6400791 Liebherr Hs Dimensions

-

Upload

andrijapopovic -

Category

Documents

-

view

24 -

download

1

description

Transcript of 6400791 Liebherr Hs Dimensions

��������� ��

������ ��� �������� ����� ���

Ñ

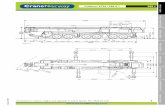

2 LRB 255

������� �� ������������

Sheave head

Tool with quick connection

Leader

Lateral inclination device

Leader support arm

Basic machine

Radius adjustment device

Longitudinal inclination device

Vertical travel device

Support arm brace

Leader swing device

Rope crowd system (RDS)

Auxiliary winch

� High engine output with automatic engine speed control

� Controlled entirely from cab� Sturdy and solid rig design� Wide longitudinal and lateral supporting system on

the basic machine through triangles� High push and pull forces� High torque� Fast and easy assembly of leader extensions

without auxiliary devices� Completely self–rigging (no auxiliary machines

required)� Large range of working tools (all piling and drilling

works can be performed)� Leader swing range +/– 90º

� Stepless inclination 1:6 forward – 1:3 backward depending on type of equipment

� Increase of effective leader length (3 m) via vertical travel device

� Adjustment of lateral inclination independent from longitudinal inclination

� Automatic vertical alignment� High alignment forces� Simultaneous control of several movements via

Load–sensing multi–circuit hydraulics� Quick change of equipment possible through quick

connection� Equipment design according to latest European

regulations and norms� High manufacturing quality through quality control

by PDE–system

��������� ������The transport weight includes the basic machine (ready foroperation), 12.6 t counterweight and leader without working tools(such as drilling drive and torque support).

�������� ��� �������Leader length 21.2 m 24.2 m 27.2 m 30.2 mWeight complete 77.8 t 78.9 t 80.0 t 81.2 t

��������� ���� �����The transport weight includes the basic machine (ready foroperation). Counterweight 12.6 t

�������Basic machine 38.5 tCounterweight 12.6 t

��������� ��������� ��� �������

��������� ������The transport weight includes the leader without working tools (suchas drilling drive and torque support).

�������� ��� �������

LRB 255 3

ÑÑ

Ñ

Leader length 21.2 m 24.2 m 27.2 m 30.2 mWeight complete 26.7 t 27.8 t 28.9 t 30.1 t

����������

4 LRB 255

��������� ��Leader length 21/24/27/30 m

��� ����� � � ���

��� ���� ����� ��� � ����� ���� �Total weight with 800 mm 3–web shoes 78.0 tGround bearing pressure 1.02 kg/cm2

Total weight with 900 mm 3–web shoes 78.5 tGround bearing pressure 0.91 kg/cm2

The operating weight includes the basic machineLRB 255 (leader length 21 m, without working tools) and 12.3 tcounterweight.

Capacity: hammer including cap plus pile 30 tMax. hammer weight 15 tMax. pile weight 15 tMax. pull, leader on ground 40 tMax. torque 300 kNm

Working radius machineCenter of rotation – front edge leader 4.0 – 5.7 m

Stepless rig inclination adjustmentLateral inclination +/–1:20Forward inclination 1:6Backward inclination 1:3

Vertical leader adjustment above ground level (depending on leader length) 3 mVertical leader adjustment below ground level (depending on leader length) 5 mLeader swing range +/–90º

ÑÑ

Ñ

Ñ

ÑÑÑÑÑÑ

ÑÑÑÑÑÑ

Ñ

ÑÑÑÑÑÑÑÑ

ÑÑÑÑ

ÑÑÑÑ

ÑÑÑÑ

ÑÑÑÑ

Ñ ÑÑ

������

Water–cooled, V 8 cylinder Liebherr diesel engine, model D 9408 TI–E, turbocharged with intercooler, power rating according toISO 9249, 400 kW (544 HP) at 1900 rpm.Option:Water–cooled, V 12 cylinder Daimler Chrysler diesel engine, model LOM 444 LA, turbocharged with intercooler, power rating according toISO 3046 IFN, 605 kW (811 HP) at 1900 rpm.The automatic limiting load control adapts perfectly the power of the mainusers to the present engine speed. Fuel tank: 810 l capacity with continuous level indicator and reservewarning.

