5

-

Upload

syed-noman-ahmed -

Category

Documents

-

view

115 -

download

1

Transcript of 5

R12 R22 R502

Compressors for R134a220-240V 50Hz & 60Hz

C O M P R E S S O R S

Collection of Datasheets

R E F R I G E R A T I O N A N D A I R C O N D I T I O N I N G

2 CK.40.B6.02 August 2001

Heat Pump Compressors

T-SeriesTL4GH (50/60Hz) Page 182

F-SeriesFR7GH (50/60Hz) Page 184

S-SeriesSC10GH (50Hz) Page 186SC12GH (50Hz) Page 188SC15GH (50Hz) Page 190SC18GH (50Hz) Page 192SC10GHH (50Hz) Page 194SC15GHH (50Hz) Page 196SC10GH (50/60Hz) Page 198SC12GH (50/60Hz) Page 200SC15GH (50/60Hz) Page 202SC18GH (50/60Hz) Page 204

Energy-optimizedCompressors

P-SeriesPLE35F (50Hz) Page 66PLE50F (50Hz) Page 68

T-SeriesTLES3F (50Hz) Page 70TLES4F (50Hz) Page 72TLES5F (50Hz) Page 74TLES6F (50Hz) Page 76TLES7F (50Hz) Page 78

N-SeriesNLE6F (50Hz) Page 80NLE7F (50Hz) Page 82NLE8FK (50Hz) Page 84NLE9F (50Hz) Page 86

Energy-optimized TropicalCompressors

N-SeriesNLE9FT (50Hz) Page 142

Variable Speed DriveCompressors

T-SeriesTLV5F (50-60Hz) Page 110TLV6F (50-60Hz) Page 112TLV7F (50-60Hz) Page 114

Standard Compressors

P-SeriesPL20F (50Hz) Page 12PL35F (50Hz) Page 14PL50F (50Hz) Page 16PL50F (HST/50Hz) Page 18

T-SeriesTL2.5F (50Hz) Page 20TL3F (50Hz) Page 22TL4F (50Hz) Page 24TL5F (50Hz) Page 26TLS4F (50Hz) Page 28TLS5F (50Hz) Page 30TLS6F (50Hz) Page 32TLS7F (50Hz) Page 34

N-SeriesNL6F (50Hz) Page 36NL7F (50Hz) Page 38NL8F (50Hz) Page 40NL9F (50Hz) Page 42NL11F (50Hz) Page 44NF7FX (50/60Hz) Page 46NF9FX (50Hz) Page 48NF10FX (50Hz) Page 50NF11FX (50Hz) Page 52

F-SeriesFR7.5F (50Hz) Page 54FR8.5F (50Hz) Page 56FR10F (50Hz) Page 58

S-SeriesSC15F (50Hz) Page 60SC18F (50Hz) Page 62SC21F (50Hz) Page 64

Tropical Compressors

T-SeriesTLS3FT (50Hz) Page 116TLS4FT (50Hz) Page 118TLS5FT (50Hz) Page 120TFS4FT (50Hz) Page 122TFS4.5FT(50Hz) Page 124

N-SeriesNL6FT (50/60Hz) Page 126NL7FT (50Hz) Page 128NL9FT (50Hz) Page 130NL10FT (50Hz) Page 132

S-SeriesSC12FT (50/60Hz) Page 134SC15FT (50/60Hz) Page 136SC18FTX (50/60Hz) Page 138SC21FTX (50/60Hz) Page 140

High Energy-optimizedCompressors

T-SeriesTLY4F (50Hz) Page 88TLY5FK (50Hz) Page 90TLX6FK (50Hz) Page 92

N-SeriesNLY5.5FK (50Hz) Page 94NLY6F (50Hz) Page 96NLY7F (50Hz) Page 98NLY9FK (50Hz) Page 100NLY5.5FK.2 (50Hz) Page 102NLY6FK.2 (50Hz) Page 104NLY7FK.2 (50Hz) Page 106NLY9FK.2 (50Hz) Page 108

Universal Compressors

P-SeriesPL35G (50/60Hz) Page 144

T-SeriesTL2.5G (50/60Hz) Page 146TL3G (50/60Hz) Page 148TL4G (50/60Hz) Page 150TL5G (50/60Hz) Page 152

F-SeriesFR6G (50/60Hz) Page 154FR7.5G (50/60Hz) Page 156FR8.5G (50/60Hz) Page 158FR10G (50/60Hz) Page 160FR11G (50Hz) Page 162

S-SeriesSC10G (50/60Hz) Page 164SC12G (50/60Hz) Page 166SC15G (50/60Hz) Page 168SC18G (50/60Hz) Page 170SC21G (50/60Hz) Page 172S-Series (Twins)SC12/12G (50Hz) Page 174SC15/15G (50Hz) Page 176SC18/18G (50Hz) Page 178SC21/21G (50Hz) Page 180

August 2001 CK.40.B6.02 3

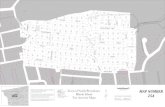

8238-3

Optimizationlevel

BlankStandard

energy levelS

Semi-direct intake

EEnergy-optimized(optimized motor)

Y, XHigh Energy-

optimized(high optimization

level)

Compressorsize

Nominaldisplacement

in cm3

Exception:For PL

compressorsthe capacity atrating point is

stated

This collection of datasheets contains information on Danfoss hermetic refrigeration com-pressors for 220-240V especially designed for refrigeration systems using refrigerantR134a (CF

3-CH

2F).

