7.2.6 APQP Phase 3 Checklist Dec 2013

-

Upload

mani-rathinam-rajamani -

Category

Documents

-

view

52 -

download

4

description

Transcript of 7.2.6 APQP Phase 3 Checklist Dec 2013

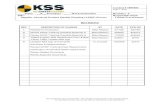

User Guide#QuestionY*NN/ARYGEvidenceActions RequiredResponsibleOpen DateDue DateStatus%Actual End Date123456789101112131415X25%N/ADeliverable RYG RatingIP50%Location: / Site:Status (%):25% - Action Identified 50% - Owner Identified75% - Action in Progress 100% - Action Closed75%RRed: Some questions have a negative answer and no recovery plan is in place or the plans identified will have an impact in program timing. Support is required. When an item is highlighted Red an assessment on the impact to the WP timing needs to be provided.Reviewed by:100%YYellow: Some questions have a negative answer but a recovery plan is in place which will prevent impact on timingReviewed with:GGreen: All questions have a positive answer (Y) and are ongoing normal program developmentDate :

&"Arial,Bold"&20 User Guide

The questions are used to evaluate the quality of the deliverable attached to the element. Typical aspects of the deliverable to be evaluated through the questions are:1. Quality/availability of the inputs needed to build the deliverable 2. Cross-functional approach to answer the deliverables3. Quality /conformity to a standard if any or to best practices 4. control of the outcome of the deliverable (e.g. action plan)

Input evidence of the answer to the question (e.g.: document reference) here. If an "X" is in the preceding N column (column D) then describe the issue here including root cause in order to identify proper actions .Actions identified based on the root cause described in the Evidence column when the RYG column is Red or Yellow.These are typical action management milestones . The due date should be aligned with the closure date of the deliverable as planned in the APQP timing. In cases where the due date is not aligned with APQP timing, the RYG status is most likely Red .Date of revision for the provided status and personnel involvedY* - Put an "X" if complete and is OK or "IP" if in-progress as planned.N - Put an "X" if it is Not OK .N/A - Put an "X" if you have agreed with your customer that this question is Not Applicable.RYG - Put an "R" here if the answer to the question is not acceptable and there is no recovery plan. Put a "Y" here if there are problems with the question but is recoverable with an action plan inplace. Put a "G" if it is on track or satisfactorily complete. When you put an "R" or "Y" you will need to complete the "Actions Required" and subsequent columns.

3.01 Process Flow Chart#QuestionY*NN/ARYGEvidenceActions RequiredResponsibleOpen DateDue DateStatus%Actual End Date1Was the manufacturing process flow chart created by a cross functional team including Manufacturing Engineering, Production and Quality (incluging others as applicable)?2Is enough information available to create the process flow chart?All input data to the manufacturing flow chart are avaiblable such as: preliminary design drawings, preliminary bill of material, process specificatioin/requirements, Preliminary Key Characteristics and Critical Items, material/ components introduction points..3Is the manufacturing flow chart specific to the product?4Does the manufacturing flow chart include manufacturing, inspection and test phases for subassemblies and finished product?The manufacturing process flow chart is not limited to final assembly, it combines final assembly and construction of all the subasseblies required to make the product.5Does the manufacturing flow chart include subcontracted activities?The manufacturing process flow requirement is cascaded to them.6Does the manufacturing flow chart include critical process steps (e.g.: long lead time equipement, processes requiring operators to be certified by external parties)7Is the manufacturing flow chart identifying quality metrics (process steps scraps %, rework %, First Pass Yield %, Non Destructive Testing FPY %, Cp and Cpk, R1, OEE,)?8Does the process flow chart include Key Characteristics and their monitoring? 9Does the process flow chart include means (machine, equipment) & tools used? In so far as they are identified.10Does the manufacturing flow chart include standard Operating Instruction needed and available at each process step?11Is the process flow chart kept up-to-date and configuration managed?12Have any additional risks including mitigation plans been identified that may affect this deliverable?131415X25%N/ADeliverable RYG RatingIP50%Location: / Site:75%RRed: Some questions have a negative answer and no recovery plan is in place or the plans identified will have an impact in program timing. Support is required. When an item is highlighted Red an assessment on the impact to the WP timing needs to be provided.Reviewed by:Status (%):25% - Action Identified 50% - Owner Identified100%YYellow: Some questions have a negative answer but a recovery plan is in place which will prevent impact on timingReviewed with:75% - Action in Progress 100% - Action ClosedGGreen: All questions have a positive answer (Y) and are ongoing normal program developmentDate :

