8-10 SHOCK ABSORBER MANUAL

Transcript of 8-10 SHOCK ABSORBER MANUAL

Maintenance &Service Manual8” - 10” HD Shock Absorbers

Certificate Number 2446/00ISO9001

HD-SA

HD

-SA

CONTENT

Parts List............................................................................... Page 1

Servicing & Maintenance....................................................... Page 2 - 3

Notes..................................................................................... Page 4

WARNING

ALWAYS THINKSAFETY FIRST!

This manual is published by and copyright © of Bulroc (UK) Ltd. All Rights Reserved. Always operate your Bulrocdrilling equipment according to the instructions contained within this operating manual. Further copies of this manualcan be downloaded from the Bulroc website; www.bulroc.com. For urgent support or sales enquiries, call Bulrocon +44 (0)1246 544700 or Skype BULROCUKSALES . E & O.E

PARTS LIST 1

Ref Description HDSA841/2” API

HDSA106 5/8” API

1 Top Connector SA08ST0804M SA10ST0880M2 Buffer SA08ST05 SA10ST053 Thrust Washer SA08ST04 SA10ST044 Nut SA08ST01 SA10ST015 Shaft SA08ST02 SA10ST026 Shaft ‘O’ Ring SA08ST03 SA08ST037 Bottom Connector SA08ST0904F SA10ST0980F

Complete Shock Absorber SA08ST04MF SA10ST080MF

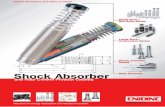

SERVICING & MAINTENANCE 2The Bulroc 8-10 inch “Down The Hole” Shock Absorbers shouldbe serviced after every 500 hours of operation or every six monthsof intermittent use.

To disassemble the unit you must first securely clamp (item 7) theBottom Connector to the bed of an appropriately sized strippingbench before attaching a Spanner to the flats on (item 1) the TopConnector. Once the Spanner is in position you can then attachthe benches Hydraulic Cylinder to the Spanner and apply thenecessary load to unscrew the Top Connector (item 1) from theShaft (item 5).

Once the Top Connector is fully removed (item 3) the ThrustWasher and (item 2) the Buffer can be pulled from their housing.

The Buffer (item 2) should be checked for any signs of damageand its thickness measured. When the thickness has worn below2” the Buffer should be replaced. Similarly if there are any signsof cracking or breaking up, the Buffer should be replaced.

In a similar way to removing the Top Connector a Spannershould now be attached to the spanner flats on (item 4) theNut, and the Hydraulic Cylinder on the stripping bench used toapply the necessary load to unscrew it from (item 7) the BottomConnector.

Once the Nut and Shaft are removed from the Bottom Connectorthe splines on both items must be checked for wear.

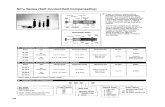

The diagram on the right shows the maximum permissible wearlimits for both items. Should either, or both items show weargreater than these values then the component, or componentsshould be replaced as excessive wear on these items willeventually result in failure of the unit and could cause loss ofthe Hammer and Button Bit down the hole.

It is recommended that every time the unit is stripped for inspection (item 6) the Shaft “O”Ring isremoved and replaced with a new one.

Before re-assembling the unit all parts should be cleaned and checked for damage. Any “burrs”or sharp edges caused by the natural wearing of the components should be removed with asmall hand grinder.

Prior to assembly all Splined and Threaded areas on the Nut, Shaft, Top Connector and BottomConnector should be coated with a good quality, heat resistant grease, which will both reducewear and aid stripping when the unit next requires servicing.

To assemble the unit first slide (item 5), the Shaft with its new “O”Ring (item 6), into (item 7) theBottom Connector. Slide the Nut (item 4) over (item 5) the Shaft making sure the splines arecorrectly engaged before screwing the Nut into the Bottom Connector. Then slide (item 3) theThrust Washer and (Item 2) the Buffer over the Shaft (item 5), onto the top face of (Item 4) theNut.

Finally screw (item1) the Top Connector down on (item 5) the Shaft making sure the Buffer andThrust Washer enter their housing as the Top Connector advances down the Shaft. The unitshould be tightened to recommended maximum torque of 2.24 Ton.m / 2243 Kgm for the 8”Shock absorber and maximum torque of 3.45 Ton.m / 3454 Kgm for the 10” shock absorber.

BORE OF NUT

O/D OF SHAFT

0.860” / 21.84mm MAXIMUM

0.690” / 17.53mm MINIMUM

SERVICING & MAINTENANCE 3

NOTES 4

This page left intentionally blank

Manufacturers of Rock Drilling EquipmentTurnoaks Business Park, Burley Close, Chesterfield ,Derbyshire S40 2UBTel: +44(0) 1246 544700 Fax: +44(0) 1246 544701E-mail: [email protected] website bulroc.com HDSA8/10 1 2 0 7 13