A new type of irreversibly reductively biodegradable hydrogel

Click here to load reader

-

Upload

miroslav-vetrik -

Category

Documents

-

view

215 -

download

1

Transcript of A new type of irreversibly reductively biodegradable hydrogel

lable at ScienceDirect

Polymer Degradation and Stability 96 (2011) 892e897

Contents lists avai

Polymer Degradation and Stability

journal homepage: www.elsevier .com/locate/polydegstab

A new type of irreversibly reductively biodegradable hydrogel

Miroslav Vetrik*, Martin Hruby, Martin Pradny, Jiri MichalekInstitute of Macromolecular Chemistry, Academy of Sciences of the Czech Republic, Heyrovsky Sq. 2, 162 06 Prague 6, Czech Republic

a r t i c l e i n f o

Article history:Received 21 December 2010Accepted 30 January 2011Available online 13 February 2011

Keywords:Biodegradable hydrogelDisulfideL-cysteineThiol

Abbreviations: Boc-Cys, N-tert-butyloxycarbonyl cypropyl)methacrylamide; DMAc, N,N-dimethylacetamiEEDQ, 2-ethoxy-1-ethoxycarbonyl-1,2-dihydroquinolinylamino)propyl]-6-{[5-({[3-(methacryloylamino)propydisulfanyl}nicotinamide N-[3-(methacryloylamino)proamino)propyl]amino}carbonyl)-2-pyridyl]disulfanyl}ni6-({5-[(propylamino)carbonyl]-2-pyridyl}disulfanyl)nic* Corresponding author. Tel.: þ420 296 809 218; fa

E-mail address: [email protected] (M. Vetrik).

0141-3910/$ e see front matter � 2011 Elsevier Ltd.doi:10.1016/j.polymdegradstab.2011.01.037

a b s t r a c t

Reductively biodegradable hydrogels based on poly[N-(2-hydroxypropyl)methacrylamide] crosslinkedwith N-[3-(methacryloylamino)propyl] -6-{[5-({[3-(methacryloylamino)propyl]amino}carbonyl)-2-pyr-idyl]disulfanyl}nicotinamide intended for tissue engineering were synthesized and characterized. Therate of irreversible reductive degradation with thiol L-cysteine (a model of human body where severalthiols are present in extracellular space) was studied using several L-cysteine concentrations. Themechanism of the irreversible reductive bond cleavage in the crosslinker structure was confirmed ona low-molecular-weight model. The hydrogel is stable during storage in phosphate buffered saline and isdegraded relatively quickly in a concentration-dependent manner after addition of L-cysteine to thesurrounding medium.

� 2011 Elsevier Ltd. All rights reserved.

1. Introduction

Extensive research effort is currently devoted to regenerativemedicine and tissue repair. Bridging the lesion of the damaged ordestroyed tissue and regeneration of the functional tissue is moreunderstood in the last two decades and examined using stem cells,present in the surrounding tissue or supplied externally [1]. Thespreading and differentiating cells however require a scaffoldresembling the extracellular matrix as a support [2].

Significant benefits may thus be expected from the implantationof biodegradable scaffolds in which the cells can grow, thusbridging the lesions. The scaffolds may eventually serve as cellcarriers for the delivery of different population of cells, such asfoetal stem cells or even embryonic stem cells, which can effec-tively repair the injured tissue [3]. After the formation of newlyreconstructed tissue, the scaffold should degrade without leavingany artificial deposits. Therefore, scaffolds utilized for cell transfershould be biocompatible and non-immunogenic, should havesuitable mechanical properties and controlled architecture and

ysteine; HPMA, N-(2-Hydrox-de; DMSO, dimethylsulfoxide;e; MA2SS, N-[3-(methacrylo-l]amino} carbonyl)-2-pyridyl]pyl]-6-{[5-({[3-(methacryloylcotinamide; Pr2SS, N-propyl-otinamide.x: þ420 296 809 410.

All rights reserved.

should be biodegradable at a reasonable rate [4], whichmakes theirpreparation difficult.