&"Arial,Bold"&20 3.01 Process Flow Chart

3.02 Floor Plan Layout#QuestionY*NN/ARYGEvidenceActions RequiredResponsibleOpen DateDue DateStatus%Actual End Date1Was the Floor plan layout created by a cross functional team including Process Engineering, Production Manager, Quality, Facilities Management, Maintenace and Health, Safety & Environment Representatives?2Have all the necessary inputs been taken into account and they are frozen at the right stage (e.g., Build Process Definition , Value Stream Mapping Analysis, Inbound / Outbound Logistics Flow, H&S and environmental rules, Plant Lay Out Blue Print and plan, existing facility utilities )?3Have Material Flow, Storage and Buffer areas been considered when defining the plant (facility) lay out?4Have People Flow (e.g., spaghetti charts) been considered when defining the lay out?5Is the floor layout optimized to remove waste (overproduction, movement, inventory, waiting, overprocessing, defects and transportation) from the process?6Have health, safety, ergonomic, environmental and facility requirements been validated in the proposed lay out?7Is the plant (facility) lay out implementation plan and its readiness in line with program schedule?8Have Capital expenditure targets been considered by the lay out? Has Capital Expenditure been approved?9Is the floor plan layout up-to-date and managed in configuration? Is it consistent with the latest process flow chart?10Have any additional risks including mitigation plans been identified that may affect this deliverable?1112131415X25%N/ADeliverable RYG RatingIP50%Location: / Site:Status (%):25% - Action Identified 50% - Owner Identified75% - Action in Progress 100% - Action Closed75%RRed: Some questions have a negative answer and no recovery plan is in place or the plans identified will have an impact in program timing. Support is required. When an item is highlighted Red an assessment on the impact to the WP timing needs to be provided.Reviewed by:100%YYellow: Some questions have a negative answer but a recovery plan is in place which will prevent impact on timingReviewed with:GGreen: All questions have a positive answer (Y) and are ongoing normal program developmentDate :

&"Arial,Bold"&20 3.02 Floor plan Layout

3.03 Prod Prep Planning#QuestionY*NN/ARAGEvidencesActions RequiredResponsibleOpen DateDue DateStatus%Actual End Date1Was this activity undertaken by a cross functional team including Manufacturing Engineering, Quality, Production, Maintenance, Human Resources and Procurement (for outsourced equipment)?Capacity2Do you have established, demonstrated capacity?Did you use OEE as the basis for your calculation?3Did you undertake your evaluation considering different volume scenarios (including retrofit and spares)?This should consider internal and supplier capacity.4Did you consider the volume profile over 1, 3 and 5 year timescales considering demand from all of your customers?This should consider internal and supplier capacity.5Did you evaluate an increase based on a surge in customer demand (eg +20% in 3 months)?This should consider internal and supplier capacity.Production Preparation Plan6Is the list of equipment requirements complete and does it cover all aspects of the manufacturing process as described in the process flow chart?7Have you confirmed the capacity for all existing equipment?8Have you confirmed the theoretical capacity for new equipment with the equipment supplier(s)?9Are specifications released and available for procurement? Are specifications complete, relevant and with the correct level of detail to allow procurement to commence?10Are all applicable customer, industry and regulatory standards taken account of in the preparation plan?11Does the plan cover outsourced parts?12Does the plan cover in house manufacturing preparation?13Does the plan cover human resources (headcount)?14Does the plan cover the tasks required in order to validate that the process is qualified?15Is the overall implementation plan validated and accepted by the customer?16Is the implementation schedule in line with programme needs?17Is there a defined reporting mechanism to track progress against the plan with an agreed escalation process for delays?The reporting method and frequency has been agreed with the customer.18Have any additional risks including mitigation plans been identified that may affect this deliverable?X25%N/ADeliverable RYG RatingIP50%Location: / Site:Status (%):25% - Action Identified 50% - Owner Identified75% - Action in Progress 100% - Action Closed75%RRed: Some questions have a negative answer and no recovery plan is in place or the plans identified will have an impact in program timing. Support is required. When an item is highlighted Red an assessment on the impact to the WP timing needs to be provided.Reviewed by:100%YYellow: Some questions have a negative answer but a recovery plan is in place which will prevent impact on timingReviewed with:GGreen: All questions have a positive answer (Y) and are ongoing normal program developmentDate :

