853 Product Manual

Transcript of 853 Product Manual

Safety Information in this Manual

Danger, Warning, and Caution symbols are used throughout the manual to help identify and avoid hazardous situations. Examples of each symbol are shown and explained below.

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury. This signal word is to be limited to the most extreme situations. It may also be used to alert against unsafe practices. (Color: red)

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury. It may also be used to alert against unsafe practices or cause product failure. (Color: orange)

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. It may also be used to alert against unsafe practices. (Color: yellow)

DANGER

WARNING

Caution

Table of Contents Chapter 1...............................................................................1-1

Product Description......................................................................... 1-1 Phase-Angle Control..................................................................... 1-2 Zero-Crossover Control ................................................................ 1-4 Standard Features ........................................................................ 1-7 Optional Features ......................................................................... 1-8 Technical Specifications ............................................................... 1-8 Part Number ................................................................................. 1-9

Chapter 2...............................................................................2-1

Hardware ........................................................................................ 2-1 Installation..................................................................................... 2-1 Enclosure...................................................................................... 2-1 Enclosure Temperature ................................................................ 2-1 Vibration........................................................................................ 2-2 Mounting ....................................................................................... 2-2 Disconnect Means ........................................................................ 2-2 Wiring............................................................................................ 2-2 Remote Feedback Wiring ............................................................. 2-4 Control Connections ..................................................................... 2-5 Digital Inputs ................................................................................. 2-6 Digital Outputs .............................................................................. 2-7 Analog Inputs................................................................................ 2-8 Analog Outputs ............................................................................. 2-9 Remote Feedback....................................................................... 2-10 Over-temperature Sensing.......................................................... 2-10

Chapter 3...............................................................................3-1

Configuration................................................................................... 3-1 Startup .......................................................................................... 3-1 Configuration Tool Installation ...................................................... 3-2 Running the Configuration Tool .................................................... 3-2 Configuration Tool Menu and Task Bar Descriptions.................... 3-5 Off-line Programming.................................................................. 3-10 On-line Programming.................................................................. 3-18 On-line Monitor ........................................................................... 3-23 Flash Programming..................................................................... 3-29

i

Loss of Communication .............................................................. 3-30

Chapter 4...............................................................................4-1

Calibration....................................................................................... 4-1 Current Rating............................................................................... 4-5 Voltage Rating .............................................................................. 4-5 Remote Voltage and Current Feedback........................................ 4-6 Calibration Procedure ................................................................... 4-7 Saving Calibration......................................................................... 4-9 Restoring Factory Calibration ..................................................... 4-10 Analog Calibration....................................................................... 4-12 Manual Calibration ...................................................................... 4-15 Magnetizing Sequence Calibration ............................................. 4-16 Repetitive Pulse Calibration........................................................ 4-16 Node Synchronization................................................................. 4-17

Chapter 5...............................................................................5-1

Local Digital Control Option ............................................................ 5-1 Display and Status ........................................................................ 5-1 Normal Mode Operation................................................................ 5-3 Display Select Mode Operation..................................................... 5-7

Chapter 6...............................................................................6-1

Serial Communication ..................................................................... 6-1 Hardware ...................................................................................... 6-1 Serial Protocols............................................................................. 6-3

Chapter 7...............................................................................7-1

Settings ........................................................................................... 7-1 Voltage Input Rating ..................................................................... 7-1 Voltage Input High Fault ............................................................... 7-1 Voltage Input Low Alarm............................................................... 7-1 Voltage Input Phase Unbalance Alarm ......................................... 7-1 Voltage L1-L2 Input Actual............................................................ 7-1 Voltage L1-L2 Input Span ............................................................. 7-1 Voltage L2-L3 Input Actual............................................................ 7-2 Voltage L2-L3 Input Span ............................................................. 7-2 Voltage L3-L1 Input Actual............................................................ 7-2 Voltage L3-L1 Input Span ............................................................. 7-2 Voltage Input Actual...................................................................... 7-2

ii

Frequency Rating.......................................................................... 7-2 Frequency Actual .......................................................................... 7-2 Voltage Output Rating................................................................... 7-2 Voltage Output PT Secondary ...................................................... 7-2 Voltage Output Limit ..................................................................... 7-2 Voltage Output Setpoint................................................................ 7-2 Voltage Output Proportional Gain ................................................. 7-3 Voltage Output Integral Gain ........................................................ 7-3 Voltage Output Derivative Gain .................................................... 7-3 Voltage X1-X2 Output Actual ........................................................ 7-3 Voltage X1-X2 Output Zero........................................................... 7-3 Voltage X1-X2 Output Span.......................................................... 7-3 Voltage X2-X3 Output Actual ........................................................ 7-3 Voltage X2-X3 Output Zero........................................................... 7-3 Voltage X2-X3 Output Span.......................................................... 7-3 Voltage X3-X1 Output Actual ........................................................ 7-3 Voltage X3-X1 Output Zero........................................................... 7-3 Voltage X3-X1 Output Span.......................................................... 7-4 Voltage Output Actual ................................................................... 7-4 Current Input Rating...................................................................... 7-4 Current Input Limit ........................................................................ 7-4 Current Input High Fault................................................................ 7-4 Current Input High Fault Retry Number ........................................ 7-4 Current Input High Fault Retry Time ............................................. 7-4 Current Input Overload Fault ........................................................ 7-4 Current Input Overload Time ........................................................ 7-4 Ground Fault Current .................................................................... 7-5 Ground Fault Time........................................................................ 7-5 Current L1 Input Actual ................................................................. 7-5 Current L1 Input Zero.................................................................... 7-5 Current L1 Input Span................................................................... 7-5 Current L2 Input Actual ................................................................. 7-5 Current L2 Input Zero.................................................................... 7-5 Current L2 Input Span................................................................... 7-5 Current L3 Input Actual ................................................................. 7-5 Current L3 Input Zero.................................................................... 7-5 Current L3 Input Span................................................................... 7-5 Current Input Actual ...................................................................... 7-6

iii

Current Input Threshold Load Failure ........................................... 7-6 Current Output Rating................................................................... 7-6 Current Output Limit...................................................................... 7-6 Current Output Setpoint ................................................................ 7-6 Current Output Proportional Gain ................................................. 7-6 Current Output Integral Gain......................................................... 7-6 Current Output Derivative Gain..................................................... 7-6 Current X1 Output Actual.............................................................. 7-6 Current X1 Output Zero ................................................................ 7-6 Current X1 Output Span ............................................................... 7-7 Current X2 Output Actual.............................................................. 7-7 Current X3 Output Actual.............................................................. 7-7 Current Output Actual ................................................................... 7-7 KVA Input Rating .......................................................................... 7-7 KVA Input...................................................................................... 7-7 Power Output Rating..................................................................... 7-7 Power Output Limit ....................................................................... 7-7 Power Output Setpoint.................................................................. 7-7 Power Output Proportional Gain ................................................... 7-7 Power Output Integral Gain .......................................................... 7-8 Power Output Derivative Gain ...................................................... 7-8 Power Output ................................................................................ 7-8 Power Factor ................................................................................ 7-8 Duty Cycle Output......................................................................... 7-8 Duty Cycle Setpoint ...................................................................... 7-8 Local Digital Control Display Selection ......................................... 7-8 Local Digital Control Setpoint........................................................ 7-8 Local Primary Analog Setpoint...................................................... 7-8 Primary Analog Setpoint Zero....................................................... 7-9 Primary Analog Setpoint Span...................................................... 7-9 Local Secondary Analog Setpoint Selection ................................. 7-9 Local Secondary Analog Setpoint ................................................. 7-9 Secondary Analog Setpoint Zero .................................................. 7-9 Secondary Analog Setpoint Span ................................................. 7-9 Analog Output #1 Selection ........................................................ 7-10 Analog Output #1........................................................................ 7-10 Analog Output #1 Bias ................................................................ 7-10 Analog Output #1 Span............................................................... 7-10

