93049 BORKE JOB - Letherer BORKE JOB MU S 26 MU S 26 TJC37 TJC37 2 ... N 24 -3269 N - O 21 -3284 O -...

Transcript of 93049 BORKE JOB - Letherer BORKE JOB MU S 26 MU S 26 TJC37 TJC37 2 ... N 24 -3269 N - O 21 -3284 O -...

24'4

"8'

15'8

"

24'4

"8'

10'8

"7'

7'

19' 10'

7'

7'1"

2'

31'

24'9

"816

'1"8

2'

2'3"8

2x10 LEDGER

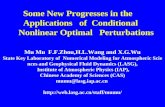

93049BORKE JOB

MU

S26

MU

S26

TJC37TJC37

2' 2'

1'6"

1'6" 2' 2'2'

10"8 2'

10'2"18'10"

2'9"2'

2'

2'

2'

2'

2'

2'1'1"610"10

2'

2'

2'7"2

1'6"6

2'

2'

2'1'0"12

1'4"1'4"1'4"1'4"1'4"1'4"1'4"1'4"1'4"1'4"1'4"

1'3"4

1'11

"4 2' 2' 1' 1' 2' 2'

1'11

"4

EJ1

EJ2

EJ2EJ2

EJ2

EJ3 EJ3

EJ3

EJ3

EJ4

EJ4EJ4

EJ4

HJ1 HJ1GS1

G1

P2

ATG

ATG

T3

TG1 G

2

G2

TG1

3 PLY

3 PLY

S1AT

1AT

1

T2T2

T1P1

P1

AT2

PAGE NO:

1 OF 1

JOB NO:

93049

Lot

: TH

OM

AS S

HAR

LEN

E BO

RKE

L

ayou

t: N

L

Des

igne

r: JA

RED

JO

RG

ENSE

N

C

ontra

ctor

: MC

CLO

UD

C

usto

mer

: MC

BAIN

BLD

G P

RO

DU

CTS

A

ddre

ss: 7

408

MIS

SAU

KEE

BLVD

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / ATG 29' Attic Girder This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x8 SP 2400f-2.0E :T3 2x6 SPF 1650f-1.5E:Bot chord 2x12 SP 2400f-2.0E :B2 2x4 SPF #1/#2: Webs 2x4 SPF Stud :W2, W5, W13, W16 2x4 SPF #1/#2:

Nail Schedule:0.131"x3", min. nailsTop Chord: 2 Rows @ 6.00" o.c. (Each Row)Bot Chord: 1 Row @ 6.00" o.c.Webs : 1 Row @ 4" o.c.Repeat nailing as each layer is applied. Use equal spacingbetween rows and stagger nails in each row to avoid splitting.4" o.c. spacing of nails perpendicular and parallel tograin required in area over bearings greater than 4"

All plates are 3X4 except as noted.

(**) 6 plate(s) require special positioning. Refer toscaled plate plot details for special positioning requirements.

115 mph wind, 15.00 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.

Wind loads and reactions based on MWFRS with additional C&Cmember design.

End verticals not exposed to wind pressure. In lieu of structural panels or rigid ceiling use purlinsto laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) TC 24 10.69 18.31 BC 120 0.00 29.00Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Live loads applied in combination per ASCE 7 sec. 2.4.1 use 0.75factor for multiple live loads.

Trusses to be spaced at 12.0" OC maximum.

Collar-tie braced with continuous lateral bracing at 24" OC. or rigidceiling.

Deflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.

PLT TYP. WAVEDESC = ATG 29' Attic Girder

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 3 QTY= 0 REV. 15.02.00C.1217.15

Maximum Reactions (lbs)Loc R / U / Rw / Rh / RL / W

X 8935 / - / 7849 / - / 107 / 5.5R 8938 / - / 7853 / - / - / 5.5Wind reactions based on MWFRSX Min Brg Width Req = 3.2R Min Brg Width Req = 3.2Bearings X & R Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 23 0B - C 21 - 2676C - D 21 - 3283D - E 24 - 3268E - F 35 - 2006F - G 37 - 1486G - H 263 - 104H - I 333 - 107

Chords Tens. Comp.

I - J 333 - 107J - K 263 - 104K - L 37 - 1489L - M 35 - 2009M - N 24 - 3269N - O 21 - 3284O - P 21 - 2677P - Q 23 0

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

X - W 42 - 36W - V 1977 - 5V - U 2041 0

Chords Tens. Comp.

U - T 2041 0T - S 1975 0S - R 7 0

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

B - X 26 - 2795B - W 2159 0W - C 0 - 1177C - V 92 - 97E - Y 1412 - 2

Webs Tens. Comp.

AB- J 205 - 12AB-AC 17 - 2411AC- K 16 - 2336AC-AD 1 - 96AD- L 0 - 14

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 12.0 "

JOB #: 93049DATE - 11/28/16

ATG 29' Attic Girder

WEIGHT =1091.0

SEQ - 37749

TYPE ATIC

3 Complete Trusses Required

17'0"

15

7'9"13

17'0"15

10'7"1 7'9"13 10'7"1

18' 11'2' 2'

29'

2'3"

8

7'6"3 13'5"4 8'0"9

8'1"

14

16'

12'

8'1"2

LEFT RAKE = 2'1"6 RIGHT RAKE = 2'1"6

A

B

CD

E

F

G

H I J

K

L

M

NO

P

Q

RSTUVWX

Y Z

AA AB AC

AD AE

11

12

6X8

H0308 5X6(**)

3X4(**)7X8

3X10

6X12(**)

1.5X3

1.5X3

3X8

6X8

3X8

10X10

6X8

3X8

1.5X3

1.5X3

6X12(**)

3X10

7X83X4(**)

5X6(**)

6X8

H0308

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / AT2 29' Attic This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x8 SP 2400f-2.0E :T3 2x6 SPF 1650f-1.5E:Bot chord 2x12 SP 2400f-2.0E :B2 2x4 SPF #1/#2: Webs 2x4 SPF Stud :W2, W5, W13, W16 2x4 SPF #1/#2:

Full Height Blocking reinforcement required toprevent buckling of members over the bearings:bearing 2 located at 18.87'

All plates are 3X4 except as noted.

(**) 6 plate(s) require special positioning. Refer toscaled plate plot details for special positioning requirements.