The programme consists of the basic types PL, TL, TLV, TF, NL, NF, FR, SC and SC Twin.

1. General

PL TL (TF similar) NL (NF similar)

FR SC SC Twin

8238-2

8238-78238-68238-5

8238-4

Compressordesign

PL

TL, TF

NL, NF

FR

SC

Applicationrange

FR134a LBP(MBP)

FTR134a LBP tropical

FKR134a LBP/(MBP) LST

FXR134a LBP/(MBP) HST

GR134a LBP/MBP/HBP

GHR134a Heat pumps

GHHR134a Heat pumps

(optimized)

TL

NL

FR

NL

ES

E

Y

5

7

7

9 .2

1.1 Compressordesignations

The compressor designations are built up according to the following system:

Example

1.2 Design Compressors with the denominations PL, PLE, TLS, TFS, TLES, TLY, NL, NF and NLE aredesigns with semi-direct intake. Compressors with the denomination NLY are designs withdirect intake. Please note that the suction and process connectors on all TLS, TLES, andTLY compressors have been interchanged as compared with the basic TL compressors.Using the wrong connector as suction connector on PL, PLE, TLS, TFS, TLES, TLY, NL, NFand NLE compressors will lead to reduced capacity and efficiency.Using the wrong connector as suction connector on the NLYs is not allowed since the com-pressor will not function.

Generation

Blank First

generation

.2 Second

generation

.3 Third

generation

etc.

F

F

GH

FK

8238-16

TLV

4 CK.40.B6.02 August 2001

1.3 Type label

1.4 Data stamping

1.5 Compressordimensions

2. Application range

FT

FK

GHH

GH

105G

6606

NL6F220-240V~50HzLBP LST/HST

8273

-3

DANFOSS COMPRESSORSBarcode onwhite background

Yellow background

Blue stripe

Application

Approvals

R134a

All compressors have a yellow label with the typedesignation. This label has a blue stripe and thetext ”R134a“.The country of origin indicated on the compres-sor paper label and on the compressor covervaries depending on the manufacturing place.Information can be found on our technical infor-mation sheet ”Country of Origin“.

The build-in conditions (total height, weight, tube dimensions etc.) are specified in theindividual datasheets including dimensioned sketches for the compressors.

The compressor type and production date are stamped on the side of the compressor. Theinformation may be as follows,

L--4F-4400F-201E2207

The first line states the model designation and the code no.L- = last letter (or last two letters) of the compressor type-4F- = nominal displacement and application4400 = 4 last digits in the code no.(- = position mark)The second line states the date of manufacture and internal Danfoss codes.F = manufacturing place (F = Germany, AL = Slovenia, AM = Mexico)20 = week 201 = 2001E = Friday (A = Monday etc.)220 = nominal voltage7 = internal Danfoss code

Compressors with denominations ending with F are primarily designed for low evaporatingtemperatures (LBP Low Back Pressure) for use in refrigerators, freezers and similarapplications in regions with stable supply voltage.

Compressors with denominations ending with FT are designed for low evaporation tem-peratures (LBP Low Back Pressure) for use in refrigerators, freezers and similar applica-tions operating in regions with unstable supply voltage.

Compressors with denominations ending with FK are F-types designed for low evaporationtemperatures with LST starting characteristics (capillary tube).

Compressors with denominations ending with FX are F-types designed for low evaporationtemperatures with HST starting characteristics (expansion valve).

Compressors with denominations ending with G are primarily designed for high evaporationtemperatures (HBP High Back Pressure) for use in liquid coolers, dehumidifiers, refrig-erated display counters, vending machines and similar applications. The compressors canalso be used for ”Heavy Duty“ purposes at low evaporating temperatures for use in refrig-erators, freezers and similar applications operating in regions with unstable supply voltage.

Compressors with denominations ending with GH are designed for high evaporating tem-peratures for cooling of electronic cabinets and for use in heat pump systems.

Compressors with denominations ending with GHH are optimized versions of GH com-pressors.The table on page 5 shows the normally recommended applications as regards voltage/frequency, ambient temperature, evaporating temperature and necessary compressorcooling. The recommendations must be regarded as a guideline only as they presupposea proper dimensioning of the refrigeration system.

