70358580 Post Tensioning 1

-

Upload

fatimahabibaganih -

Category

Documents

-

view

17 -

download

0

description

Transcript of 70358580 Post Tensioning 1

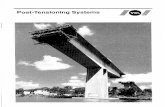

POST-TENSIONING Principles and Applications Elements

Text Box: Prepared by: Danny M. Francisco. C.E., G.E. Tel. 6770359 (Office) Mobile: 0557124793 Email: [email protected] by:Prepared by:Danny M. Francisco. C.Danny M. Francisco. C.Tel. 6770359 (Office)Tel. 6770359 (Office)Mobile: 0557124793Mobile: 0557124793Email: danilo.aramco.comEmail: danilo.aramco.com

Objectives:

1. To know the brief history of post-

tensioning.

2. To understand the basic

post-tensioning.

3. To identify the

tensioning.

4. To know

tensioning

History

�The first patent for prestressed concrete issued to P.H. Jackson of San Francisco He obtained a US patent for tightening rods in artificial stones (concrete concrete arches used for slabs

Shortly thereafter, in 1888, C.E.W. Doehring

Germany also obtained a patent for prestressing

concrete slabs with metal wires. However,

development of prestressed concrete

attributed to Eugene Freyssinet

In 1928, Freyssinet begun strength

steel wire for prestressing

In 1940, Professor Gustav Magnel of Belgium

developed a system of curve, multi-wire tendons in

flexible rectangular ducts.

The first use of post-tensioning in the US was on the Walnut Lane Bridge in Philadelphia in 1949. This landmark bridge had precast girders tensioned with the Magnel system.

Ulrich Finsterwalder-German Civil Engineer

Tie-Back Anchorage

Tie-Down Anchorage

Over the years, there have been a number of significant

technological developments that have helped advance the

state-of-the-art of post tensioning and have contributed to its

continued growth. These developments include:

1. Introduction of strand system

2. Development of ductile iron castings for single strand tendons

3. Introduction of the �load-balancing�design method

4. Introduction of �banded�tendon layout for 2-way slab system

5. Segmental bridge construction

6. Use of computers and design

7. Formation of Tensioning Institute

8. Improvements

�In the United States, early bonded post-tensioning system used high-strength stress-relieved steel wires, bars, or strand. The button-headed tendon system used ¼inch wire bundled together, greased, and wrapped with Kraft paper as sheathing. through a stressing head and were �button headed�to anchor them. Machinery was used upset the ends of the wires to create the head anchors. The post-tensioning elongation was held or a threaded nut.

�The button-headed tendon system had two major problems. The first problem was that had to be an exact length. Any deviation the tendon length and the length required either a new tendon forms before pouring the �Second, because shims ended up on the outside slab, they have concrete pour.

�The first strand tendon system �developed by Edward K. Riceand others at Atlas Prestressing Corporation-used ½inch sever-wire prestressing strand and an anchorage assembly manufactured coiled wire and a plate and anchored wedge chucks. The strand was also andwrapped with Kraft paper.

�Since 1985, post-tensioning usage has continued to grow at a rapid pace, averaging 8.5% annual as shown.

�In the last 50 years, prestressed concrete has grown to be a multibillion-dollar industry in North America and is used in many different construction applications. Figure shows the relative usage tensioning by market value.

Principles:

�Prestressing

General:

Pre-stressing is a method of reinforcing concrete. Externally applied loads induce internal stresses (forces) in concrete during the construction and services phases of a member. The concrete is pre-stressed to counteract these anticipated stresses during the service life of the member.

�There are two commonly used stressing concrete. One is called pre-tensioning. The prefix �pre�means that the pre-stressing steel is stressed before the concrete is cast. This method consists of first stressing high-strength steel strands or wires between buttresses, steel. Once the concrete has reached a certain the steel is cut buttresses to stressing force This process typically a precast complete pre-tensioned job site and

�The other method of pre-stressing concrete is called post-tensioning. The prefix �post�means that the pre-stressing steel is stressed after the concrete Instead of stressing the high-strength steel between buttresses at a precast plant. The installed on the job site after the contractor the member. The high-strength steel is housed in a sheathing or duct that prevents concrete. The steel is attached ends of the member by design anchorage devices. Once the concrete steel is stressed to tensioning has stressed concrete while construct the including final position in-place).

