70-TMSS-01-R0

-

Upload

tori-small -

Category

Documents

-

view

74 -

download

0

description

Transcript of 70-TMSS-01-R0

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 2 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

TABLE OF CONTENTS

1.0 SCOPE 2.0 CROSS REFERENCES 3.0 APPLICABLE CODES AND STANDARDS 3.1 Saudi Arabian Standards Organization (SASO) 3.2 American Society of Testing Material (ASTM) 3.3 Other International Standards 4.0 MATERIALS AND SURFACE PREPARATION 4.1 Reinforcement 4.2 Portland Cement 4.3 Sand 4.4 Mixing Water 4.5 Curing Compound 4.6 Paint 4.7 Surface Preparation 4.8 Admixtures 5.0 MORTAR LINING 5.1 Cement Mortar 5.2 Thickness 5.3 Equipment 5.4 Machine Lining 5.5 Lining of Specials 5.6 Defective Lining 5.7 Curing of Lining 5.8 Mortar Lining Test Cylinders 6.0 HANDLING 6.1 Manufacture 6.2 Delivery 7.0 TESTING REQUIREMENTS AND SUBMITTALS 7.1 Testing Requirements 7.2 Submittals 8.0 DATA SCHEDULE

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 3 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

1.0 SCOPE 1.1 This Transmission Material Standard Specification (TMSS) specifies the minimum

requirements for shop-applied internal cement mortar lining of Steel pipe to be used in the underground piping for fire protection system of the Saudi Electricity COMPANY (SEC) in the Kingdom of Saudi Arabia.

1.2 This specification defines the requirements for shop application of cement mortar lining

to the internal surfaces of steel pipe. It includes materials, surface preparation, application and testing.

1.3 This specification does not address coating external pipe surfaces or field application of

lining. 2.0 CROSS REFERENCES This Transmission Material Standard Specification shall be read in conjunction with the latest

revisions of SEC General Specification No. 01-TMSS-01, titled "General Requirements for All Equipment/ Materials" which shall be considered as an integral part of this TMSS.

This TMSS shall also be read in conjunction with SEC Purchase Order or Contract Schedules

for project, as applicable. 3.0 APPLICABLE CODES AND STANDARDS The latest revisions/amendments of the following Codes and Standards at the time of bidding or

purchase shall be applicable for the equipment/material covered in this TMSS. In case of conflict, the vendor/manufacturer may propose equipment/material conforming to one group of Industry Codes and Standards quoted hereunder without jeopardizing the requirement of this TMSS.

3.1 Saudi Arabian Standards Organization (SASO) 3.1.1 SASO 143 Portland Cement, Ordinary and Rapid Hardening 3.1.2 SASO 224 Steel Fabric for Reinforcement of Concrete

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 4 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

3.2 American Society of Testing Material (ASTM) 3.2.1 ASTM A 82 Specification for Steel Wire, Plain, for Concrete Reinforcement 3.2.2 ASTM A 185 Specification for Steel Welded Wire, Fabric, Plain, for Concrete

Reinforcement 3.2.3 ASTM A 496 Specification for Steel Wire, Deformed, for Concrete

Reinforcement 3.2.4 ASTM A 497 Specification for Steel Welded Wire Fabric, Deformed, for

Concrete Reinforcement 3.2.5 ASTM A 641 Specification for Zinc-Coated (Galvanized) Carbon Steel Wire 3.2.6 ASTM C 31 Standard Practice for Making and Curing Concrete Tests

Specimen in the Field 3.2.7 ASTM C 33 Specification for Concrete Aggregates 3.2.8 ASTM C 35 Specification for Inorganic Aggregates for Use in Gypsum Plaster 3.2.9 ASTM C 39 Test Method for Compressive Strength of Cylindrical Concrete

Specimens 3.2.10 ASTM C 136 Test Method for Sieve Analysis of Fine and Course Aggregates 3.2.11 ASTM C 142 Test Method for Clay Lumps and Friable Particles in Aggregates 3.2.12 ASTM C 150 Specification for Portland Cement 3.2.13 ASTM C 172 Method of Sampling Freshly Mixed Concrete 3.2.14 ASTM C 309 Specification for Liquid Membrane-Forming Compounds for