iv

Analog Output #2 Selection ........................................................ 7-10 Analog Output #2........................................................................ 7-10 Analog Output #2 Bias ................................................................ 7-10 Analog Output #2 Span............................................................... 7-10 Control Word............................................................................... 7-11 Status Word ................................................................................ 7-12 Ramp Up Time............................................................................ 7-13 Ramp Down Time ....................................................................... 7-13 Configuration Word ..................................................................... 7-13 Control Strategy Selection .......................................................... 7-14 Magnetizing Sequence Calibration ............................................. 7-14 Repetitive Pulse Calibration........................................................ 7-14 Load Type Selection ................................................................... 7-14 Product Type .............................................................................. 7-14 Serial Number ............................................................................. 7-14 Control Power Time On .............................................................. 7-14 Output Time On .......................................................................... 7-14 KW-Hour ..................................................................................... 7-14 Software Version......................................................................... 7-14 Network Loss .............................................................................. 7-15 Network Address......................................................................... 7-15 Network Baud Rate..................................................................... 7-15 MODBUS Address ...................................................................... 7-15 MODBUS Baud Rate .................................................................. 7-15 Network Type.............................................................................. 7-15 Fault Code .................................................................................. 7-15 Fault Index .................................................................................. 7-15 Fault Buffer #1 ............................................................................ 7-15 Fault Buffer #2 ............................................................................ 7-16 Fault Buffer #3 ............................................................................ 7-16 Fault Buffer #4 ............................................................................ 7-16 Fault Buffer #5 ............................................................................ 7-16 Fault Buffer #6 ............................................................................ 7-16 Fault Buffer #7 ............................................................................ 7-16 Fault Buffer #8 ............................................................................ 7-16

Chapter 8...............................................................................8-1

Troubleshooting .............................................................................. 8-1 Control PCB LED Indicators ......................................................... 8-2

v

Local Digital Control Option LED Indicators.................................. 8-3 Fault and Alarm Codes ................................................................. 8-4 Fault Reset ................................................................................... 8-9 Fault Buffer ................................................................................... 8-9 Troubleshooting Guide................................................................ 8-10

Appendix A ..........................................................................A-1

Mechanical Dimensions ..................................................................A-1

Appendix B ..........................................................................B-1

Electrical Drawings..........................................................................B-1

Glossary.................................................................................... i

vi

List of Figures

Figure 1-1 853 DSPC Schematic Diagram...................................................................1-1 Figure 1-2 Phase-Angle Control Half Cycles................................................................1-2 Figure 1-3 Phase-Angle Duty Cycle Output .................................................................1-3 Figure 1-4 Zero-Crossover Control ..............................................................................1-4 Figure 1-5 Zero-Crossover Current Input Limit.............................................................1-5 Figure 1-6 Zero-Crossover Control Magnetizing Sequence .........................................1-6 Figure 1-7 Zero-Crossover Control Repetitive Pulse....................................................1-6 Figure 2-1 Mounting Dimensions .................................................................................2-2 Figure 2-2 Cover screw locations.................................................................................2-3 Figure 2-6 Digital Input Schematic ...............................................................................2-7 Figure 2-8 Analog Output Schematic ...........................................................................2-9 Figure 3-1 Control PCB LED Location..........................................................................3-1 Figure 3-3 Configuration Tool.....................................................................................3-11 Figure 3-4 Ratings & Limits Tab.................................................................................3-12 Figure 3-5 Control Configuration Tab.........................................................................3-14 Figure 3-6 Fault Setup Tab ........................................................................................3-15 Figure 3-7 PID Setup Tab ..........................................................................................3-16 Figure 3-8 Network Tab..............................................................................................3-17 Figure 3-9 Configuration Tool On-Line .......................................................................3-19 Figure 3-10 Monitor Summary Tab ............................................................................3-24 Figure 3-11 Monitor Control Tab ................................................................................3-26 Figure 3-12 Monitor Status Tab..................................................................................3-27 Figure 3-13 Fault History............................................................................................3-28 Figure 3-14 Flash Programming.................................................................................3-29 Figure 4-1 Calibration (Voltage Tab) ............................................................................4-1 Figure 4-2 Voltage Calibration......................................................................................4-2 Figure 4-3 Current Calibration......................................................................................4-3 Figure 4-4 Analog Calibration.......................................................................................4-4 Figure 5-1 Local Digital Control Panel..........................................................................5-1 Figure 6-1 Nine Pin to Nine Pin Null Modem Cable Diagram .......................................6-1 Figure 6-2 Twenty-five Pin to Nine Pin Null Modem Cable Diagram ............................6-1 Figure 8-1 Control PCB LED indicator location ............................................................8-2 Figure 8-2 Local Digital Control ....................................................................................8-3 Figure A-1 Mechanical Dimensions..............................................................................A-1 Figure B-1 Electrical Schematic Left Side ....................................................................B-2 Figure B-2 Electrical Schematic Right Side..................................................................B-3 Figure B-3 40A Wiring Diagram ...................................................................................B-4 Figure B-4 90A Wiring Diagram ...................................................................................B-5 Figure B-5 175A Wiring Diagram .................................................................................B-6 Figure B-6 350A Wiring Diagram .................................................................................B-7

vii

List of Tables

Table 1-1 Technical Specifications...............................................................................1-8 Table 2-1 Wiring Information ........................................................................................2-4 Table 2-2 Digital Interface Plug ....................................................................................2-6 Table 2-3 Relay Contact Ratings .................................................................................2-7 Table 2-4 Analog Interface Plug...................................................................................2-8 Table 3-1 Status Lamp Description ............................................................................3-20 Table 5-1 Display Selections........................................................................................5-2 Table 5-2 Digital Control Status ...................................................................................5-3 Table 5-3 Pushbutton function in Normal mode, Local Digital Control .........................5-4 Table 5-4 Pushbutton function in Normal mode, Local Analog Control ........................5-5 Table 5-5 Pushbutton function in Normal mode, Remote Control ................................5-6 Table 5-6 Pushbutton function in Display Select Mode, Local Control .........................5-7 Table 5-7 Pushbutton function in Display Select Mode, Remote Control .....................5-8 Table 6-1 Serial Port Configuration ..............................................................................6-2 Table 6-2 MODBUS RTU Query (from Master) ............................................................6-3 Table 6-3 MODBUS RTU Read Response (from 853) .................................................6-4 Table 6-4 MODBUS RTU Write Response (from 853) .................................................6-4 Table 6-5 MODBUS RTU Exception Response (from 853 DSPC)...............................6-5 Table 6-6 MODBUS RTU Exception Codes .................................................................6-5 Table 6-7 General 8 Byte Query (from Master) ............................................................6-6 Table 6-8 General 8 Byte Response (from 853)...........................................................6-7 Table 7-1 List of Settings..............................................................................................7-1 Table 8-1 Control PCB LED Indicators.........................................................................8-2 Table 8-2 Local Digital Control LED Indicators.............................................................8-3 Table 8-3 Fault and Alarm Codes ................................................................................8-4 Table 8-4 Troubleshooting Guide...............................................................................8-11

viii

Chapter 1

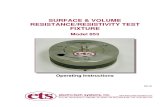

Product Description

The 853 Digital SCR Power Controller (DSPC) from Spang Power Electronics offers the latest in Digital Signal Processing (DSP) technology and software. The DSPC is designed for a three-phase application. The 853 DSPC uses an advanced, dsp-based firing circuit to control a three phase, six SCR AC Switch. The 853 DSPC is capable of firing into either direct or transformer coupled loads. The basic circuit configuration is shown in the figure below.