�Types of post-tensioning system:�In most post-tensioned construction, the pre-stressing tendons are embedded in the concrete before the concrete is cast. These internally post-tensioned systems can be either bonded or unbonded. In some bridge applications, the post-tensioning tendons are mounted outside the structural members. These are referred to as external post-tensioning systems.

�In un-bonded systems, the strand is kept unbonded the surrounding concrete throughout its In bonded systems, grout is injected in bond the pre-stressing strand to the surrounding concrete after it has been stressed. has cured (hardened), the system integral system without any between steel and concrete. grouted post-tensioned systems are bonded. Unbonded systems between the strand throughout it service strand systems and all external tensioning systems this category.

�Unbonded Post-Tensioning Systems:�The tendons in an unbonded system typically consist of single-strand that coated with corrosion-inhibiting coating and protected by extruded plastic sheathing. This allows the strand to move inside the plastic sheathing and prevent the ingress of water. �The strands are anchored to the concrete ductile iron anchors and hardened steel wedges. supported by chairs and bolsters maintain the desired profile. Figure components and construction sequence for an unbonded system.

�Depending on the exposure of the single-strand unbonded system, it can be classified as a standard or encapsulated system. Encapsulated systems are required environment where there is a possibility of tendon exposure to chlorides or other deleterious substances. tendons are designed to prevent any ingress of water during and after construction. Figure shows an example of a standard and encapsulated tendon.

�Bonded Post-Tensioning System:�Bonded post-tensioning systems consist of tendons with multi strands or bars. The strands or bars are placed in corrugated galvanized steel, high density polyethylene (HDPE) or polypropylene (PP) ducts. Depending on the site system used, the strands may be installed before isplaced or the ducts may be installed without the strands are then pulled or pushed through concrete has hardened, the tendons are stressed and ducts filledwith grout. Inlets and outlets are provided at high/low points to ensure that the grout fills the ducts completely. Figure shows components of a typical multi grouted system. The grout provides an alkaline environment stressing strands from corrosion. It surrounding concrete.

Illustrations:

�Concrete has a low tensile strength but compression. The tensile strength 10% of its compressive strength. concrete members are likely to �Consider a beam of plain

As the load increases, the beam deflects slight falls abruptly. Under load, the stresses in be compressive in the top, but tensile in can expect the beam to crack at the even with a relatively small load, because of concrete�s low tensile strength. In order to resist tensile stresses or counter the low tensile strength which plain concrete cannot resist, it can be reinforced steel reinforcing bars or stressing.

�In the usual reinforced concrete beam, the concrete cannot be used efficiently, certain may be applied to the beams that result member in which all the concrete can bending stresses. �Introducing a means of pre-compressing the tensile zones of the concrete anticipated tensile stresses eliminate cracking and durable concrete member. compressing a concrete element, applied load, and achieving structure.

�The function of Prestressing (pre-tensioning or POST-TENSIONING) is to place the structure under compression in those region causes tensile stresses. Compressive introduced into areas where tensile under load will resist or annul stresses. �So the concrete now tensile strength of tensile stresses compression the bottom

�Tension caused by the load will first have cancel the compression induced by the tensioning before it can crack the concrete. pre-compression stresses can also be overcome the diagonal stresses. procedure is to design to eliminate working loads.

�However, bending is only one of the conditions involved. There is also shear. Vertical and horizontal shear forces are set up within and these will cause diagonal tension diagonal compression stresses of �As concrete is weak in tension, reinforced concrete beam will diagonal tension stresses the support. In pre-stressed concrete, the compression stresses overcome these tension

�Simple illustration #1: �Row of books

�Prof. Gustav Magnel, one of the pioneers prestressed concrete used this illustration simply explained to his students using books.

�Illustration #2:�Figure 1.4 shows a plainly reinforced concrete simple-span beam and a fixed cantilever beam cracked under applied load.