Curing Concrete 3.2.15 ASTM C 494 Specification for Chemical Admixtures for Concrete

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 5 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

3.3 Other International Standards 3.3.1 AASHTO M 148 Types of Curing Agents Materials. 3.3.2 ACI 212.3R Chemical Admixture for Concrete 3.3.3 AWWA C 205 Cement-Mortar Protective Lining and Coating for Steel

Water Pipe - 4 in. and Larger - Shop Applied 3.3.4 BS 812, Part 117 Water Soluble Chloride Salts 3.3.5 BS 812, Part 118 Sulfate Content 3.3.6 BS 6319 Part 3 Testing of Resin Compositions for Use in Construction Part 3: Methods for Measurement of Modulus of Elasticity

in Flexure and Flexural Strength 3.3.7 BS 8110 Part 1 Test Method for Liquid Membrane-Forming Compounds

Curing efficiency 3.3.8 SIS-05-59-00 Pictorial Surface Preparation Standard 3.3.9 Water Regulatory Advisory Scheme (WRAS) (Formerly W.R.C) Test Reports for Materials as Suitable for Use in Contact

With Potable Water 3.3.10 SSPC SP1 Solvent Clearing 3.3.11 SSPC SP6 Commercial Blast Cleaning 3.3.12 SSPC SP10 Near White Metal Blast

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 6 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

4.0 MATERIALS AND SURFACE PREPARATION 4.1 Reinforcement 4.1.1 Wire-fabric reinforcement for lining of specials shall be 2 X 4 W 0.5 welded

wire fabric. The wire shall conform to SASO/SSA 224 and/or ASTM A 185 or ASTM A 497.

4.1.2 Ribbon-mesh reinforcement for lining of specials shall be 25 mm X 25 mm mesh

of 18-gauge wire or 38 mm X 38 mm mesh of 17-gauge wire. The wire shall conform to the requirements of SASO/SSA 224 and/or ASTM A82. Mesh shall not be crimped.

4.2 Portland Cement Portland cement shall conform to the requirements of SASO 143 and/or ASTM C 150,

Type V. 4.3 Sand Sand shall consist of inert materials having hard, strong, durable, uncoated grains

conforming to ASTM C 33. Sand shall be fine aggregate as defined in ASTM C 136. Deleterious substances shall not exceed the following limits:

Properties

Maximum limits

Clay lumps and Friable Particles

3.00% by weight

Acid Soluble Chlorides Cl

0.06% by weight

Acid Soluble Sulfates SO3

0.40% by weight

4.4 Mixing Water

Water shall be clean, colorless and free from injurious quantities of organic matter, alkali, salt or other impurities that might reduce the strength, durability, or other desirable qualities of the mortar. Mixing water shall not contain more than 500 ppm of total dissolved solids. Water shall be as per 70-TMSS-03.

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 7 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

4.5 Curing Compound High efficiency curing compound shall be used for curing cement-mortar lining. It shall

be resin based and available in various pigmented grades, giving 90% or greater curing efficiency when tested to BS 7542 and complying with BS 8110 part 1, ASTM C 309 and AASHTO M 148. The aluminized grade should comply with the DTp Specifications for Highway Works. If the cement coated steel Pipe is to be used for potable water, it should comply with the requirements of the United Kingdom Water fittings By-laws Scheme and listed in the Directory of Materials.

4.6 Paint The paint or other materials to prevent the rusting of steel surfaces at holdbacks or

mortar lining before pipe installation shall be quick-drying, corrosion-resistant material with good bonding properties to steel and shall dry tack-free and smooth within 4 hours after application.

The paint shall be fire proof and compatible with potable water, and shall be used only

after approval by the COMPANY Representative. 4.7 Surface Preparation All surfaces to be cement mortar lined shall be cleaned in accordance with St 2 1/2 of

SIS-05-59-00 at the time of application of the cement mortar. 4.8 Admixtures Admixtures shall be as per ASTM C 494, Type A or D.