115 mph wind, 15.00 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.

Wind loads and reactions based on MWFRS with additional C&Cmember design. End verticals not exposed to wind pressure.

In lieu of structural panels or rigid ceiling use purlinsto laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) TC 24 10.69 18.31 BC 120 0.00 29.00Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607.Live loads applied in combination per ASCE 7 sec. 2.4.1 use 0.75

factor for multiple live loads.Collar-tie braced with continuous lateral bracing at 24" OC. or rigidceiling.Attic room loading from 6-6-0 to 22-6-0: Live Load: 40 PSF. Dead

Load: 10 PSF Ceiling: 10 PSF, Kneewalls: 10 PSFDeflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.Truss designed for unbalanced snow load based on Pg=50.00 psf,

Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.

PLT TYP. WAVEDESC = AT2 29' Attic

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 0 REV. 15.02.00C.1217.15

Maximum Reactions (lbs)Loc R / U / Rw / Rh / RL / W

X 2121 / - / 603 / - / 214 / 5.5AF 1437 / - / 351 / - / - / 5.5R 1886 / 2 / 447 / - / - / 3.5Wind reactions based on MWFRSX Min Brg Width Req = 2.0AF Min Brg Width Req = 1.5R Min Brg Width Req = 1.8Bearings X, AF, & R Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 137 0B - C 143 - 1759C - D 158 - 1944D - E 176 - 1898E - F 228 - 1462F - G 236 - 1380G - H 169 - 902H - I 212 - 943

Chords Tens. Comp.

I - J 212 - 943J - K 171 - 875K - L 237 - 1371L - M 228 - 1452M - N 182 - 1696N - O 164 - 1741O - P 155 - 1515P - Q 137 0

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

X - W 214 - 214W - V 1238 - 92V - U 1225 - 45

Chords Tens. Comp.

U - T 2449 - 90T - S 1028 - 8S - R 3 - 1

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

B - X 174 - 2021B - W 1359 0W - C 22 - 497

Webs Tens. Comp.

AB- J 545 - 72AB-AC 126 - 923AC- K 122 - 837

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 24.0 "

JOB #: 93049DATE - 11/28/16

AT2 29' Attic

WEIGHT =363.7

SEQ - 37762

TYPE ATIC

19'1"4 9'10"12

17'0"

15

7'9"13

17'0"15

10'7"1 7'9"13 10'7"1

18' 11'2' 2'

29'

2'3"

8

7'6"3 13'5"4 8'0"9

8'1"

14

16'

12'

8'1"2

LEFT RAKE = 2'1"6 RIGHT RAKE = 2'1"6

A

B

CD

E

F

G

H I J

K

L

M

NO

P

Q

RSTUVWX

Y Z

AA AB AC

AD AE

AF

11

12

6X8

H0308 5X6(**)

3X4(**)7X8

3X10

6X12(**)

1.5X3

1.5X3

3X8

6X8

3X8

10X10

6X8

3X8

1.5X3

1.5X3

6X12(**)

3X10

7X83X4(**)

5X6(**)

6X8

H0308

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / AT2 29' Attic This dwg. prepared by the ITW job designer program from truss mfr's layout.

PLT TYP. WAVEDESC = AT2 29' Attic

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 0 REV. 15.02.00C.1217.15

C - V 131 - 134E - Y 763 0V - Y 745 0Y - Z 12 - 38F - Z 1 - 13Z -AA 12 - 38G -AA 125 - 726AA-AB 132 - 744H -AB 388 - 78I -AB 74 - 305

AC-AD 6 - 123AD- L 9 - 1AD-AE 6 - 123AE- T 393 - 79AE- M 469 - 79T - O 530 - 96O - S 80 - 778S - P 1125 - 9P - R 185 - 1823

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 24.0 "

JOB #: 93049DATE - 11/28/16

AT2 29' Attic

WEIGHT =363.7

SEQ - 37762

TYPE ATIC

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / AT1 29' Attic This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x8 SP 2400f-2.0E :T3 2x6 SPF 1650f-1.5E:Bot chord 2x12 SP 2400f-2.0E :B2 2x4 SPF #1/#2: Webs 2x4 SPF Stud :W2, W5, W13, W16 2x4 SPF #1/#2:

Full Height Blocking reinforcement required toprevent buckling of members over the bearings:bearing 1 located at 0.00' bearing 2 located at 28.54'

All plates are 3X4 except as noted.

(**) 6 plate(s) require special positioning. Refer toscaled plate plot details for special positioning requirements.

115 mph wind, 15.00 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.

Wind loads and reactions based on MWFRS with additional C&Cmember design. End verticals not exposed to wind pressure.

In lieu of structural panels or rigid ceiling use purlinsto laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) TC 24 10.69 18.31 BC 120 0.00 29.00Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607.Live loads applied in combination per ASCE 7 sec. 2.4.1 use 0.75

factor for multiple live loads.Collar-tie braced with continuous lateral bracing at 24" OC. or rigidceiling.Attic room loading from 6-6-0 to 22-6-0: Live Load: 40 PSF. Dead

Load: 10 PSF Ceiling: 10 PSF, Kneewalls: 10 PSFDeflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.Truss designed for unbalanced snow load based on Pg=50.00 psf,

Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.

PLT TYP. WAVEDESC = AT1 29' Attic

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 19 REV. 15.02.00C.1217.15

Maximum Reactions (lbs)Loc R / U / Rw / Rh / RL / W

X 2542 / - / 663 / - / 214 / 5.5R 2542 / - / 663 / - / - / 5.5Wind reactions based on MWFRSX Min Brg Width Req = 2.4R Min Brg Width Req = 2.4Bearings X & R Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 137 0B - C 127 - 2214C - D 126 - 2840D - E 144 - 2794E - F 213 - 1826F - G 221 - 1756G - H 173 - 829H - I 216 - 868

Chords Tens. Comp.

I - J 216 - 868J - K 174 - 829K - L 221 - 1759L - M 213 - 1828M - N 144 - 2795N - O 126 - 2841O - P 127 - 2214P - Q 137 0

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

X - W 215 - 213W - V 1591 - 29V - U 1849 0

Chords Tens. Comp.

U - T 1849 0T - S 1591 0S - R 5 0

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

B - X 158 - 2488B - W 1733 0W - C 0 - 1246C - V 554 - 90E - Y 1456 0

Webs Tens. Comp.