Reinforced concrete

��Figure 1.5 shows the same unloaded beams Figure 1.5 shows the same unloaded beams prestressing forces applied by stressing prestressing forces applied by stressing high strength tendons. By placing the prestressing strength tendons. By placing the prestressing in the simplein the simple--span beam and high in the span beam and high in the cantilever beam, compression is induced cantilever beam, compression is induced tension zones; creating upward tension zones; creating upward PostPost--tensioned tensioned

��While figure1.6 shows the two prestressed While figure1.6 shows the two prestressed after loads have been applied. The loads after loads have been applied. The loads both the simpleboth the simple--span beam and cantilever beam span beam and cantilever beam to deflect down, to deflect down, ��creating tensile stresses in the bottom creating tensile stresses in the bottom simplesimple--span beam and top of the cantilever span beam and top of the cantilever PostPost--tensioned Fig. 1.6)(Fig. 1.6)

��The designer shall be able to balance the effects of load The designer shall be able to balance the effects of load prestressing in such a way that tension from the loading is prestressing in such a way that tension from the loading is compensated by compression induced by the postcompensated by compression induced by the post--tensioning. Figure 1.6 shows that tension is eliminated tensioning. Figure 1.6 shows that tension is eliminated under combination of Figures 1.4 and 1.5. Also construction under combination of Figures 1.4 and 1.5. Also construction materials (concrete and steel) are used more efficiently; materials (concrete and steel) are used more efficiently; optimizing materials, construction effort and cost. optimizing materials, construction effort and cost. Fig. 1.4 Fig. 1.4 Fig. 1.5 Fig. 1.5 Fig. 1.6Fig. 1.6

�One of the things that happen to a concrete, masonry wall, is that they are subjected that cause them to flex and bend. this includes slabs on ground where the slabs are forced upward elevated concrete slabs where applied loads pull down supports, and walls that lateral forces from bending creates the concrete and the use of reinforcing

�Illustration #3:

�Since steel has a high capacity to tensile forces, it can be embedded concrete at the tension zones that tensile failures could the tensile forces to be reinforcing steel. Adding tensioned reinforcing combines reinforcing the tension advantages of masonry structure.

�Additional benefits are obtained when tensioned reinforcing is installed in draped profile instead of running in a straight typical draped profile in an elevated slab would route the post-tensioned reinforcing through a high point over supports, and through a low point supports. Now, optimum in the tension zones, compressed, and tensioned reinforcing is creating an spans where

�Consider a beam with a force P applied at each end along beam�s center line.

�This force applies a uniform compressive stress across the section equals to P/A.

�Consider next a vertical load Wapplied to the section and the corresponding bending moment diagram applied to this

�The stress distribution from the flexure of beam is calculated from M/Z, where Mis the bending moment and Zis the section modulus. By considering the deflected shape of can be seen that the bottom surface tension. The corresponding stress drawn.

�As previously discussed that concrete is strong compression but not in tension. Only small stresses can be applied before cracks the effectiveness of the section will �By combining the stress distribution applied pre-compression and the applied it can be seen that there is

�In addition, the technique known �load balancing�offers the designer a powerful tool. In this, forces exerted by stressing tendons are modeled equivalent upward forces slab. These forces are balance the applied balancing a chosen loading, it is possible and also to make the beam

Load Balancing by Prestressing

�In order to use the load balancing technique, pre-stressing tendons must be set to follow profiles that reflect the bending moment from applied loadings. Generally, profiles are used.

Comparison between Post-tensioning and Pretensioning:

�Post-tensioning can be done on the job reinforcing bars placement, installation steel form erection, concrete post-tensioning of strands until placement.

�Bridge abutments and piers can be done simultaneously while fabricating the post-tensioned I-girders (beams).

�Pretensioning normally requires large open areas usually in a factory and being done between end anchorage, bulkheads or abutments.

�Camber is the upward deflection in flexural members due to an eccentrically applied prestressing force. Camber is divided categories i.e., initial camber and term camber. Initial camber is induced the prestressing force at the the net upward deflection algebraically summing deflection caused by weight (.beam) and the larger .ps) caused by the prestressing eccentricity �e�below the center section.

�The components of camber due to self-weight and prestressing force.�For straight tendon profile:�.beam =5wLs4

384EcI

�.ps = PeLs2

8EcI

�The magnitude difference .ps -.beam) between above two

��The three figures below illustrate the elastic components The three figures below illustrate the elastic components beam camber and deflection immediately after released.beam camber and deflection immediately after released.Load applied to the beam at released Load applied to the beam at released Deflection due to beam Deflection due to beam Camber Camber

Definition of commonly used terms:

�Aggressive Environment �An environment in which structures are exposed to direct or indirect application of deicing chemicals, seawater, brackish water, or spray from these water sources; and salt-laden air as occurs in the vicinity of seacosts. Aggressive environment also include structures where stressing pockets directly in contact with soils which contain chloride levels considered y the geotechnical engineer to be harmful to metals.�Anchor Cavity �The opening in the anchor or anchor block designed to accommodate the strand passing the proper seating �Anchor Nut �Threaded device bar and plate.