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 8 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

5.0 MORTAR LINING 5.1 Cement Mortar Cement mortar shall be composed of cement, sand and water, well mixed and of proper

consistency to obtain a dense, homogeneous lining that will adhere firmly to the pipe surface. If an admixture is to be used, it shall be subject to review and acceptance by the COMPANY. Proportions of sand to cement shall not be more than 3 parts sand to 1 part cement, by weight with a modified styrene butadiene rubber emulsion with the following requirements as given in the Table.

Range

Min-Max (N/mm2) Test Method Parameter

28.0- 35.0 BS 6319, Part 2 Compressive Strength

2.7- 3.3

ASTM C 190

Tensile strength

7.9- 9.0

BS 6319, Part 3

Flexural strength

2.6 -20.0

BS 6319, Part 4

Slant shear bond

Max. 0.15% of cement by weight

BS 812

Soluble Chloride- (Cl) Content

To improve chemical resistance of cement mortar lining, SEC approval shall be

obtained by submitting the technical information for the different materials with supporting documents with the guarantees as required by the COMPANY.

5.2 Thickness 5.2.1 Cement mortar lining shall be uniform in thickness, except at joints or other

discontinuities in the pipe wall. Lining thickness and tolerance shall be as listed in Table 1. Ends of lining shall be left square and uniform with regard to the longitudinal axis of the pipe.

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 9 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

Table 1 - Cement-Mortar Lining Thickness and Tolerance

Nominal Pipe Size in mm Lining Thickness in mm Tolerance mm

100-250 6 -1.6 + 3.2

280-580 8 -1.6+3.2

600-900 10 -1.6 + 3.2

Greater than 900 13 -1.6 + 3.2

The thickness of the lining shall be checked at site and approved by the

COMPANY Representative. 5.2.2 For sleeved pipe, there shall be no cutback. The cement mortar lining shall be

flush with the end of the pipe. 5.2.3 For pipe that has been specifically designated for butt welding, the cement

mortar lining shall be cut back a minimum of 10 mm to a maximum of 25 mm from the end of the pipe.

5.3 Equipment 5.3.1 Lining Straight sections of pipe shall be lined by use of a spinning machine specifically

designed and built for the purpose of rotating the pipe section and centrifugally applying cement-mortar linings to the interior of the steel pipe or by a method known to provide equivalent results

5.3.2 Mixing The mortar shall be mixed in batches. The amount of cement and sand entering

into each batch shall be measured by weight. The quantity of water entering the mixer shall be measured automatically by an adjustable device, or it shall be otherwise measured to ensure that the correct quantity of water is being added. the mix shall be used only after COMPANY Representative's approval.

5.4 Machine Lining 5.4.1 Bracing When required to prevent distortion or vibration during the spinning, each

section of pipe shall be suitably braced with external supports appropriate to the equipment.

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 10 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

5.4.2 Placement In application of lining by machine, the entire quantity of mortar required for

completion of the lining of the section of pipe shall be placed without interruption.

5.4.3 Finish After the mortar has been distributed to a uniform thickness, the rotation speed

shall be increased to produce a dense mortar with a smooth surface. 5.4.4 Surplus Water Provision shall be made for removal of surplus water by air blowing, tilting of

the pipe, or other methods approved by the COMPANY. 5.5 Lining of Specials 5.5.1 General The application of cement-mortar lining to miters, angles, bends, reducers and

other special sections, the shape of which precludes application by the spinning process, shall be accomplished by mechanical placement, pneumatic placement, or hand application and finished to produce a smooth, dense surface.

5.5.2 Reinforcement Wire-fabric reinforcement or ribbon-mesh reinforcement shall be applied to the

interior of fittings larger than 610 mm and shall be secured at frequent intervals by tack welding to the pipe, by clips, or by wire. Repaired areas of machine applied linings at miters, pipe ends, outlets and other cuts made in the lining for fabrication of the fitting need not be reinforced if the width of the repair area does not exceed 300 mm. Repairs for widths exceeding 150 mm shall be bonded to the steel and adjacent faces of the lining with a bonding agent.