AB- J 468 - 73AB-AC 101 - 1728AC- K 96 - 1656AC-AD 8 - 99AD- L 2 - 6

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 24.0 "

JOB #: 93049DATE - 11/28/16

AT1 29' Attic

WEIGHT =363.7

SEQ - 37760

TYPE ATIC

17'0"15

7'9"13

17'0"15

10'7"1 7'9"13 10'7"1

18' 11'2' 2'

29'

2'3"

8

7'6"3 13'5"4 8'0"9

8'1"

14

16'

12'

8'1"2

LEFT RAKE = 2'1"6 RIGHT RAKE = 2'1"6

A

B

CD

E

F

G

H I J

K

L

M

NO

P

Q

RSTUVWX

Y Z

AA AB AC

AD AE

11

12

6X8

H0308 5X6(**)

3X4(**)7X8

3X10

6X12(**)

1.5X3

1.5X3

3X8

6X8

3X8

10X10

6X8

3X8

1.5X3

1.5X3

6X12(**)

3X10

7X83X4(**)

5X6(**)

6X8

H0308

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / AT1 29' Attic This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x8 SP 2400f-2.0E :T3 2x6 SPF 1650f-1.5E:Bot chord 2x12 SP 2400f-2.0E :B2 2x4 SPF #1/#2: Webs 2x4 SPF Stud :W2, W5, W13, W16 2x4 SPF #1/#2:

Full Height Blocking reinforcement required toprevent buckling of members over the bearings:bearing 1 located at 0.00' bearing 2 located at 28.54'

All plates are 3X4 except as noted.

(**) 6 plate(s) require special positioning. Refer toscaled plate plot details for special positioning requirements.

115 mph wind, 15.00 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.

Wind loads and reactions based on MWFRS with additional C&Cmember design. End verticals not exposed to wind pressure.

In lieu of structural panels or rigid ceiling use purlinsto laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) TC 24 10.69 18.31 BC 120 0.00 29.00Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607.Live loads applied in combination per ASCE 7 sec. 2.4.1 use 0.75

factor for multiple live loads.Collar-tie braced with continuous lateral bracing at 24" OC. or rigidceiling.Attic room loading from 6-6-0 to 22-6-0: Live Load: 40 PSF. Dead

Load: 10 PSF Ceiling: 10 PSF, Kneewalls: 10 PSFDeflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.Truss designed for unbalanced snow load based on Pg=50.00 psf,

Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.

PLT TYP. WAVEDESC = AT1 29' Attic

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 19 REV. 15.02.00C.1217.15

Maximum Reactions (lbs)Loc R / U / Rw / Rh / RL / W

X 2542 / - / 663 / - / 214 / 5.5R 2542 / - / 663 / - / - / 5.5Wind reactions based on MWFRSX Min Brg Width Req = 2.4R Min Brg Width Req = 2.4Bearings X & R Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 137 0B - C 127 - 2214C - D 126 - 2840D - E 144 - 2794E - F 213 - 1826F - G 221 - 1756G - H 173 - 829H - I 216 - 868

Chords Tens. Comp.

I - J 216 - 868J - K 174 - 829K - L 221 - 1759L - M 213 - 1828M - N 144 - 2795N - O 126 - 2841O - P 127 - 2214P - Q 137 0

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

X - W 215 - 213W - V 1591 - 29V - U 1849 0

Chords Tens. Comp.

U - T 1849 0T - S 1591 0S - R 5 0

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

B - X 158 - 2488B - W 1733 0W - C 0 - 1246C - V 554 - 90E - Y 1456 0

Webs Tens. Comp.

AB- J 468 - 73AB-AC 101 - 1728AC- K 96 - 1656AC-AD 8 - 99AD- L 2 - 6

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 24.0 "

JOB #: 93049DATE - 11/28/16

AT1 29' Attic

WEIGHT =363.7

SEQ - 37760

TYPE ATIC

17'0"15

7'9"13

17'0"15

10'7"1 7'9"13 10'7"1

18' 11'2' 2'

29'

2'3"

8

7'6"3 13'5"4 8'0"9

8'1"

14

16'

12'

8'1"2

LEFT RAKE = 2'1"6 RIGHT RAKE = 2'1"6

A

B

CD

E

F

G

H I J

K

L

M

NO

P

Q

RSTUVWX

Y Z

AA AB AC

AD AE

11

12

6X8

H0308 5X6(**)

3X4(**)7X8

3X10

6X12(**)

1.5X3

1.5X3

3X8

6X8

3X8

10X10

6X8

3X8

1.5X3

1.5X3

6X12(**)

3X10

7X83X4(**)

5X6(**)

6X8

H0308

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / AT1 29' Attic This dwg. prepared by the ITW job designer program from truss mfr's layout.

PLT TYP. WAVEDESC = AT1 29' Attic

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 19 REV. 15.02.00C.1217.15

V - Y 1395 0Y - Z 8 - 102F - Z 1 - 10Z -AA 8 - 102G -AA 95 - 1653AA-AB 101 - 1729H -AB 468 - 73I -AB 74 - 299

AD-AE 8 - 99AE- T 1397 0AE- M 1454 0T - O 554 - 91O - S 0 - 1248S - P 1733 0P - R 157 - 2488

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 24.0 "

JOB #: 93049DATE - 11/28/16

AT1 29' Attic

WEIGHT =363.7

SEQ - 37760

TYPE ATIC

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / S1 29' Scissor This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x4 SP 2850f-2.3EBot chord 2x4 SP 2850f-2.3E Webs 2x4 SPF Stud :W9, W13 2x4 SPF #1/#2:

All plates are 3X5 except as noted. 115 mph wind, 15.00 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.Wind loads and reactions based on MWFRS with additional C&C

member design.End verticals not exposed to wind pressure. Calculated horizontal deflection is 0.61" due to live load and 0.32"

due to dead load.In lieu of structural panels or rigid ceiling use purlinsto laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) TC 24 10.65 18.35 BC 75 0.24 10.32 BC 100 10.32 18.68 BC 75 18.68 28.76Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607. Trusses to be spaced at 16.0" OC maximum.

Deflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.

Truss designed for balanced snow load based on Pg=50.00 psf,Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.