�Anchorage �A mechanical device comprising all components required to anchor the prestressing permanently transfer the post-tensioning force from the prestressing steel to the concrete.

�Anchorage Zone �The portion of the member through which the concentrated prestressing force is transferred to the concrete and distributed section. Its extent is equal dimension of the cross section. For anchorage end of the member, the disturbed regions ahead of

The general expression zones.

�Anticipated set �The expected movement of the wedges into the anchorage during the transfer of the force to the anchorage device.

This is that set which was assumed to occur calculation of post-tensioning forces immediately after load transfer

�AUTS �Actual Ultimate Tensile Strength: breaking strength obtained representative strand or anchorage. For multi-strand or bar tendons, AUTS the AUTS of a single the number of such in the tendon. samples must be from which strands or and used in efficiency

�Back-Up Bars �Reinforcing bars placed in concrete in the anchorage zone to position the anchor and help distributing the loads. �Banded Tendons �Group(s) of closely speced tendons in slabs placed together in a narrow strip, usually along the column line.�Bar �Bars used in post-tensioning tendons conforming ASTM A722, Standard Specification for Uncoated High-Strength Bar for Prestressing Concrete. Bars have minimum ultimate tensile 150,000 psi (1035 Mpa).

Type I Bar has and Type II deformations. tensioning bars are high-strength steel bars, normally from to 44mm (5/8 to 1-3/4in) coarse

�Barrel Anchor �A cylindrical metal device housing the wedges and normally used with a bearing plate to transfer the prestressing force to the concrete.�Barrier Cable �High-strength steel strand erected around the perimeter of a structure and at open to prevent automobiles and pedestrians from falling over open sides.�Basic Bearing Plate �Flat plate bearing directly against concrete meeting the analytical Covered by this definition plates, sheared or torch from readily available plates, normally ASTM A36. �Bearing Plate �A plate which the concrete and an overall anchorage hardware that

�Blowout �A localized concrete failure which occurs during or after stressing.�Bonded Tendons �Tendon in which prestressing steel is bonded to concrete either directly or through grouting.�Bursting Steel �Reinforcing steel used to control the bursting forces developed at the bearing side of the anchor as the concentrated anchor force spreads out in all directions.�Cable �A term used by some to strand or a single-strand tendon. �Camber �An upward deflection is caused by application of prestressing is intentionally built in a structural form to improve or to nullify the element under loads,

�Chair �Hardware used to support or hold post-tensioning tendons or reinforcing.

Bars in their proper position to prevent before and during concrete placement.

�Coating �Material used to protect the steel from corrosion and �Confinement Reinforcement -Non-prestressed reinforcement in reinforcement anchorage the local zone. reinforcement reinforcing

�(Cont�d) Confinement reinforcement:

For basic bearing plates, confinement reinforcement required in that volume of concrete in which compressive stresses exceed acceptable limits for unreinforced concrete determine by rational analysis. For special confinement reinforcement is system dependent as determined by tests on individual anchorages. reinforcement, in the portion surrounding the special bearing plate and immediately ahead the confinement required in the particular system.

�Coupler �A device designed to ends of two strands together, thereby transferring end to end of the

The means by transferred length prestressing another tendon.

�Creep �Time dependant deformation (shortening) of concrete under sustained stress (load).�Curvature Friction �Friction resulting from bends or curves in the specified prestressing tendon profile.

�Distributed Tendons �Single or group of tendons in a slab that are uniformly distributed, usually to the bonded tendons and spaced at a maximum of eight times the slab thickness or 5 feet

�Duct �A conduit (plain or corrugated) prestressing steel �Eccentricity �Distance between concrete cross-section and center prestressing member.

�Effective Prestress -Stress remaining in prestressing steel after all losses have occurred.�Elastic Shortening �The shortening of a member that occurs immediately after the application of force.

�Elongation �Increase in the length of the prestressing under the applied prestressing �Encapsulated System �A post-tensioning system that prevents the ingress of stages of construction, anchorage from contact

�Fixed End Anchorage �An anchorage where prestressing operations. end anchorages from contact with concrete.