&"Arial,Bold"&20 3.03 Production Preparation Planning

3.04 Oper Staff & TrainPlan#QuestionY*NN/ARYGEvidenceActions RequiredResponsibleOpen DateDue DateStatus%Actual End Date1Was the operator staffing and training plan created by a cross functional team including Production, Quality and Human Resources?2Did you evaluate the new skill requirements against the existing skills matrix?3Did you use the capacity evaluation of manpower requirements to determine the level of human resources which you require?4Do you have a timing plan in place for the recruitment of suffient operators which is in line with program timing requirements?5Do you have a timing plan in place for the training of sufficient operators to an appropriate level in line with program timing requirements?6Have you identified and secured the appropiate resources to train/certify the operators in line with your plan?7Do you have an agreed reporting schedule in place which tracks progress on recruitment and training?Does this report status to the customer if required?8Is the recruitment progressing to plan?Recruitment is complete for the current phase of the program.9Is the training progressing to plan?Training and cross training is complete for the current phase of the program.101112131415X25%N/ADeliverable RYG Rating25%50%Location: / Site:Status (%):25% - Action Identified 50% - Owner Identified75% - Action in Progress 100% - Action Closed75%RRed: Some questions have a negative answer and no recovery plan is in place or the plans identified will have an impact in program timing. Support is required. When an item is highlighted Red an assessment on the impact to the WP timing needs to be provided.Reviewed by:100%YYellow: Some questions have a negative answer but a recovery plan is in place which will prevent impact on timingReviewed with:GGreen: All questions have a positive answer (Y) and are ongoing normal program developmentDate :

&"Arial,Bold"&20 3.04 Operator Staffing and Training Plan

3.05 PFMEA#QuestionY*NN/ARYGEvidenceActions RequiredResponsibleOpen DateDue DateStatus%Actual End Date1Was the PFMEA flow chart created by a cross functional team including Design Engineering, Manufacturing Engineering, Production and Quality (incluging production control & supply chain if applicable)?2Was one of the team members trained in FMEA methodology?3Was the Process Flow used as the basis of the PFMEA exercise?All subcontracted activities have been considered.4Did the activity consider similar parts and PFMEAs as part of the activity?5Were historical non-conformance and warranty issues reviewed and included in the scope of the activity?6Is the PFMEA documented and recorded on a suitable template? Is the document date and configuration controlled?7Have all potential failure modes been properly evaluated considering Severity, Occurence and Detection for the initial RPN calculation?8Has the scoring been consistent using a methodology based on industry guidance for ranking rules?9Have Process Key Characteristics / Critical Items / Product Key Characteristics been considered and highlighted in the PFMEA analysis in order to assure them and ultimately minimize the variation where applicable?10Do all failure modes with high RPNs have an action, action owner, and a due date?Action plan is progressing to plan at date of review.11Is PFMEA Analysis up to date reflecting the latest information on product performance (ie, Shopfloor feedback, Continuous Improvement process or operations, Functionnal evolution, Non conformities etc.)?12Have RPNs been reassessed only following the implementation of identified actions and evaluation of the effectiveness of the action?13Has action been taken to ensure that defects are not passed on to the next process step?14Have any additional risks including mitigation plans been identified that may affect this deliverable?X25%N/ADeliverable RYG RatingIP50%Location: / Site:Status (%):25% - Action Identified 50% - Owner Identified75% - Action in Progress 100% - Action Closed75%RRed: Some questions have a negative answer and no recovery plan is in place or the plans identified will have an impact in program timing. Support is required. When an item is highlighted Red an assessment on the impact to the WP timing needs to be provided.Reviewed by:100%YYellow: Some questions have a negative answer but a recovery plan is in place which will prevent impact on timingReviewed with:GGreen: All questions have a positive answer (Y) and are ongoing normal program developmentDate :