F

FX

G

August 2001 CK.40.B6.02 5

rosserpmoC ]zH/V[sniaMerutarepmettneibmA

C°23 C°83 C°34PBL PBH PBL PBH PBL PBH

FKF

2.KFXF

F05-53-02LP 05/452-891 S SF05-53ELP 05/452-891 *S *S

F5-4-3-5.2LT 05/452-891 S SF6-5-4SLT 05/452-891 S S

F7SLT 05/452-891 S *SF4-3SELT 05/452-891 S S S

F5SELT 05/452-891 S S *S )1

F6SELT 05/452-891 S *S *SF7SELT 05/452-891 S *S

F4YLT 05/452-891 S S SKF5YLT 05/452-891 S S *SKF6XLT 05/452-891 *S *S

F7-6-5VLT 06-05/452-891 S S S

XF7FN05/242-891 S F1

06/242-891 F1 F1

XF9FN 05/242-891 F/O 1 F/O 1

XF01FN 05/242-891 F1 F2

XF11FN 05/242-891 F2 F2

F9-8-7-6LN 05/452-891 S SF11LN 05/452-891 F/O 1 F/O 1

KF8ELN-F9-7-6ELN 05/452-891 S SKF9-5.5YLN-F7-6YLN 05/452-891 *S *S *S

2.KF9-7-6-5.5YLN 05/452-891 *S *S *SF01-5.8-5.7RF 05/452-891 S SF12-81-51CS 05/452-891 F/O 1 F/O 1

TFXTF

TF5.4-4SFT 05/242-671 S S STF5-4-3SLT 05/452-781 S S S

TF6LN05/452-781 S S S06/452-891 S S S

TF7LN 05/452-781 S S F/O 1

TF01-9LN 05/452-781 S F/O 1 F/O 1

TF9ELN 05/452-781 S S S

TF51-21CS05/452-781 F/O 1 F/O 1 F2

06/452-891 F/O 1 F/O 1 F2 ***

XTF12CS-81CS05/452-781 F2 F2 F2

06/452-891 F2 F2 F2

G

G53LP05/452-891 F2 F2 F2 F2

06/452-891 F2 F2

G5.2LT

05/452-781

S S S05/452-891 S S F2

06/452-89106/452-702 S S F2

G5-4-3LT05/452-781

S S S05/452-891 F2 F2 F2

06/452-891

G6RF05/452-781

S S S05/452-891 F2 F2 F2

06/452-891

G5.7RF05/452-781

S S 1F/O05/452-891 F2 F2 F2

06/452-891

G01-5.8RF05/452-781

S F/O 1 F/O 105/452-891 F2 F2 F2

06/452-891G11RF 05/452-891 F2 F2 F2 F2 F2 F2

01CS05/452-781

F1 F1 F105/452-891 F2 F2 F2

06/452-891

G81-51-21CS05/452-781

F/O 1 F/O 1 F/O 105/452-891 F2 F2 F2

06/452-891

G12CS05/452-781

F2 F2 F2 **05/452-891 F2 F2 F2

06/452-891

G21/21CSniwTG51/51CS

G81/81CS05/452-891 F2 F2 F2 F2 F2 F2

niwTG12/12CS 05/452-891 F2 F2 F2 F2 F2 ** F2

HG

HG4LT05/452-891

F2 F2 F206/452-891

HG7RF05/452-891

F/O 1 F/O 1 F/O 106/452-891

HG51-21-01CS 05/452-891 F1 F1 F1

HG81CS 05/452-891 F2 F2 F2

HG81-51-21-01CS05/452-891

F2 F2 F206/452-891

HHG HHG51-01CS 05/452-891 O O O

*=

Run

cap

acito

r co

mpu

lsor

y*1)

=R

un c

apac

itor

reco

mm

ende

d**

=N

ot a

pplic

able

bel

ow -

25°C

eva

pora

ting

tem

pera

ture

in 4

3°C

am

bien

t te

mp.

abo

ve 2

40V

***

=O

/F1 po

ssib

le a

t 22

0V n

omin

al (

187-

242V

)

The

app

licat

ion

limits

reg

ardi

ng e

vapo

ratin

g te

mpe

ratu

res

and

mot

or s

yste

ms

are

spec

ified

in

the

indi

vidu

al c

ompr

esso

r da

tash

eets

.

S=

Sta

tic c

oolin

g no

rmal

ly s

uffic

ient

O=

Oil

cool

ing

F1

=Fa

n co

olin

g 1.

5 m

/s (

com

pres

sor

com

part

men

t te

mpe

ratu

re e

qual

to

ambi

ent

tem

p.)

F2

=Fa

n co

olin

g 3.

0 m

/s n

eces

sary

=O

utsi

de a

pplic

atio

n ra

nge,

not

rec

omm

ende

d

6 CK.40.B6.02 August 2001

2.1 Design limits

Condensing temperatureWinding temperature

In order to secure a satisfying lifetime of the compressor, and to protect the compressoragainst overload, some design criteria for the appliances must be fulfilled.Both the condensing temperature and the compressor temperature should be kept aslow as possible. This can be done by using well-dimensioned condenser surfaces and byensuring good ventilation around the compressor under all operating conditions.In order to protect the compressor against overload, the compressor has to start andwork properly through pressure peaks obtained in the highest ambient temperature andlowest obliging voltage. At peak load the condensing temperature must not exceed 70°C.The winding temperature must not exceed 135°C.At stable operation conditions the condensing temperature must not exceed 60°C. Thewinding temperature must not exceed 125°C.These limitations secure a protection of valves, gaskets, oil, and motor insulation.

3. Electrical equipment The compressors are equipped with a single-phase AC motor. With the exception of thesmallest TL and the biggest SC compressors the TL, TLS, NL, FR, and SC compressorsare designed with universal motors which means that they can obtain a high (HST) or lowstarting torque (LST) depending on the external electrical equipment used.The electrical equipments are classified as ”normal tight“ (IP20)The motor protector is built into the motor (winding protector).Earth connections are located on the bracket around the current lead-in of the compressor.No attempt must be made to start the compressor without a complete starting device.