�Friction Loss �The loss of force in a prestressing tendon resulting from friction created between the strands and sheathing due to curvature and wobble during stressing. �General zone �The region in which the concentrated prestressing force spreads out to a more linear stress distribution over the cross section of the structural member (Saint Venant Region). It includes general zone extends from the the axis of the member for a distance member. The height of the depth of the member. �Grout �A mixture of cementitious or without mineral admixtures or fine proportion to produce consistency segregation.

�GUTS �Guaranteed Ultimate Tensile Strength: This is the tensile strength of the material that can be assured by the Manufacturer. GUTS should not be confused �fpu�the specified ultimate tensile strength (AASHTO LRFD). (The term �GUTS�has been replaced by two definitions, �MUTS�and �AUTS�by the Post-Tensioning Institute.)

�HDPE �Acronym for High Density Polyethylene HDPE has a minimum density of 0.941 gram per cubic centimeter in post-tensioning. �Initial Concrete Strength �The strength of the concrete necessary for the post-tensioning operation.

�Initial Prestress �The force in the tendon immediately transferring occurs after

�Inlet �The opening used to inject grout into the duct. �Intermediate Anchorage �An anchorage located at any point along the tendon length, which can be used to stress a given length of tendon without the need Normally used at concrete pour breaks. �Jack Calibration �A chart showing the related gauge pressure to actual force applied to a tendon. �Jack Gripper Plates �Steel plates designed to grippers in place in the jack.

�Jack Grippers �Wedges used in during the stressing �Jack �A mechanical hydraulic) apply force

�Jacking Force �The maximum temporary force exerted by the jack on the tendon. �Live End �Stressing End.�Local Zone �The local anchorage zone is the volume concrete surrounding and immediately ahead of the anchorage device where the concrete compressive stresses exceed acceptable values for unconfined without confinement reinforcement). defined as a rectangular prism of concrete surrounding the bearing plate and any integral The transverse dimension prism are equal to the bearing plate, including any integral confinement, plus the supplier�s specified minimum edge

The length of loaded concrete surface of device of the

�Material Certification �Documentation from manufacturer that confirms that the quality of material supplied meets all project requirements.

�Modulus of Elasticity �Ratio of stress to corresponding strain for tensile or compressive stresses proportional limit of material.

�Monostrand �One single-strand.

�Multistrand �More than one single-strand in a tendon. �MUTS �Minimum Ultimate measured as a force, single strand or bar outside of the the multiple of strand or bar strand or bar

MUTS is the sectional of strand nominal stress.

�Non-Aggressive Environment �All environments not specifically defined as aggressive, including enclosed buildings. �Outlet �Opening to allow the escape of air, water, grout and bleed water from the duct during operation. �P/T Coating �material used to protect against corrosion and reduce friction between prestressing steel and sheathing. For unbonded meet or exceed the performance outlined in the PTI Specifications for Unbonded �Pocket Former �A temporary device used at the end to provide a cavity can be grouted prestressing

�Post-Tensioning System �This is the proprietary system where the necessary hardware (anchorage, wedges, strands, bars, couplers, etc.) is supplied by a particular manufacturer or manufacturers of post-tensioning components and may also include ducts and local zone reinforcement. �Post-tensioning �Method of prestressing in which tensioned after concrete has �Potable Water �Water defined by EPA (Protection Agency) to

�Prestressed Concrete �Structural concrete in which internal stresses are potential in concrete applied loads.

�Prestressing Steel �High-Strength steel, most commonly 7-wire strand, used to impart prestress forces to concrete.

�The steel element of a post-tensioning tendon, which is elongated and anchored to provide permanent prestressing force.

�Pretensioning �A method of prestressing in tendons are tensioned before placed.

�Profile �The path of a tendon end.

�Pump �A hydraulic pressure

�Reference Point �The painted mark placed on a tendon tail used to measure the elongation of a tendon after stressing.

�Seating Loss �The relative movement of the wedges the anchor cavity during the transfer force to the anchorage resulting prestressing force.

�Set �The total movement of behind the anchoring the jack to the permanent

�Set movement respect to deformation

�Sheathing �A material encasing prestressing steel to prevent bonding of the prestressing steel with surrounding concrete, provide corrosion protection, contain post-tensiong coating.