Figure 1-1 853 DSPC Schematic Diagram

1-1

Product Description February 2004

Phase-Angle Control

In Phase-Angle control, the line is connected to the load for a portion of each half cycle. It is disconnected from the load for the remainder of the half cycle. The period during which the load is connected is varied in response to the control signal providing proportional control of power to the load. A sample picture of Phase-Angle control is shown below.

Figure 1-2 Phase-Angle Control Half Cycles

1-2

February 2004 Product Description

Phase-Angle Control Method

The 853 DSPC controls its output based on regulation mode. The regulation modes are Open Loop, Voltage Output, Current Output, and Power Output. Each mode regulates to within 1% of rated output. The Current Input Limit is accomplished by comparing the Current Input to the Current Input Limit. If the Current Input exceeds the Current Input Limit the Current Output setpoint is lowered, which in turn will lower the Current Input. A flow diagram of the control is shown below.

Figure 1-3 Phase-Angle Duty Cycle Output

RFI

Phase-Angle control can generate Radio Frequency Interference (RFI). This may, depending upon the installation and magnitude, affect other electronic equipment (computers, telephones, etc.). Where RFI may be a problem, Zero-Crossover control can be used for many of the electric heating applications. The source inductance, load inductance, and circuit impedances determine the amount of RFI generated by Phase-Angle control. Additional components may be required to reduce or eliminate RFI, such as the use of an isolation transformer between the line and the 853 DSPC or the addition of line filters.

1-3

Product Description February 2004

Zero-Crossover Control

In Zero-Crossover control, the line is connected to the load for a number of complete cycles. It is then disconnected for a number of complete cycles. This on-off pattern is repeated continuously with the 853 DSPC turning on (and off) at the zero crossing of the sine wave. The ratio of the number of cycles ON to the number OFF is varied in response to the control signal providing proportional control of the power to the load. The 853 DSPC has predefined the total number of cycles ON and OFF to be 100. This will allow the output to be set to 1% or 1 cycle out of 100. A sample picture of the Zero-Crossover control is shown below.

Figure 1-4 Zero-Crossover Control

Multiple 853 DSPC’s can achieve power leveling by using the Network Address and Node Synchronization. This allows each independent 853 DSPC to start at a different time based on the Network Address, which allows one 853 DSPC to turn on when the other unit is off, therefore causing power leveling on the common AC power source.

Zero-Crossover Control Method

The Zero-Crossover control method is based on calculation. The actual voltage output, current output, and power output are calculated every cycle and compared to each respective setpoint. The cycles continue until the calculated feedback exceeds its respective setpoint and then the unit turns off after the next cycle. This necessitates a minimum of two cycles or 2% output since the first cycle is used for calculation and turn off does not occur until after the second cycle.

1-4

February 2004 Product Description

Zero-Crossover Current Input Limit

The Zero-Crossover control method controls cycles and can only control Current Input by applying Phase-Angle control to the individual cycles. The Phase-Angle control of the individual cycles will limit the input current, and since the Zero-Crossover control is adaptive, the number of cycles will automatically increase based on the voltage output, current output, and power output setpoints. The Phase-Angle control of individual cycles does eliminate some of the features of the Zero-Crossover control such as high power factor and low RFI. However, it does protect the load by limiting the current that in some cases would be more important than the Zero-Crossover features. A sample picture of the Zero-Crossover control with Current Input Limit is shown below.

Figure 1-5 Zero-Crossover Current Input Limit

Heating Loads

Resistance type heating loads fall into two general categories. The first category consists of heating elements made from materials that exhibit relatively constant resistance whether hot or cold. These include such elements as nichrome, calrod, chromolox and various steels. No particular precautions need be taken in using such materials. The second category consists of elements made from materials that exhibit low initial (cold) resistance such as tungsten, molybdenum, platinum, moly-disilicide, silicon carbide (which ages) and quartz infrared lamps. Such elements require the use of the current limit option that prevents more than a preset value of current from flowing during the initial low resistance condition of the elements.

Zero-Crossover Load Type

The very nature of Zero-Crossover control, firing full cycles of power, tends to cause large inrush currents into the load. This is especially true when transformers are connected to the output. This is because transformers rely on their magnetic field to limit the current, which is present only after current has been flowing for a short time. In order to eliminate this problem from happening, the Load Type setting can be set for Direct Coupled or Transformer Coupled loads. Transformer Coupled loads require two additional settings; Magnetizing Sequence and Repetitive Pulse.

1-5

Product Description February 2004

Magnetizing Sequence

The Magnetizing Sequence causes the specified number of cycles to start in Phase-Angle control in order to limit the current inrush when the 853 DSPC is first turned on. A sample picture of the Zero-Crossover control magnetizing sequence is shown below.

Figure 1-6 Zero-Crossover Control Magnetizing Sequence

Repetitive Pulse

After the cycle has started, the Repetitive Pulse causes only the first cycle to start in Phase-Angle control again in order to limit the current inrush. A sample picture of the Zero-Crossover control Repetitive Pulse is shown below.

Figure 1-7 Zero-Crossover Control Repetitive Pulse

1-6

February 2004 Product Description

Standard Features

The 850 Series digital product family offers the following features:

• Flexibility. Configurable operating modes, ratings, limits, external inputs, and setpoints.

• On-Board Diagnostics. Fault memory (the last eight faults are available in fault buffer storage) allows the user to record problems and, through the use of a computer, observe trends that could indicate a need for process modification, troubleshooting or preventative maintenance.

• Computerized Setup and Calibration. RS-232 serial Configuration Tool for setup, digital calibration and diagnostics

• Touch-Proof Mechanical Design prevents unintentional contact with hazardous voltage

• Advanced Process and Fault Monitoring. Real-time monitor of voltage, current, power and fault conditions. Real-time adjustment of the setpoint. Changes can be made any of four different ways:

Locally, using an analog control signal. Locally, using the Configuration Tool software. Locally, with optional Local Digital Control feature. Remotely, with optional Network Communications feature.

• Operates on universal line voltages, from 24 to 600 VAC and 50/60 Hz.

• DSP-based control

• 1600 Volt SCR's

• 20KHZ pulse transformer coupled SCR gating circuit

• 50KHZ digital firing control

• True RMS calculation of voltage, current, and power at 10KHZ sampling

• Simultaneous regulation of voltage, current, and power

• User-configurable analog input

• User-configurable analog outputs

• Non-volatile storage of all digital settings

• Support of MODBUS RTU protocol

• Support of multiple baud rates on the serial port

1-7

Product Description February 2004

Optional Features

The following optional features are available for the 853 DSPC:

• Network Interface, allowing for remote control and monitoring of the 853. The networks supported are DeviceNet™, MODBUS (MODBUS RTU protocol), Profibus, and Ethernet (MODBUS TCP protocol).