������ ������

The main pumps are operated by a distributor gearbox. Axial pistondisplacement pumps work in open circuits supplying oil only whenneeded (flow control on demand).The hydraulic pressure peaks are absorbed by the integrated automaticpressure compensation, which relieves the pump and saves fuel.Pump for working tools: 2x 300 l/min and 1x 400 l/minSeparate pump for kinematics: 69 l/minSeparate pump for crowd system: 310 l/minHydraulic oil tank: 1000 lMax. working pressure: 350 barNo auxiliary power packs are required as application specific hydraulicssupply power to all components.The cleaning of the hydraulic oils occurs via an electronically monitoredpressure and return filter. Any clogging is shown on the display in the cab.The use of synthetic environmentally friendly oil is also possible.

���� ���� ������

Crowd force push/pull: 450/450 kNLine pull (nominal load): 150 kNRope diameter: 24 mmMax. line speed: 0–87 m/min

�����

Consists of single row ballbearing, fixed axial piston hydraulic motor,spring loaded and hydraulically released multi–disc holding brake,planetary gearbox and pinion.Free swing with hydraulic moment control reduces wear to a minimum,because rotation moment is sustained through the hydraulic system bythe diesel engine.Swing speed from 0 – 4.5 rpm is continuously variable.

�����

Propulsion through axial piston motor, hydraulically released springloaded multi–disc brake, maintenance free crawler tracks, hydraulic chaintensioning device.

Telescopic undercarriage: 0 – 1.5 km/h3–web track shoes: (optional 900 mm) 800 mm Track force: 630 kN

������

The control system – developed and manufactured by Liebherr – isdesigned to withstand extreme temperatures and the many heavy–dutyconstruction tasks for which this machine has been designed. Completemachine operating data are displayed on a high resolution monitorscreen.To ensure clarity of the information on display, different levels of data areshown in enlarged lettering and symbols. Control and monitoring of thesensors are also handled by this high technology system.Error indications are automatically displayed on the monitor in clear text.The crane is equipped with proportional control for all movements, whichcan be carried out simultaneously.The “Redundant” control system allows restricted operation of themachine in the event of a failure on the electronic base control or itssensors.Two joysticks are required for operation. Pedal control can be changed tohand control.Options :� PDE : Process data recording� GSM modem

����� ��������

Noise emissions correspond with 2000/14/EC directive on noise emissionby equipment used outdoors.

��������� ����� ���

������� ��� �

Line pull (nominal load): 80 kNRope diameter: 20 mmDrum diameter: 320 mmMax. line speed: 0–60 m/minThe winches are noted for their compact, easily mounted design.Propulsion is via a maintenance free planetary gearbox in oil bath. Loadsupport by the hydraulic system; additional safety factor by aspring–loaded, multi–disc holding brake.

LRB 255 5

�������� ������� �������� ����

����� ������ ��������Drilling drive I – torque 1st gear 255 kNm

2nd gear 127 kNmDrilling drive – torque 1st gear 250 kNm

2nd gear 125 kNm

�������� ������ ���� ��������

Max. drilling diameter 1000 mm

Drilling drive I – speed 1st gear 13 rpm 2nd gear 26 rpm

Drilling drive II – torque 1st gear 143 kNm 2nd gear 71 kNm

Drilling drive II – speed 1st gear 15 rpm 2nd gear 30 rpm

Max. drilling diameter 1200 mm

Drilling drive – speed 1st gear 20 rpm 2nd gear 40 rpm

Ñ

6 LRB 255

�������� �� ���� ����������������� ���

LRB 255 7

����� ��������Drilling drive – torque 1st gear 250 kNm

2nd gear 125 kNmfor casing installation 1st gear 290 kNm

Drilling drive – speed 1st gear 20 rpm 2nd gear 40 rpm

Max. drilling diameterwith adapter 3000 mm

Max. drilling diameterwithout casing oscillator 2200 mm

Max. drilling diameterwith casing oscillator 1800 mm

Line pull kelly winch 250 kNmLine speed kelly winch 0 – 70 m/min

Ñ

Line pull kelly winch 200 kNmLine speed kelly winch 0 – 90 m/min

Transport dimensions Working dimensions

Kelly type Lmm

Weightkg

L1mm

Rmm

Drilling depthmm

3/24 10000 6000 24000 11000 22000

3/28 11000 6600 28000 10000 26000

3/32 12500 7300 32000 8500 30000

3/36 13500 8000 36000 7500 34000

4/48 14000 8500 48000 7000 46000

4/65 17500 10500 65000 3500 63000

���� ������ ���� ������������ ����

�������� ������ �����Static moment 0 – 40 kgmMax. speed 2000 rpmMax. centrifugal force 1750 kNWeight without clamp 6200 kgDynamic weight without clamp 4400 kgMax. amplitude 0 – 16 mmLength 2300 mmWidth 750 mmHeight (without clamp) 2500 mmMin. width 500 mm