PLT TYP. WAVEDESC = S1 29' Scissor

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 12 REV. 15.02.00C.1217.15

Maximum Reactions (lbs)Loc R / U / Rw / Rh / RL / W

X 1338 / - / 480 / - / 143 / 5.5N 1338 / - / 480 / - / - / 5.5Wind reactions based on MWFRSX Min Brg Width Req = 1.5N Min Brg Width Req = 1.5Bearings X & N Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 94 0B - C 35 - 1517C - D 0 - 2780D - E 0 - 3750E - F 0 - 4385F - G 0 - 3146

Chords Tens. Comp.

G - H 0 - 3146H - I 0 - 4385I - J 0 - 3750J - K 0 - 2780K - L 29 - 1517L - M 94 0

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

X - W 151 - 242W - V 1489 - 113V - U 2788 - 33U - T 3724 0T - S 2886 0

Chords Tens. Comp.

S - R 2886 0R - Q 3724 0Q - P 2788 0P - O 1489 0O - N 26 - 204

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

B - X 95 - 1196B - W 1188 0W - C 0 - 1020C - V 923 0V - D 0 - 852

Webs Tens. Comp.

S - H 314 - 46H - R 2538 0R - I 462 - 32I - Q 0 - 597Q - J 670 0

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 16.0 "

JOB #: 93049DATE - 11/28/16

S1 29' Scissor

WEIGHT =203.2

SEQ - 37764

TYPE SCIS

17'0"15

7'9"13

17'0"15

13'5"8

8'2"15

13'5"8

10'7"1 7'9"13 10'7"1

10'4"9 8'2"15 10'4"92' 2'

29'

2'3"

8

9'1"

2

12'

8'1"2

LEFT RAKE = 2'8"9 RIGHT RAKE = 2'8"9

A

B

C

D

E

F G H

I

J

K

L

M

N

O

P

Q

RST

U

V

W

X

11

12

1112

3X6

1.5X4

5X5

3X4

3X4

6X8

6X81.5X3

3X8

6X8

6X8

3X4

3X4

5X5

1.5X4

3X6

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / S1 29' Scissor This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x4 SP 2850f-2.3EBot chord 2x4 SP 2850f-2.3E Webs 2x4 SPF Stud :W9, W13 2x4 SPF #1/#2:

All plates are 3X5 except as noted. 115 mph wind, 15.00 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.Wind loads and reactions based on MWFRS with additional C&C

member design.End verticals not exposed to wind pressure. Calculated horizontal deflection is 0.61" due to live load and 0.32"

due to dead load.In lieu of structural panels or rigid ceiling use purlinsto laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) TC 24 10.65 18.35 BC 75 0.24 10.32 BC 100 10.32 18.68 BC 75 18.68 28.76Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607. Trusses to be spaced at 16.0" OC maximum.

Deflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.

Truss designed for balanced snow load based on Pg=50.00 psf,Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.

PLT TYP. WAVEDESC = S1 29' Scissor

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 12 REV. 15.02.00C.1217.15

Maximum Reactions (lbs)Loc R / U / Rw / Rh / RL / W

X 1338 / - / 480 / - / 143 / 5.5N 1338 / - / 480 / - / - / 5.5Wind reactions based on MWFRSX Min Brg Width Req = 1.5N Min Brg Width Req = 1.5Bearings X & N Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 94 0B - C 35 - 1517C - D 0 - 2780D - E 0 - 3750E - F 0 - 4385F - G 0 - 3146

Chords Tens. Comp.

G - H 0 - 3146H - I 0 - 4385I - J 0 - 3750J - K 0 - 2780K - L 29 - 1517L - M 94 0

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

X - W 151 - 242W - V 1489 - 113V - U 2788 - 33U - T 3724 0T - S 2886 0

Chords Tens. Comp.

S - R 2886 0R - Q 3724 0Q - P 2788 0P - O 1489 0O - N 26 - 204

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

B - X 95 - 1196B - W 1188 0W - C 0 - 1020C - V 923 0V - D 0 - 852

Webs Tens. Comp.

S - H 314 - 46H - R 2538 0R - I 462 - 32I - Q 0 - 597Q - J 670 0

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 16.0 "

JOB #: 93049DATE - 11/28/16

S1 29' Scissor

WEIGHT =203.2

SEQ - 37764

TYPE SCIS

17'0"15

7'9"13

17'0"15

13'5"8

8'2"15

13'5"8

10'7"1 7'9"13 10'7"1

10'4"9 8'2"15 10'4"92' 2'

29'

2'3"

8

9'1"

2

12'

8'1"2

LEFT RAKE = 2'8"9 RIGHT RAKE = 2'8"9

A

B

C

D

E

F G H

I

J

K

L

M

N

O

P

Q

RST

U

V

W

X

11

12

1112

3X6

1.5X4

5X5

3X4

3X4

6X8

6X81.5X3

3X8

6X8

6X8

3X4

3X4

5X5

1.5X4

3X6

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / S1 29' Scissor This dwg. prepared by the ITW job designer program from truss mfr's layout.

PLT TYP. WAVEDESC = S1 29' Scissor

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 12 REV. 15.02.00C.1217.15

D - U 670 0U - E 0 - 597E - T 462 0T - F 2538 0F - S 314 - 41G - S 60 - 263

J - P 0 - 852P - K 923 0K - O 0 - 1020O - L 1188 0N - L 79 - 1196

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 16.0 "

JOB #: 93049DATE - 11/28/16

S1 29' Scissor

WEIGHT =203.2

SEQ - 37764

TYPE SCIS

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / GS1 29' Gable This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x4 SPF #1/#2Bot chord 2x4 SPF #1/#2 Webs 2x4 SPF Stud :W9, W13 2x4 SPF #1/#2:

All plates are 1.5X3 except as noted. 115 mph wind, 15.00 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.Wind loads and reactions based on MWFRS with additional C&C

member design.End verticals not exposed to wind pressure. Truss designed to support 1-4-0 top chord outlookers and cladding

load not to exceed 2.00 PSF one face and 16.0" span opposite face.Top chord must not be cut or notched.

See DWGS A11515ENC101014, GBLLETIN1014, & GABRST101014for gable wind bracing requirements.In lieu of structural panels or rigid ceiling use purlins

to laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) TC 24 10.65 18.35 BC 75 0.24 10.32 BC 100 10.32 18.68 BC 75 18.68 28.76Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607.