• Local Digital Control. User has a 4-digit LED display, 12 independent status LEDs and 4 pushbuttons, which allow local control of the 853. The user can control unit output and change the desired set point, as well as monitor voltage, current, or power on the LED display. Fault and alarm conditions are displayed.

Technical Specifications

Table 1-1 Technical Specifications

Input Line Voltage 24 to 600 VAC RMS

Input Line Frequency 50/60 ± 2 HZ

Current Rating 40 to 350 A; consult factory for higher ratings

40A - 1,800A for 10 msec

90/175A - 8,000A for 10 msec

Current Surge Rating

350A - 14,500A for 10 msec

40A - 16,200 A2sec

90/175A - 320,000 A2sec

Fuse I2t Rating

350A - 1,051,000 A2sec

Control Voltage 85 to 265 VAC

Control Power 50 VA

Analog Inputs (2) 0 to 5 VDC or 0 to 20mA (250Ω)

Analog Outputs (2) 0 to 5 VDC or 0 to 20mA (10V max)

Digital Inputs 0 to 5 VDC

Regulation 1 %

Isolation to ground 2500 VAC

Ambient Temperature Range 0 to 50ºC

1-8

February 2004 Product Description

Part Number

The Part Number format for the 853 DSPC series product is 853-AAAA-00-00 and is described in detail below.

853 AAAA 00 00

Product Series

Current Rating: 40A 90A 175A 350A

Product Options: Dx - DeviceNet™

Px - Profibus Ex - Ethernet

x1 - Local Control x2 - Remote Control

SL – Special Lugs Reserved

for future use.

1-9

Chapter 2

Hardware

Installation

DANGER

The user is responsible for conforming to all applicable local, national, and international codes; wiring practices, grounding, disconnects, and overcurrent protection are of particular importance. Failure to observe this precaution could result in severe bodily injury or loss of life.

Prior to installation, the 853 DSPC should be carefully checked for shipping and/or handling damage such as loose or broken parts or wires. All covers and panels should be removed for internal inspection and any shipping braces should be removed.

WARNING

The 853 DSPC is intended to be mounted in a protective enclosure to prevent the hazard of electrical shock. Unless supplied with an enclosure, it is considered to be a component that must be mounted in an enclosure by the user.

Enclosure

The 853 DSPC must be mounted in a protective enclosure to prevent the hazard of electrical shock and also to avoid exposing the circuitry to damaging contaminants. A NEMA 1 enclosure for providing protection from electric shock is available as an option. If the 853 DSPC must be located in an area of dust, falling debris, splashing or falling water, adequate protection must be supplied. These conditions necessitate the use of a special NEMA enclosure. Custom NEMA enclosures for the afore-mentioned conditions are also available.

WARNING

An incorrectly applied or installed system can result in component damage or reduction in product life. Wiring or application errors, incorrect or inadequate AC supply, or excessive ambient temperature may result in malfunction of the system.

Enclosure Temperature

The 853 DSPC is rated at 50°C maximum ambient temperature. If the 853 DSPC is mounted in an enclosure other than one designed and built by Spang Power Electronics, care must be taken to allow sufficient cooling air to the SCR heatsink. Consult the factory for enclosure temperatures above 50°C but less than 65°C.

2-1

Hardware February 2004

Vibration

If the mounting site has a vibration concern, the 853 DSPC should be mounted using industry standard shock mounting techniques.

Mounting

Allow four inches on each side and a minimum of four inches above and below the 853 DSPC for adequate cooling. It is recommended that the enclosure exhaust vents be located above the top of the heatsink. Allow additional room for wiring as required by the individual application.

Figure 2-1 Mounting Dimensions

Disconnect Means

It is required that a circuit breaker, fused disconnect or fuses be installed upstream of the 853 DSPC for wire protection. Fuses are not necessary if the distribution system current surge rating is limited to below the specification for the unit. Optional semiconductor fuses (externally mounted) are available to prevent surge or transient currents from damaging the semiconductors. The semiconductor fuses are oversized (90A for the 40A unit, 250A for the 90/175A unit and 500A for the 350A unit) to prevent nuisance fuse blowing and, for this reason, cannot be used for steady state overload protection.

Wiring

Wire should be sized in accordance with the appropriate specific code guidelines. Ambient operating temperature should be taken into account. All large cables should be routed to allow access to the 853 DSPC. It is up to the discretion of the installer to allow access room to service the unit.

2-2

February 2004 Hardware

The Phillips head cover screws are located at the four corners of the unit, and are removed to open the covers on their inside hinges, providing access to the power wiring terminals.

Figure 2-2 Cover screw locations

The input power lugs are located under the top cover. The output power lugs, the remote feedback terminal block, and the chassis ground lug are located under the bottom cover as shown in the following figure.

Figure 2-3 Input and Output Power Lug locations (175A unit)

2-3

Hardware February 2004

Table 2-1 Wiring Information

Power Lugs Ground Lug Feedback Terminal Unit size

Wire Range Screw Head Wire Range Screw Head Wire Range Screw Head

40A 14-2 [8*] AWG Slotted 14-2 [8*] AWG Slotted 8-24 [14*] AWG Slotted

90A 14-1/0 [4*] AWG Slotted 14-2 [8*] AWG Slotted 8-24 [14*] AWG Slotted

175A 6-250MCM[2/0*] AWG 5/16 inch hex 14-2 [4*] AWG Slotted 8-24 [14*] AWG Slotted

350A 4-500MCM [350MCM*] AWG

1/2 inch hex 6-3/0 [2*] AWG ¼ inch hex 8-24 [14*] AWG Slotted

Note: Size in brackets [*] is recommended for 90ºC wire insulation.

Remote Feedback Wiring

If remote feedback is used, the connections are made to the Remote Feedback Terminal. Current feedback is connected to TB1 terminals 1 (+) and 2 (common), and voltage feedback is connected to TB2 terminals 1 (X1), 2 (X2) and 3 (X3).

The current feedback signal should be about 2.5 Vrms at the rated output current, and the voltage feedback signal should be in the same range as the input voltage. Allowable ranges are 300-600V, 150-300V, 75-150V, 37.5-75V and 24-37.5V.

Figure 2-4 Remote Feedback Terminals Note: The existing current and voltage feedback connections must be removed and insulated

before connecting new remote current and voltage feedback to the Remote Feedback Terminal.

2-4

February 2004 Hardware

Control Connections

Control connections are made using the pluggable terminal blocks that are located on the right side of the 853 DSPC. These terminals accept fine stranded wire up to 12 AWG.

The 853 DSPC requires 85-265VAC 50/60Hz @ 50VA control power for the circuit boards and cooling fans. This must be wired to the two-position plug labeled Control Power.

Figure 2-5 Control Connectors The following figure shows a typical wiring diagram for control connections.

Figure 2-6 Typical Control Connections

2-5

Hardware February 2004

WARNING

This equipment is at line voltage when AC power is connected. Disconnect and lock out all ungrounded conductors of the AC power line. Failure to observe these precautions could result in severe bodily injury or loss of life.

Digital Inputs

The digital inputs (Remote/Local, Enable, and External Fault) provide power for each input designed for low voltage contacts or switches. The voltage/current rating of the contact or switch should be 15V and 10mA. If interfacing to automated equipment, it is possible to connect a 10V signal directly into the input without using the power connection.