&"Arial,Bold"&20 3.05 Process Failure Mode and Effects Analysis (PFMEA)

3.06 Process KCs#QuestionY*NN/ARYGEvidenceActions RequiredResponsibleOpen DateDue DateStatus%Actual End Date1Was the activity undertaken by a cross functional team including Manufacturing Engineering, Quality and Operations?2Has the team considered the Product Key Characteristics in this activity?3Has the team considered the PFMEA in this activity?4Has the team considered lessons learned from previous projects in this activity?5Is there agreement between all functions on the final list of Process Key Characteristics?6Have any additional risks including mitigation plans been identified that may affect this deliverable?789101112131415X25%N/ADeliverable RYG RatingIP50%Location: / Site:Status (%):25% - Action Identified 50% - Owner Identified75% - Action in Progress 100% - Action Closed75%RRed: Some questions have a negative answer and no recovery plan is in place or the plans identified will have an impact in program timing. Support is required. When an item is highlighted Red an assessment on the impact to the WP timing needs to be provided.Reviewed by:100%YYellow: Some questions have a negative answer but a recovery plan is in place which will prevent impact on timingReviewed with:GGreen: All questions have a positive answer (Y) and are ongoing normal program developmentDate :

&"Arial,Bold"&20 3.06 Process Key Characteristics

3.07 Pre Launch Control Plan#QuestionY*NN/ARYGEvidenceActions RequiredResponsibleOpen DateDue DateStatus%Actual End Date1Was the control plan created by a cross functional team including Manufacturing Engineering, Quality, Design Engineering and Operations, Supply Chain and Maintenance (as required)?2Are all the high risk failure modes identified in the PFMEA addressed in the Control Plan?3Is the control plan consistent with customer requirements?4Are the different Control plan versions and their applicability tracked?Control plan version has to be aligned with the part configuration.Track evolution is including the reason of change for each control5Does the Control Plan cover all issues identified during the development process?6Are all Product and Process Key Characteristics (and Critical Items) included and highlighted in the control plan?7Are the methods (inspection gate, SPC chart,...) used to record results referenced in the control plan ?8In case of out-of-tolerances, is the Reaction Plan (Out of Control Action Plan (OCAP)) available at the work station and referenced into the control plan?9Are all specifications required by the control plan (tolerances, measurement specification, test frequency and sample size, control method, reaction plan) implemented on the shop floor?10Are all active Control Plan items cascaded to the shop floor documentation and performed?11Are key characteristics identified by the customer cascaded down to subsupplier control plans?12Is the control plan regularly updated (in accordance with customer requirements) and reflects the current manufacturing activities (Feedback loop, root causes analysis and process control improvement)? 13Have any additional risks including mitigation plans been identified that may affect this deliverable?14X25%N/ADeliverable RYG RatingIP50%Location: / Site:Status (%):25% - Action Identified 50% - Owner Identified75% - Action in Progress 100% - Action Closed75%RRed: Some questions have a negative answer and no recovery plan is in place or the plans identified will have an impact in program timing. Support is required. When an item is highlighted Red an assessment on the impact to the WP timing needs to be provided.Reviewed by:100%YYellow: Some questions have a negative answer but a recovery plan is in place which will prevent impact on timingReviewed with:GGreen: All questions have a positive answer (Y) and are ongoing normal program developmentDate :