Trusses to be spaced at 16.0" OC maximum.

Deflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.Truss designed for balanced snow load based on Pg=50.00 psf,

Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.Shim all supports to solid bearing.

PLT TYP. WAVEDESC = GS1 29' Gable

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 1 REV. 15.02.00C.1217.15

Maximum Reactions (lbs), or *=PLFLoc R / U / Rw / Rh / RL / W

AL 1008 / 261 / 423 / - / 286 / 5.5AE*355 / - / 128 / - / - / 98.9T 1006 / 261 / 444 / - / - / 5.5Wind reactions based on MWFRSAL Min Brg Width Req = 1.7AE Min Brg Width Req = -T Min Brg Width Req = 1.7Bearing AE is a rigid surface.Bearings AL & T Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 191 0B - C 258 - 713C - D 324 - 828D - E 354 - 728E - F 257 - 459F - G 284 - 383G - H 764 - 127H - I 354 - 5I - J 354 - 5

Chords Tens. Comp.

J - K 354 - 5K - L 354 - 5L - M 762 - 10M - N 284 - 382N - O 258 - 458O - P 355 - 726P - Q 321 - 826Q - R 264 - 710R - S 191 0

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

AL-AK 343 - 417AK-AJ 358 - 416AJ-AI 553 - 343AI-AH 721 - 266AH-AG 735 - 261AG-AF 356 - 179AF-AE 363 - 177AE-AD 410 - 393

Chords Tens. Comp.

AC-AB 410 - 392AB-AA 410 - 392AA- Z 363 0Z - Y 355 0Y - X 733 - 35X - W 719 - 39W - V 550 - 74V - U 65 - 152

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 16.0 "

JOB #: 93049DATE - 11/28/16

GS1 29' Gable

WEIGHT =239.6

SEQ - 37772

TYPE GABL

10'4"9 8'2"15 10'4"9

17'0"15

7'9"13

17'0"15

13'5"8

8'2"15

13'5"8

10'7"1 7'9"13 10'7"1

10'4"9 8'2"15 10'4"92' 2'

29'

2'3"

8

9'1"

2

12'

8'1"2

17'2"4

LEFT RAKE = 2'8"9 RIGHT RAKE = 2'8"9

A

B

C

D

E

F

G

H I J K L

M

N

O

P

Q

R

S

TU

V

W

X

YZ

AAABACADAE

AFAG

AH

AI

AJ

AKAL

AM

AN

AO

AP

AQAR

ASAT

AU

AV

AW

AX

11

12

1112

3X4

3X4

3X4

3X4

5X53X6

3X4

3X4

4X6

4X6

3X8

4X6

4X6

3X4

3X4

3X65X5

3X4

3X4

3X4

3X4

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / GS1 29' Gable This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x4 SPF #1/#2Bot chord 2x4 SPF #1/#2 Webs 2x4 SPF Stud :W9, W13 2x4 SPF #1/#2:

All plates are 1.5X3 except as noted. 115 mph wind, 15.00 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.Wind loads and reactions based on MWFRS with additional C&C

member design.End verticals not exposed to wind pressure. Truss designed to support 1-4-0 top chord outlookers and cladding

load not to exceed 2.00 PSF one face and 16.0" span opposite face.Top chord must not be cut or notched.

See DWGS A11515ENC101014, GBLLETIN1014, & GABRST101014for gable wind bracing requirements.In lieu of structural panels or rigid ceiling use purlins

to laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) TC 24 10.65 18.35 BC 75 0.24 10.32 BC 100 10.32 18.68 BC 75 18.68 28.76Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607.

Trusses to be spaced at 16.0" OC maximum.

Deflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.Truss designed for balanced snow load based on Pg=50.00 psf,

Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.Shim all supports to solid bearing.

PLT TYP. WAVEDESC = GS1 29' Gable

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 1 REV. 15.02.00C.1217.15

Maximum Reactions (lbs), or *=PLFLoc R / U / Rw / Rh / RL / W

AL 1008 / 261 / 423 / - / 286 / 5.5AE*355 / - / 128 / - / - / 98.9T 1006 / 261 / 444 / - / - / 5.5Wind reactions based on MWFRSAL Min Brg Width Req = 1.7AE Min Brg Width Req = -T Min Brg Width Req = 1.7Bearing AE is a rigid surface.Bearings AL & T Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 191 0B - C 258 - 713C - D 324 - 828D - E 354 - 728E - F 257 - 459F - G 284 - 383G - H 764 - 127H - I 354 - 5I - J 354 - 5

Chords Tens. Comp.

J - K 354 - 5K - L 354 - 5L - M 762 - 10M - N 284 - 382N - O 258 - 458O - P 355 - 726P - Q 321 - 826Q - R 264 - 710R - S 191 0

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

AL-AK 343 - 417AK-AJ 358 - 416AJ-AI 553 - 343AI-AH 721 - 266AH-AG 735 - 261AG-AF 356 - 179AF-AE 363 - 177AE-AD 410 - 393

Chords Tens. Comp.

AC-AB 410 - 392AB-AA 410 - 392AA- Z 363 0Z - Y 355 0Y - X 733 - 35X - W 719 - 39W - V 550 - 74V - U 65 - 152

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 16.0 "

JOB #: 93049DATE - 11/28/16

GS1 29' Gable

WEIGHT =239.6

SEQ - 37772

TYPE GABL

10'4"9 8'2"15 10'4"9

17'0"15

7'9"13

17'0"15

13'5"8

8'2"15

13'5"8

10'7"1 7'9"13 10'7"1

10'4"9 8'2"15 10'4"92' 2'

29'

2'3"

8

9'1"

2

12'

8'1"2

17'2"4

LEFT RAKE = 2'8"9 RIGHT RAKE = 2'8"9

A

B

C

D

E

F

G

H I J K L

M

N

O

P

Q

R

S

TU

V

W

X

YZ

AAABACADAE

AFAG

AH

AI

AJ

AKAL

AM

AN

AO

AP

AQAR

ASAT

AU

AV

AW

AX

11

12

1112

3X4

3X4

3X4

3X4

5X53X6

3X4

3X4

4X6

4X6

3X8

4X6

4X6

3X4

3X4

3X65X5

3X4

3X4

3X4

3X4

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / GS1 29' Gable This dwg. prepared by the ITW job designer program from truss mfr's layout.