The digital interface consists of the thirteen-position plug labeled Digital Interface. The following table describes each terminal and its default operation. Terminals 1, 3, 5, 7 and 9 provide 15 volts through a 470 Ω resistor in order to develop a 10 volt, 10 mA signal into the appropriate digital input. A typical schematic of the digital inputs follows the table.

Table 2-2 Digital Interface Plug

Terminal Number

Terminal description Standard operation (see Note below)

1 External Fault #1 power

2 External Fault #1 input

Shorting 1 to 2 provides an external fault input. Open indicates no remote fault.

3 External Fault #2 power

4 External Fault #2 input

Shorting 3 to 4 provides an external fault input. Open indicates no remote fault.

5 External Fault #3 power

6 External Fault #3 input

Shorting 5 to 6 provides an external fault input. Open indicates no remote fault.

7 Remote/local power

8 Remote/local input

Shorting 7 to 8 puts the unit into remote mode. Open defaults to local mode.

9 Enable power

10 Enable input

Shorting 9 to 10 enables the unit. Open inhibits operation.

11 Fault common Fault relay common connection.

12 Fault NC Contact opens when a fault occurs.

13 Fault NO Contact closes when a fault occurs.

Note: The external faults are programmed by default as normally open (NO). Refer to the Settings Chapter (Configuration Word) for more information on contacts.

2-6

February 2004 Hardware

Figure 2-6 Digital Input Schematic

External Fault Input

One typical use for the External Fault Input would be the micro switch on an external semiconductor fuse. The default state is for a normally open switch to indicate a “normal” condition. It may be programmed by the user for a normally closed switch to indicate a “normal” condition.

Remote/Local Input

The Remote/Local Input is used to select the control mode. Remote control is selected to allow control from the network (when present). The default state (open) is for local control.

Enable Input

The Enable Input is used to provide a local enable/inhibit function. The default state (open) inhibits the unit (prevents the SCR from firing).

Digital Outputs

The digital outputs (Fault – Common, NC, and NO) are relay contacts from a miniature relay on the digital control printed circuit board. It is very important to not exceed the contact ratings listed in the table below.

Table 2-3 Relay Contact Ratings

Load Type Voltage Current

Resistive 125VAC 0.30A

Resistive 30VDC 1.0A

Inductive 125VAC 0.20A

Inductive 30VDC 0.50A

2-7

Hardware February 2004

A pilot relay can be used to interface to larger relays or contactors if required.

Analog Inputs

The analog input (Analog Setpoint) is designed to accept potentiometer, voltage, or current inputs. The potentiometer input is designed for a 10K potentiometer that is connected between the Analog Supply, Analog Setpoint, and Analog Ground. The voltage input requires a 0 to 5VDC input to achieve 0 to 100% setpoint. The current input requires a 0 to 20mA input to achieve 0 to 100% setpoint. In order to use the current input, jumper JP2 must be shorted for the Primary Analog Input and jumper JP4 must be shorted for the Secondary Analog Input. This connects a 249 ohm resistor into the circuit for the current input to use. It is possible to use a 4 to 20mA current input by utilizing the Primary or Secondary Analog Setpoint Zero calibration to offset the 4mA input to be 0% setpoint. Also, other voltages and currents less than 5VDC and 20mA are acceptable by utilizing the Primary or Secondary Analog Setpoint Span calibration to set 100% setpoint.

The analog interface consists of the ten-position plug labeled Analog Interface. The following table describes each terminal and its default operation.

Table 2-4 Analog Interface Plug

Terminal Number Terminal description Standard operation

1 Analog #1 supply

2 Analog #1input

3 Analog #1 ground

Connecting a 10k potentiometer with JP2 OFF provides a local analog control.

4 Analog #2 supply

5 Analog #2input

6 Analog #2 ground

Connecting a 10k potentiometer with JP4 OFF provides a local analog control.

7 Analog #1 output

8 Analog #1ground

Provides a configurable analog output of 0-5 volts (JP3 on) or a mA output (JP3 off).

9 Analog #2 output

10 Analog #2ground

Provides a configurable analog output of 0-5 volts (JP5 on) or a mA output (JP5 off).

2-8

February 2004 Hardware

The Analog Input Circuit. If a mA input signal is desired, Jumper JP2 (input #1) or JP4 (input #2) is inserted to connect the 249 ohm burden resistor. If a 0-5 volt signal is desired, connect the signal source between terminal 2 (+) and 3 (-) for input #1 or 5 (+) and 6 (-) for input #2.

Figure 2-7 Analog Input Schematic Analog Outputs

The analog output (Analog Output) is designed to be a current or voltage output. The Primary or Secondary Analog Output Selection defines what internal signal is connected to the Primary or Secondary Analog Output. The analog output will generate 0 to 20mA for 0 to 100% of the selected internal signal. To convert the analog output to voltage, jumper JP3 must be shorted for the Primary Analog Output and jumper JP5 must be shorted for the Secondary Analog Output, which connects a 249 ohm resistor, that converts 0-20mA to 0-5VDC. Alternatively, a 500 ohm resistor can be connected externally that converts 0-20mA to 0-10VDC. Just as on the analog input, the analog output can calibrate the output for different levels by using the Primary or Secondary Analog Output Bias and the Primary or Secondary Analog Output Span.

The Analog Output Circuit. If a 5 volt output signal is desired, Jumper JP3 (output #1) or JP5 (output #2) is inserted to connect the 249 ohm burden resistor. If a 10 volt signal is desired, an external 500 ohm resistor should be connected across the appropriate output terminals.

Figure 2-8 Analog Output Schematic

2-9

Hardware February 2004

Remote Feedback

It is standard for the output voltage and current to be sensed internally. The 853 DSPC also provides for a separate voltage and current feedback from a remote source, such as the secondary of a transformer on the output of the 853 DSPC. An internal terminal board is provided for remote voltage and current feedbacks. The voltage potential transformer (PT) used for the remote voltage feedback must be designed such that the PT output voltage is close to the input voltage of the 853 DSPC. The Voltage Output PT Secondary setting is used to define the specific PT output connected as a remote voltage feedback. The current transformer (CT) burden resistor must be selected such that 100% current output, defined by Current Output Rating will equal 2.5V. For example, if a CT with a rating of 1000 to 1 is used on a 350A 853 DSPC unit, the burden resistor would be 2.5V/.35A or 7.14 ohms.

Over-temperature Sensing

A temperature sensor is mounted on the heatsink of the 853 DSPC to detect and indicate an over temperature condition. The standard temperature sensor is supplied with contacts that are normally closed (NC).

2-10

Chapter 3

Configuration

Startup

WARNING

An incorrectly applied or installed system can result in component damage or reduction in product life. Wiring or application errors, incorrect or inadequate AC supply, or excessive ambient temperature may result in malfunction of the system.

Once the 853 is mounted, and the wiring is in place, apply control power to the unit. It is not necessary for main power to be applied at this time.

DANGER

This equipment is at line voltage when AC power is connected. Disconnect and lock out all ungrounded conductors of the AC power line. Failure to observe these precautions could result in severe bodily injury or loss of life.

When control power is applied, check the LED’s on the control board to verify that the power supplies are on and the DSP is operating. At this time the red FAULT LED will be on, the three green power supply status LED’s will be on, and the HEARTBEAT LED will be blinking at about a 1 second rate.