�Slab Bolster �Continuous hardware used to support hold post-tensioning tendons in place prior to and during concrete placement. �Special Bearing Plate �Any hardware that transfers tendon anchor forces into the concrete but does not meet analytical design definition are devices single or multiple plane bearing surfaces, wedge plate confinement

�Split Pocket Former �A temporary two-piece device used at the intermediate end during casting of the concrete to provide an opening in the concrete, allowing stressing equipment access to the anchor

�Stage Stressing �Sequential stressing of tendons in separate steps or stages in lieu tendons during the same stressing

�Strand Slippage �Slippage or relative movement strand with respect seating loss.

�Strand �High-strength steel around a tendons a 7-wire strand.

�Stressing End Anchorage �The anchorage at the end of a tendon where the prestressing jack is attached tendon during stressing operations.

�Stressing Equipment �Consists normally of a jack, pump, hoses, and a pressure gauge.

�Stressing Force �See jacking force.�Stressing Pocket �The void created by the pocket between the stressing of the concrete to allow access for stressing void is filled in with grout to provide for the tendon end.

�Stressing Record �A permanent record elongations

�Stressing End �The end of the tendon at which the prestressing force is applied. �Temperature Tendons �Tendons used to resist shrinkage and temperature stresses.

�Tendon Group �More than one strand of Prestressed steel tied together to form �Tendon Support System �The required support chairs, bolsters, maintain the tendon �The excess strand beyong end anchor.

�Tendon �In post-tensioned applications, the tendon is a complete assembly consisting of anchorages, prestressing steel, and sheathing with post-tensioning coating for unbonded applications or ducts with grout for bonded applications. A single or group of prestressing and their anchorage assemblies, which impart a compressive force to a structural member. Also included are ducts, grouting attachment and grout. The main stressing element is usually a high strength steel member made up of a number of strands, wires or bars. �Thixotropic �The property of a material that enables it to stiffen in a short time while viscosity when mechanically reversible.

�Threshold Inspector �This is a term by certain states to define inspects structures of defined also inspects tensioning

�Ultimate Strength �The tension force or stress that is required to fail a steel element in tension.

�Unbonded tendon �Tendon in which prestressing steel is prevented from bonding to concrete and is free to move relative to concrete. The prestressing transferred to concrete at the tendon anchorages only. �Water reducing Admixture �An admixture that either increases the slump of freshly increasing the water reduced amount of to factors other than entrainment.

�Wedge Plate �The hardware multistrand bearing

�Wedges �Pieces of tapered metal with serrations, which bite into the prestressing steel (strand) transfer of the prestressing force.

�Wedge Set �See seating loss.

�Wobble friction �The friction caused by the unintended deviation of the

�Wire �A single, small diameter, wire, typically the basic component

�Yield Strength �The stress at exhibits a proportionality of stress

Anchor assemblyBanded Tendons Barrier Cable Barrel Anchor Bearing Plate

Text Box: General zone General zone

Text Box: Local Zone Local Zone

Text Box: Stressing End Anchorage Stressing End Anchorage Text Box: Temperature Tendons Temperature Tendons Wedge Plate

�Materials used in Post-tensioning:

Spiral Rebar

�Prestressing Steel:�Strand �The most commonly used prestressing material in not only North America is a 7-wire carbon steel strand. Seven-wire has a center wire enclosed tightly by six helically wound outer conforming to ASTM A416 Grade ultimate strength of 279 ksi (1860MPa). is also available (with an ultimate for use, for barrier cable applications. ASTM A416 also sets forth other requirements strand size, tolerances, stress corrosion and bond.�For each grade, relaxation and stress

�Almost all of the prestressing strand supplied today is low relaxation steel. Up until 1970�s, stress-relieved strands were common; however they are rarely used today. Relaxation defined as the reduction in force over time in a highly stressedtendon at a given elongation. Low relaxation strand must conformto the Supplement I requirements of ASTM A416, relaxation loss after 1000 hours of testing minimum ultimate tensile strength (MUTS) or 3.5% at 80% of MUTS.

�Stress relieved strand, in contrast, is not subject to any relaxation loss limit under ASTM A416. Relaxation losses for such tendons typically run at 4.5%, 8%, of the initial stress in the free tendon (i.e., strand is not associated with a concrete for an initial stress equal to 0.6, 0.7, and 0.8 of MUTS, respectively.

