantilever. Then SU-8 2015 was patterned on top of the first layer to fabricate the 15µm-thick frame. In a third step, we deposited a thin layer of titanium by thermal deposition. The sacrificial aluminum substrate was wet-etched

by Ferric chloride. B. Device Structure

Fig.2 The flow sensor design and the cantilever (inset)

A flow sensor was fixed between two layers of PDMS film, then placed in the compartment, as shown in Fig.2. The fluid flowed through an inlet (right), a nozzle, the sensor and was drained via the outlet (left). The sensor remains in the horizontal position when there is no fluid flow, and deflects due to fluid pressure when there is a flow. These two states are indicated by the straight and dotted lines in Fig.2, respectively. The beam of laser light is reflected, by a thin layer of titanium on top of the sensor, and received by a camera once the sensor begins to bend. To test this new sensor, we subjected it to a variable flow rate created by a pump. A modulation of the flow rate impacts the sensor deflection, the angle of reflection, and in turn the light intensity received by the camera. We evaluated the performance of the sensor by documenting the resultant image intensity in response to a variable flow rate.

III. RESULTS

Fig.3 Cantilever deflection under a uniform load

Fig.4 Sensor output to an on-and-off flow with an 8-sec duty

cycle at 60 ml/hr.

Fig.5 Sensor output for different flow rates.

The flow sensor was modelled as a cantilever, deflected by the uniformly distributed fluid pressure, as shown in Fig.3. The deflection of the sensor is given as

(1) where I is the area moment of inertia, E is Young’s modulus, 𝑙 is the length of the sensor, and ω is the distributed pressure from the fluid. Themaximumdeflectionaty=l is

In this model, the deflection of the sensor is directly proportional to the equally distributed load from the fluid. Fig.4 shows the sensor output when a flow of 60 ml/hr was modulated by a square wave with a duty cycle of 8-sec. The solid line represents the varied light intensity measured at the top of the cantilever. Control signal measured from the background is shown as the dotted line in the figure. The light intensity captured by the camera varied with the flow, while the background intensity barely changed, proving the sensor deflection was due to the fluid flow, rather than light noise or other circumstantial factors. Fig.5 shows the sensor output amplitude at different flow rates. The amplitude of the sensor at each flow rate tracks the increase in the flow rate. In this way, the bending angle of the sensor is proportional to be proportional to the flow rate.

IV. CONCLUSION We have designed and fabricated a novel sensor, and successfully demonstrated its operation. The new flow sensor responded linearly to flow rates of 20-90 ml/hr, which correspond to flow rates in hydrocephalus. These results suggest that the new sensor could form the basis of a smart shunt solution for hydrocephalus.

REFERENCES [1] Sakka, Laurent, Guillaume Coll, and Jean Chazal. “Anatomy and

physiology of cerebrospinal fluid.” European annals of otorhinolaryngology, head and neck diseases 128.6 (2011): 309-316.

[2] Dunbar, Howard S., Thomas C. Guthrie, and Barbara Karpell. "A study of the cerebrospinal fluid pulse wave." Archives of neurology 14.6 (1966): 624-630.

[3] Bering Jr, Edgar A., and Osamu Sato. "Hydrocephalus: changes in formation and absorption of cerebrospinal fluid within the cerebral ventricles." Journal of neurosurgery 20.12 (1963): 1050-1063.

[4] Scarff, John E. "Treatment of hydrocephalus: an historical and critical review of methods and results." Journal of Neurology, Neurosurgery & Psychiatry 26.1 (1963): 1-26.

[5] Davidoff, Leo M. "Treatment of hydrocephalus: historical review and description of a new method." Archives of Surgery 18.4 (1929): 1737-1762.

[6] Post, Elisabeth M. "Currently available shunt systems: a review." Neurosurgery 16.2 (1985): 257-260.

[7] Kadowaki, Chikafusa, et al. “Factors affecting cerebrospinal fluid flow in a shunt.” British journal of neurosurgery 1.4 (1987): 467-475. 3. Sainte-Rose, C., et al. "Mechanical complications in shunts." Pediatric neurosurgery 17.1 (1991): 2-9.

[8] Pudenz, Robert H., and Eldon L. Foltz. "Hydrocephalus: overdrainage by ventricular shunts. A review and recommendations." Surgical neurology 35.3 (1991): 200-212.

[9] Sainte-Rose, C., et al. "Mechanical complications in shunts." Pediatric neurosurgery 17.1 (1991): 2-9.

0.6

0.7

0.8

0.9

1

1.1

0 8 16 24 32 40 48 56 64

Out

put

ampl

itude

[a.u

.]

Time(s)

Sensor Control

R²=0.98759

0

0.2

0.4

0.6

0.8

1

20 30 40 50 60 70 80 90

Out

put

ampl

itude

[a.u

.]

Flow rate (ml/hr)