5.5.3 Thickness Thickness shall be as required for spun lining straight sections, except that it

may be varied by feathering or filleting to a smooth transition with adjoining sections of pipe.

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 11 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

5.5.4 Handwork Cement mortar for handwork shall be of the same materials and in the same

sand-cement proportions as the mortar for machine lining except that plaster sand conforming to ASTM C 35 may be used in place of sand conforming to ASTM C 33. Areas shall be cleaned to remove loose or other foreign matter that would interfere with the adherence of the cement-mortar and, if necessary, shall be moistened with water just before the placing of the mortar.

5.6 Defective Lining 5.6.1 General All defects including but not restricted to sand pockets, voids, oversanded areas,

blisters and cracking as a result of impacts, shall be cut out and replaced by hand or pneumatic placement to the same thickness as required for the mortar lining.

5.6.2 Lining Cracks Temperature and shrinkage cracks in the mortar lining less than 1.6 mm in width

need not be repaired. Cracks wider than 1.6 mm need not be repaired if it can be demonstrated to the satisfaction of the COMPANY that the cracks will heal autogenously under continuous soaking in water. The autogenous healing process may be demonstrated by any procedure that keeps the lining of the pipe continually wet or moist. Pipe used in the demonstration shall be representative of the pipe to be supplied, and water for the moistening of the pipe shall be chemically similar to the water to be carried in the pipeline.

5.7 Curing of Lining 5.7.1 General Immediately after completion of spinning, the pipe sections shall be moved to a

curing area. Care shall be taken to prevent any damage. Linings shall be acceleratedly cured or moist cured. Accelerated curing or moist curing may be used interchangeably on a time-ratio basis of 5-1/3 hours of moist curing to 1 hour of accelerated curing, except that moist curing may be used only if the minimum ambient temperature exceeds 5°C continuously during the required minimum curing period. In any case, lining shall be kept continually moist until the completion of the minimum specified curing period.

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 12 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

5.7.2 Moist Curing On arrival at the curing area, but not later than 30 minutes after completion of

the lining operation, pipe ends shall be covered with plastic or wet burlap. No credit shall be allowed for any time during which the temperature drops below 10°C. The lining shall be kept moist for four days before shipment. The ends of the pipe sections shall be kept closed during the curing period, with plastic end caps except when sprinkling heads are used or accelerated curing is being substituted. If the plastic end caps are installed at that time, they can be used for shipping to the jobsite as indicated in Section 6.2.2. The SUPPLIER shall exercise care and diligence to avoid drying out or cracking of the lining.

5.7.3 Accelerated Curing Accelerated curing may begin immediately on arrival of the pipe at the curing

area, but the temperature of the pipe shall not exceed 32°C for 3 hours or until the mortar has taken its final set, whichever occurs first. The lining shall be cured for a total period of 18 hours before shipment.

5.7.4 Alternative Curing Methods Alternative curing methods may be substituted provided that the method used

produces as cured lining equivalent to that set forth in Section 5.7.2 and Section 5.7.3.

5.8 Mortar Lining Test Cylinders 5.8.1 Mortar Test Cylinders A set of at least two standard test cylinders, 150 mm in diameter by 300 mm in

length, shall be made each day from the mortar lining for each shift to satisfy the 7-day and 28-day strength quality control requirements of Section 5.8.4. The mortar shall be removed from the mix in accordance ASTM C 172 or samples may be prepared by omitting sufficient water from the production mix to obtain 25 mm to 75 mm slump. Test cylinders shall be made in conformance with ASTM C 31. The test cylinders shall be cured with the pipe at the same temperature and for the same total length of time. Other sized cylinders, such as 50 mm X 100 mm, may be used to test compressive strength.