Figure 3-1 Control PCB LED Location

With control power applied and status lights operating properly, the unit is ready for configuration. Configuration consists of telling the unit what it is rated (power rating, input and output voltage and current, etc.) and what type of control is to be used. Configuration is accomplished using the Configuration Tool software running on a host computer, connected to the unit via the Serial Interface Port. In most cases, the unit will be pre-configured at the factory, and only minor changes (such as limit settings and/or control mode) will be made at the user site.

3-1

Configuration February 2004

The Serial Interface consists of a standard DB9 connector (9 pin male), which plugs into the host computer’s serial port using a Null Modem cable. The wiring for typical Null Modem cables is illustrated in the Serial Communication Chapter.

Configuration Tool Installation

The 853 Configuration Tool is a serial configuration/monitoring tool that runs on a Windows-based PC. The minimum system requirements are:

Windows 95, 32MB ram, 10MB hard disk space, an available serial port

The 853 Configuration Tool allows off-line editing and storage of configuration files. The Configuration Tool also allows on-line, real-time changes to the 853 settings through the serial port. The capabilities of the Configuration Tool include: on-line configuration, setpoint changes, operation, monitoring, calibration, and file storage and retrieval.

The Configuration Tool is delivered on CD-Rom and includes ‘auto-run’ capability. However, should the CD NOT run automatically once inserted into the cd-rom drive, browse for the cd-rom drive, and double-click on the file ‘setup.exe’.

The Configuration Tool default install location is:

C:\Program Files\Spang Power Electronics\ 853 Configuration Tool vxxx

Once successfully installed, the Configuration Tool will be accessible via the Start Menu.

Note: The install process updates the computer’s system registry with the required configuration information.

Running the Configuration Tool

Run the Configuration Tool from the start menu:

Start button -> Programs -> Spang Power Electronics -> Configuration Tool vxxx

3-2

February 2004 Configuration

Click on the [Start] button to continue the Configuration Tool startup (the program will automatically continue after 10 seconds).

At this point the Configuration Tool is off-line, that is, the Tool is not communicating with the 853. The setting values have been read from a setup (.csv) file stored on the computer running the configuration tool. There are five settings 'tabs' which can be viewed off-line.

While off-line, settings can be modified two ways: either by opening an existing setup file, whose data is read into the Configuration Tool, or by modifying the settings individually in the six “Settings” tabs of the Configuration Tool.

3-3

Configuration February 2004

3-4

February 2004 Configuration

Configuration Tool Menu and Task Bar Descriptions

The 853 Configuration Tool menu bar is shown below, followed by a description of each option.

File Menu

File Menu including the ‘Save Calibration’ menu choice.

The ‘Save Calibration’ menu choice is visible only under certain conditions, and should be used only by authorized service personnel.

File Menu including the ‘Restore Calibration’ menu choice.

The ‘Restore Calibration’ menu choice is visible only under certain conditions, and should be used only by authorized service personnel.

File Option Description

Open Open a standard dialog box listing the configuration files available for loading and editing. (Configuration files are of the form <filename>.csv) and are read from and saved to the host system.

Save Save and close changes made to the configuration file.

Print Open the Print Preview window; display 853 settings in tabular form.

Print Setup Open the standard dialog box that provides the selection of a printer and print characteristics.

Save Calibration Save current calibration values as factory defaults in 853 eeprom.

Restore Calibration

Restore calibration values from factory defaults stored in 853 eeprom.

Exit Close the Configuration Tool

3-5

Configuration February 2004

Com Setup Menu

Com Options Description

Com1

Com2

Com3

Com4

The Com Setup menu is used to select the serial port on the host computer available for use with the 853.

Window Menu

Window Options Description

Settings Open the Settings Pane. (This is the default upon program entry).

Monitor Establish on-line communication and open the Monitor pane to view 853 DSPC operation.

Calibration Establish on-line communication and open the Calibrate pane.

Fault History Open the Fault History window (useful only if on-line).

Flash Programming

Open the Flash Programming window. Intended for use by authorized service personnel only.

3-6

February 2004 Configuration

Help Menu

Help Options Description

Manual

About

Open (in a separate browser window) this product manual in pdf format.

Display the version number of the Configuration Tool software.

3-7

Configuration February 2004

Taskbar

The Configuration Tool Taskbar provides shortcuts to frequently used options.

Taskbar Items

Description

Open Folder Same as the File->Open menu option

Floppy Same as the File->Save menu option.

Printer Same as the File->Print menu option.

Monitor Same as the Window->Monitor menu option.

Calibrate Same as the Window->Calibrate menu option.

Settings This button appears on the taskbar if either the Monitor or Calibration window is visible. Same as the Window->Settings menu option.

Fault Same as the Window->Fault History menu option.

Offline/Online Toggle between Off-line programming and On-line communication with the 853. The caption and color of the button indicate the current status of communication between the configuration tool and the 853 DSPC.

A Red button with an Offline caption indicates No Communication between the Configuration Tool and the 853 DSPC.

A Yellow button with an Online caption indicates one of two possibilities: the 853 DSPC is under Remote (network) Read Only control; or the 853 DSPC is under Analog (vs Digital) control).

A Green button with an Online caption indicates Read/Write local communication between the Configuration Tool and 853 DSPC.

3-8

February 2004 Configuration

Print Preview

The File->Print menu selection, or the printer icon on the Taskbar, opens the Print Preview window. The Print Preview window displays a tabular summary of the settings stored in the Configuration Tool.

Figure 3-2 Print Preview Window

Click [Print] to send a copy of the table to the printer port of the host computer.

Click [Close] to exit the Print Preview window.

3-9

Configuration February 2004

Off-line Programming

Off-line programming allows the user to edit 853 settings without actually writing them to the controller. All work is done on the host computer and can be saved.

The Configuration Tool starts in Off-Line Programming mode. The tool opens with the last settings file saved. If there is no saved settings file, the default settings are loaded from the default.csv file ( included with the configuration tool).

Load/Save the Configuration File

To load a configuration file from the host computer to the Configuration Tool,

Select the File->Open menu option, (or click the file folder icon on the Taskbar)

Browse the files in the ‘file open’ dialog, and select the desired configuration (*.csv) file.

The settings as defined in the configuration file are loaded into the Configuration Tool, and can be viewed and/or modified.

To save settings to a .csv file on the host computer,

Select the File->Save menu option, (or click the floppy icon on the Taskbar)

Specify <filename>.csv .

The settings currently in the Configuration Tool are written to the specified file on the host computer.

3-10

February 2004 Configuration

Configuration Tool Settings Windows

The initial 853 Configuration Tool window is shown below.

Figure 3-3 Configuration Tool

The left pane is used for general status and control information related to the 853 DSPC. In Off-line mode, only control information is visible in the left-hand pane:

‘Regulation Mode’ is a drop-down box containing the regulation choices.

‘Local Control’ is a button that toggles between Local Analog and Digital control.

On start up, the right-hand side of the window displays the Settings tab, as read from the latest (or default) configuration file. Settings information is organized into several tabs: Ratings and Limits, Control Configuration, Fault Setup, PID Setup, and Network. Offline programming allows edits to any writable setting, as defined in the Settings Chapter. Read-only settings are indicated by a (cyan) shadowed background and cannot be changed.