The compressors can be supplied with the following motor systems:

PL, TL, NL, FR TFS

8073

8074

Compressors with the motor type Resistant StartInduction Run (RSIR) have a starting device forLow Starting Torque (LST). The design of theelectrical equipment depends on the actual com-pressor design. The following designs of startingdevices exist:a) PTC + cord relief + cover, the motor protectoris built into the motor (winding protector), usedfor compressors with the denominations PL, TL,NL, FR, and SC.b) Relay housing including motor protector + cordrelief + cover, used for compressors with thedenomination TFS.The PTC starting device requires a pressure-equalization before each start. This startingdevice is normally used in well-designed re-

frigerating systems with capillary tube as throttling device. The PTC needs a compressorstandstill period of 5 minutes to cool down before each start.

3.1 LST (RSIR)

SC

8190

August 2001 CK.40.B6.02 7

Compressors with the motor type Capacitor Start Induction Run (CSIR) have a startingdevice for High Starting Torque (HST). This starting device consists of a starting relay anda starting capacitor and is used for compressors with the denominations TL, NL, NF, FRand SC. The following designs of starting devices exist:a) Relay + starting capacitor + cord relief + cover, used for compressors with the denomi-nations TL, NL, FR and SC.b) Relay housing including motor protector + starting capacitor + cord relief (2x) + cover,used for compressors with the denomination NF.The starting device requires no pressure-equalization before each start and is normallyused in refrigerating systems with expansion valve as throttling device or in capillary tubesystems where pressure equalizing is not obtained during the standstill periods. The starting

device is mandatory for NF-FX compressors andfor some of the biggest SC compressors.The starting capacitor is designed for short timecut-in. ”1.7% ED“, which is stamped on the star-ting capacitor, means for instance max. 10 cut-ins per hour each with a duration of 6 seconds.

3.2 LST (RSCR) Compressors with the motor type ResistantStart Capacitor Run (RSCR) have a startingdevice for Low Starting Torque (LST). This start-ing device consists of a PTC and a run capacitorand is mandatory for compressors with the de-nominations PLE, TLY and NLY. The PTC start-ing device requires a pressure-equalizationbefore each start. This starting device is nor-mally used in well-designed refrigerating sys-tems with capillary tube as throttling device.

PLE, TLES, TLY, NLE, NLY

PL, TL, NL, FR NF

SC

8077

-2

8076

8088

8075

3.3 HST (CSIR)

8 CK.40.B6.02 August 2001

3.4 HST (CSR)

SC

8191

Compressors with the motor type Capacitor StartRun (CSR) have a starting device for HighStarting Torque (HST). This starting device con-sists of a starting relay, a starting capacitor, arun capacitor, a terminal board, a cord relief,and a cover. The starting device is mandatoryfor some of the biggest SC compressors. Thestarting capacitor is designed for short time cut-in. ”1.7% ED“, which is stamped on the startingcapacitor, means for instance max. 10 cut-insper hour each with a duration of 6 seconds.

8434

3.5 Electronic unit(variable speed)

The variable speed compressor motorsare electronically controlled. No attempmust be made to start the compressorwithout a complete electronic unit, asspecified in the data sheet for the com-pressor type in question.The electronic unit has a built-in over-load protection as well as thermal pro-tection. In case of activation of thisprotection the electronic unit will pro-tect the compressor motor as well asitself. When the protection has beenactivated, the electronic unit automa-tically will restart the compressor aftera certain time. The electronic unitprovides the compressor with HighStarting Torque (HST) which meansthat a pressure-equalizeation of thesystem before start is not necessary.

The compressors are equipped with permanent magnet rotors (PM motor) and 3 identicalstator windings. The electronic unit is mounted directly on the compressor and controls thePM motor.Connecting the motor to AC mains, by fault, will damage the magnets and lead to drasticallyreduced efficiency, or even non functioning.

For further information on which starting device to use on individual compressors, pleaserefer to the actual datasheets (some compressors have limitations for either LST or HST).

TLV

August 2001 CK.40.B6.02 9

The electrical equipments are equipped with connectors depending on the ordered codenumber,

Starting relays: 6.3 mm spade connectors onlyPTCs: 6.3 or 4.8 mm spade connectors and screwsVariable speed electronic unit: 6.3 spade connectors only

The power supply must be connected as shown in the wiring diagrams for the chosenelectrical equipment given in the actual datasheets.

The compressors have been approved in respect of safety by testing authorities in themajority of Western European countries. Actual standards to which the compressorshave been approved are specified in the individual datasheets. Approval markings appearon the compressor labels.

To fulfil the requirements of EN 60355-2-34 the protectionscreen 103N0476 must be applied to the PTC starting device.

Most compressors which are capableof running at 60Hz have been approvedin respect of safety by testing authori-ties UL and CSA.Actual standards to which the com-pressors have been approved arespecified in the individual datasheets.Approval markings appear on a sepa-rate approval mark label.

The compressors are dried to a maximum moisture content of 60 to 75 mg depending onthe compressor size. The maximum impurity content is 40 to 50 mg depending on thecompressor size.