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 13 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

5.8.2 Centrifugal Test Cylinders Centrifugally spun test cylinders may be substituted for mortar test cylinders.

Test cylinders shall be spun about their longitudinal axes in 150 mm diameter by 300 mm long steel molds at a speed that will simulate the compaction of mortar in the lining to produce a spun cylinder wall thickness of at least 38 mm. The net cross sectional area of the hollow cylinder shall be used to determine its compressive strength. Damaged cylinders shall not be tested.

5.8.3 Test Cylinders All test cylinders shall be tested in accordance with ASTM C 39 by an approved

independent testing laboratory unless the supplier has approved testing facilities at the work site. In such an event, the test shall be conducted by the supplier. All cylinder tests shall be conducted at the expense of the supplier. Certified test reports will be submitted by the supplier if required by the contract documents of the COMPANY. Tests ordered by the COMPANY in addition to those required in Section 5.8.1 shall be at the expense of the COMPANY. Retests shall be the supplier's responsibility.

5.8.4 Strength of Mortar Lining Mortar test cylinders shall attain a minimum compressive strength of 18 MPa in

7 days and 31 MPa in 28 days. Pipe made with mortar lining that does not meet the strength requirements set forth herein shall be subject to rejection. The average of any 10 consecutive strength tests of cylinders representing each mortar mix shall be equal to or greater than the specified strength, and not more than 20 percent of the strength tests shall have values less than the specified strength. No cylinder test result shall be less than 80 percent of the specified strength.

If the 7-day test specimen shows 28-day strength values, then the 28-day test

need not be completed.

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 14 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

6.0 HANDLING 6.1 Manufacture During the entire period of the application of the lining and the curing thereof, the

section shall be carefully supported and handled to avoid damage to the mortar. If a pipe section must be moved, such operation shall be done with every reasonable precaution to protect against damage. Any damaged portion of the lining shall be cut out and replaced.

6.2 Delivery 6.2.1 Care shall be exercised during loading, hauling and unloading to prevent damage

to any of the components of the completed pipe. Pipe and specials shall be suitably braced, supported to provide sufficient bearing area to prevent damage to the lining and tied to prevent shifting or distortion of the pipe during transportation.

6.2.2 Plastic End Caps Plastic end caps shall be securely fastened to the pipe ends of completed pipe for

protection of the cement-mortar lining. End caps shall be maintained in place until time of installation.

6.2.3 Loading, and Stacking during storage, transportation and handling shall conform

to the Steel Pipe Manufacturer Specifications. Any Steel pipe with visible damage, dent or abrasion resulting in deformation shall be rejected. Calculations for static load stress shall be based on the force caused by the mass of the pipe, W (N/M) including the weight of the cement mortar lining.

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 15 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

7.0 TESTING REQUIREMENTS AND SUBMITTALS The COMPANY reserves the right to obtain samples, of either the delivered product or its

constituent components, which COMPANY deems necessary to verify compliance to any of the quality requirements stated in this specification.

7.1 Testing Requirements The following tests shall be performed prior to and during lining. The tables below show

the property to be tested, the test method, and the frequency for testing. The acceptance criteria are as given in Section 4.0. The COMPANY reserves the right to require more frequent or additional test if these criteria are not satisfied.

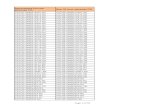

7.1.1 Sand

Test

Test Method

Frequency

Gradation

ASTM C 136

Weekly

Deleterious Substances (Clay)

ASTM C142

Monthly

Acid Soluble Chloride

BS 812

Monthly

Acid Soluble Sulfates

BS 812

Monthly

7.1.2 Cement Mortar

Parameter

Test Method

Frequency

Compressive Strength

BS 6319, Part 2

Weekly

Tensile strength

ASTM C 190

Weekly

Flexural strength

BS 6319, Part 3

Weekly

Slant shear bond

BS 6319, Part 4

Weekly

Soluble Chloride Content

BS 812

Weekly

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 16 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

7.2 Submittals 7.2.1 The following reports shall be submitted before the start of work on cement

lining of Steel pipes. The submittal shall be made at least two weeks in advance and approval obtained from the COMPANY. Under no circumstances work is permitted without the approval.