Max. rated energy 65 kNmMin. energy 25 kNm

������� �����

Blow rate max. energy: 80 blows/minMax. blow rate: 120 blows/minMax. inclination 1 : 1

8 LRB 255

ÑÑ

Length 5350 mmTotal weight 10400 kgRam weight 4650 kg

���� � ���� ������ �������� �� �

Max. pressing force per cylinder 2000 kNNumber of cylinders 4Total weight 12000 kgSuitable for all kind of steel sheet piles, single or in pairs, for pressing ofwalls or boxes.

���� � ���� ����

LRB 255 9

Ñ

10 LRB 255

���������� ��� ���� �������� � ���� ���� ��� � ����� ��������

See technical datasheet HS 843 HD

Set value, digitaldisplay Y direction

Freefall HW 1and HW 2

Vibrator Swing speed(1–2–3)

Engine speed

Drive limit

Acoustic alarmdeactivation

Page forward/back symbol

Adjustmentpage symbol

Drilling operationpreselection

Set value,digitaldisplay X direction

Cable lengthmeasurement

Clamping headpressure

Inclination digitaldisplay

Analog inclinationdisplay

Vibrator frequency display

Cylinder for support arm brace

Blocking carriagelocked

Adjustment carriage locked

Vibrator pumppressure

Additional pump 2pressure

�������� ������� ���

��� ���������� ����� The rig inclination in x– and y– directions is shown on the cab screenin large letters and in crosshair.

�������� ��� ���������A push button automatically adjusts the rig to vertical position,independent of the current inclination.

�������� �������� ��������� � ���A push button increases or reduces the rig radius, without modifyingthe adjusted inclination.

������ ���� �������The length of the unreeled rope is measured on the crowd winch anddisplayed in large letters on the cab screen.

������� �����The vibrator control consists of stepless adjustment of the vibratorfrequency, automatic clamping head system and steplessadjustment of eccentrics.

��������� �� ���An interface transmits the data of the control system, e.g. workingdepth to the connected PDE system.

LRB 255 11

Ñ

��� � ����� ��� ����� �� (Additional equipment)�� ����� ��������� ��������� �� ���� ��� ������� ���� �� �������

��� � �����

Example of a protocol (in required language):

��� ����� Measurements are constantly calculated during the workingprocess. No special measuring process is required. External systemscan also be connected to the system.

�� ���� �� �� ����� ����Measurement data relevant to the working process is displayedon the monitor in the cab.The operator can then control the process and, if necessary,correct it.

������ ���� ����������The working process and the measurement can be interrupted atany time. The measurements are automatically continued uponresumption of work.

������ �� �� ����� ��������� ����All data is stored on a memory card. This can be read via a PC.Thereby an evaluation and processing of data can also beperformed at a later time. For example, for:

� client certifications� conveying daily production data, down time, etc.� Soil condition report

������� ����A protocol can be printed out from the cab printer after eachworking process.

���� ��� � ���A GSM modem can be connected to the PDE making longdistance data transmission possible.

External sensors

������������ ����� �������� ��� �� �� �� ������������������� ��� ! ��� � � �"��� ��� ! ��� � �##$��%����$����&�%�����'(����$�)%%%����'(����$�)

LRB

255

– 8

900

570

14 –

02/

2004

Sub

ject

to c

hang

e w

ithou

t not

ice.

![INDEX [] LG-1550 LIEBHERR LTM 1500 LIEBHERR LTM-1400 LIEBHERR LTM-1225 LIEBHERR LTM-1220 LIEBHERR ... Cranes_over100tons.pdf](https://static.fdocuments.us/doc/165x107/5b07232e7f8b9ae9628e08fa/index-lg-1550-liebherr-ltm-1500-liebherr-ltm-1400-liebherr-ltm-1225-liebherr.jpg)