The refrigerant charge must never be too large to be contained on the condenser side ofthe refrigeration system. Only the refrigerant amount which is necessary for the systemto function must be charged.The refrigerant amount may be critical as regards oil foaming and liquid hammer afterlong standstill periods. Because of this, limitations of refrigerant charges have beenintroduced. The maximum refrigerant charge is specified in the individual datasheets.If these limitations cannot be complied with, the risk may be reduced if a crankcase heateris properly used or if a pump down system is established.

The compressors are supplied charged with dried and degassed oil, which is normallysufficient for the lifetime of the compressor. The refrigeration systems and the systemcomponents must be dimensioned in such a way that the oil can be lead back continuouslyto the compressor housing without accumulating in the system, e.g. without oil pocketsand with sufficient gas velocity. The compressors use polyolester oils and are approvedonly for these oils and R134a.The oil charge is specified in the individual datasheets.

3.6 Connections

5. Max. refrigerantcharge

6. Oil charge

3.7 Approvals

4. Moisture andimpurities

7363

R

TL3G230V-60Hz1PHTHERMALLYPROTECTEDApproval mark

8284

-4

Protection screen

10 CK.40.B6.02 August 2001

8. Condition at delivery

Soldering problems caused by oil in the connectors can be avoided by placing the com-pressor on its baseplate some time before soldering it into the system. The compressormust never be placed upside down when mounting the rubber grommets in the baseplate.Instead place the compressor on its side with the connectors upwards.

7. Mounting

7.1 Mountingaccessories

The mounting accessories for the compressors are available in two versions, with bolt jointor snap-on joint. The code numbers for the mounting accessories are specified in the in-dividual compressor datasheets.These rubber grommets are designed for the 16 mm holes of the baseplate:Bolt joint for one compressor in a bag 118-1917 or 118-1946Bolt joint in quantities 118-1918 or 118-1945Snap-on in quantities 118-1919 or 118-1944Snap-on for one compressor in a bag 118-1947

These rubber grommets are designed for the 19 mm holes of the baseplate:Bolt joint in quantities 118-1948

The compressors are delivered without mounted starting devices on pallets with the di-mensions 1144 x 800 mm. Quantities per pallets are specified in the individual data-sheets. Electrical equipment is packed in separate boxes.The most important performance controls carried out during manufacturing are,

• A high potential insulation test with 1650V for 1 second• Pumping capacity• Tightness of discharge side and discharge valve• Tightness of compressor housing• Check of the right oil charge• Noise test

The compressors are supplied with sealed connectors and the sealing should not beremoved before the system assembly takes place(max. 15 minutes with open connectors).

The Twin version consists of two SC compressors mounted on a common baseplate. Thetwo compressors are joined by an oil-equalizing tube and also have an intake manifoldwith screw connector for a service valve or a solder connector (these parts are suppliedas accessories).Each Twin compressor is supplied with two sets of electrical equipment and mountingaccessories. To ensure optimum starting characteristics and the smallest possible mainsload we recommend that the compressors be equipped with a time-delay relay for start ofthe second compressor.Twin compressors can operate with capacity regulation dependingon the controls used.

9. Twin-compressors

Bolt joint Snap-on joint

3327-2

9

Compressor base Grommet sleeveWasher Nut M6

Cabinet base Screw M6 x 25 Rubber grommet

9

Washer

Compressor base

Clip

Steel pin

7382-2

Cabinet base Rubber grommet

August 2001 CK.40.B6.02 11

11. Warnings

10. Conversion fromR12 to R134a

Normally, the capillary tube shall be adjusted at low evaporating temperatures. Comparedto an optimized R12 system with the same evaporator capacity, the R134a system musthave an increased resistance defined as approx. 10% less N

2 flow at 10 bar inlet pressure.

The same size of capillary tube as used for R12 can be used at high evaporating tempe-ratures.

A drier with 3Å desiccant of Molecular Sieves must always be used.

Rules for dryness and cleanliness of system components (DIN 8964) are transferred toR134a systems.

The system components must not contain mineral oil or greasy substances.

The compressors must be soldered into the system no later than 15 minutes after theconnector seals have been removed.

The same evacuation procedure as for R12 systems must be used.

Max. 1% non-condensable gases.

The system must not contain any chlorine.

The charging equipment must only be used for R134a.

If the same vacuum pump is to be used for R12 and R134a systems, a special Ester oilmust be used in agreement with the pump supplier.

No high potential test nor start tests must be carried out while the compressor is undervacuum.No attempt must be made to start the compressor without a complete starting device.Allow the compressor to assume a temperature above 10°C before starting the first timein order to avoid starting problems.Anti-freeze agents must not be used in the compressors as such agents are damaging toseveral of the materials used. In particular, the ethyl or methyl alcohol contents of suchanti-freeze agents have a destructive effect on the synthetic motor insulation.