PLT TYP. WAVEDESC = GS1 29' Gable

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 1 REV. 15.02.00C.1217.15

AD-AC 410 - 393 U - T 60 - 172

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

B -AL 299 - 879B -AM 495 - 77AM-AJ 495 - 77AJ- C 102 - 424C -AN 139 - 5AN-AI 130 - 6AI- E 63 - 35E -AO 133 - 259AO-AG 134 - 263AG- G 290 - 113G -AP 279 - 744AP-AE 279 - 744AE- H 107 - 737H -AQ 85 - 54AR-AC 86 - 54J -AC 60 - 279

Webs Tens. Comp.

AC-AS 85 - 39AT- L 85 - 39L -AA 37 - 735AA-AU 279 - 742AU- M 280 - 742M - Y 289 - 113Y -AV 133 - 262AV- O 132 - 258O - W 49 - 29W -AW 130 0AW- Q 139 0Q - V 99 - 422V -AX 494 - 74AX- R 493 - 74T - R 300 - 877

Maximum Gable Forces Per Ply (lbs)Gables Tens.Comp.

AM-AK 16 - 28D -AN 41 - 94F -AO 20 - 45AO-AH 19 - 11AP-AF 20 0AQ- I 63 - 307AD-AR 63 - 309

Gables Tens. Comp.

AS-AB 63 - 308K -AT 63 - 307Z -AU 20 0X -AV 19 - 11AV- N 20 - 45AW- P 40 - 94U -AX 16 - 28

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 16.0 "

JOB #: 93049DATE - 11/28/16

GS1 29' Gable

WEIGHT =239.6

SEQ - 37772

TYPE GABL

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / T1 14'10"8 Special This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x4 SPF #1/#2Bot chord 2x4 SPF #1/#2 Webs 2x4 SPF Stud

115 mph wind, 21.23 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.

Wind loads and reactions based on MWFRS with additional C&Cmember design.

(J) Hanger Support Required, by others(J) Hanger Support Required, by others

In lieu of structural panels or rigid ceiling use purlinsto laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) TC 24 0.00 2.16 TC 24 12.71 14.88 BC 120 0.00 14.88Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607.

Deflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.

Truss designed for balanced snow load based on Pg=50.00 psf,Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.

PLT TYP. WAVEDESC = T1 14'10"8 Special

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 4 REV. 15.02.00C.1217.15

Maximum Reactions (lbs)Loc R / U / Rw / Rh / RL / W

H 885 / 7 / 293 / - / 83 / -F 885 / 7 / 293 / - / - / -Wind reactions based on MWFRSH Min Brg Width Req = -F Min Brg Width Req = -

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 0 - 23B - C 74 - 956

Chords Tens. Comp.

C - D 74 - 956D - E 0 - 23

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

H - G 1194 - 103

Chords Tens. Comp.

G - F 1194 - 103

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

A - H 31 - 110H - B 128 - 1379B - G 125 - 609C - G 471 0

Webs Tens. Comp.

G - D 125 - 609D - F 128 - 1379E - F 31 - 110

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 24.0 "

JOB #: 93049DATE - 11/28/16

T1 14'10"8 Special

WEIGHT =89.4

SEQ - 37709

TYPE SPEC

2'1"5

7'2"12 7'2"12

2'1"5

2'1"5 5'3"15 5'3"15 2'1"5

14'10"8

1'7"

4

6'5"

14

17'2"4

LEFT RAKE = 2'8"9 RIGHT RAKE = 2'8"9

A B

C

D E

FGH

11

12

1.5X3

4X4

5X5

4X6

3X8

5X51.5X3

4X4

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / T1 14'10"8 Special This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x4 SPF #1/#2Bot chord 2x4 SPF #1/#2 Webs 2x4 SPF Stud

115 mph wind, 21.23 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.

Wind loads and reactions based on MWFRS with additional C&Cmember design.

(J) Hanger Support Required, by others(J) Hanger Support Required, by others

In lieu of structural panels or rigid ceiling use purlinsto laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) TC 24 0.00 2.16 TC 24 12.71 14.88 BC 120 0.00 14.88Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607.

Deflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.

Truss designed for balanced snow load based on Pg=50.00 psf,Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.

PLT TYP. WAVEDESC = T1 14'10"8 Special

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 4 REV. 15.02.00C.1217.15

Maximum Reactions (lbs)Loc R / U / Rw / Rh / RL / W

H 885 / 7 / 293 / - / 83 / -F 885 / 7 / 293 / - / - / -Wind reactions based on MWFRSH Min Brg Width Req = -F Min Brg Width Req = -

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 0 - 23B - C 74 - 956

Chords Tens. Comp.

C - D 74 - 956D - E 0 - 23

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

H - G 1194 - 103

Chords Tens. Comp.

G - F 1194 - 103

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

A - H 31 - 110H - B 128 - 1379B - G 125 - 609C - G 471 0

Webs Tens. Comp.

G - D 125 - 609D - F 128 - 1379E - F 31 - 110

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 24.0 "

JOB #: 93049DATE - 11/28/16

T1 14'10"8 Special

WEIGHT =89.4

SEQ - 37709

TYPE SPEC

2'1"5

7'2"12 7'2"12

2'1"5

2'1"5 5'3"15 5'3"15 2'1"5

14'10"8

1'7"

4

6'5"

14

17'2"4

LEFT RAKE = 2'8"9 RIGHT RAKE = 2'8"9

A B

C

D E

FGH

11

12

1.5X3

4X4

5X5

4X6

3X8

5X51.5X3

4X4

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / T2 8' Common This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x4 SPF #1/#2Bot chord 2x4 SPF #1/#2 Webs 2x4 SPF Stud

115 mph wind, 19.35 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.

Wind loads and reactions based on MWFRS with additional C&Cmember design.

In lieu of structural panels or rigid ceiling use purlinsto laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) BC 96 0.00 8.00Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607.

Deflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.

Truss designed for balanced snow load based on Pg=50.00 psf,Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.