Many authors thus consider biodegradable biomaterials to besuperior to non-degradable matrices from the point of view oftissue regeneration. The biodegradability of most supports relies onhydrolytic degradation [5e7], spontaneous or enzyme e catalysed[8e10]. Although hydrolytically biodegradable scaffolds can beprepared from a variety of materials, they still havemany importantdisadvantages, such as problems with their storage in an aqueousenvironment and the fact that their hydrolysis is accompanied bya swelling phase, which constricts the growing cells, modifiesscaffold micro-architectural properties, etc. Enzymatic degrad-ability reduces storage problems in aqueous environment, since theenzymes are present in the environment only after implantation.However, many problems remain, e.g., the steric hindrance of thepolymer gel against enzyme degradation, the difficulty of predict-ing the particular enzymatic activity in situ, a more limited choice ofpolymer materials etc.

However, there are also other chemical mechanisms ofachieving degradability in vivo. One of these is the reductivedegradability of disulfide bonds by a disulfideethiol exchangereaction or reduction with thiols omnipresent in the organism(glutathione, serum albumin, cysteine, homocysteine, glycylcys-teine; Fig. 1) [7,11,12]. The scaffold would thus be hydrolyticallystable during storage, but in the organism it would degrade,forming water-soluble, non-toxic fragments, which can by releasedby the organism. Moreover, disulfides and thiols are scavengers ofreactive oxygen species and nitric oxide (NO), which are present ininflamed/damaged regions and are considered to rank amonginflammation mediators [13]. The exchange reaction with the

SS

R SH

SS R

SH

SS

R SH

R SS R

SH

polymerpolymer

+

polymer

polymer

+exchange

polymer polymer

+2 polymer

+reduction

2

Fig. 1. Scheme of disulfide degradation modes with thiols.

M. Vetrik et al. / Polymer Degradation and Stability 96 (2011) 892e897 893

extracellularmatrix should lead to the reversible binding of lamininand integrin via disulfide bonds, which should in turn also promotethe growth of cells, but may also lead to nonspecific interactionswith the cells.

The approach of reductive biodegradability has been mainlydescribed for water-soluble gene delivery systems [14,15], but alsoin several cases for hydrogel scaffolds made of hyaluronan, poly(g-glutamic acid) and similar polymers of biological origin [7,11,12].Such hydrogels are prepared by functionalisation of the biomole-cules with thiol-containing agents and subsequent oxidation of themacromolecule-bound thiols to disulfides by air or by dilutedhydrogen peroxide (oxidative crosslinking). However, such hydro-gels have several drawbacks e poor mechanical properties, difficultfunctionalisation with specific cell proliferation and differentiationpromoting ligands, a chemically and structurally less definedproduct (since natural polymer is used as starting material) isformed, etc.

The use of synthetic polymers for such purposes offersseveral additional advantages. The chemical surroundings of thedisulfide bond may be fine-tuned to achieve the degradation half-life adjustable over a much wider range, such gels are muchmore defined, have better mechanical properties, are easier toprepare and functionalize with the use of suitable vinyl comono-mers, etc.

NN S S

O

NH

O

NH

Po

Polymer

N SH

O

NH

Polymer

R SH reduction

Fig. 2. Tautomeric stabilization of the thiol cleavage prod

Most thiols exchange with disulfides reversibly. However, somedisulfides (e.g., 2,20-dipyridyl disulfide type) are cleaved irrevers-ibly into two separate parts due to the strong tautomeric stabili-zation of the thiol cleavage product into preferred non-thioltautomer (2-thiopyridone in this case) [16]. If such disulfide bondsirreversibly cleavable by thiols (see Fig. 2) are employed, it shouldenable to avoid the side reactions after degradation (re-gelationafter exposure of the degraded polymer to air, re-conjugation withthiol-containing proteins such as opsonins, unwanted additionalswelling during degradation, etc.). To best of our knowledge, nosuch gel was described in literature to date. In this paper, wedescribe the reductively cleavable hydrogel scaffold intended forthe use in tissue engineering, using crosslinker with irreversiblythiol-cleavable bonds. Easy to prepare, stable in water solutions(PBS), which allow storage our material for a long time and non-toxic products of degradation can be easy released by organism.

2. Materials and methods

2.1. Materials

N-(3-Aminopropyl)methacrylamide hydrochloridewaspurchasedfrom Polysciences Europe GmbH (Eppelheim, Germany). All other

lymer

NH S

O

NH

Polymer

more stable non-thiol tautomer

ucts formed from the 2,20-bipyridyl disulfide bond.

M. Vetrik et al. / Polymer Degradation and Stability 96 (2011) 892e897894

chemicals were purchased from SigmaeAldrich Ltd. (Prague, CzechRepublic).

