A Height Adjusting Toolpost

-

Upload

kwayneolson6081 -

Category

Documents

-

view

32 -

download

0

description

Transcript of A Height Adjusting Toolpost

ADJUSTINGTOOLPOSTBy James Smith

TH I S D E V I C E R E P R E S E N T S amethod of lathe tool heightadjustment and though I do

not claim originality, I cannot recallhaving seen the idea publishedbefore.

I have been using this tool holdernearly seven years, and it has notgiven me the slightest trouble. Infact, it has saved me considerabletime in tool setting. The holder itselfis simply an improvement on theDrummond split toolbox type, whichclamps to a pillar, cast integral withthe topslide.

This pillar on my lathe has a1/2 in. Whit. tapped hole in the centre

about I 1/2in. deep-for what reasonI am not sure unless it was for holdingthe slide in a jig, the pillar havingbeen turned first while the vee-slideswere machined. However, I thoughtthat the tapped hole could be usedfor tool height setting, so the improvedtool holder was evolved.

Would not reach centreThe original toolbox had a square

hole for the tool, which, when usinga right- or left-hand cranked tool,meant bringing the cross-slide wellout or turning the box almost through90 deg. I did not like this at all. Andwhen the toolbox was set with thesquare hole parallel to the bed forboring and the cross-slide was screwedin as far as it would go, the toolboxwould not reach the centre unless Itook off the whole topslide and put itin the farthest tee-slot.

So I decided to make a new onewith screw-height adjustment,, andwhich would reach the centre withoutthe necessity to change to anothertee slot.

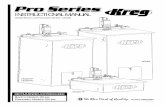

The modified toolbox is made outof a block of cast steel, but cast ironwould do just as well. The split bushis made of mild steel and the ring ofholes under the bolt head is for turn-

Side elevation oft h e t o o l h o l d e r

I I ‘=I-/ I \

Top Right: Plan view

Right: Sectional view

SQUARE FLANGED COLLARED PILLAR

P LLARt 4

F INE THREA-SCREWED ,INFOP REST

E n d e l e v a t i o nof the holder

1 m

TOP REST I

I I,

Below right: Sectional plan

ing back the clamping-bolt shouldthere be any thread stretching, thusthe nut handle is always about45 deg. off vertical. The drawing willshow how simple the adjustments are.Personally, I do not like any toolholders in which the front and toprake angles are altered so as to obtaindead centre.

This improved tool holder is onlyadaptable at present to the MyfordDrummond,. but it would be easy tofasten a 1 1/4 in. dia. pillar either witha square flange or shouldered andscrewed with a fine thread to manyexisting lathes.

I am surprised that this simpleholder has not been thought ofbefore. I can assure readers that it isquite solid when taking very heavycuts. q

31

l III

t_

5 JULY 1956 MODEL ENGINEER