PLT TYP. WAVEDESC = T2 8' Common

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 6 REV. 15.02.00C.1217.15

Maximum Reactions (lbs)Loc R / U / Rw / Rh / RL / W

H 607 / 8 / 207 / - / 79 / 3.5F 607 / 8 / 207 / - / - / 3.5Wind reactions based on MWFRSH Min Brg Width Req = 1.5F Min Brg Width Req = 1.5Bearings H & F Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 82 0B - C 56 - 439

Chords Tens. Comp.

C - D 56 - 439D - E 82 0

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

H - G 83 - 79

Chords Tens. Comp.

G - F 13 - 2

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

B - H 103 - 574B - G 253 - 2C - G 139 - 10

Webs Tens. Comp.

G - D 253 - 3D - F 102 - 574

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 24.0 "

JOB #: 93049DATE - 11/28/16

T2 8' Common

WEIGHT =49.7

SEQ - 37685

TYPE COMN

6'8" 6'8"

4' 4'

8'1'4" 1'4"

1'2"

4'2"

4'4"

6

17'2"4

LEFT RAKE = 1'8" RIGHT RAKE = 1'8"

A

B

C

D

E

FGH

912

3X4

1.5X4

4X4

3X8

3X4

1.5X4

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / T2 8' Common This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x4 SPF #1/#2Bot chord 2x4 SPF #1/#2 Webs 2x4 SPF Stud

115 mph wind, 19.35 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.

Wind loads and reactions based on MWFRS with additional C&Cmember design.

In lieu of structural panels or rigid ceiling use purlinsto laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) BC 96 0.00 8.00Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607.

Deflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.

Truss designed for balanced snow load based on Pg=50.00 psf,Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.

PLT TYP. WAVEDESC = T2 8' Common

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 6 REV. 15.02.00C.1217.15

Maximum Reactions (lbs)Loc R / U / Rw / Rh / RL / W

H 607 / 8 / 207 / - / 79 / 3.5F 607 / 8 / 207 / - / - / 3.5Wind reactions based on MWFRSH Min Brg Width Req = 1.5F Min Brg Width Req = 1.5Bearings H & F Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 82 0B - C 56 - 439

Chords Tens. Comp.

C - D 56 - 439D - E 82 0

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

H - G 83 - 79

Chords Tens. Comp.

G - F 13 - 2

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

B - H 103 - 574B - G 253 - 2C - G 139 - 10

Webs Tens. Comp.

G - D 253 - 3D - F 102 - 574

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 24.0 "

JOB #: 93049DATE - 11/28/16

T2 8' Common

WEIGHT =49.7

SEQ - 37685

TYPE COMN

6'8" 6'8"

4' 4'

8'1'4" 1'4"

1'2"

4'2"

4'4"

6

17'2"4

LEFT RAKE = 1'8" RIGHT RAKE = 1'8"

A

B

C

D

E

FGH

912

3X4

1.5X4

4X4

3X8

3X4

1.5X4

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / TG1 8' Special Girder This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x4 SPF #1/#2Bot chord 2x6 SP 2700f-2.0E Webs 2x4 SPF Stud

Special loads------(Lumber Dur.Fac.=1.15 / Plate Dur.Fac.=1.15) TC- From 98 plf at -1.33 to 98 plf at 0.85 TC- From 49 plf at 0.85 to 49 plf at 4.00 TC- From 49 plf at 4.00 to 49 plf at 6.85 TC- From 98 plf at 6.85 to 98 plf at 9.33 BC- From 5 plf at -1.33 to 5 plf at 0.00 BC- From 10 plf at 0.00 to 10 plf at 8.00 BC- From 5 plf at 8.00 to 5 plf at 9.33 BC- 885.00 lb Conc. Load at 0.85, 2.85, 4.85, 6.85

115 mph wind, 19.35 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.

Wind loads and reactions based on MWFRS. In lieu of structural panels or rigid ceiling use purlinsto laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) BC 96 0.00 8.00Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607.

Deflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.

Truss designed for balanced snow load based on Pg=50.00 psf,Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.

PLT TYP. WAVEDESC = TG1 8' Special Girder

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 2 REV. 15.02.00C.1217.15

Maximum Reactions (lbs)Loc R / U / Rw / Rh / RL / W

H 2250 / 43 / - / - / - / 3.5F 2131 / 44 / - / - / - / 3.5Wind reactions based on MWFRSH Min Brg Width Req = 2.1F Min Brg Width Req = 2.0Bearings H & F Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 82 - 11B - C 22 - 1672

Chords Tens. Comp.

C - D 23 - 1679D - E 82 - 11

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

H - G 31 0

Chords Tens. Comp.

G - F 33 0

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

B - H 46 - 1467B - G 1257 - 8C - G 1718 - 7

Webs Tens. Comp.

G - D 1256 - 8D - F 48 - 1478

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 24.0 "

JOB #: 93049DATE - 11/28/16

TG1 8' Special Girder

WEIGHT =54.7

SEQ - 37712

TYPE SPEC

6'8" 6'8"

4' 4'

8'1'4" 1'4"

1'2"

4'2"

4'4"

6

17'2"4

LEFT RAKE = 1'8" RIGHT RAKE = 1'8"

A

B

C

D

E

FGH

912

3X8

2X6

4X6

7X8

3X8

2X6

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / TG1 8' Special Girder This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x4 SPF #1/#2Bot chord 2x6 SP 2700f-2.0E Webs 2x4 SPF Stud

Special loads------(Lumber Dur.Fac.=1.15 / Plate Dur.Fac.=1.15) TC- From 98 plf at -1.33 to 98 plf at 0.85 TC- From 49 plf at 0.85 to 49 plf at 4.00 TC- From 49 plf at 4.00 to 49 plf at 6.85 TC- From 98 plf at 6.85 to 98 plf at 9.33 BC- From 5 plf at -1.33 to 5 plf at 0.00 BC- From 10 plf at 0.00 to 10 plf at 8.00 BC- From 5 plf at 8.00 to 5 plf at 9.33 BC- 885.00 lb Conc. Load at 0.85, 2.85, 4.85, 6.85

115 mph wind, 19.35 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.

Wind loads and reactions based on MWFRS. In lieu of structural panels or rigid ceiling use purlinsto laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) BC 96 0.00 8.00Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607.

Deflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00.

Truss designed for balanced snow load based on Pg=50.00 psf,Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.