2.2. Methods

2.2.1. Synthesis of monomers and biodegradation modelsN-(2-Hydroxypropyl)methacrylamide (HPMA) was synthesized

by methacryloylation of 1-amino-2-propanol by methacryloyl-chloride as described in [17]. The reductively degradable crosslinkerN-[3-(methacryloylamino)propyl]-6-{[5-({[3-(methacryloylamino)propyl]amino} carbonyl)-2-pyridyl]disulfanyl}nicotinamideN-[3-(methacryloylamino)propyl]-6-{[5-({[3-(methacryloylamino)propyl]amino}carbonyl)-2-pyridyl]disulfanyl}nicotinamide (MA2SS) and thebiodegradation model N-propyl-6-({5-[(propylamino)carbonyl]-2-pyridyl}disulfanyl)nicotinamide (Pr2SS) were prepared according tothe following procedure (see Fig. 3 for scheme):

6,60-Dithiodinicotinic acid (1.00 g, 3.24 mmol), 2-ethoxy-1-ethoxycarbonyl-1,2-dihydroquinoline (EEDQ, 1.68 g, 6.81 mmol)and the particular amine [N-(3-aminopropyl)methacrylamidehydrochloride (1.16 g, 6.49 mmol) þ ethyldiisopropylamine(0.904 mL, 6.49 mmol) in the case of MA2SS or 1-aminopropane(0.550 mL, 6.69 mmol) in the case of Pr2SS, respectively] weredissolved in anhydrous N,N-dimethylacetamide (DMAc, 12 mL) andstirred at room temperature for 24 h. The reaction mixture wasthen poured into water (70 mL), cooled to 5 �C and filtered. Theprecipitate was washed with water and dried in vacuum. Theresulting solid was treated in ultrasound bath for 5 min in diethylether (10 mL), the resulting suspension was filtered, the solid waswashed with diethyl ether and dried in vacuum. Yield 1.36 g (81%)for MA2SS and 0.98 g (77%) for Pr2SS.

MA2SS: 1H NMR (DMSO-d6): s ¼ 1.67 (m, 4H), 1.84 (s, 6H), 3.15(m, 4H), 3.26 (m, 4H), 5.30 (s, 2H), 5.63 (s, 2H), 7.70 (d, 2H), 7.93 (t,2H), 8.16 (d, 2H), 8.65 (t, 2H), 8.87 (s, 2H). 13C NMR (DMSO-d6):s ¼ 18.6 (2C), 29.0 (2C), 36.6 (2C), 37.1 (2C), 118.9 (2C), 119.2 (2C),128.1 (2C), 136.8 (2C), 140.0 (2C), 148.5 (2C), 159.8 (2C), 164.0 (2C),167.5 (2C). Elemental analysis (found/calculated): C 56.26%/56.10%,

SS

O

O

NH

NH

NH

NH

O

O

SS

COO

C

ONH

NH2 . HCl

Et3N, EEDQMA

2SS

Fig. 3. Synthesis of crosslinker MA

H 5.63%/5.79%, N 14.84%/15.10%, S 11.60%/11.52%. TLC (silica, aceticacideethanol 1:99 v/v): homogenous, RF ¼ 0.69.

Pr2SS: 1H NMR (DMSO-d6): s ¼ 0.88 (t, 6H), 1.53 (m, 4H), 3.22(m, 4H), 7.70 (d, 2H), 8.18 (d, 2H), 8.63 (t, 2H), 8.88 (s, 2H). 13C NMR(DMSO-d6): s¼ 11.3 (2C), 22.2 (2C), 40.9 (2C), 119.1 (2C), 128.2 (2C),136.7 (2C), 148.4 (2C), 159.7 (2C), 163.9 (2C). Elemental analysis(found/calculated): C 54.99%/55.36%, H 5.26%/5.68%, N 14.47%/14.35%, S 16.87%/16.42%. TLC (silica, acetic acideethanol 1:99 v/v):homogenous, RF ¼ 0.88.