3-11

Configuration February 2004

Ratings and Limits Tab

The Ratings and Limits Tab holds the settings for

Voltage Input Rating

*Voltage Output Rating

Voltage Output Limit

*Voltage Output PT Secondary

Power Output Rating - Read Only

Power Output Limit

KVA Input Rating – Read Only

Current Input Rating

Current Output Rating

Current Input Limit

Current Output Limit

Frequency Rating

Ramp Up Time

Ramp Down Time

* For a direct-coupled load (Load Type) the Voltage Output Rating and the Voltage Output PT Secondary are Read Only and follow the Voltage Input Rating.

Figure 3-4 Ratings & Limits Tab

3-12

February 2004 Configuration

White fields indicate Read/Write

Cyan fields indicate Read Only information

3-13

Configuration February 2004

Control Configuration Tab

The Control Configuration Tab holds settings for

Control Strategy

Load Type

* Magnetizing Sequence

* Repetitive Pulse 1 and 2

Primary Analog Output Selection

Secondary Analog Output Selection

Secondary Analog Setpoint Selection

Local Digital Display Selection

* Only used for Zero Crossover with transformer coupled load applications.

The [Auto Set] function allows the 853 to automatically tune the repetitive pulses for the minimum measured current pulses. To enable the [Auto Set] function, insert jumper JP1 with control power applied to the unit.

Figure 3-5 Control Configuration Tab

White fields indicate Read/Write

Cyan fields indicate Read Only information

3-14

February 2004 Configuration

Fault Setup Tab

The Fault Setup Tab holds the settings for:

Voltage Input High

Voltage Input Low

Voltage Input Phase Unbalance

Current Input High

Current Input High Retries

Current Input High Retry Time

Ground Fault Current

Ground Fault Time

Current Input Overload

Current Input Overload Time

Current Input Threshold Load Failure

Figure 3-6 Fault Setup Tab

White fields indicate Read/Write

Cyan fields indicate Read Only information

3-15

Configuration February 2004

PID Setup Tab

The PID Setup Tab holds the PID settings for

Power Output Voltage Output Current Output

Proportional Gain

Integral Gain

Derivative Gain

Proportional Gain

Integral Gain

Derivative Gain

Proportional Gain

Integral Gain

Derivative Gain

Figure 3-7 PID Setup Tab

White fields indicate Read/Write

Cyan fields indicate Read Only information

3-16

February 2004 Configuration

Network Tab

The Network Tab holds settings for

Network Type

Network Baud Rate

Network Address

MODBUS Address

MODBUS Baud Rate

Network Loss Option

Software Version

Serial Number

Figure 3-8 Network Tab

White fields indicate Read/Write

Cyan fields indicate Read Only information

3-17

Configuration February 2004

On-line Programming

On-line programming involves actual serial communication between the configuration tool and the 853 DSPC. Settings are read from and written to the 853 DSPC using a serial protocol described in the Serial Communication chapter. The On-line communication capability of the configuration tool allows real-time monitoring and calibration of the 853 DSPC.

To establish on-line communication between the Configuration Tool and the 853 unit,

Connect a standard, 9-pin null modem cable from the serial port of the host computer to the serial port of the 853

Assign the correct comm port to the configuration tool

Click [Online/Offline] on the taskbar

If any settings have been modified using the configuration tool offline, the following message will appear:

If settings have been modified offline, either individually or by loading a .csv file, the user has the option of transferring, or writing, the settings stored in the 853 Configuration Tool to the 853. If no modifications have been made, the prompt will not appear.

Click Yes to write settings from the tool to the 853; click No if settings are NOT to be written to the 853.

Depending on the response, the configuration tool will either write its settings to the 853 and then read them all back, or will read all settings from the 853 into the configuration tool. In either case, online communication is established. The On-line indicator turns green in the Tool Bar.

Note: If the serial link cannot be established, the following message appears:

Check both ends of the serial connection, make sure that power is applied to the 853 (check LEDs) and click [Online] again. If there is still no communication, with the serial cable

connected, cycle power to the unit, and click [Online].

3-18

February 2004 Configuration

When the Configuration Tool is communicating on-line with the 853 DSPC, status, control and setting information is continuously read from the 853 DSPC and refreshed in the Configuration Tool. Additional status and control information is visible in the left-hand pane.

Note that when only the control power is applied, a low voltage warning (A-34) is displayed. This is normal, and will remain as long as the main power is off. It is not necessary to be On-line to review and change the settings – but it is necessary to be On-line to write the changes to the unit. It is also necessary for the Remote/Local switch to be in the Local position for the Configuration Tool to allow on-line changes to the settings.

Figure 3-9 Configuration Tool On-Line

3-19

Configuration February 2004

Status indicators are described in the table below:

Table 3-1 Status Lamp Description

Lamp Color Description

Enable input

Green

Red

The 853 DSPC is Enabled

The 853 DSPC in Inhibited

Output Status Green

Red

Output is ON

Output is OFF

Remote/Local input Green

Red

Local control is active

Remote (network) control is active

On/Off button Toggles the 853 output

Alert indicator Flashing Yellow

Flashing Red

Indicates an Alarm Condition (described in the message box below the lamps)

Indicates a Fault Condition is present (described in the lower message box)

Note: During normal operation, message reads: No detected faults or alarms

Fault Reset button Click to send a ‘Fault Reset’ to the 853. The 853 will attempt to recover from the alert condition. If recovery is accomplished, normal operation will resume.

On-Line Navigation and Changes

To edit settings:

• Press [Tab] or [Enter] to move forward and select a setting • Press [Shift+Tab] to move backward and select a setting • Double-click the mouse over a setting to select it • Once selected, enter the desired setting value or click a choice from the drop down list • Press [Tab], [Enter] or click outside setting • Press [Escape] to cancel.

When a change is made to a setting, the following prompt appears:

3-20

February 2004 Configuration

A Yes response to the message prompts the Configuration Tool to write the setting to the 853 DSPC. If unsuccessful, an error message may appear, and the setting reverts to its previous value.

Factors Affecting Write Capability

Write capability from the configuration tool to the 853 DSPC is affected by several factors:

No writes are accepted from the configuration tool to the 853 DSPC if the Remote/Local input is in Remote. The 853 DSPC must be in Local mode to enable Configuration Tool control.

The Configuration Tool is considered to be a source of Local Digital control to the 853 DSPC. If the 853 DSPC is operating under Local Analog control, setpoints cannot be written from the Configuration Tool to the 853 DSPC. The following prompt will appear:

In order to write a setpoint from the Configuration Tool to the DSPC, the unit must be under Local Digital control.

3-21

Configuration February 2004

The 853 DSPC settings related to actual 853 DSPC status, such as voltage out, power out, current out, etc, are Read Only, and cannot be written under any circumstances.

Rating information, PT Secondary, frequency, Control strategy, Load Type, zero calibration, and magnetic sequencing can be written only when the 853 DSPC output is off.

Voltage Output Span and Current Output Span can be written only when the 853 DSPC output is on.

When a setting cannot be written the following message appears:

Refer to the Settings Chapter for programming factors specific to each setting.

3-22

February 2004 Configuration

On-line Monitor

The Monitor mode provides a real-time view of 853 operation. Each setting in Monitor mode is updated approximately every 2 seconds.

To access the on-line Monitor mode, select the Window Monitor menu item, or click [Monitor] on the Taskbar.

Monitor information is organized into several tabs: Summary, Control, Status and Timing. Read-only settings are indicated by a (cyan) shadowed background and cannot be changed.