a. Cement Mill Test Report b. Material Test Report For Sand c. Trial Mix Design and Test Report for Strength Parameters of Cement

Mortar d. Test Report for Modified Styrene Butadiene Rubber Emulsion as

specified in section 5.1. 7.2.2 The following test reports shall be submitted on a monthly basis during the work

execution and the complete set of reports shall be submitted at the end of project. a. Surface preparation report for the steel pipe and the COMPANY

Representative acceptance of surface preparation b. Compressive strength test reports at 7 and 28 days for cement mortar

samples taken during the lining procedures c. COMPANY Representative acceptance of completed Cement Mortar

Lining

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 17 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

8.0 DATA SCHEDULE

SHOP-APPLIED INTERNAL CEMENT MORTAR LINING OF STEEL PIPE

SEC Enquiry No. Date: SEC Purchase Order No. Date: or Contract No. SEC PTS No./Project Title with J.O. No. REFERENCE SECTION NO. DESCRIPTION 'A' 'B' 'C' 4.0 MATERIALS 4.1 Reinforcement 4.2 Portland Cement 4.3 Sand 4.4 Mixing Water 4.5 Curing Compound 4.6 Paint 4.7 Surface Preparation 'A' - SEC SPECIFIED DATA/PARAMETERS 'B' - BIDDER/SUPPLIER/VENDOR/CONTRACTOR PROPOSED DATA/PARAMETERS 'C' - REMARKS SUPPORTING THE PROPOSED DEVIATIONS IN COLUMN 'B' (*) - DATA/PARAMETERS TO BE PROVIDED/PROPOSED BY THE BIDDER/SUPPLIER/ VENDOR/CONTRACTOR IN COLUMN 'B'

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 18 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

8.0 DATA SCHEDULE

SHOP APPLIED INTERNAL CEMENT MORTAR LINING OF STEEL PIPE

SEC Enquiry No. Date: SEC Purchase Order No. Date: or Contract No. SEC PTS No./Project Title with J.O. No. REFERENCE SECTION NO. DESCRIPTION 'A' 'B' 'C' 5.0 MORTAR LINING 5.1 Cement Mortar 5.2 Thickness 5.5.2 Reinforcement 5.5.3 Thickness 5.5.4 Handwork 5.8.4 Strength of mortar lining 7.0 TESTING REQUIREMENTS 7.1.1 Sand 7.1.2 Cement Mortar Yes/No 'A'- SEC SPECIFIED DATA/PARAMETERS 'B'- BIDDER/SUPPLIER/VENDOR/CONTRACTOR PROPOSED DATA/PARAMETERS 'C'- REMARKS SUPPORTING THE PROPOSED DEVIATIONS IN COLUMN 'B' (*)- DATA/PARAMETERS TO BE PROVIDED/PROPOSED BY THE BIDDER/SUPPLIER/ VENDOR/CONTRACTOR IN COLUMN 'B'

TRANSMISSION MATERIALS STANDARD SPECIFICATION 70-TMSS-01, Rev. 0

PAGE NO. 19 OF 19 70TMSS01R0/SZA

Date of Approval: October 10, 2007

8.0 DATA SCHEDULE

SHOP APPLIED INTERNAL CEMENT MORTAR LINING OF STEEL PIPE

ADDITIONAL TECHNICAL INFORMATION OR FEATURES TO BE FURNISHED BY SEC:

A.

ADDITIONAL SUPPLEMENTARY DATA OR FEATURES PROPOSED BY BIDDER/VENDOR/SUPPLIER/CONTRACTOR:

B.

OTHER PARTICULARS TO BE FILLED UP BY BIDDER/VENDOR/SUPPLIER/ CONTRACTOR:

C.

Actual Manufacturer

of Equipment/Material Vendor/Supplier/

Contractor Name of the Company Location and Address Name and Signature of Authorized Representative and Date Official Seal/Stamp of the Company & Date