2.2.2. Synthesis of hydrogelsThe hydrogels were prepared by radical UV polymerization of

hydroxypropyl methacrylate (HPMA, 0.250 g, 1.74 mmol) andMA2SS (0.100 g, 0.180 mmol, respectively) with 2-hydroxy-2-methylpropiophenone (0.014 g, 85.3.10�6 mmol) as the UV initiatorin different amounts of dimethylsulfoxide (DMSO, 1.00 g, 0.75 g or0.50 g, respectively) as solvent. Polymerization was done in poly-meric blocks equipped with quartz glass on front side [18] made ofhard-aluminium flow forms with an area of 5 � 1 cm, fitted withreinforced polypropylene foils and firmly closed using screwclamps. The thickness of the unswollen original samples corre-sponded to the thickness of the silicone seals (1 mm) used. Thepolymerization proceeded for a period of 30 min at r.t. using irra-diation with wide spectral UV lamp (6 � 125 W; Tesla, Prague,Czech Republic). After polymerization the hydrogels were washedby DMSO (five times for five days) after by H2O (five times for fivedays) and finally phosphate buffered saline, pH 7.4 (PBS; five timesfor five days).

The hydrogels were characterized by volume fraction of drypolymer content in equilibrium-swollen hydrogel ZV according toEq. (1):

Zv ¼ mD=ðmSrDÞ (1)

where mS and mD are the weights of swollen and dry hydrogel(xerogel), respectively, rD is the density of the dry gel (xerogel;rD¼ 1.2 g cm�3), density of the swollen gel is assumed to be the sameas the density of water, i.e. 1.0 g cm�3 due to high water content.

H

OOH

SS

O NH

O NH

NH2

EEDQPr

2SS

2SS and model subtrate Pr2SS.

M. Vetrik et al. / Polymer Degradation and Stability 96 (2011) 892e897 895

2.2.3. Degradation of model compound Pr2SSThe solution of Pr2SS (10 mM in DMAc) and the solution of

N-tert-butyloxycarbonyl cysteine (Boc-Cys, 10 mM in DMAc) weremixed at room temperature to obtain the molar ratios of reactantsBoc-Cys:Pr2SS 0.25, 0.50, 0.75, 1, 2, 3 and 4, respectively. Afterincubation at room temperature (5 h for equilibrium experiments,0 min, 5 min, 20 min, 30 min, 1 h, 2 h and 7 h for the reaction rateexperiments), the reactionmixtures were analyzed by both UVeVISspectrophotometry (equilibrium þ reaction rate experiment) andhigh performance liquid chromatography (HPLC, equilibriumexperiments only).

UVeVIS spectrophotometry: The reaction mixture was dilutedwith methanol (1 þ 299 v/v) and absorbance was recorded ina 1 cm optical length quartz cuvette in the range 190e600 nm ona Helios Alpha (Spectronic Analytical Instruments, Leeds, UnitedKingdom) UVeVIS spectrophotometer. The absorbances wererecalculated to the initial concentration of Pr2SS 33 mM.

HPLC: The reaction mixture was diluted with DMAc (1 þ 19 v/v)and analyzed on the Chromolith Performance RP-18e C18 silicacolumn (100 � 4.6 mm i.d., Merck, Darmstadt, Germany) usingthe following gradient method: flow 1 mL min�1, watereacetonitrileetrifluoroacetic acid; A: 950:50:1 v/v/v, B: 50:950:1 v/v/v, program 0e2 min 100% A, 2e8 min gradient to 100% B, 8e10 min100%B,10e11min gradient to 100%A,11e17min 100%A (column re-equilibration). Analysis was performed on a Shimadzu HPLC system(Shimadzu Co., Kyoto, Japan) equipped with refractive index, fluo-rescence and PDA (diode array) UVeVIS detectors (scanned range200e400 nm). The standard of “reduced Pr2SS“ (N-propyl-6-thioxo-1,6-dihydro-3-pyridinecarboxamide) was obtained by dissolutionof Pr2SS (0.2 mg mL�1) in the 3-mercaptopropionic acideDMAc(1:9 v/v) mixture and the only UV316nm-active peak (tR ¼ 6.76 min)was attributed to reduced Pr2SS.

Degradation rate was followed by UVeVIS spectrophotometryby mixing the solutions of Boc-Cys and Pr2SS to obtain 0.420, 0.084and 0.017 mM Boc-Cys and 5:1 Boc-Cys to Pr2SS molar ratio andfollowing absorbance in a 1 cm optical length quartz cuvette at316 nm during incubation at 37 �C.