&"Arial,Bold"&20 3.07 Pre Launch Control Plan

3.08 MSA Plan#QuestionY*NN/ARYGEvidenceActions RequiredResponsibleOpen DateDue DateStatus%Actual End Date1Was the MSA Plan created by a cross functional team including Manufacturing Engineering, Production and Quality (Plus design engineering as required)?2Has the pre-launch control plan been released and references method/control device information needed for MSA activity?3Has the list of measurement systems to be validated been created using:> Criticality of the measurements (as a minimum anything linked to a key characteristic)> Past experience of using the measurement system and evidence of its capabilityand been approved by the cross functional team?4Is there an MSA leader assigned to each of the MSA activities to be performed?5Are the objectives of each test to be done clear and communicated to all involved parties (i.e. affected operation, MSA Leader, measurement experts)?6Is the accuracy of the control device acceptable for the measurement system application?7Is there a calibration plan and protocol for the measurement devices to be used in the gage R&R nd in line with the applicable standards and methods?8For each measurement system has a gage R&R target value been defined?9Is the MSA Plan communicated and agreed by all interested parties (i.e. management in the operation affected, Metrology Management )?10Have the training needs to perform the measurement identified and planned ?11Have any additional risks including mitigation plans been identified that may affect this deliverable?12131415X25%N/ADeliverable RYG Rating25%50%Location: / Site:Status (%):25% - Action Identified 50% - Owner Identified75% - Action in Progress 100% - Action Closed75%RRed: Some questions have a negative answer and no recovery plan is in place or the plans identified will have an impact in program timing. Support is required. When an item is highlighted Red an assessment on the impact to the WP timing needs to be provided.Reviewed by:100%YYellow: Some questions have a negative answer but a recovery plan is in place which will prevent impact on timingReviewed with:GGreen: All questions have a positive answer (Y) and are ongoing normal program developmentDate :

&"Arial,Bold"&20 3.08 Measurement System Analysis (MSA) Plan

3.09 Mfg Process Doc#QuestionY*NN/ARYGEvidenceActions RequiredResponsibleOpen DateDue DateStatus%Actual End Date1Was the manufacturing documentation created by a cross functional team including Manufacturing Engineering, Production, Quality and Facilities Maintenance (including other functions as required)?2Is there a completed Manufacturing and Inspection File related to the product including all relevant information: Configuration controlled drawing, Traveller Sheet, Routings, Bill Of Material, Work instructions, manufacturing and test/inspection tools?3Are all relevant technical and test specifications to be applied to the product defined in the manufacturing and inspection file?4Are all documents needed for production (manufacture, installation, storage, handling, part list, acceptance test sheet, control report, delivery procedures,...) listed and released?5Are work instructions defined? Work instructions provide operators with a detailed description to produce in a standardized serial production condition.6Is all material needed listed for all Workstations?7Has all documentation been reviewed and understood by the operators? The operator is trained to the work instructions and training records are kept.8Is the configuration management process formalized and the associated requirements properly cascaded into the Manufacturing and Inspection folder? Content of folder is consistent with the latest process and product definition.9Has there been regular assessments to verify the update of the Manufacturing and Inspection File and its implementation (SOIs) in production?101112X25%N/ADeliverable RYG RatingIP50%Location: / Site:Status (%):25% - Action Identified 50% - Owner Identified75% - Action in Progress 100% - Action Closed75%RRed: Some questions have a negative answer and no recovery plan is in place or the plans identified will have an impact in program timing. Support is required. When an item is highlighted Red an assessment on the impact to the WP timing needs to be provided.Reviewed by:100%YYellow: Some questions have a negative answer but a recovery plan is in place which will prevent impact on timingReviewed with:GGreen: All questions have a positive answer (Y) and are ongoing normal program developmentDate :