12 CK.40.B6.02 August 2001

April 2001 CD.41.B7.02 1

Application MBP

Evaporating temperature range °C -25 to 0

Voltage range V/Hz 198 - 254 /50

Motor type RSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor PL20F

Code number 101G0100

Displacement cm3 1.41

Oil quantity cm3 150

Maximum refrigerant charge g 300

Free gas vol. in compressor cm3 800

Weight without electrical equipment kg 3.8

Data Sheet (Replaces CD.41.B6.02)

General

Application

Design

Motor size watt 29

LRA (rated after 4 sec. UL984) LST A 1.2

Cut-in current LST A 5.7

Resistance, main and start winding (25°C) Ω 84.0/19.0

Approvals EN 60335-2-34 with Annex AA

Motor

Dimensions

Height mm A 129

B 127

B1 120

B2 73

Suction connector location/I.D. mm C 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Compressors on a pallet pcs. 150

PL20FStandard CompressorR134a220-240V 50Hz

B A

206

170

70

ø16C

ED

130

8241

204

35 100

B2

B1

ø9

46 59

60.5

50

127

101G

0100

PL20F

R134a

8270

-2

DANFOSS COMPRESSORSBarcode onwhite background

Yellow background

Blue stripe

Application

Approvals

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

August 2001 CK.40.B6.02 13

2 CD.41.B7.02 April 2001

8224

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

Power consumption watt

Current consumption A

COP (ASHRAE) W/W

Capacity (ASHRAE) watt

Accessories

seciveD .giF F02LP

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a1100N3018100N301

revoC b 1940N301

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F02LP 0.61 0.91 4.52 5.63 6.94 9.46 6.28

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F02LP 7.91 4.32 3.13 0.54 3.16 3.08 201

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F02LP 0.24 4.34 4.64 5.15 2.75 3.36 7.96

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F02LP 53.0 53.0 63.0 73.0 93.0 14.0 34.0

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F02LP 83.0 44.0 55.0 17.0 78.0 30.1 91.1

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F02LP 74.0 45.0 76.0 78.0 70.1 72.1 74.1

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

COP (EN 12900/CECOMAF) W/W

Capacity (EN 12900/CECOMAF) watt

14 CK.40.B6.02 August 2001

July 2001 CD.41.E2.02 1

Application MBP

Evaporating temperature range °C -25 to 0

Voltage range V/Hz 198 - 254 /50

Motor type RSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor PL35F

Code number 101G0202

Displacement cm3 2.00

Oil quantity cm3 150

Maximum refrigerant charge g 300

Free gas vol. in compressor cm3 830

Weight without electrical equipment kg 4.1

Data Sheet (Replaces CD.41.E1.02)

General

Application

Design

Motor size watt 43

LRA (rated after 4 sec. UL984) LST A 1.7

Cut-in current LST A 5.6

Resistance, main and start winding (25°C) Ω 52.0/19.0

Approvals EN 60335-2-34 with Annex AA

Motor

Dimensions

Height mm A 134

B 132

B1 125

B2 73

Suction connector location/I.D. mm C 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Compressors on a pallet pcs. 150

PL35FStandard CompressorR134a220-240V 50Hz

B A

206

170

70

ø16C

ED

130

8241

204

35 100

B2

B1

ø9

46 59

60.5

50

127

101G

0202

PL35F

R134a

8270DANFOSS COMPRESSORSBarcode on

white background

Yellow background

Blue stripe

Application

Approvals

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

August 2001 CK.40.B6.02 15

2 CD.41.E2.02 July 2001

8224

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

Power consumption watt

Current consumption A

COP (ASHRAE) W/W

Capacity (ASHRAE) watt

Accessories

seciveD .giF F53LP

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a1100N3018100N301

revoC b 1940N301

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F53LP 23 63 54 06 97 101 521

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F53LP 93 44 55 47 79 421 551

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F53LP 05 25 75 46 27 08 88

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F53LP 05.0 05.0 15.0 35.0 55.0 85.0 26.0

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F53LP 46.0 96.0 97.0 49.0 01.1 62.1 24.1

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F53LP 87.0 58.0 79.0 61.1 63.1 55.1 67.1

Capacity (EN 12900/CECOMAF) watt

COP (EN 12900/CECOMAF) W/W

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

16 CK.40.B6.02 August 2001

April 2001 CD.41.F2.02 1

Application LBP

Evaporating temperature range °C -35 to -10

Voltage range V/Hz 198 - 254 /50

Motor type RSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor PL50F

Code number 101G0220

Displacement cm3 2.50

Oil quantity cm3 150

Maximum refrigerant charge g 300

Free gas vol. in compressor cm3 850

Weight without electrical equipment kg 4.3

Data Sheet (Replaces CD.41.F1.02)

General

Application

Design

Motor size watt 54

LRA (rated after 4 sec. UL984) LST A 2.2

Cut-in current LST A 6.0

Resistance, main and start winding (25°C) Ω 38.0/20.0

Approvals EN 60335-2-34 with Annex AA

Motor

Dimensions

Height mm A 137

B 135

B1 128

B2 73

Suction connector location/I.D. mm C 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Compressors on a pallet pcs. 150

PL50FStandard CompressorR134a220-240V 50Hz

B A

206

170

70

ø16C

ED

130

8241

204

35 100

B2

B1

ø9

46 59

60.5

50

127

101G

0220

PL50F

R134a

8270

-3

DANFOSS COMPRESSORSBarcode onwhite background

Yellow background

Blue stripe

Application

Approvals

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

August 2001 CK.40.B6.02 17

2 CD.41.F2.02 April 2001

8224

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

Power consumption watt

Current consumption A

Capacity (ASHRAE) watt

Accessories

seciveD .giF F05LP

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a1100N3018100N301

revoC b 1940N301

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F05LP 2.41 2.62 0.04 1.54 8.55 1.47 2.59