2.2.4. In vitro degradation of the hydrogelsThe weighted strips of hydrogels (weight m0, ca 1 � 1 cm)

swollen in PBS were immersed in the 50 mL solution of L-cysteine(0 mmol L�1, 0.33 mmol L�1, 4.2 mmol L�1, 12.6 mmol L�1 and42 mmol L�1, respectively) and tetracycline (0.23 mmol L�1) in PBSand maintained at 37 �C. Every day the hydrogel was weighted (m),re-immersed in fresh L-cysteine solution and returned to theincubator. Then, degree of degradation (d) was calculated accordingto Eq. (2):

d ¼ ðm�m0Þ=m0 (2)

wherem is the weight of polymer sample in the observed time andm0 is weight of polymer sample at the beginning of the degradationstudy.

3. Results and discussion

The hydrogels were designed to contain poly[N-(2-hydrox-ypropyl)methacrylamide] (polyHPMA) polymer chains soluble inwater crosslinked with biodegradable irreversibly thiol-cleavabledisulfide crosslinker MA2SS. PolyHPMA is a hydrophilic polymerwith known biocompatibility [19]. During cleavage of crosslinkernetwork density decreases and the material becomes soluble inwater, which should allow its elimination from organism by kidneys.

We first synthesized the crosslinker with 2,20-dipyridyl disulfidetype bonds, MA2SS, by EEDQ-mediated amino-carboxylic acid

condensation in good yield (81%). The hydrogels were synthesizedby radical copolymerization of this crosslinker with HPMA as mainmonomer using 2-hydroxy-2-methylpropiophenon as an UV initi-ator. Three different concentration of DMSO were used (1.00 g,0.75 g and 0.5 g per 0.25 g HPMA) to set best condition duringdegradation study, because in case of in vivo study, long timewashing for eliminationmonomer and all other chemical present inhydrogel after the polymerization reaction is necessary and alsonetwork density decreases when increasing dilution of the poly-merization mixture.

Solvation of polymer chains is important for the polymerdegradation rate [20], because all the thiols present in organismthat would degrade the implant are very hydrophilic, and also stericaccessibility of the disulfide crosslinks is increased with thehydrogel expansion in water. The solvation of the polymer chainsalso influences compactness of the gel and thus diffusion rate ofbiological thiols into it. Quantitative measure of the polymersolvation may be expressed as volume fraction of dry polymer inequilibrium e swollen hydrogel e ZV. For all three polymer gels,there were not found any significant differences among thesamples (ZV is the same for all samples containing different amountof solvent in polymerization mixture, Zv 1 ¼ 0.2, Zv 0.75 ¼ 0.2 andZv 0.5 ¼ 0.19 for the solvent weights 1 g, 0.75 g and 0.50 g, respec-tively). The degree of solvation is thus probably influenced only byhydrophobicity of the polymer, which is the same for all samplessince they were prepared from the same ratio of hydrophilic HPMAand relatively hydrophobic crosslinker. The mechanical properties(resistance against fragmentation) of the gel are significantly betterfor the gels with lower solvent content in polymerization mixturein analogy to most hydrogel systems described in literature [21].

The total concentration of all free thiols in plasma is mostlygiven by the free thiol groups on the Cys 34 position on serumalbumin. The average content under normal conditions is 0.7 freethiol (SH) groups per albumin molecule [22]. The content of serumalbumin (Mw ¼ 67 kDa) in human blood (30e50 g/L) [23] thuscorresponds to the pool of SH groups 0.31e0.52 mM. The Cys 34 SHgroup is highly reactive [24], however steric considerations espe-cially in the case of the reaction with polymer are to be responded.The content of low-molecular-weight thiols in blood plasma issignificantly lower. L-Cysteine is the most abundant low-molecular-weight thiol in blood plasma (9 mmol/L SH) and also some otherthiols are present in blood plasma (glutathione and L-cysteinylglycine aa 1.5 mmol/L SH, L-homocysteine 0.15 mmol/L SH) [25].However, there are also significantly higher concentrations ofdisulfides present in blood plasma (L-cysteine 150 mmol/L disulfidegroups (SS), glutathione 2 mmol/L SS, L-cysteinyl glycine 11 mmol/LSS, L-homocysteine 7 mmol/L SS) [25], that may also promotedegradation due to SHeSS exchange reaction (see Fig. 1), wherethiol is a catalyst only. Degradation kinetics may also be acceleratedby cell membrane-bound reductases, omnipresent on the surface ofmammalian cells, and diffusion of thiols from the surrounding ofthe implant is also of limited rate [26]. More to that, the commer-cially available albumin samples are more oxidized than in bloodplasma, where the redox state is actively maintained by the cells.On the other hand, maximum degradation rate of the gel is to beexpected in the place of maximal metabolic activity (i.e. cellgrowth), which is favourable.

