A Comprehensive Study on Rib circular Knitting Machine

-

Upload

shoaib-al-mukit -

Category

Education

-

view

390 -

download

6

Transcript of A Comprehensive Study on Rib circular Knitting Machine

Presentation Name: A Comprehensive Study on Rib Circular Knitting machine.

Submitted by: Abdullah All Mukit Shoaib(ID: BTX140200344) and MD. Tarek HasanRidoy (ID: BTX140200358)

Submitted to: Farhana Afroz, Lecturer at Northern University Bangladesh

Submitt Date:

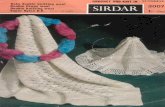

Features of rib fabric

1. Rib has a vertical cord appearance.2. 1×1 rib has the appearance of technical face of plain fabric3. Relaxed 1×1 rib is theoretically twice as thick and 12 the width of an equivalent plain fabric.4. It is more expensive fabric to produce than plain fabric.5. It can be unravel from the end knitted last by the free loop head through to the back of each stitch. 6.It is a heavier structure.7. It has very little curling tendency.8. Rib structures are elastic from fitting and retain warmth better than plain structure.

Stitch Pattern of Milano Rib

• Feed 1 : Knit on all dial and cylinder needles

• Feed 2 : Knit on all dial needles (only back loops)

• Feed 3 : Knit only on all cylinder needles (only face loop)

2. Double Pique

Double Pique : Two varieties of double pique are French pique and Swiss pique. Both these are produced on a 4 feed cycle. Both the structure are almost similar and there is a little difference in knitting cycle. Both are heavy, stable structures and they do not curl. These structures are also termed as drap or sheet fabrics because of the poor width wise extensibility.

Stitch Pattern of French Pique

Feed 1 : Knit on all short and long needles in cylinder and only on short needles in dial.

Feed 2 : Knit only on long needles in dial (no knitting cylinder needle)

Feed 3 : Knit on all short and long needles in only on long dial needles.

Feed 4 : Knit only on short needles in dial

Swiss Pique: The fabric is produced with smaller and finer loops than French double pique.

Stitch Pattern of Swiss Pique

• Feed 1 : Knit on all long and short needles in cylinder and only on long needles in dial

• Feed 2 : Knit on all long dial needles only

• Feed 3 : Knit on all long and short needles in cylinder and only on short needles in dial

• Feed 4 : Knit on all short dial needles only

3. Pique Poplin

Pique Poplin : It is a six feed structure with knit and float stitch combination. At feeds 2,3,5 and 6, there is no knitting with cylinder needles.

Stitch Pattern of Pique Poplin

• Feed 1 : Knit all needles of cylinder and only short needles of dial

• Feed 2 : Knit only long needles of dial

• Feed 3 : Knit only short needles of dial

• Feed 4 : Knit all needles of cylinder and only long needles of dial

• Feed 5 : Knit only short needles of dial

• Feed 2 : Knit only loop needles of dial

Evermonte: In this eight feed repeat structure, four courses (1,2,5 and 6) use every other needle on both needles beds. Course 1 and 2 tuck on dial and courses 5 and 6 tuck on cylinder. These tuck stitches cause pearl effect to the fabric.

• Feed 1 : Knit all short needles of cylinder and tuck all long needles of dial

• Feed 2 : Knit all long cylinder needles and tuck all short dial needles

• Feed 3 : Knit all dial needles only

• Feed 4 : Knit all cylinder needles only

• Feed 5 : Tuck all long cylinder needles and knit all short dial needles

• Feed 6 : Tuck all short cylinder needles and knit all long dial needles

• Feed 7 : Knit all cylinder needles only

• Feed 8 : Knit dial needles only

Rib circular knitting machine : The structure in which the face and back loop occurs along to the coarse successively but all the loops of a wale is same is called rib structure. The circular knitting machine which is used to produce the rib structures is known as rib machine.

Feature of rib circular knitting machine :

01. In a dial cylinder rib machine there is one set of needles on the circumference of the vertical cylinder and another set of needles on a horizontal dial.

02. So two sets of needles remain at the right angle with each other.

03. Here both the dial and cylinder rotates but the cam systems with the feeders remain stationary.

04. The dial needles get its motion from its butt which is placed on the cam truck.

05. cylinder needles moves vertically and dial

needles moves horizontally. Cylinder needles also get its motion from it.

Description of yarn fabric path diagram : Is the circular knitting m/c ,yarn is supplied from the set of packages which is placed in the creel. When supplying the yarn from the packages tensioner & anti snail device are placed over & in contact with the yarn. The yarns is fed from the feeder to the needles of the needles of the dial & cylinder. In successively, the knitted fabric is produced by the action of needles, cam & sinker. The produced knitted fabric is passed over & in contact with the fabric spreader & fabric withdraw roller. Finally the fabric is wound in the fabric winding roller

Yarn fabric path diagram flow chart

Creel

Feeder

Needles

fabric spreader

fabric withdraw roller

fabric winding roller

Functions of rib circular machine's different part

1.Creel:Creels are the knitting elements which carry the yarn packages to feed the knitting zone.

2.Feeder:The feeders feed the yarn into the needles hooks and control the needle latches in their position while the needles attain their position.

3.Dial:Dial is the upper steel needle bed used in double jersey knitting mc. Into the grooves of the dial ,the needles are mounted horizontally and near allowed to move radically in and out by their dial cam.

4. Guide: Guides control the yarn path which is very necessary

Functions of rib circular machine's different part

5. Needle: It is the principal element of knitting m/c. The function of the needle to retain old loop & to receive the new loop.

6. Cam: The cams are the mechanical devices which convert the rotary m/c drive into a suitable reciprocating action for the needles.

7. Cylinder: The cylinder is a steel circular bed having grooves on its outer periphery where the needles are mounted.

8.Fabric Spreader: A simple fabric spreader is a solid wooden plate, placed above the take down rollers & held in position by the fabric tube.

9.Cloth roller: this mechanism withdraw the fabric from the needles & winds them into cloth roller

Knitting action of the rib circular machine

1 .Rest position: The rest position for the cylinder and dial needles. Needles are constant. Loops are present in their hooks. Latches are close. 2. Tucking position for dial needle: The dial needle moves forward. Loop is present on the latch. Latch is open. Cylinder needle is in the rest position.3. Tucking position for cylinder needle: The cylinder needle moves forward. The cylinder loop is present on the latch. Here dial needle holds down the fabric on the cylinder needle. So that the latch of the cylinder needle is opened.4. Clearing position of dial needle: The dial needle further moves forward to clear the old loop from its latch. Here dial latch is open.

Knitting action of the rib circular machine 5 .Clearing position of cylinder needle: The cylinder needle will further move forward to clear the old loop from its latch. Cylinder latch is open.6 .Yarn presenting position: The cylinder and dial needles are pulled back again and they move into their yarn presenting position. The newly presented yarn is laid in the open needle hooks of both the needles.7. Cast on position: The cylinder and dial needles are pulled further and move into their cast on position. Here the loops lie over the closed needle head and the newly presented yarn is held in the closed needle head.8 .Knock-over position: The cylinder and dial needles are pulled further .The new yarn is drawn through the loops of the both needles. The loops are knocked-over as stitches and new loops are formed out of the yarn presented.

Courtesy

• Knitting Technology by David J Spencer

• http://www.slideshare.com

• http://www.textilelearner.blogspot.com

• Lecture Sheet of University