PLT TYP. WAVEDESC = TG1 8' Special Girder

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 2 REV. 15.02.00C.1217.15

Maximum Reactions (lbs)Loc R / U / Rw / Rh / RL / W

H 2250 / 43 / - / - / - / 3.5F 2131 / 44 / - / - / - / 3.5Wind reactions based on MWFRSH Min Brg Width Req = 2.1F Min Brg Width Req = 2.0Bearings H & F Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 82 - 11B - C 22 - 1672

Chords Tens. Comp.

C - D 23 - 1679D - E 82 - 11

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

H - G 31 0

Chords Tens. Comp.

G - F 33 0

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

B - H 46 - 1467B - G 1257 - 8C - G 1718 - 7

Webs Tens. Comp.

G - D 1256 - 8D - F 48 - 1478

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 24.0 "

JOB #: 93049DATE - 11/28/16

TG1 8' Special Girder

WEIGHT =54.7

SEQ - 37712

TYPE SPEC

6'8" 6'8"

4' 4'

8'1'4" 1'4"

1'2"

4'2"

4'4"

6

17'2"4

LEFT RAKE = 1'8" RIGHT RAKE = 1'8"

A

B

C

D

E

FGH

912

3X8

2X6

4X6

7X8

3X8

2X6

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / G2 8' Gable This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x4 SPF #1/#2Bot chord 2x4 SPF #1/#2 Webs 2x4 SPF Stud

All plates are 1.5X3 except as noted. 115 mph wind, 19.35 ft mean hgt, ASCE 7-10, CLOSED bldg,Located anywhere in roof, RISK CAT II, EXP B, wind TC DL=4.2 psf,wind BC DL=6.0 psf.Wind loads and reactions based on MWFRS with additional C&C

member design.The studded portion of the truss is designed to support 1-4-0 topchord outlookers and 2.00 PSF cladding load one face, and 24.0"span on opposite face. Top chord must not be cut or notched.Vertical and roof plane diaphragms, and connections by others.

See DWGS A11530ENC101014, GBLLETIN1014, & GABRST101014for gable wind bracing requirements.In lieu of structural panels or rigid ceiling use purlins

to laterally brace chords as follows: CHORD SPACING(IN OC) START(FT) END(FT) BC 96 0.00 8.00Apply purlins to any chords above or below fillersat 24" OC unless shown otherwise above.

Bottom chord checked for 10.00 psf non-concurrent bottom chordlive load applied per IBC-15 section 1607.

Deflection meets L/360 live and L/240 total load. Creep increasefactor for dead load is 2.00. Truss designed for balanced snow load based on Pg=50.00 psf,

Ct=1.10, Ce=1.00, CAT II & Pf=38.50 psf.Fasten rated sheathing to one face of this frame.

PLT TYP. WAVEDESC = G2 8' Gable

DESIGN CRIT=IBC 2015 /TPI-2014 FT/RT=3%(0%)/0(0) PLY= 1 QTY= 2 REV. 15.02.00C.1217.15

Maximum Reactions (lbs), or *=PLFLoc R / U / Rw / Rh / RL / W

L* 166 / 22 / 44 / - / 14 / 96.0H 383 / 177 / 101 / - / - / 3.5Wind reactions based on MWFRSL Min Brg Width Req = -H Min Brg Width Req = 1.5Bearings L & H Fcperp = 565psi.

Maximum Top Chord Forces Per Ply (lbs)Chords Tens.Comp.

A - B 116 0B - C 123 - 99C - D 210 - 84

Chords Tens. Comp.

D - E 210 - 84E - F 123 - 99F - G 116 0

Maximum Bot Chord Forces Per Ply (lbs)Chords Tens.Comp.

L - K 55 - 57K - J 53 - 57

Chords Tens. Comp.

J - I 53 - 57I - H 51 - 54

Maximum Web Forces Per Ply (lbs)Webs Tens.Comp.

B - L 187 - 366

Webs Tens. Comp.

F - H 187 - 366

Maximum Gable Forces Per Ply (lbs)Gables Tens.Comp.

C - K 121 - 264J - D 0 - 288

Gables Tens. Comp.

I - E 121 - 264

**WARNING** READ AND FOLLOW ALL NOTES ON THIS DRAWING!**IMPORTANT** FURNISH THIS DRAWING TO ALL CONTRACTORS INCLUDING THE INSTALLERSTrusses require extreme care in fabricating, handling, shipping, installing and bracing. Refer to and follow the latest edition of BCSI (BuildingComponent Safety Information, by TPI and SBCA) for safety practices prior to performing these functions. Installers shall provide temporarybracing per BCSI. Unless noted otherwise,top chord shall have properly attached structural sheathing and bottom chord shall have a properlyattached rigid ceiling. Locations shown for permanent lateral restraint of webs shall have bracing installed per BCSI sections B3, B7, or B10,as applicable. Apply plates to each face of truss and position as shown above and on the Joint Details, unless noted otherwise. Refer todrawings 160A-Z for standard plate positions.

ITW Building Components Group Inc. shall not be responsible for any deviation from this drawing,any failure to build the truss in conformancewith ANSI/TPI 1, or for handling, shipping, installation and bracing of trusses.A seal on this drawing or cover page listing this drawing, indicates acceptance of professional engineeringresponsibility solely for the design shown.The suitability and use of this drawing for any structure is the responsibility of the Building Designer per ANSI/TPI 1 Sec.2.

TC LL 40.00 PSF

TC DL 7.00 PSF

BC DL 10.00 PSF

BC LL 0.00 PSF

TOT. LD 57.00 PSF

DUR. FAC 1.15

SPACING 24.0 "

JOB #: 93049DATE - 11/28/16

G2 8' Gable

WEIGHT =46.9

SEQ - 37688

TYPE GABL

8'

6'8" 6'8"

4' 4'

1'4" 1'4"

1'2"

4'2"

4'4"

6

17'2"4

LEFT RAKE = 1'8" RIGHT RAKE = 1'8"

A

B

C

D

E

F

G

HIJK

L

912

2X6

4X4

2X6

Job:(93049) / -MCBAIN BLDG PRODUCTS /THOMAS SHARLENE BORKE / G2 8' Gable This dwg. prepared by the ITW job designer program from truss mfr's layout.Top chord 2x4 SPF #1/#2Bot chord 2x4 SPF #1/#2 Webs 2x4 SPF Stud