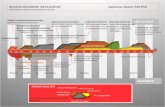

However, this all makes in vitro simulation of the degradation inhuman organism very difficult. We have chosen five model L-cysteine concentrations e 0 mmol L�1 (stability against hydrolysis,not present in the Fig. 4), 0.33 mmol L�1 (biologically relevant freethiol concentration if we consider reactivity of albumin and of low-molecular-weight thiols comparable) and three higher concentra-tions due to mechanistic study e 4.2 mmol L�1, 12.6 mmol L�1 and42 mmol L�1. Lower L-cysteine concentrations comparable to free

-1,00

-0,80

-0,60

-0,40

-0,20

0,000 10 20 30 40 50 60

t, days

δ

1

1. ccys= 0.33 mmol/L2. ccys= 4.2 mmol/L3. ccys= 12.6 mmol/L4. ccys= 42 mmol/L

2

1

-1,00

-0,80

-0,60

-0,40

-0,20

0,000 10 20 30 40 50 60

t, days

δ

1. ccys= 0.33 mmol/L2. ccys= 4.2 mmol/L3. ccys= 12.6 mmol/L4. ccys= 42 mmol/L

234

234

1

3-1,00

-0,80

-0,60

-0,40

-0,20

0,000 10 20 30 40 50 60

t, days

δ

234

1

1. ccys= 0.33 mmol/L2. ccys= 4.2 mmol/L3. ccys= 12.6 mmol/L4. ccys= 42 mmol/L

Fig. 4. Rate of hydrogel degradation. Concentration of L-cysteine (mg per 100 mLwater) is 51 (1), 153 (2) and 510 (3), respectively.

0,0

10,0

20,0

30,0

40,0

50,0

60,0

70,0

80,0

90,0

100,0

0 0,5 1 1,5 2 2,5 3 3,5 4

Boc-Cys/Pr2SS (mol/mol)

th

io

py

rid

on

e re

le

as

ed

(%

th

eo

ry

)

UV-VISHPLC

Fig. 5. The “reduced Pr2SS” formation during the Pr2SS degradation in equilibrium atdifferent Boc-Cys:Pr2SS molar ratios in methanol. C e UVeVIS, - e HPLC.

M. Vetrik et al. / Polymer Degradation and Stability 96 (2011) 892e897896

low-molecular-weight thiol concentration (9 mmol/L SH) in bloodwere not studied, because in such case it is not possible to maintaindefined concentration in model stock solution (stoichiometrydisulfide in gel vs. thiol in external volume of L-cysteine solution istoo shifted to complete depletion of external thiol, traces of oxygenthat oxidizes free thiols). All the observed degradation rates exceptthat without L-cysteine are thus the upper limit that may beexpected in vivo.

The rate of degradation of hydrogels is shown on Fig. 4 and isexpressed as time dependence of the degree of degradation (d),

only one degradation graph is presented, other two degradationrate have similar slope and can be found in Supplementarymaterials. The higher is the network density (i.e. the lower issolvationwith water expressed as ZV), the slower is the degradationrate. This effect is most plausibly caused by the fact that morecrosslinks have to be cleaved in more densely crosslinked gel todissolve it. Also hydrophobic nature of the crosslinker maycontribute to this effect (causing the decrease of equilibriumcontent of water in gel, which leads to less expanded and less thiol-accessible polymer chains). The complete degradation time is ca 60days and is expected to be significantly longer under in vivoconditions (similarly as for a system with reversibly reductivelydegradable bonds [5]).

The gels are completely stable in PBS without cysteine (i.e. arestable against hydrolysis) and the higher is the L-cysteine concen-tration, the faster is the degradation of the gel. It is important thatthe swelling phase was not observed during degradation in anycase. This is most plausibly because the reaction of thiols and thusdissolution of the gel from the surface is faster than diffusion intogel and breaking disulfide bonds inside the gel, making the polymerchains more flexible and able to expand and swell the gel. This ishighly advantageous especially for the porous 3D scaffolds, wherethe swelling phase during degradation may mechanically oppressthe growing and differentiating cells.

This hypothesis was tested by a reaction on low-molecular-weight model, where the steric considerations and diffusion playmuch lower role and the reaction progress may be followed easily.For the in vitromodel experimentswith the SeS bond cleavagewiththiol, the dipropylamide derivative of 6,60-dithiodinicotinic acid(Pr2SS) was synthesized. Pr2SS has the same chemical surroundingof the disulfide bond as MA2SS has (6,60-dithiodinicotinic acidaliphatic diamide), but unlike MA2SS it does not contain activateddouble bond, that may complicate the model experiments withMichael-type thiol additions. Due to solubility considerations, thereaction was carried on in organic solvent and Boc-Cys was used asmodel thiol.

As assayed by UVeVIS spectrophotometry, substituted 2-thio-pyridone formation during the disulfide bond cleavage leads todramatic difference in the UVeVIS spectra. Namely, 2-thiopyr-idone “reduced Pr2SS” absorbs at 316 nm, where the original

M. Vetrik et al. / Polymer Degradation and Stability 96 (2011) 892e897 897

disulfide is practically transparent (see Supplementary material).The reaction extent may thus be followed by UVeVIS spectro-photometry. The first experiment was done with various disul-fideethiol ratios and the reaction was allowed to reachequilibrium before measurement. The data reveal (see Fig. 5), thatthe equilibrium is nearly completely shifted towards completeconsumption of the aliphatic thiol, the same molar amount ofsubstituted 2-thiopyridone is released as is the amount of thealiphatic thiol added. The dependence is linear (linear regressionR2 ¼ 0.995) up to the stoichiometry 1:2, in accordance with theory(the two thiols are consumed to completely reduce one disulfidebond, see Fig. 1). The data from UVeVIS spectrophotometry wellmatch with the analysis of the substituted 2-thipyridoneconcentration determined by HPLC (see Fig. 5, correlation coeffi-cient 0.997).

Reaction rate of the disulfide bond degradation on the low-molecular-weight model was followed using the same concen-trations of thiol as in the case of the gel degradationand the thioledisulfide molar ratio 5:1. The degradation of thelow-molecular-weight model follows the first order kinetics(R2 ¼ 0.998, 0.997 and 0.977 for the Boc-Cys concentrations 0.420,0.084 and 0.017 mM, respectively) with the corresponding half-lives T1/2 41.2 � 2.7 min, 56.6 � 4.5 min and 90.8 � 18.8 min forthe Boc-Cys concentrations 0.420, 0.084 and 0.017 mM, respec-tively. The degradation of the low-molecular-weight modelis thus much faster than the degradation of the gel undercomparable thiol concentration, which means that the degrada-tion rate and missing of the swelling phase is diffusion-driven asexpected.

4. Conclusions

Irreversibly reductively biodegradable hydrogels polyHPMAcrosslinked with disulfide crosslinker intended for tissue engi-neering were synthesized and characterized. The rate of reductivedegradation with thiol L-cysteine (a model of the humanorganism where several thiols are present in the extracellularspace) was studied using several L-cysteine concentrations andthe mechanism of the irreversible reductive bond cleavage in thecrosslinker structure was confirmed on a low-molecular-weightmodel. The hydrogel is stable during storage in phosphate buff-ered saline and is degraded relatively quickly after addition of L-cysteine to the surrounding milieu in a concentration-dependentmanner.

Acknowledgements

Financial support of the Grant Agency of the Czech Republic(grants #P108/10/1560, #P207/10/P054, #P108/10/1560 and#MEYS 1M 0538) is gratefully acknowledged.

Appendix. Supplementary material

Supplementary material related to this article can be found atdoi:10.1016/j.polymdegradstab.2011.01.037.

References

[1] Branski LK, Gauglitz GG, Herndon DN, Jeschke MG. A review of gene and stemcell therapy in cutaneous wound healing. Burns 2009;35(2):171e80.

[2] Lim SH, Mao HQ. Electrospun scaffolds for stem cell engineering. Adv DrugDeliv Rev 2009;61(12):1084e96.

[3] Teng YD, Lavik EB, Qu X, Park KI, Ourednik J, Zurakowski D, et al. Proc NatlAcad Sci USA 2002;99:3024e9.

[4] Friedman JA, Windebank AJ, Moore MJ, Spinner RJ, Currier BL, Yaszemski MJ.Neurosurgery 2002;51:742e51. Discussion 751e752.