3-23

Configuration February 2004

Summary Tab

The Monitor Summary Tab includes the following data

Duty Cycle Setpoint

Duty Cycle Output

Power Output Setpoint

Power Output

Voltage Input

Voltage Output Setpoint

Voltage Output

Current Input

Current Output Setpoint

Current Output

Analog Input

KVA Input

Power Factor

Frequency Actual

The Duty Cycle Setpoint can be written ONLY under Open Loop regulation.

Figure 3-10 Monitor Summary Tab

3-24

February 2004 Configuration

White fields indicate Read/Write

Cyan fields indicate Read Only information

Green field indicates regulation mode

Amber field indicates alarm status

The operating setpoint for each of the regulation modes is shown in the middle column. The setpoint associated with the selected regulation mode is displayed with a green background.

To change a setpoint:

Select the setpoint to change and enter the desired value

Press [Enter] or click outside the field to write the new setpoint.

• Setpoints can be modified only under Local DIGITAL control.

• Modified setpoints are italicized until written to the 853.

• Press the [Escape] key to cancel.

• The Duty Cycle Setpoint cannot be written unless Open Loop regulation mode is selected.

• The setpoint associated with the selected regulation mode is the control setpoint. The other setpoints become operating limits of their respective control loops.

3-25

Configuration February 2004

Control Tab

The Monitor Control Tab includes the following data for monitor only

Voltage L1-L2 Input Actual

Voltage L2-L3 Input Actual

Voltage L3-L1 Input Actual

Voltage Input Actual

Current L1 Input Actual

Current L2 Input Actual

Current L3 Input Actual

Current Input Actual

Local Primary Analog Setpoint

Voltage X1-X2 Output Actual

Voltage X2-X3 Output Actual

Voltage X3-X1 Output Actual

Voltage Output Actual

Current X1 Output Actual

Current X2 Output Actual

Current X3 Output Actual

Current Output Actual

Local Secondary Analog Setpoint

Figure 3-11 Monitor Control Tab

Cyan fields indicate Read Only information

3-26

February 2004 Configuration

Status Tab

The Monitor Status Tab includes the following data

Monitor Status Word Status Word Bit Number

At Setpoint

Phase Rotation

External Input #1

External Input #2

External Input #3

Regulation Limit

Calibration/Programming Jumper

Bit 9

Bit 10

Bit 11

Bit 12

Bit 13

Bits 6, 7, and 8

Bit 15

Figure 3-12 Monitor Status Tab

Green field indicates on status

3-27

Configuration February 2004

Fault History

The fault history lists the last eight faults recorded by the 853 DSPC. The information is read from the 853 DSPC and displayed in tabular form.

To access the on-line Fault History mode, select the Fault History menu item, or click [Fault] on the Taskbar.

Figure 3-13 Fault History

Included in the Fault History table is the fault code, a description, and time (in hours) of the fault.

Click the [Print] button to send a copy of the information to the printer port of the host computer.

Click the [Close] button to close the Fault History window and return to the previous window.

With JP1 installed, click the [Zero] button to clear the fault buffers.

3-28

February 2004 Configuration

Flash Programming

WARNING

During flash programming, an interruption in the serial communication, either by loss of power or a disconnected serial cable, will corrupt the 853 DSPC flash memory. This will require the 853 DSPC to be sent back to the factory for programming.

The Flash Programming function is available to authorized service personnel only and is used to update the 853 DSPC software.

Figure 3-14 Flash Programming

3-29

Configuration February 2004

Loss of Communication

Momentary loss of communication between the Configuration Tool and 853 DSPC results in the most-recently-read setting to be displayed on a Red background. Subsequent communication recovery restores the normal background color.

If serial communication is not recovered within a reasonable time, the configuration tool will go Offline.

3-30

Chapter 4

Calibration

Proper calibration of the 853 validates the values displayed on the Local Digital Control panel and made available over the network interface. Unit calibration also validates the analog signal levels. The feedback signal levels correlate to the internal gain capability of the 853. Changing the Voltage/Current Ratings or the Analog Input/Output signal levels requires recalibration.

Figure 4-1 Calibration (Voltage Tab)

4-1

Calibration February 2004

Voltage Calibration

The [Cal Enable] button must be clicked to enable voltage calibration.

Voltage X1-X2 Output Zero and Span

Voltage X2-X3 Output Zero and Span

Voltage X3-X1 Output Zero and Span

Voltage L1-L2 Input Span

Voltage L2-L3 Input Span

Voltage L3-L1 Input Span

The [Zero] button, when clicked, uses the actual control reading and the zero adjustment, as currently set, to calculate a new zero adjustment. The result is an incremental change. The output must be off to zero the output voltages.

The [Set] button, when clicked, uses the actual control reading, the measured signal (meter reading), and the span adjustment, as currently set, to calculate a new span adjustment. The result is an incremental change.

The [Manual] button, when clicked, opens an input window for direct entry of calibration values. Jumper JP1 must be installed to enable Manual Calibration.

Figure 4-2 Voltage Calibration

White fields indicate Read/Write

Cyan fields indicate Read Only information

4-2

February 2004 Calibration

Current Calibration

The [Cal Enable] button must be clicked to enable current calibration.

Current L1 Input Zero and Span

Current L2 Input Zero and Span

Current L3 Input Zero and Span

Current X1 Output Zero and Span

The [Zero] button, when clicked, uses the actual control reading and the zero adjustment, as currently set, to calculate a new zero adjustment. The result is an incremental change.

The [Set] button, when clicked, uses the actual control reading, the measured signal (meter reading), and the span adjustment, as currently set, to calculate a new span adjustment. The result is an incremental change.

The [Manual] button, when clicked, opens an input window for direct entry of calibration values. Jumper JP1 must be installed to enable Manual Calibration.

Figure 4-3 Current Calibration

White fields indicate Read/Write

Cyan fields indicate Read Only information

4-3

Calibration February 2004

Analog Calibration

The Calibration Analog Tab holds the calibration settings for

Primary Analog Setpoint Zero and Span Secondary Analog Setpoint Zero and Span

The [Zero] button, when clicked, uses the actual control reading and the zero adjustment, as currently set, to calculate a new zero adjustment. The result is an incremental change.

The [Set] button, when clicked, uses the actual control reading, the measured signal (meter reading), and the span adjustment, as currently set, to calculate a new span adjustment. The result is an incremental change.

Check the Enable box for Analog Output Calibration. Use the slide bars to adjust Analog Output Bias and Span. Uncheck the Enable box after Analog Output Calibration.

Analog Output #1 Bias and Span Analog Output #2 Bias and Span

The [Manual] button, when clicked, opens an input window for direct entry of calibration values. Jumper JP1 must be installed to enable Manual Calibration.

Figure 4-4 Analog Calibration

White fields indicate Read/Write

Cyan fields indicate Read Only information

4-4

February 2004 Calibration

Current Rating

The current feedback signal (at rated current) of the 853 must be between 1.25Vrms and 2.85Vrms. The typical unit is setup for a current feedback signal level of 2.50Vrms using the burden resistor of the current transformer. Standard units have the following burden resistors and feedback signals.

Unit Size CT Burden Resistor Feedback Signal

40A 800:1 62Ω 2.46Vrms

90A 1800:1 56.2Ω 2.53Vrms

175A 3500:1 41.2Ω 2.40Vrms

350A 7000:1 49.9Ω 2.50Vrms