�Minimizing relaxation loss reduces overall prestress a result enables to take advantage prestressing

�If a structure is exposed to an aggressive environment, the designer may elect corrosion protective coating for the as epoxy coating or hot dip galvanizing. coated strands shall conform Standards Specification for Coated Seven-Wire Strand. Galvanized ASTM A475-98, Standard Specification Coated Steel Wire strand. coated or galvanized strand post-tensioning applications The designer of these materials

�Bars�Prestressing bars are high-strength steel bars that are cold-stressed to not more than 80% MUTS and then stress relieved to produce the desired mechanical properties. They have a minimum ultimate tensile strength of 150 ksi (1036 MPa). Prestressing bars are rolled from properly heat ingot �or strand-cast steel. They can be manufactured as a smooth round (Type I) or with deformations similar to a common reinforcing bar (Type II). Deformed prestressing bars have deformations that are arranged in a thread pattern on couplers and nuts. Plain before they can be used system. Bars used in tensioned structures Prestressed Concrete, meet the requirements of High-Strength Supplementary These requirements chemical dimension,

�Wires�Wires used for prestressing generally conform to ASTM A421, Uncoated Stress-Relieved Wire for Prestressed Concrete. Rods manufacture wires by open hearth furnace process. Heat treatment stressed relieve the wires so mechanical properties are manufactures with various sectional shapes and surface conditions: smooth versus indented, A421 also has a supplement relaxation wires. Wires are tensioning applications are still used the world.

Types of Prestressing tendons: Typical shapes and commonly available diameters.

Properties of Prestressing Steel

�Mechanical Properties: Certain mechanical properties of prestressing steel must properly design a post-tensioned structure. ASTM specifications identify requirements fpu; yield limit fpy, modulus the total elongation under the design strength of substantially less than bonded construction, greater than or properties for relaxation strands, bars are shown

Prestressing Steel

fpu ksi (MPa)

fpy ksi (MPa)

Ep ksi (MPa)

% Elongation [Gauge Length]

Relaxation

Low-Relaxation 7-Wire strand Grade 270 per ASTM A416/416M

270 (1860)

0.90 fpu

28,500 (196,500)

3.5 [24 in (610 mm)]

[2.5% @ 70% MUTS] or [3.5% @ 80% MUTS]

Stress-Relieved Wire per ASTM A421/421M

235 -250 (1620 -1725)

0.85 fpu

29,000 (200,000)

4 [10 in (250 mm)]

Low-Relaxation Wire per ASTM A421/421M

235 -250 (1620 -1725)

0.90 fpu

29,000 (200,000)

4 [10 in (250 mm)]

[2.5% @ 70% MUTS] or [3.5% @ 80% MUTS]

Prestressed Bars Grade 150 per ASTM A722

150 (1035)

Type I: 0.85 fpu Type II: 0.80 fpu

29,700 (205,000)

4 [20 bar dia.] 7 [10 bar dia.]

�The typical values shown in the table are used for design purposes; however, the material properties for the prestressing supplied to the project may vary and specification minimums.

�Knowing the actual properties during inspection and future example, when evaluating of-tolerance elongations during should compare modulus of elasticity) provided mill in design. explain

�Ductility �Ductility is an essential property of a prestressing material. Standard specifications prescribe ductility requirements, which are usually as a minimum percent elongation gauge length under total load. A416 prestressing strand, elongation is specified length of not less than For ASTM A722 prestressing minimum percent 4% and 7% prestressing

�Static and Fatigue Testing �Tendons in prestressed concrete structures and anchors normally do not experience cycling significant enough to cause problems. For those applications fatigue is a concern, such tensioned bridge and cable-stayed bridges, fatigue resistance can be increase material selection and Tendon fatigue will structure and or unbonded. wedge connection is the most regards

�Where fatigue is a possible concern, the engineer should confirm that the intended tensioning system has been dramatically and qualified in accordance with Acceptance Standards for Post-Tensioning Systems for bonded tendons with the post-tensioning project specifications unbonded tendons. For bridges, AASHTO requires anchorage and coupler tendon, be dynamically 500,000 cycles and 50 cycles

Application of Post-tensioning

�Today, post-tensioning is used for a wide range of applications including: