6.4 Polymerization processes · Polymers are macromolecules of natural or synthetic origin which...

Transcript of 6.4 Polymerization processes · Polymers are macromolecules of natural or synthetic origin which...

369VOLUME V / INSTRUMENTS

6.4.1 Polymerization reactions

Polymers are macromolecules of natural or synthetic originwhich present different chemico-physical properties,allowing them to be used in numerous sectors of humanactivity. Worldwide polymer production is in the order of abillion tonnes a year and now involves all industrial sectors:from transportation to food products, from construction tomaterials for the electronics industry, from textiles topharmaceuticals.

Polymers are made starting from relatively simplemolecules known as monomers, which are assembled withone another with different mechanisms and geometries toform macromolecules which may contain from a few tens (inthis case we speak of oligomers) to several thousandmonomer units. Generally speaking, this assembly processtakes place through two possible chemical mechanisms: astep-growth mechanism and a chain-growth mechanism.

In the light of the chemical reactions characterizing thepolymerization process, a simple classification of syntheticpolymers can be established. The most common arethermoplastic polymers, consisting of linear or branchedmacromolecules and with a melting point above which theyliquefy reversibly. In the presence of high degrees of cross-linking, and therefore far higher molecular weights,thermosets are obtained which decompose when thetemperature rises but do not melt. Finally, elastomers arealso linear or branched macromolecules, but contain doublebonds which at a later stage are made to react with a suitablecross-linking agent at high temperature, to obtain across-linked material with the properties typical of rubbers.

Step-growth mechanismThis polymerization reaction is characterized by the fact

that all the molecules present in the reaction environment(monomers, oligomers and polymers) maintain the sameprobability of reacting throughout the process. This is thecase of polyesters, which are synthesized with theesterification reaction starting from monomers containingtwo acid groups (A) or two alcohol groups (B). For example,polyethylene terephthalate is obtained from terephthalic acidand diethanol. Generally speaking, using A�A and B�Bto represent the two monomers, where A and B represent the

acid and alcohol groups, the following reactionstoichiometry is obtained:

[1]

Other reactions leading to the synthesis of other types ofmacromolecules can be represented in a similar way, as forthe polyamides, in which the reagent groups are an amineand a carboxylic acid, or the polyurethanes, obtained forexample from a diol and a diisocyanate.

The same polymerization mechanism is applied tomonomers containing both functional groups, as shownschematically by the following reaction stoichiometry:

[2]

This is the case, for example, of the reaction betweenamino acids in which the peptide bond, typical of thestructure of proteins, is formed from an amine group and acarboxyl group:

[3]

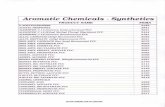

Some of these reactions are shown in Table 1, where itcan be seen that the addition of a monomer unit often entailsthe elimination of a molecule of low molecular weight, suchas water or methanol. This is an important characteristic ofthis type of polymerizations, which in order to be completedrequire the removal from the reaction environment of theselow molecular weight species.

As is clear from reaction stoichiometry [1], the monomerunits alternate along the chain. As such, to obtain completeconversion and thus macromolecules with a high molecularweight, it is necessary to operate with an exact equivalenceof functional groups.

Kinetically, the main characteristic of the step-growthmechanism is that the polymer chains remain active, andthus continue to grow, throughout the polymerizationprocess, in other words for the entire time needed tocompletely consume the monomer species. In fact, since thereactive groups remain unaltered in the final polymer chains,these may begin to grow again at any time if placed in

||||||||��➤ H N R COHN R' COOH + H26888 6888 6888 6888

22O

H N R COOH + H N R' COOH 2 26888 6888 6888 6888 ��➤||||||||||

nn

A A B A B A6888 6888 6888 6888 6888 6B( ) ( ) −��➤||||||||

2

8888B

B B6888 6 ��➤|||||||| 8888 6888 6888 6888 6888 6888A A B B A A( ) −n 1

n nA A B B6888 6888( )+ ( ) ��➤||||||||

6.4

Polymerization processes

contact with monomers. For this reason, these polymers aredescribed as living, and this property is exploited in many oftheir applications.

In the case of monomers containing two reactive groups,linear chains are obtained, as shown in equation [1]. Bycontrast, in the case of monomers containing three or morereactive groups, non-linear chains are obtained which maypresent very different structures. A typical situation is theformation of structures with an extremely high molecularweight, in which the chains are strongly interconnected andform a macroscopic phase whose chemico-physicalproperties are completely different from those of the startingmixture of monomers or the corresponding linear polymers.These macromolecules are often known as gels and can beseparated from the rest of the reagent mixture since they areinsoluble in all solvents. Another peculiar structure is that ofcopolymers synthesized from monomers containing two ormore type A functional groups and monomers containingtwo or more type B functional groups, which react with oneanother but not with themselves and where at least one of thetwo monomers has at least three such functional groups. Inthis case, hyper-cross-linked polymers are obtained whosestructure is relatively compact but which have an extremelyhigh molecular weight.

An example of this type is polycarbosilaneobtained by the synthesis of monomer species in whichgroups A and B above are a CH�CH2 group and a Si�Hgroup. These structures are particularly useful for varioustypes of applications in the surface coating sector since,compared with linear polymers of identical chemicalcomposition and equal molecular weight they aresignificantly less viscous.

Chain-growth mechanismsThis polymer formation mechanism is characterized by a

sequence of three processes: the first is initiation in whichan active centre is created; this may be a free radical, acation or an anion. On this centre the addition reaction of the

monomer species takes place, also involving the formationof a similar active centre on the unit added (allowing for thesuccessive addition of various monomer units and thus theformation of the polymer chain). Finally, there are reactionswhich lead to the interruption of the chain’s propagationand therefore to the production of a definitive or deadpolymeric chain, which is no longer able to add monomerunits. These reactions are known as terminations if theyentail the disappearance of the active centre, or chaintransfers if the active centre is simply transferred to anothermolecule, thus allowing for the propagation of a new chain.

Kinetically, the fundamental property of the chaingrowth mechanism is that the life time of the growing chain,in other words the time between the activation of a chain andits termination, is extremely short with respect to theduration of the polymerization process. As such, unlike thestep-growth mechanism, new active centres must becontinually created during the process, to replace thosesuppressed by the termination reactions and allow theprocess itself to be completed.

As mentioned above, depending on the nature of theactive centre which allows the polymer chain to propagate,free radical, cationic or anionic polymerizations mayoccur. Some catalytic polymerizations, such as those ofolefins on Ziegler-Natta catalysts, also follow an identicalreaction mechanism, also known as a coordinationmechanism. Table 2 lists some polymers which areproduced through these various chain growth mechanisms.Below, the kinetics of radical polymerization will be dealtwith in more detail, as this is certainly the most commontype of polymerization.

6.4.2 Kinetics of step-growthpolymerization

In step-growth polymerization, the life time of the polymerchains is comparable with the characteristic time of the

PROCESS ENGINEERING ASPECTS

370 ENCYCLOPAEDIA OF HYDROCARBONS

Table 1. Polymers produced by step polymerization

Polyester

Polyamide

Polyurethane

Polyester

HOOCn COOH OH HO C O HCO

O

� �n HO (2 n�1)H2O(CH2)2 (CH2)2

O n

HOOCn COOH �n H2N NH2(CH2)4 (CH2)6 HO C

H

CN

O

�(2n�1)H2O(CH2)6(CH2)4

O

H

HN

n

(n�1) HO OH �n OCN(CH2)4 (CH2)6 HO

H

OCN OH(CH2)6(CH2)4 (CH2)4

O

H

NCO

O

NCO

n

n HO COOH n HO HCO � (n�1)H2O

O n

process, in other words the time needed to completelyconsume the monomer species. As such, in contrast toradical polymerization, in this case the molecular weight ofall the chains increases in a uniform way throughout theprocess. As a consequence, high molecular weights arereached only for very high conversions and as such duringmost of the process viscosity remains moderate making heatexchange processes relatively easy.

Considering two bifunctional monomers, such as a dioland a diacid, the reaction occurs according to reactionstoichiometry [1]. In the kinetic treatment of these processesit is usually assumed that the reactivity of the functionalgroups is independent of the length of the chain to whichthey are attached. When, as is often the case in practice, theinitial molar concentration of the two monomers is identical,the conversion of the functional groups XA�(NA0�NA)�NA0,where NA and NA0 represent the number of moles of thediacid, at generic time t and initial time t�0 respectively, isgiven by

[4]

where k is the second order kinetic constant of theesterification reaction [1] and A0 is the initial concentrationof the diacid.

In these systems, the mean numerical chain length, inother words the mean number of units present in a chain, nN,is simply given by the ratio of the number of moles of A atthe beginning to the number at generic time t of the process,which in terms of conversion gives

[5]

showing that high molecular weights can only be obtainedfor very high conversions. Furthermore, when even a verysmall deviation from the stoichiometric composition of thetwo monomers is present, the maximum admissiblemolecular weight decreases significantly. Consequently,chain-growth polymerization techniques are normallyused in order to obtain polymers with a high molecularweight.

To estimate the distribution of the lengths ofpolymer chains, it is necessary to calculate theprobability of a chain consisting of r monomer units.This can be done by considering that this chain mustconsist of (r�1) functional groups which have reactedand one which has not reacted. Since the probability

that a functional group chosen at random in the reagentmixture has reacted is given by the conversion XA, it ispossible to calculate the fraction of chains N(r) whichhave length r as follows:

[6]

This in turn makes it possible to calculate the fraction ofmonomer units contained in chains of length r

[7]

whose mean value is given by:

[8]

Figs. 1 and 2 show distributions for some characteristicvalues of the conversion XA. It is evident that for conversionsof about 99%, the mean values of the chain lengths are in theorder of a few hundred. Additionally, the mean ponderalvalue is always higher than the mean numerical value. Therelationship between the two, s, generally known aspolydispersity:

nXXW

A

A

=+−

1

1

W r rX XAr

A( ) = −( )−( )1 2

1

N r X XAr

A( ) = −( )−( )11

nNN XN

A

A A

= =−

01

1

XA ktA = −

+1

1

10

POLYMERIZATION PROCESSES

371VOLUME V / INSTRUMENTS

XA � 0.95

XA � 0.97

XA � 0.99

N (

r)

0.01

0

0.02

0.03

chain length, r1000 200

Fig. 1. Numerical distribution of chain lengths, N(r), for a polymer produced by step polymerization.

Table 2. Polymers produced by different types of chain polymerization

Radical Cationic Anionic Coordination

Polyethylene Polyisobutylene Polybutadiene Polyethylene

Polyvinylchloride Polyvinyl ether Polymethyl cyanoacrylate Polypropylene

Polystyrene Polyoxymethylene

Polyacrylonitrile Polyamide

Polymethyl metacrilate Polydimethylsilane

Polytetrafluorethylene

Polyvinylidenec fluoride

[9]

supplies an estimate of the breadth of distribution. At thebeginning of the process, XA�0 and s�1, since all thechains (monomers) are of equal length. As conversionincreases, so does polydispersity, which nevertheless remainsfairly low. When conversion is complete (XA�1), we obtains�2 which, compared with the values typical of chainpolymerization processes, is a fairly low value.

We can conclude that step polymerization processes, likeall living processes, are characterized by a high degree ofuniformity of the polymer chains. This is true particularly ofthe distribution of polymer chain lengths which is generallyfairly narrow, though characterized by fairly low averagevalues. These decrease still further when shifts away fromthe stoichiometric composition of the two monomers orimpurities are present.

6.4.3 Radical chain polymerization

InitiationThe radical generation reaction most frequently adopted

is the thermal decomposition of a relatively unstablechemical species, such as a peroxide. The choice of theinitiator is generally made on the basis of the temperatureand duration of the process, to guarantee the necessaryproduction of radicals until the monomer species have beenfully consumed.

The typical decomposition stoichiometry of a peroxide isas follows:

[10]

However, of the radicals produced by this or similardecomposition reactions, only a fraction give rise to achain able to propagate. This is indicated by a magnitudeknown as the initiator efficiency ( f ) which has values inthe range of 0.2 to 1. The mechanism mainly responsiblefor this phenomenon is the recombination reaction of thetwo radicals just formed. This reaction is encouraged bythe so-called ‘cage effect’, due to the cage formed by the

solvent and monomer molecules which surround theinitiator molecules at the moment of their decomposition.The two radicals formed must be able to diffuse outsidethis cage before the recombination reaction takes place.Therefore, efficiency values will generally decrease as theviscosity of the reagent system increases and thus aspolymerization proceeds. It is worth noting that therecombination reaction does not always lead to thereconstitution of the original initiator molecule, whichwould thus be able to produce radicals again. This is true,for example, of azobisisobutylonitrile (AIBN), whosedecomposition takes place through the removal of anitrogen molecule.

A peculiar situation arises in the case ofpolymerizations which must be conducted at lowtemperatures; it is difficult to find initiators for these ableto produce enough radicals to sustain the development ofthe polymerization reaction. In this instance, it is possibleto accelerate the decomposition reaction of the initiatorphotochemically, using visible or ultraviolet radiation.Alternatively, the reaction may be catalyzed with areducing agent, such as a Fe2� salt, giving rise to an oxidereduction reaction which leads to the formation of aradical species and which becomes dominant with respectto non-catalyzed decomposition [10]

[11]

Types of radiation whose photons are sufficientlyenergetic, such as UV or gamma rays, can be used to initiateradical polymerization reactions even in the absence of aninitiator. This method, which has the advantage of beingcompletely temperature-independent, is mainly used inpolymer post-treatment cross-linking processes.

At sufficiently high temperatures, the monomermolecules themselves may give rise to decompositionreactions with the formation of radicals. A typical example isstyrene which, through a fairly complex mechanism, is ableto give rise to a radical production mechanism which followsa third order kinetics with respect to the concentration ofmonomer. This reaction is used in high temperature bulkpolymerization processes of styrene, used to produceoligomer species.

Generally speaking, the decomposition of the monomerwith the formation of radicals is in fact an undesiredreaction. It may take place during the storage ortransportation of the monomers, leading, generally over longperiods of time, to their polymerization. To avoid this,polymerization inhibitors are introduced. These are chemicalspecies such as hydroquinones, able to react rapidly with anyradicals that may form, producing species which are stillradicals but stable and therefore unable to initiate a chain ofradical reactions.

PropagationThe chemical species most frequently used in

polymerization processes are vinyl monomers, consisting ofan ethylene molecule in which only one of the two carbonatoms has one or two substituents (CH2�CHR orCH2�CRR') so that the double bond opening reaction isnot excessively sterically inhibited. In the propagationreaction the radical on the growing chain opens themonomer’s double bond, adding it to the chain andtransferring radical activity to it:

Fe RO OR' Fe RO R'O2 3+ ++ + +6888 �� � �➤||||||||

RO OR' RO R'O6888

kd���� � �➤|||||||| +

σ = = +nn

XW

NA1

PROCESS ENGINEERING ASPECTS

372 ENCYCLOPAEDIA OF HYDROCARBONS

XA � 0.95

XA � 0.97

XA � 0.99

chain length, r

W(r

). 102

1.0

0

2.0

1000 200 300

Fig. 2. Ponderal distribution of chain lengths, W(r), for a polymer produced by step polymerization.

[12]

The propagation reaction generally follows anArrhenius type kinetics. Since the monomer species isable to diffuse significantly faster than the large radicalmacromolecules, diffusion processes do not limit thekinetics of these reactions. However, this is no longer truewhen the reaction temperature falls below the vitreoustransition temperature and the reagent system passes fromthe viscous liquid to the solid state. Under theseconditions, the diffusion of the monomer is stronglyinhibited and the propagation reaction, and with it theentire polymerization process, is blocked. Thisphenomenon is responsible of the numerous instancesfound in practice of these reactions, in which it isimpossible to attain complete conversion.

Another potentially important aspect in this context isthe depropagation reaction. The temperature value at whichthe velocity of this reaction is equal to that of thepropagation reaction, thus creating conditions ofequilibrium, is known as the ceiling temperature. Using theusual condition of thermodynamic equilibrium andindicating the variation of Gibbs free energy linked to thepropagation reaction with DG(T ), we obtain:

[13]

where M is the concentration of the monomer. From [13] it isobvious that this equilibrium temperature depends on theconcentration of monomer present in the reagent system. Itis worth noting that most polymerization processes areconducted at temperatures such that the depropagationreaction is negligible until the conversion of the monomer ispractically complete.

TerminationsThe reactions responsible for the suppression of a

radical, ignoring the possible presence of inhibitors orimpurities, are bimolecular terminations between twogrowing radical chains. The most frequent reaction of thistype is the combination of the two radicals with formation ofa single dead chain:

[14]

An alternative reaction is termination bydisproportionation, in which one of the two radical chainsremoves a hydrogen atom from the other, inducing theformation of a double terminal bond on it:

[15]

It should be noted that in this case the two chainsterminate, keeping their individuality and in particular theirlength unaltered, in contrast to what occurs in the case oftermination by combination.

Kinetically, termination by combination presents thepeculiarity of being controlled by diffusion phenomena, afact generally described as the Trommsdorff effect. This is areaction characterized by a reactive act, the combination ofthe two radicals, which is extremely fast. However, it mustbe proceeded by a fairly complex diffusion process whichmust lead to the superimposition of two specific points (theradicals) of two macromolecules which have a coilconformation. The relative movements of these twomolecules are significantly reduced by the numerousinteractions between the atoms of the two reagent moleculesand with those of the other macromolecules surroundingthem. The result of the Trommsdorff effect is a kineticconstant that, in contrast to the classic Arrhenius effect,presents a strong dependence on the viscosity of the reagentsystem and a far more modest dependence on temperature,typical of material diffusion processes. Furthermore, thiskinetic constant is relatively insensitive to the chemicalnature of the radical species involved, but far more sensitiveto their dimensions.

In some cases, termination by disproportionation is alsocontrolled by the Trommsdorff effect, though this occurs lessfrequently than for termination by combination. This is dueto the reactive act which, since it involves the cleavage of aC�H bond, is significantly slowed.

Chain transferThese are reactions which stop the growth of the radical

chain, but do not suppress radical activity, which instead istransferred to another chemical species from which a newchain begins to propagate. If the radical does not change itsown activity in the transfer, the velocity of monomerconsumption and therefore the duration of thepolymerization process, are not altered by this reactionwhich does, however, affect the length of the polymer chainsproduced. Considering the effects which transfer reactionsmay have on the structure of the molecules produced, adistinction must be made between different cases.

These are known as transfer to small molecule reactionswhen the radical is transferred to a solvent, monomer orchain transfer agent molecule, which is a species deliberately

ktd

R RR R

n�1 m�1

R

ktd

R

n�1 m�1

ktc

R

m�n�1

R

ktc

R

m�1n�1

∆G T RT M( ) = ln

k p

RR

n

R

kp

n�1

POLYMERIZATION PROCESSES

373VOLUME V / INSTRUMENTS

added to the reaction environment to limit the length of themacromolecules produced. It should be noted that each ofthese reactions often corresponds to a different terminalgroup on the final polymer chain. Measuring the distributionof these terminal units is often an excellent way ofidentifying and quantifying the kinetics of these reactions.

The chain transfer to monomer reaction may proceed inaccordance with the following stoichiometry:

[16]

The radical species formed leads, after the addition of asuitable number of monomer units, to a dead polymer chaincharacterized by a terminal double bond, identical to thatproduced by termination by disproportionation.

It is worth observing that propagation and transfer tomonomer reactions involve the same reagents and aretherefore inseparable, but always occur simultaneously andproportionally to their respective kinetic constants. For anygiven monomeric species the transfer to monomer reactiontherefore determines the maximum attainable molecularweight, were it possible to suppress every other termination.Since the cleavage of the C�H bond required by thetransfer reaction [16] is certainly more difficult than theopening of the double bond involved in the propagationreaction [12] there is a difference of at least three orders ofmagnitude between the two reactions for the monomerscommonly used.

Transfer reactions may also involve macromolecules, asin the case of the transfer to polymer reaction:

[17]

In this case, the growing radical removes a hydrogenatom from any point on a dead chain, leaving behind aradical which may propagate to create a new chain. However,since the new chain is joined to the earlier one at a pointwhich in reaction [17] is represented by a tertiary carbon, aside branch is formed.

This reaction presents two important peculiarities withrespect to all the reactions hitherto considered: the ability to

reactivate a dead chain and the formation of non-linear orbranched chains. This significantly complicates thedescription of the process kinetics and enormously broadensthe range of structures which can be formed, making adetailed mathematical description unrealistic.

Since the transfer reaction may take place on any one ofthe monomer units present in the dead polymer chain, thecorresponding reaction velocity is proportional to the massconcentration and not to the molar concentration. This alsoexplains why the transfer to polymer reaction, although itinvolves two macromolecules, is not controlled by theTrommsdorff effect. Although the reactive act is very similarto that of the disproportionation reaction, the diffusionprocess is significantly facilitated by the fact that any pointin the dead chain can react.

The transfer to polymer reaction may also beintramolecular; in other words, the radical positioned at theend of a chain may remove a hydrogen atom from within thechain itself. In most cases, this occurs through a backbitingreaction, in which the chain, folding in upon itself, allowsthe extraction of a hydrogen atom from a monomer unit onlya few units away from the radical end. The number of suchunits and the fact that this reaction may or may not occurdepend on the specific chemical structure of the chain,which determines its intramolecular mobility. In any case,this reaction produces short branches distinct from the longbranches typical of the intermolecular transfer reactiondescribed above. A typical polymer in which short branchesprevail over long ones is low density polyethylene (LDPE).In this case, the short branches consist of no more than fouror five monomer units and have a concentration at least anorder of magnitude higher than that of long branches.

b-scission reaction. The b-scission reaction occursstarting from a radical located at any point along thepolymer chain. It entails the cleavage of the C�C bond inthe b position with respect to the radical and leads to theformation of a dead polymer chain with a terminal doublebond and an active radical chain of smaller size than theoriginal chain:

[18]

Since b-scission always occurs after the formation of aradical inside the chain and therefore after a transfer topolymer or backbiting reaction, the entire process can beseen as a chain transfer reaction, with the peculiarity that itentails the rupture of the macromolecule transferred.

This reaction obviously presents a high activation energyand is determining only at very high temperatures. A typicalinstance is the high temperature bulk polymerization ofstyrene, where the distribution of the molecular weights ofthe oligomers produced is controlled by the backbitingreaction followed by b-scission.

Controlled or pseudo-living radical polymerizationAs seen above, the fundamental characteristic of the

kinetics of chain polymerization with respect to steppolymerization is that in the former the life of the radical

kR

n

Rk

n

kfp

R RR R

R

kfp

R

kfm

RR

R

kfm

PROCESS ENGINEERING ASPECTS

374 ENCYCLOPAEDIA OF HYDROCARBONS

chains is significantly shorter than the duration of thepolymerization process. This means that some polymer chainsare produced at the beginning and others at the end of theprocess, when many of the operating conditions, such as theconcentration of the various reagent species, viscosity andtemperature may be very different. This can give out somedifferences between lenght and composition of polymer chains,that imply unwanted lack of uniformity in the final product.

This situation does not occur in the step polymerizationsseen earlier in which the chains, described as living, all growat the same time throughout the process and are thereforemore uniform. The fact that the chains are living andtherefore remain reactive even after the synthesis processmay lead to significant advantages in subsequentapplications, such as the creation in situ of cross-linksbetween macromolecules, and above all the production ofblock copolymers. For all these reasons, it is of interest to beable to conduct radical chain reactions under theseconditions as well.

Since the termination reactions between radicalsdescribed above are irreversible and certainly impossible toeliminate, the objective is to attain controlled or pseudo-living conditions, under which termination reactions aresignificantly reduced, if not completely eliminated. This isdone by introducing reversible termination reactions into thesystem with a capping species, indicated by X, throughwhich the growing radical chains form so-called sleepingchains, unable to propagate but also to terminate. In thiscase, every radical chain R may follow three differentreactions: propagate with a monomer molecule, terminateirreversibly with another R radical or react reversibly withthe X species to form a sleeping chain. Since bimoleculartermination is the only one of the second order with respectto the concentration of radicals, its velocity with respect tothe other two can be lowered by reducing the totalconcentration of radicals in the system. This creates aconcentration of ‘sleeping’, and therefore living, chainswhich is higher than that of dead chains, making it possibleto approach the conditions of living polymerization.

These conditions are attained by selecting theconcentration and reactivity of the X species in such a wayas to bring most of the radicals into the system in the form ofsleeping species. In this case, the process is extremely slow,since the concentration of radical chains which consume themonomer is low; by way of compensation, the formation ofdead chains is reduced significantly. Each chain thus growsduring numerous time intervals distributed within thepolymerization process. During each of these a fewmonomer units are added, after which the chain returns tothe sleeping state in which termination cannot occur.

It is important to note that this mechanism only works toreduce the effect of bimolecular terminations; it isineffective in reducing the dead chains produced by thetransfer to monomer reaction.

Living polymerization is normally initiated byintroducing an initiator into the system which also containsthe X species, indicated by RX. Through various activationsand disactivations, this species inserts several (n) monomerunits M giving rise to the sleeping species which take theform R�(Mn)�X.

Different chemical systems can be selected to create theconditions described above, giving rise to various livingpolymerization mechanisms.

Nitroxide Mediated Polymerization (NMP). This livingpolymerization mechanism consists in the reversiblecombination of the growing living chain R�n and the so-calledpersistent radical species X� (for example the nitroxideradical group) to form the sleeping polymer chain, RnX:

[19]

Today various possibilities for carrying out this processexist, based on different types of persistent radicals. Ofthese, the most widely used is certainly2,2,6,6-tetramethylpiperidin-1-oxyl (TeMPO), which has thelimitation that it is difficult to apply to monomers other thanstyrene and that it requires relatively high polymerizationtemperatures (120-140°C).

Atom Transfer Radical Polymerization (ATRP). Thismechanism is based on the radical addition by atomictransfer reaction and is catalyzed by a metal (typicallycopper): the homolytic cleavage of the bond in an organichalogenide occurs through the transfer of halogen to themetal complex accompanied by the oxidation of the metal.The catalytic cycle is ended by the return of the halogen tothe end product by the transition metal. It is clear that, if theradical produced can carry out propagation reactions beforegiving rise to the inverse transfer reaction and if this productis still able to give rise to a transfer cycle, the reaction can beused to produce the same exchange between active andsleeping species seen in the former mechanism. Theresulting reversible reaction can be shown as follows:

[20]

where X indicates the halogen, Me(n) the metal at oxidationstage n and L the binder.

The ATRP mechanism owes its success to the fact that itcan be applied to a broad range of monomers, such asstyrene, the acrylates, metacrylates, acrylamides andacrylonitrile, making it possible to use this technique toproduce different types of block polymers of considerablepractical interest. The presence in the system of a metal anda relatively complex binder needed to bring it into solution,and the strong colouring normally conferred upon thepolymer by this complex are the main disadvantages of thisprocess.

Degenerative Transfer (DT). In both the mechanismsseen above the exchange between the active and sleepingstate is based on a reversible termination reaction (though adifferent one). As a consequence, the exchange reactionaffects the total concentration of radicals. In living radicalpolymerizations by degenerative transfer, the exchangereaction takes place through the direct transfer of theterminal group from the active to the sleeping chain. Ifiodine is used as the chain terminal, the exchange reactionmay be represented as follows:

[21]

Since this reaction does not alter the total concentrationof active radicals, the total concentration of chainsterminated by bimolecular termination is equal to half theinitial concentration of initiator. As such, the initialconcentration of the species containing iodine (describedbelow simply as the chain transfer agents) determines thefinal degree of polymerization, assuming that the initialconcentration of initiator is small with respect to the initialconcentration of chain transfer agent.

R R I R R I� ���n m m n+ +➤||||||||

R X Me L R X Me L�nn

nn+ ++

6888( ) ( )/ /1

R X R X � �n n+ ������

POLYMERIZATION PROCESSES

375VOLUME V / INSTRUMENTS

����

����

Polymerization by Reversible Addition-FragmentationTransfer (RAFT). The RAFT process can be seen as aparticular example of degenerative transfer. The so-calledRAFT transfer agent has the general structureQ�Y�C(Z)�Y, where Y is sulphur, C is carbon, Z is agroup which is normally phenylic and Q is the living group.The reaction proceeds through the interaction between aradical chain and a sleeping chain with the formation of areaction intermediate from which the reaction may return tothe initial radical or proceed with the transfer of the groupY�C(Z)�Y from the sleeping species to the active chain:

[22]

The correct choice of the Q group is of fundamentalimportance not only because it will later become a chainterminal group (with the other terminal being occupied bythe RAFT group), but above all because it determines theinitial reactivity of the RAFT agent, significantly influencingthe stability of the intermediate radical with respect to theactive radical chain.

Although the most important results have been obtainedfor the RAFT polymerization of styrene, the process iseffective for various other monomer species, such asacrylates and metacrylates. Additionally, this process iseffective at moderate temperatures and may be successfullyapplied to emulsion polymerization systems, where it ispossible to exploit the segregation of the radicals in theparticles to improve the productivity of the process. Asignificant disadvantage of this process is the need toremove sulphur from the reaction product, since this oftenhas an undesired effect on the colour of the end product.

Non-linear chainsThe main mechanism used to create non-linear

polymer chains is based on the formation of a radical on adead polymer chain; its propagation forms a so-called longbranch. This occurs through the transfer to polymerreaction (the backbiting reaction produces only shortchains, not considered in this instance), whose importanceincreases as conversion proceeds and thus as theconcentration of dead chains increases. An alternativemechanism is linked to the propagation of the terminaldouble bond which exploits the residual reactivity leftinside the dead chain by some termination reactions and inparticular termination by disproportionation, transfer tomonomer and b-scission. In this case, too, a point iscreated on the chain from which three branches ofcomparable length depart, as shown in Fig. 3 A.

As in the case of step polymerization, the most effectiveprocedure for producing strongly non-linear chains is basedon the use of monomers which have more than one reactivefunctional group, as in the case of the dienes or divinylmonomers. In this way, dead polymer chains are obtainedwhich, however, contain various double bonds which maypropagate with other growing radical chains through cross-linking reactions. As shown in Fig. 3 B, each of thesereactions creates a cross-linking point, in other words acentre from which four branches of comparable dimensionsbegin.

The cross-linking reaction increases the molecularweight of the macromolecules extremely effectively andtherefore easily leads to the formation of gels. This systembehaves in a very similar way to step polymerizationsystems, since the polymer chains remain reactive even afterthe termination reaction due to the presence of the internaldouble bonds. However, the cross-linking shown in Fig. 3 Bis not the only reaction which may lead to the formation ofgels in the radical polymerization process. To obtain a gel,the macromolecules must grow exponentially and thereforesignificantly faster than by simply adding monomer units asin propagation. This condition is created by the cross-linkingreaction, but may also be attained by coupling two reactions:one which reactivates the dead chains, such as the transfer topolymer reaction, and another which couples them, such asbimolecular termination by combination. If the latter isreplaced by termination by disproportionation, it is possibleto obtain polymers with very high degrees of ramificationbut which are not gels, since the contribution to growthprovided by the termination by combination reaction islacking.

6.4.4 Kinetics of radical polymerization

Below, a radical polymerization reaction is considered withthe aim of deriving appropriate kinetic expressions todescribe its evolution over time in terms of the compositionand properties of the polymer produced. We consider ageneric system in which all the reactions listed below (withthe corresponding expressions of reaction velocity) arepresent:

[23] initiation: I R1 r�2fkdI�RI

propagation: R�n�M Rn�1 r�kpMR�n

R�n�M R�1�Pn r�kfmMR�n

chain transfers: R�n�S R�1�Pn r�kfsSR�n����➤||||||||k fs

����➤||||||||k fm

����➤||||||||kp

����➤||||||||

��➤|||||||| RR R YC(Z)Y�m n+

R YC Z YR R YC Z YR•� ��n m n m+ ( ) ( ) ➤||||||||

PROCESS ENGINEERING ASPECTS

376 ENCYCLOPAEDIA OF HYDROCARBONS

A

B

� monomer

� monomer

Fig. 3. Diagram showingpropagation reactions of the terminal double bond (A) and cross linkingreactions (B).

����

R�n�R�m Pn�m r�ktcR�nR�m

terminations: R�n�R�m Pn�Pm r�ktdR�nR�m

where n, m�1,…,�

It should be noted that the capital letters indicate boththe symbol for and (in italics) the molecular concentration ofthe species involved. Specifically, Rn and Pn representmacromolecules containing n radical and dead monomerunits respectively, M is the monomer, I the initiator and S achain transfer agent. The reactions reported have beendiscussed above; the reactions leading to the formation ofbranches have been omitted here to limit the treatmentexclusively to linear chains.

The kinetics of all the reactions considered are of thesecond order, with the one exception of the decomposition ofthe initiator which is of the first order. For each of thesereactions it is possible to calculate a characteristic time,indicating the order of magnitude of the time needed for thereaction to unfold completely under the typical conditions ofthe processes considered. Calculating these times makes itpossible to outline in a simple and easily understood way thepeculiar properties of the kinetics of radical polymerizationprocesses. It appears that these processes occur throughreactions characterized by three different characteristic timelevels, whose relative values determine not only the kineticsof the evolution of the process but also the properties of thepolymer produced, such as the length and composition of thechains.

The characteristic time of the process indicates the timerequired for its completion, which in the instance underexamination corresponds to the complete consumption of themonomer species. The velocity at which the monomer isconsumed is given by:

[24]

where R is the sum of the concentrations of all the radicalspresent in the system, R���

n�1R�n. It is thus possible todefine as the characteristic time of this second order processthe magnitude:

[25]

where kpR represents the pseudo-first order kinetic constantfor the monomer consumption reaction. Under the typicalconditions of such processes, the characteristic time tM is inthe order of 103-104 s.

The characteristic time tI of the decomposition of theinitiator, which is a first order process, is simply given by theinverse of the first order kinetic constant, kd:

[26]

Since, as noted earlier, the polymerization processrequires a continuous production of radicals in order tounfold, this characteristic time must be higher, though not bymuch, than that of the process, in other words tI �tM.

By contrast, the characteristic times of all the reactionsleading to the interruption of the growth of themacromolecule by termination or transfer are of a far lowerorder of magnitude. These are the characteristic times of thetermination reaction by combination, ttc, and by

disproportionation, ttd, of the chain transfer to monomerreaction tfm and of the chain transfer to transfer agentreaction tfs, all defined as the reciprocals of the pseudo-firstorder kinetic constants of the corresponding reactions:

[27]

For every specific polymerization system only some ofthese reactions may occur and with frequencies that differdepending on the chemistry of the system. Generallyspeaking, the reaction which dominates the terminationprocess is the one with the shortest characteristic time,which in the most common systems is in the order of 1 s.This determines the average time available to each radical topropagate and add monomers before chain terminationoccurs. It therefore corresponds to the life time of the chainswhich, as noted above, is significantly shorter than thecharacteristic time of the process, tM.

The third level of characteristic times corresponds to thefastest processes, in other words the addition of the singlemonomer unit by the radical. As in the case of thecharacteristic time of the process, reference is made to thepropagation reaction, but in this case the process ofdisappearance of the radical species is considered. Thecorresponding characteristic time is therefore defined by

[28]

which is in the order of 10�3-10�4 s.The kinetic evolution of a radical polymerization process

depends on the interaction between these three process andespecially on the relationship between their characteristictimes. This also determines the properties of the polymerchains produced. For example, the number of monomer unitscontained on average within a polymer chain is given by therelationship between the characteristic time of the dominanttermination process, which as mentioned above is of thesecond order, and the characteristic time of the propagationprocess. To speak of polymers, this ratio must be in the orderof at least 100 or 1,000.

However, for a more accurate quantitative description,we must fall back on the material balances of the reagentspecies, considering for each of these all the reactions inwhich it is involved. The form taken by these balanceshowever, depends on the type of reactor under considerationand this would significantly lengthen the discussion. Assuch, the discussion below will make reference to the mostcommonly used batch reactors, into which all the reagentsare introduced at the beginning of the process, withoutfurther additions or withdrawals during the reaction.

Monomer consumptionThe monomer is mainly consumed by the growing

radical chains present in the reactor. The first step istherefore to calculate the overall concentration R of thesechains, independently of their length. This concentration canbe calculated from the overall material balance of the activechains:

[29]

where kt�ktc�ktd is the overall kinetic constant of thebimolecular termination reactions and RI the velocity at

ddRt

R k RI t= − 2

τ ppk M

= 1

τ τ τ τtctc

tdtd

fmfm

fsfk R k R k M k

= = = =1 1 1 1

ssS

τ Idk

= 1

τMpk R

= 1

ddMt

k RMp= −

����➤||||||||ktd

����➤||||||||ktc

POLYMERIZATION PROCESSES

377VOLUME V / INSTRUMENTS

which radicals are produced. If these are produced by thedecomposition of an initiator I as indicated by the first of thereactions [23], we have:

[30]

In turn, the concentration of the initiator, I, is obtainedfrom a material balance which in the simplest instance of anisothermal reactor leads to the analytical equation

[31]

where I0 is the initial concentration of initiator.As has already been shown, the essential feature of

radical chain polymerization processes is that thecharacteristic time of chain termination is very shortcompared to that of their production, comparable to that ofthe decomposition of the initiator, tI. This makes it possibleto apply to their balance [29] the pseudostationary stateapproximation according to which the accumulation termcan be ignored with respect to the terms of generation andconsumption. This reduces [29] to an algebraic equationwhich makes it possible to calculate the concentration ofradicals as

[32]

where kt�ktc�ktd. At this point, it is possible to consider thematerial balance for the monomer species which, againreferring to an isothermal batch reactor, is reduced to

[33]

Assuming that the velocity at which radicals areproduced, RI , remains constant during the process and thatthe kinetic constants ktc and kp do not vary, the aboveformula can be analytically integrated, leading to the typicalexponential equation for the concentration of the monomer:

[34]

M0 is the initial concentration of monomer.From this equation, it emerges that for a given initiation

system (which thus has the value RI), the kinetics ofmonomer consumption is determined solely by the ratiokp ��1

kt. This also means that measuring the velocity ofmonomer consumption makes it possible at most to estimatethe value of this ratio, but not the absolute value of theindividual kinetic constants. As a consequence, the literatureoften reports the values of the ratio kp ���

1

kt for differentmonomer species. The absolute values of the kineticconstants can be estimated using more complex techniques,such as pulsed laser polymerization, which requires thecharacterization of the length of the polymer chainsproduced.

In practice, equation [34] is only an approximation,since the terms of the balance [33] vary over time.Particularly important is the effect of the variation of thesystem’s viscosity which, through the Trommsdorff effect,produces a decrease in the termination by combinationconstant and therefore a rapid increase in theconcentration of radicals and thus the velocity ofmonomer consumption. This effect may be compoundedby the decrease in the reactor’s heat exchange coefficient,

caused by the increase in the viscosity of the reagentsystem which leads to a decrease of the velocity at whichthe heat produced is lost and therefore an increase intemperature which further accelerates the monomerconsumption process. In conclusion, the monomerconcentration profiles within the reactor deviate from theideal exponential form, as shown in Fig. 4.

Chain length distributionThe applicative properties of a polymer are determined

by the composition and the structure of the macromoleculesof which it is formed. As will be seen below, themacromolecules are not all identical but generally constitutea population of individuals with different characteristics; it isthe distribution of these characteristics, and not simply theirmean values, which determines the applicational propertiesof a polymer material. As such it is particularly important todescribe the kinetics through which these distributionsevolve as a function of the particular operating conditions ofthe polymerization process. To this end, specific materialbalances are used, known as population balances, whichrefer to specific individuals in these populations and inparticular to those characterized by a particular value of thecharacteristic element under consideration. If the latter is thelength of the polymer chain (also known as the degree ofpolymerization, which represents the number of monomerunits in the chain) the corresponding population balancesmake it possible to calculate the Chain Length Distribution(CLD).

The CLD of the dead polymer chains present in a batchreactor at the end of the process can be calculated with thefollowing steps: calculation of the instantaneous CLD, inother words the CLD of the chains produced at a giveninstant during the polymerization process; and summingtogether all the instantaneous CLDs, weighed against thecorresponding quantities of polymer produced, to calculatethe cumulative CLD, in other words that of the end product(see also chap. 8.1).

It should be remembered that this procedure is possiblethanks to the peculiar characteristic of these processes,where the chains are produced in extremely short timeintervals with respect to the duration of the process.

The numerical instantaneous chain length distribution,fN(n), such that fN(n)dn represents the numerical fraction ofpolymer chains of length n produced at a given instant, isgiven by the equation

M M kRk

tpI

t

= −

0

exp

ddMt

k MRp= −

RRk

I

t

=

I I k td= −( )0exp

R fk II d= 2

PROCESS ENGINEERING ASPECTS

378 ENCYCLOPAEDIA OF HYDROCARBONS

1

eq. [34]

Trommsdorff effect

time

conv

ersi

on

Fig. 4. Role of the Trommsdorff effect on the pattern of conversion as a function of time in a batch reactor.

[35]

into which two new adimensional kinetic parameters havebeen introduced, defined as the relations between thecharacteristic times:

[36]

[37]

where a�b�g. From the equations above, it can beobserved that the kinetic parameters b and g influence theinstantaneous CLD in different ways, even though it hasbeen ascertained that as both increase, the chains obtainedare, on average, shorter. This is reasonable, since highervalues of these parameters correspond to higher values ofterminations with respect to propagation. It is interesting tonote that parameters b and g comprise the characteristictimes of termination processes which are qualitativelydifferent from one another. In the former we findtermination by combination, where the chains whichterminate lose their identity in the termination process,forming a single chain whose length is the sum of the twooriginal chains. By contrast, g comprises three terminationprocesses which resemble one another in that the chain’sidentity remains unaltered during termination. This structuraldifference between the terminations means that they affectthe CLD differently and that the relevant kinetic parameterstherefore appear in different adimensional parameters.

In practical applications, another type of CLD is alsoused, the ponderal chain length distribution, indicated byfw(n). This is the fraction of monomer units present in chainsof a given length n and can be calculated directly from thecorresponding numerical distribution with the equation:

[38]

As an example, the two distributions are shown in Fig. 5for the same polymer. It can be observed that the ponderaldistribution tends to give greater weight to the longest chainsand therefore has a higher mean value. Using equations [35]and [38] it is possible to obtain the following analyticalequations for the mean numerical molecular weight nN andthe mean ponderal molecular weight nW:

[39]

[40]

From these equations, simply by multiplying by themolecular weight of the monomer, it is possible to obtain themean numerical and ponderal molecular weights, whichrepresent the averages of the numerical and ponderalMolecular Weight Distributions (MWD) respectively.

In the ideal case of a population of polymer chainswhich are all of equal length, the numerical and ponderalCLDs coincide and both are given by a distribution of Diracdelta type. If the breadth of this distribution is increased, the

two CLDs become increasingly different. It is thereforenatural to introduce a specific parameter, known as thepolydispersity of distribution, defined as the relationshipbetween the mean ponderal and numerical molecularweights:

[41]

which takes on a unitary value for Dirac delta distributionsand increases as the breadth of distribution increases. Thisparameter is widely used in practice as a measurement ofdistribution breadth.

Through equations [35-41], it is possible to obtain agood description of the instantaneous CLD, in other words ofthe characteristics of the infinitesimal quantity of polymerproduced at a given instant during the polymerizationprocess. Generally speaking, however, as mentioned above,we are interested in calculating the properties of the endproduct, in other words the entire population of polymerchains found inside the reactor at the end of the process. Inthe case of a batch reactor, this entails calculating the so-called cumulative CLD, fN

c(n,t), which corresponds to theaverage of all the instantaneous CLDs weighed against thecorresponding quantities of polymer produced from thebeginning of the process until a given time t:

[42]

where the term dP�dt represents the overall productionvelocity of polymer chains of any length. This is obtained byadding the corresponding quantity relative to a specificchain length given by equation [35] over all the possiblevalues for this length, and is given by:

[43]

The procedure reported above for calculating the CLD ofthe end product is also a useful conceptual tool for definingthe optimal operating conditions to create a polymer withspecific properties. For example, it is frequently considerednecessary to create a polymer in a batch reactor with a verynarrow distribution of molecular weights, in other words

ddPt

Rp= +( )γ β1

2

f n tP t

f n t PtN

cN, ,( ) = ( ) ( )

1 dd

number of chaains of length produced in a given time

nuunit

number of chains of lengt

� ��� ���

dtt

0

∫hh

produced until a given time nt

� ��� ����

σγ β γ β

γ β= =

+( ) +( )+( )

nn

W

N

2 3

2

1

2

2

nW =+( )+( )

2 3

2

2

γ β

γ β

nN =+1

1

2γ β

f nnf n

nf nW

N

Nn

( ) =( )

( )=

∞

∑1

γττ

ττ

ττ

= + + = + +k Rk M

kk

k Sk M

td

p

fm

p

fs

p

p

td

p

fm

p

fs

βττ

= =k Rk M

tc

p

p

tc

f nn

N n( ) =+( )

+ −( )+

α

α

γ αβγ β1

11

2

1

2

POLYMERIZATION PROCESSES

379VOLUME V / INSTRUMENTS

nN nW n

fN(n) fW(n)f(n)

Fig. 5. Comparison of the instantaneous numerical distribution,fN(n), and ponderal distribution, fW(n), of chain lengths.

with the minimum possible polydispersity; this problem canbe broken down into two successive stages. First, theconditions required to create an instantaneous CLD withminimum polydispersity are identified; it is then ensuredthat the same instantaneous CLD is always producedthroughout the process. It is clear that, by adding portions ofpolymer whose CLDs are different, even if they have lowpolydispersity, the end product obtained is strongly non-uniform, as shown schematically in Fig. 6. Below, twoexamples of this approach are examined.

Consider the suspension polymerization of vinylchloride, where the dominant termination process is chaintransfer to monomer. From equations [36] and [37], it can beseen that in this case g��b and the mean values of theinstantaneous CLD [39-41] can therefore be simplified asfollows:

[44]

Considering furthermore that in this case g�kfm�kp, itfollows that this parameter is essentially a function oftemperature alone. Since the instantaneous polydispersity isa fixed value, if we wish to minimize the polydispersity ofthe cumulative CLD, it is simply necessary to ensure that thesame instantaneous CLD is produced during the entireprocess. This can be achieved, at a good approximation, bymaintaining a constant mean value for the instantaneousCLD, which, as shown by the equations above, is in this casea function of temperature alone. On the basis of thissimplified analysis it is therefore possible to conclude thatkeeping the batch reactor isothermal during the processmakes it possible to obtain the narrowest cumulative CLDpossible, corresponding specifically to a polydispersity valueof two.

Another interesting instance is that of some styrenepolymerization processes, where the dominant terminationmechanism is termination by combination. In this case gband the mean values of the instantaneous CLD [39-41] cantherefore be simplified as follows:

[45]

where the kinetic parameter is defined by equation [36],which using [32] gives: b���

14422

ktcRI �kpM. It should be notedthat in this case, too, the instantaneous polydispersity is

lower than when the dominant termination processes arethose appearing in the g parameter. This is a consequence ofthe fact that the process of combination entails an averagingoperation on the length of the dead chains, leading to agreater uniformity in their distribution. This operation doesnot occur when other termination processes are dominant.

In this case it is therefore possible to create a cumulativeCLD with a polydispersity of 1.5, as long as thepolymerization conditions are such as to keep theinstantaneous CLD, and therefore the value of the parameterb, constant. This is not an easy task since, as can be seenfrom the expression reported above for this parameter, itdepends on variables such as the concentration of monomerand the production velocity of the radicals. Results whichare satisfactory at least from the practical viewpoint can beobtained by using different polymerization techniques suchas those based on semibatch reactors with the addition overtime of initiator and monomers, or on emulsion processes.

6.4.5 Radical copolymerizationprocesses

The need to create polymeric materials whose properties areincreasingly tailored to specific applications often entails theintroduction along the chain of different monomer species,which help to confer specific chemico-physical properties onthe chain. This leads to the appearance of a new dimensionin the characterization of the population of polymer chains,which refers to their composition. Specifically, two types ofdistribution are introduced. The Chain CompositionDistribution (CDD) describes the fraction of chains whichhave a given overall monomer composition, independently ofthe order of the monomers within the chain itself; the ChainSequence Distribution (CSD) describes the probability offinding a given sequence of monomer units inside the chain.The ability to control these distributions is an essential factorin a good copolymerization process, since they determine theapplicative properties of the copolymers produced.

The distribution of the monomer units along a polymerchain is controlled by the propagation reactions, whosenumber depends on the monomer species involved. Adoptingthe terminal kinetic model, it is assumed that the reactivityof a radical chain is determined only by the last unit added,that on which the radical activity is found. In this context, inthe case of a copolymerization involving two monomers, Aand B, two types of radical chains may be formed. Using A�nand B�n to indicate two chains containing a total of nmonomer units but in which the radical activity occurs on aunit of type A or B respectively, since each of these chainsmay react with a monomer unit of type A or B, a total of fourpropagation reactions will occur, two of which are describedas direct and two as cross:

[46]

[47]

[48]

[49]

Next to each of these propagation reactions thecorresponding expression giving the reaction velocity is

B A A� � ���n n pBA nr k B A+ =+➤||||||||

1

A B B� � ���n n pAB nr k A B+ =+➤||||||||

1

B B B� � ���n n pBB nr k B B+ =+➤||||||||

1

A A A� � ���n n pAA nr k A A+ =+➤||||||||

1

n nN W= = =2 3 3

2β βσ

n nN W= = =1 22

γ γσ

PROCESS ENGINEERING ASPECTS

380 ENCYCLOPAEDIA OF HYDROCARBONS

instantaneous, t1

cumulative, t3

instantaneous, t3

instantaneous, t2

fN(n)

n

Fig. 6. Schematic diagram of the instantaneous CLDat three different times, t1�t2�t3 (dashed curves)and the corresponding cumulative CLD (non-normalized) at time t3 (continuous curve).

shown. In accordance with the terminal kinetic model thevelocities are described by second order kinetics, whosekinetic constants are determined exclusively by the type ofunit on which the radical activity in the reagent chain isfound and by the monomer species involved.

In these processes, in addition to propagation reactions,initiation, termination and chain transfer reactions are alsopresent, identical to those present in homopolymerizationbut greater in number since more radical types are present.

A more accurate kinetic model, the penultimate kineticmodel, makes it possible to take account of the effect of thepenultimate monomer unit on the reactivity of the radical.This naturally entails an increase in the number of possiblepropagation reactions since each of the reactions [46-49]takes place at a different velocity depending on whether themonomer unit before the one on which the radical activity islocated is of type A or B. This model is not often used inpractice, due in part to the good results generally obtainedusing the terminal kinetic model.

Chain length distributionThe first piece of information needed to describe the

growth kinetics of copolymer chains concerns thecomposition of the reagent mixture in terms of active radicalchains. Specifically, it is necessary to know the fraction ofchains which terminate with each of the monomer unitspresent since, according to the terminal kinetic modeladopted, this defines its reactivity.

To this end, it is necessary to consider the materialbalances of the radical species, differentiating them only onthe basis of the type of radical unit. In these balances, allthe reactions entailing the disappearance or the productionof a given type of radical must be taken into consideration.In addition to the initiation and termination reactions,which lead to the formation or elimination of a radicalspecies, we must therefore also consider cross-propagationreactions, since these modify the type of radical unit.Considering that these reactions are generally considerablyfaster than those of termination and initiation, the latter aregenerally ignored in the context of long chainapproximation. Consider for example a polymerizationwith three monomers, A, B and C. Using A�, B� and C� toindicate the overall concentration of radical chains whichterminate with each of the three monomer units, thebalances mentioned above take the form

[50]

[51]

[52]

Adding together the above equations member bymember, it follows that the variation over time of the totalconcentration of radicals, R�A��B��C� is zero. Obviously,this is incorrect and reflects the fact that these balances werewritten in the context of long chain approximation. In fact,they only make it possible to calculate the composition ofthe mixture of radicals and not the absolute values of theirconcentrations. Introducing the molar fractions pi of radicalchains of all types:

[53]

and substituting in equations [50] and [51] in which theterms of accumulation are ignored according to theapproximation of pseudostationary state, we obtain

[54]

[55]

[56]

It should be noted that the final consistency equation isadded to close the system; its solution provides the desiredcomposition of the reagent system in terms of chains withdiffering radical activity. This system can easily be extendedto any number of monomer species and in particular producesthe following solution for a binary system:

[57]

These equations are valid in the context of long chainapproximation which can be applied with a good degree ofaccuracy to all copolymers with the exception of blockcopolymers. The latter consist of a very few homopolymersequences, reflecting the fact that cross propagations are farslower than direct propagations, to such an extent that theyare comparable to terminations and initiations. Obviously, inthis case the latter cannot be ignored in balances [50-52].

The description of the kinetic behaviour of a systeminvolving numerous monomer species certainly appearsfairly complex due to the high number of reagent speciesinvolved. However, in the context of the approximationsdescribed above, a very simple analytical solution can bedeveloped, known as the pseudokinetic approach. Thisinvolves using the same equations derived above fordescribing the kinetics of the homopolymerization process,replacing the kinetic constants of the reactions involved withappropriate pseudokinetic constants. The latter are obtainedfrom the real kinetic constants of the copolymerizationprocess through suitable averages weighed against the molarfractions of the different radical species in the system.

These averages differ depending on the order of thereaction with respect to the radical species. Specifically, withreference to a ternary system, for the propagation reaction ofthe monomers A, B and C, we have:

[58]

[59]

[60]

from which the overall pseudokinetic propagation constantk*

p is obtained by an average weighed against the molarfractions of the monomers xA, xB and xC:

[61]

For chain transfer reactions, we obtain the followingequations for the pseudokinetic constants:

[62]

[63] k k p k p k pfs fsA A fsB B fsC C∗ = + +

k k p k p k pfm fmA A fmB B fmC C∗ = + +

k k x k x k xp pA A pB B pC C∗ ∗ ∗ ∗= + +

k k p k p k ppC pAC A pBC B pCC C∗ = + +

k k p k p k ppB pAB A pBB B pCB C∗ = + +

k k p k p k ppA pAA A pBA B pCA C∗ = + +

pk A

k A k Bp

k Bk A k BA

pBA

pBA pABB

pAB

pBA pAB

=+

=+

p p pA B C+ + = 1

k Bp k Bp k A k C ppAB A pCB C pBA pBC B+ − +( ) = 0

k Ap k Ap k B k C ppBA B pCA C pAB pAC A+ − +( ) = 0

p AR

p BR

p CRA B C= = =� � �

ddCt

k A C k B C k A k B CpAC pBC pCA pCB

�� � �= + − +( )

ddBt

k A B k C B k A k C BpAB pCB pBA pBC

�� � �= + − +( )

ddAt

k B A k C A k B k C ApBA pCA pAB pAC

�� � �= + − +( )

POLYMERIZATION PROCESSES

381VOLUME V / INSTRUMENTS

which differ for termination reactions since these are of thesecond order with respect to the radical species

[64]

[65]

In the context of the pseudokinetic model it is thuspossible to calculate the total concentration R of radicalsusing the same equation [32], replacing the kinetic constantsof homopolymerization with the correspondingpseudokinetic constants:

[66]

This in turn makes it possible to calculate the velocity atwhich the individual monomeric species is consumed; forexample, that of monomer A:

[67]

The CLD of a copolymer can also be calculated usingthe same equations [35-41] valid for the homopolymer, usingthe corresponding pseudokinetic constants to calculateparameters b and g. In this case, the variable M representsthe total concentration of all the monomer species in thesystem.