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F05LP 4.71 3.23 3.94 6.55 9.86 5.19 811

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F05LP 6.34 9.15 0.06 7.26 1.86 5.67 6.58

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F05LP 74.0 84.0 05.0 15.0 35.0 55.0 85.0

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F05LP 23.0 05.0 76.0 27.0 28.0 79.0 11.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F05LP 04.0 26.0 28.0 98.0 10.1 02.1 83.1

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

COP (EN 12900/CECOMAF) W/W

Capacity (EN 12900/CECOMAF) watt

COP (ASHRAE) W/W

18 CK.40.B6.02 August 2001

April 2001 CD.41.G2.02 1

Application MBP

Evaporating temperature range °C -25 to 0

Voltage range V/Hz 198 - 254 /50

Motor type CSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C F2

38°C F2

Compressor PL50F

Code number 101G0222

Displacement cm3 2.50

Oil quantity cm3 150

Maximum refrigerant charge g 300

Free gas vol. in compressor cm3 850

Weight without electrical equipment kg 4.3

Data Sheet (Replaces CD.41.G1.02)

General

Application

Design

Motor size watt 54

LRA (rated after 4 sec. UL984) HST A 4.2

Cut-in current HST A 4.2

Resistance, main and start winding (25°C) Ω 38.0/14.0

Approvals EN 60335-2-34 with Annex AA

Motor

Dimensions

Height mm A 137

B 135

B1 128

B2 73

Suction connector location/I.D. mm C 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Compressors on a pallet pcs. 150

PL50FStandard CompressorHST Starting CharacteristicsR134a220-240V 50Hz

B A

206

170

70

ø16C

ED

130

8241

204

35 100

B2

B1

ø9

46 59

60.5

50

127

101G

0222

PL50F

R134a

8283

-2

DANFOSS COMPRESSORSBarcode onwhite background

Yellow background

Blue stripe

Application

Approvals

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

August 2001 CK.40.B6.02 19

2 CD.41.G2.02 April 2001

8225

10 11

131214

b

d

a2

c

c

Main winding Start windingWinding protector

Accessories

Capacity (ASHRAE) watt

Power consumption watt

Current consumption A

COP (ASHRAE) W/W

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F05LP 0.04 1.54 8.55 1.47 2.59 021 841

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F05LP 3.94 6.55 9.86 5.19 811 841 381

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F05LP 0.85 7.06 1.66 5.47 6.38 7.39 501

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F05LP 05.0 15.0 35.0 55.0 85.0 26.0 66.0

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F05LP 96.0 47.0 48.0 99.0 41.1 82.1 14.1

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F05LP 58.0 29.0 40.1 32.1 14.1 85.1 47.1

seciveD .giF F05LP

yalergnitratS 2a 1206U711

revoC b 1940N301

06roticapacgnitratS µF c 4105U711

feilerdroC d 0101N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CFan cooling, 220V 50Hz

COP (EN 12900/CECOMAF) W/W

Capacity (EN 12900/CECOMAF) watt

20 CK.40.B6.02 August 2001

June 2001 CD.42.S4.02 1

Application MBP

Evaporating temperature range °C -25 to 0

Voltage range V/Hz 198 - 254 /50

Motor type RSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor TL2.5F

Code number (small baseplate) 102G4200

Code number (large baseplate) 102G4201

Displacement cm3 2.61

Oil quantity cm3 180

Maximum refrigerant charge g 400

Free gas vol. in compressor cm3 1600

Weight without electrical equipment kg 6.7

Data Sheet (Replaces CD.42.S3.02)

General

Application

Design

Motor size watt 60

LRA (rated after 4 sec. UL984) LST A 2.3

Cut-in current LST A 7.0

Resistance, main and start winding (25°C) Ω 40.0/15.0

Approvals EN 60335-2-34 with Annex AA, CCIB

Motor

TL2.5FStandard CompressorR134a220-240V 50Hz

157

6660

.5

102 96117

297151

°20

°

45°

170178

70 100

ø16

186204

ø9

3510

5

107

105

BA

30°

31.5°28°

176222

E

8428

Cor

DD

orC

ø3.6

ø19

101.

613

6

102G

4200

TL2.5F

8271

-2

DANFOSS COMPRESSORS

Barcode onwhite background

Yellow background

Blue stripe

Application

Approvals

R134a

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

Dimensions 102G4200 102G4201

Height mm A 163

B 159

Suction connector location/I.D. mm C 6.2 ±0.09 6.5 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09 6.5 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20 5.0 +0.12/+0.20

Compressors on a pallet pcs. 125

August 2001 CK.40.B6.02 21

2 CD.42.S4.02 June 2001

Power consumption watt

Current consumption A

Capacity (ASHRAE) watt

Accessories

8217

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

seciveD .giF F5.2LT

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a1100N3018100N301

revoC b 0102N301

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F5.2LT 23 73 74 56 68 011 731

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F5.2LT 93 54 85 08 601 631 961

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F5.2LT 45 75 36 17 08 98 89

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F5.2LT 44.0 54.0 64.0 94.0 25.0 55.0 85.0

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F5.2LT 95.0 46.0 57.0 19.0 70.1 42.1 04.1

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F5.2LT 37.0 97.0 29.0 21.1 33.1 35.1 37.1