&"Arial,Bold"&20 3.09 Manufacturing Process Documentation

3.10 Supply Chain Risk#QuestionY*NN/ARYGEvidenceActions RequiredResponsibleOpen DateDue DateStatus%Actual End Date1Was the activity undertaken a cross functional team including Procurement, Quality, Production control & planning (including finance if applicable)?2Is there a supply chain map specific to the product and does it reflect the current Supply Chain process (including sub assemblies and procured parts)?3Does the supply chain map identify major Suppliers (single source, critical suppliers,...)?4Does the supply chain map identify bottlenecks from the capacity analysis?5Does the supply chain map consider stocking policy and stock locations?6Does the supply chain map capture Supply Chain Indicators such as On Time Delivery, Rejection Rate? 7Is the supply shain map up-to-date and reflect the current condition? Is there a "future state" map defined to address concerns identified (eg extra capacity, sole source, long leadtime etc)?8Has the supply chain risk register considered the impact of supplier failure to our business?Consider how long production would stop before a new supplier could be introduced. Estimate the cost to evaluate an alternative source (tooling, testing, Customer approvals etc). Consider the technical complexity of product any emergency stock.9Has the supply chain risk register considered the risk of financial, quality, delivery, geo-political problems at suppliers?10Have the risks been evaluated and prioritised?11Is there a clear mitigation plan in place for all major risks?Action, owner and due date clearly defined.12Have any additional risks including mitigation plans been identified that may affect this deliverable?131415X25%N/ADeliverable RYG RatingIP50%Location: / Site:Status (%):25% - Action Identified 50% - Owner Identified75% - Action in Progress 100% - Action Closed75%RRed: Some questions have a negative answer and no recovery plan is in place or the plans identified will have an impact in program timing. Support is required. When an item is highlighted Red an assessment on the impact to the WP timing needs to be provided.Reviewed by:100%YYellow: Some questions have a negative answer but a recovery plan is in place which will prevent impact on timingReviewed with:GGreen: All questions have a positive answer (Y) and are ongoing normal program developmentDate :

&"Arial,Bold"&20 3.10 Supply Chain Risk Management

3.11 Prod Readiness Review#QuestionY*NN/ARYGEvidenceActions RequiredResponsibleOpen DateDue DateStatus%Actual End Date1Has the Production Readiness Review been supported by a multifunctional team involving Operations, Supply Chain, Quality, Manufacturing Engineering, Design Engineering, Customer Support and chaired by the Program Leader, in charge of this product? 2Are all component products qualified (materials, parts, constituent assy, equipment) and available at the correct design configuration?Internal and outsourced suppliers.3Is the production process and equipment in place and ready for use?Processes are qualified to the appropriate specifications.Where applicable TRL (technology readiness level) and MRL (manufacturing readiness level) have been achieved in line with program requirements.4Is the product definition finished and released? All concessions are closed. All forecast modifications have been implemented.Design Verification & Validation is complete.5Does the current production condition reflect the latest design & engineering documentation?6Is the production manufacturing documentation in place and reflects the current product and process definition?7Are sufficient operators trained and in place?8Are ERP and information systems configured to the latest product and process definitions?9Is the capacity ramp up plan in place and sufficient to meet projected customer demand?In house and suppliers.10Have Operations, Quality and Procurement confirmed that the production process is ready to enter into serial production phase?11Has management confirmed that they are satisfied that the production process is ready to enter serial production phase?12Is all material needed available at all Workstations?13Have any additional risks including mitigation plans been identified that may affect this deliverable?X25%N/ADeliverable RYG RatingIP50%Location: / Site:Status (%):25% - Action Identified 50% - Owner Identified75% - Action in Progress 100% - Action Closed75%RRed: Some questions have a negative answer and no recovery plan is in place or the plans identified will have an impact in program timing. Support is required. When an item is highlighted Red an assessment on the impact to the WP timing needs to be provided.Reviewed by:100%YYellow: Some questions have a negative answer but a recovery plan is in place which will prevent impact on timingReviewed with:GGreen: All questions have a positive answer (Y) and are ongoing normal program developmentDate :

&"Arial,Bold"&20 3.11 Production Readiness Review