Chain composition distributionThe distribution of the different monomer species along

the polymeric chain is determined by the probability thateach radical adds one or other of the monomeric speciespresent. In turn, this probability is determined by the intrinsicreactivity of the individual monomer and its concentration.Generally speaking, different monomers have differentreactivities and are therefore consumed in different waysduring the polymerization process, with the consequence thatthe monomeric composition varies over time. Since the lifetime of the chains is far shorter than that of the process,chains will be produced at different moments throughout theprocess and therefore presumably with differingcompositions since they are produced from differentcompositions of the monomer mixture. This process, usuallydescribed as compositional drift, often represents asignificant problem from the applicative point of view, sinceit gives rise to highly non-uniform end products, in the sensethat the chains have very different compositions.

To study this process quantitatively, it is necessary tocalculate the average composition of a polymer chain. Sinceduring the life of a polymer chain the consumption ofmonomer and therefore changes in composition arenegligible, we can calculate the composition of the chainstarting from the instantaneous velocity of consumption ofthe individual monomer species. So, for example, in the caseof two monomer species A and B, the molar fraction FA ofmonomer A present inside a copolymer chain produced at agiven instant is given by the equation:

[68]

where RpA and RpB represent the consumption velocities ofthe different monomer species calculated with [67] at that

same moment. With appropriate modifications, [68] can berewritten as

[69]

This equation indicates that the instantaneouscomposition of the polymer chain is determined by the molarfraction of the monomer species xA and xB, and by twoadimensional kinetic parameters:

[70]

which are known as reactivity ratios and for each type ofradical represent the relationship between the kineticconstant of direct and cross-propagation.

Equation [69] is normally plotted on a graph in the formof a Mayo and Lewis diagram. As shown in Fig. 7, thisdiagram shows the instantaneous composition of thepolymer chains FA as a function of the monomer compositionxA of the mixture from which they are generated. Thediagonal represents the case in which the monomers haveidentical reactivity, in other words rA�1 and rB�1 in [69],and the polymer chains therefore have the same compositionas the monomer mixture from which they derive, in otherwords FA�xA. Generally speaking, however, monomers havediffering reactivity and the resulting diagram may takevarious forms, as demonstrated by the different curves inFig. 7. For example, if monomer A is more reactive withboth radical species, then rA�1 and rB1 and the polymerchains are richer in monomer A than the monomer mixturefrom which they derive. By contrast, if rA1 and rB�1, thepolymer chains are enriched in monomer B. These twosituations are illustrated in Fig. 7 by curves I and IIrespectively.

However, if rA1 and rB1, cross-propagation reactionsprevail over direct propagation reactions. In this case,

rkk

rkkA

pAA

pABB

pBB

pBA

= =

Fr x x x

r x x x r x x xAA A B A

A A B A B B A B

=+( )

+( ) + +( )

FR

R RApA

pA pB

=+

R k ARpA pA= ∗

RR

k kI

tc td

=+∗ ∗

k k p k p k pk

td tdAA A tdBB B tdCC C

t

∗ = + ++

2 2 2

2 ddAB A B tdAC A C tdBC B Cp p k p p k p p+ +2 2

k k p k p k pk

tc tcAA A tcBB B tcCC C

t

∗ = + ++

2 2 2

2 ccAB A B tcAC A C tcBC B Cp p k p p k p p+ +2 2

PROCESS ENGINEERING ASPECTS

382 ENCYCLOPAEDIA OF HYDROCARBONS

FA

xA0

1

10

III

II

I

Fig. 7. Mayo and Lewis diagram showing the instantaneous molar fraction FA of monomer A as a function of its molar fraction xA in the reagent mixture of monomers for three different pairs of values of the reactivity ratios: rA�1 and rB1 (curve I), rA1 and rB�1 (curve II) and rA1 and rB1 (curve III).

depending on the monomer composition, either monomer Aor monomer B may be more reactive. The result is curve IIIin Fig. 7, characterized by a specific point, known as theazeotrope, in which the polymer chains and the monomermixture from which they derive have the same composition.The same is true if direct propagations prevail over crosspropagations, in other words rA�1 and rB�1.

Using the Mayo and Lewis diagram it is also possible tofollow the process of compositional drift mentioned earlierin quantitative terms. Consider a copolymerization system inwhich the Mayo and Lewis diagram is the one shown in Fig. 8and assume that the monomer mixture initially introducedinto the reactor has the composition xA0. The firstinfinitesimal amount of polymer produced has thecomposition FA0 indicated in the figure; since FA0�xA0, itfollows that a portion more concentrated in monomer A thanthe original mixture is removed from the monomer mixture.As a consequence, the molar fraction of A, xA, in the reactordecreases and with it the molar fraction of this monomer inthe polymer. However, since the molar fraction of A in thepolymer remains higher than in the monomer, both continueto decrease giving rise to the process of compositional drift.The breadth of this variation can be calculated qualitativelyby observing that at the end of the process, when themonomers have fully reacted, the mean molar fraction of Apresent overall in all the polymer chains must be identical tothat initially present in the monomer phase, in other wordsxA0. From the diagram in Fig. 8 it is easy to deduce that forthe mean value of FA to be equal to xA0, since the first chainshave a composition of FA0, the last chains produced musthave a fairly low content of A.

Controlling the composition of copolymersIn most cases, the applicative properties of a copolymer

require that the polymer chains be highly uniform, especiallyin terms of composition. As seen above, this is impossible toachieve using a batch reactor because of the process ofcompositional drift. It is therefore necessary to use asemibatch reactor into which suitable quantities of monomer

are introduced during the process so as to keep thecomposition of the reagent monomer mixture andconsequently the chains produced during the processconstant over time. There are two different strategies whichmake it possible to attain this objective.

Feed Controlled Process. This operating methodology isbased on slowing down the process to the point where it cantake place, for most of the time, under pseudostationaryconditions so that the velocities of consumption of theindividual monomers are identical to the feed rate andtherefore easy to control. This situation is attained byadopting a feed time, tf , which is extremely long comparedto the characteristic time of monomer consumption:

[71]

In this way the characteristic time of the process isidentical to the feed time and the monomer consumptionprocess, whose characteristic time at this point becomesmuch shorter, is in pseudostationary conditions with respectto the feed time.

The feed controlled process therefore simply involvesfeeding in a monomer mixture with the same composition asthe polymer desired, but at a sufficiently slow rate to meetcondition [71], without necessarily knowing either theprocess kinetics or the corresponding Mayo and Lewisdiagram. As a consequence, chains with the desiredcomposition are produced for most of the process; however,productivity decreases as the process is slowed downbecause the feed rate is far lower than the velocity at whichthe monomers are able to react. This operating procedure istherefore usually described as starved.

In these processes, the concentration of monomer in thereactor essentially remains constant throughout the process.This may be particularly advantageous in various situations,such as that discussed in the context of equation [45] wherethe aim is to produce a very narrow distribution of molecularweights (for a homo- or copolymer) when bimoleculartermination by combination is dominant.

Other important characteristics of these processes are theease of temperature control, resulting from the low monomerconsumption velocity and the fact that conversion inside thereactor is always extremely high. This means that theconcentration of polymer significantly prevails over that ofmonomer; consequently transfer to polymer reactions andthe kinetics controlled by the Trommsdorff effect tend toprevail.

Power Feed Process. This second operating procedure,usually described as power feed, is more ambitious than theformer procedure since it aims not only to keep thecomposition of the chains produced uniform over time, butalso to maintain high process productivity. However,achieving this requires a greater understanding of thekinetics of polymerization and in particular the Mayo andLewis equation which determines the monomer compositionneeded to create a polymer chain with the desiredinstantaneous composition. The procedure therefore requiresthat a given initial quantity of monomers with thiscomposition be introduced into the reactor, and then that thereactor be fed with a flow of these so as to keep thecomposition constant throughout the process. The flow rateis calculated to feed in the necessary amount to balance anyimbalances in composition due to the differing reactivity of

τ fpk R