[5] Pradny M, Michalek J, Lesny P, Hejcl A, Vacik J, Slouf M, et al. Macroporoushydrogels based on 2-hydroxyethyl methacrylate. Part 5: hydrolyticallydegradable materials. J Mater Sci Mater Med 2006;17:1357e64.

[6] Vetrik M, Hruby M, Pradny M, Krumbholcova E, Michalek J, editors.Proceedings of the 11th International Chemistry Conference and Exhibition inAfrica, Luxor, Egypt, vol. 71; 2010.

[7] Liu YC, Shu XZ, Prestwich GD. Biomaterials 2005;26:4737e46.[8] Pradny M, Kopecek J. Hydrogels for site-specific oral delivery. Poly[(acrylic

acid)-co-(butyl acrylate)] crosslinked with 4,4’-bis(methacryloylamino)azo-benzene. Makromol Sci 1990;191:1887e97.

[9] Kim SW. Polym Mater Sci Eng 2003;89:178.[10] Skarda V, Rypacek F. J Bioact Compat Polym 1997;12:186.[11] Brown AL, Srokowski EM, Shu XZ, Prestwich GD, Woodhouse KA. Macromo-

lecular Biosci 2006;6:648e57.[12] Matsusaki M, Yoshida H, Akashi M. Biomaterials 2007;28:2729e37.[13] PeunovaN, ScheinkerV, ClineH, EnikolopovGJ. Neuroscience2001;21:8809e18.[14] Ou M, Kim TI, Yockman JW, Borden BA, Bull DA, Kim SW. Polymer transfected

primary myoblasts mediated efficient gene expression and angiogenicproliferation. J Controlled Release 2010;142(1):61e9.

[15] Manickam DS, Li J, Putt DA, Zhou QH, Wu C, Lash LH, et al. Effect of innateglutathione levels on activity of redox-responsive gene delivery vectors.J Controlled Release 2010;141(1):77e84.

[16] Grassett DR, Murray JF, Brokke ME, Gutman AD. J Med Chem 1967;10:1170e2.[17] Strohalm J, Kopecek J. Poly[N-(2-hydroxypropyl)methacrylamide]. IV. Hetero-

geneous polymerization. Angew Makromol Chem 1978;70:109.[18] Smetana Jr K, Vacik J, Souckova D, Krcova Z, Sulc J. The influence of hydrogel

functional groups on cell behavior. J Biomed Mater Res 1990;24:463e70.[19] Lammers T, Ulbrich K. HPMA copolymers: 30 years of advances. Adv Drug

Deliv Rev 2010;62(2):119e21.[20] Cretu A, Kipping M, Adler HJ, Kuckling D. Synthesis and characterization of

hydrogels containing biodegradable polymers. Polym Int 2008;57(7):905e11.[21] Johnson BD, Beebe DJ, Crone W. Effects of swelling on the mechanical prop-

erties of a pH-sensitive hydrogel for use in microfluidic devices. Biomater SciEng C Biomim Supramol Sys 2004;24(4):575e81.

[22] Banford JC, Brown DH, Hazelton RA, McNeil CJ, Smith WE, Sturrock RD.Altered thiol status in patients with rheumatoid arthritis. Rheumatol Int1982;2(3):107e11.

[23] Kuroda K, Nakashima J, Kanao K, Kikuchi E, Miyajima A, Horiguchi Y, et al.Interleukin 6 is associated with cachexia in patients with prostate cancer.Urology 2007;69(1):113e7.

[24] Kratz F, Warnecke A, Scheuermann K, Stockmar C, Schwab J, Lazar P, et al.Probing the cysteine-34 position of endogenous serum albumin with thiol-binding doxorubicin derivatives. Improved efficacy of an acid-sensitivedoxorubicin derivative with specific albumin-binding properties compared tothat of the parent compound. J Med Chem 2002;45(25):5523e33.

[25] Andersson A, Lindgren A, Arnadottir M, Prytz H, Hultberg B. Subjects and inpatients with renal or liver failure. Clin Chem 1999;45(7):1084e6.

[26] Saitoa G, Swanson JA, Leea KD. Drug delivery strategy utilizing conjugation viareversible disulfide linkages: role and site of cellular reducing activities. AdvDrug Deliv Rev 2003;55:199e215.