COP (ASHRAE) W/W

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

Capacity (EN 12900/CECOMAF) watt

COP (EN 12900/CECOMAF) W/W

22 CK.40.B6.02 August 2001

June 2001 CD.42.I6.02 1

Application MBP

Evaporating temperature range °C -25 to 0

Voltage range V/Hz 198 - 254 /50

Motor type RSIR/CSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor TL3F

Code number 102G4300

Displacement cm3 3.13

Oil quantity cm3 180

Maximum refrigerant charge g 400

Free gas vol. in compressor cm3 1600

Weight without electrical equipment kg 6.7

Data Sheet (Replaces CD.42.I5.02)

General

Application

Design

Motor size watt 75

LRA (rated after 4 sec. UL984) LST/HST A 2.8/4.5

Cut-in current LST/HST A 7.5/4.5

Resistance, main and start winding (25°C) Ω 31.5/15.0

Approvals EN 60335-2-34 with Annex AA, CCIB

Motor

DimensionsHeight mm A 163

B 159

Suction connector location/I.D. mm C 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Compressors on a pallet pcs. 125

TL3FStandard CompressorR134a220-240V 50Hz

157

6660

.5

102 96117

297151

°20

°

45°

170178

70 100

ø16

186204

ø9

3510

5

107

105

BA

30°

31.5°28°

176222

E

8263

Cor

DD

orC

102G

4300

TL3F

8271

-3

DANFOSS COMPRESSORS

Barcode onwhite background

Yellow background

Blue stripe

Application

Approvals

R134a

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

August 2001 CK.40.B6.02 23

2 CD.42.I6.02 June 2001

8217

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

8219

10 11

131214

b

d

a2

c

c

Main winding Start windingWinding protector

Accessories

Power consumption watt

Current consumption A

COP (ASHRAE) W/W

Capacity (ASHRAE) watt

LST

HST

seciveD .giF F3LT

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a1100N3018100N301

yalergnitratS 2a 7006U711

revoC b 0102N301

06roticapacgnitratS µF c 4105U711

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F3LT 24 84 06 28 801 831 371

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F3LT 25 95 47 101 331 171 412

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F3LT 66 96 67 78 99 111 421

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F3LT 05.0 15.0 25.0 45.0 75.0 16.0 76.0

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F3LT 46.0 96.0 97.0 49.0 90.1 42.1 93.1

C°\.pmoC 52- 3.32- 02- 51- 01- 5- 0F3LT 87.0 58.0 79.0 61.1 53.1 35.1 27.1

Capacity (EN 12900/CECOMAF) watt

COP (EN 12900/CECOMAF) W/W

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

24 CK.40.B6.02 August 2001

June 2001 CD.42.Z2.02 1

Application LBP

Evaporating temperature range °C -35 to -10

Voltage range V/Hz 198 - 254 /50

Motor type RSIR/CSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor TL4F

Code number 102G4400

Code number 102G4426

Displacement cm3 3.86

Oil quantity cm3 180

Maximum refrigerant charge g 400

Free gas vol. in compressor cm3 1600

Weight without electrical equipment kg 6.7

Data Sheet (Replaces CD.42.Z1.02)

General

Application

Design

Motor

TL4FStandard CompressorR134a220-240V 50Hz

157

6660

.5

102 96117

297151

°20

°

45°

170178

70 100

ø16

186204

ø9

3510

5

107

105

BA

30°

31.5°28°

176222

E

8263

Cor

DD

orC

102G

4400

TL4F

8271

-4

DANFOSS COMPRESSORS

Barcode onwhite background

Yellow background

Blue stripe

Application

Approvals

R134a

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

Dimensions 102G4400 102G4426

Height mm A 163

B 159

Suction connector location/I.D. mm C 6.2 ±0.09 6.5 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09 6.5 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20 5.0 +0.12/+0.20

Compressors on a pallet pcs. 125

Motor size watt 85

alternative motor 80

LRA (rated after 4 sec. UL984) LST/HST A 3.2/4.8

alternative motor 3.2/4.6

Cut-in current LST/HST A 7.5/4.8

alternative motor 7.8/4.6

Resistance, main and start winding (25°C) Ω 25.7/16.3

alternative motor 26.8/13.5

Approvals EN 60335-2-34 with Annex AA, CCIB

August 2001 CK.40.B6.02 25

2 CD.42.Z2.02 June 2001

8217

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

8219

10 11

131214

b

d

a2

c

c

Main winding Start windingWinding protector

Accessories

LST

HST

Power consumption watt

Current consumption A

COP (ASHRAE) W/W

Capacity (ASHRAE) watt

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F4LT 13 44 16 76 18 701 731

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F4LT 83 45 57 38 001 131 071

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F4LT 06 07 18 58 39 701 221

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F4LT 15.0 35.0 55.0 65.0 85.0 36.0 96.0

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F4LT 25.0 36.0 57.0 97.0 88.0 00.1 21.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F4LT 46.0 77.0 29.0 89.0 80.1 42.1 83.1

seciveD .giF F4LT

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a1100N3018100N301

yalergnitratS 2a 9006U711

revoC b 0102N301

06roticapacgnitratS µF c 4105U711

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

Capacity (EN 12900/CECOMAF) watt

COP (EN 12900/CECOMAF) W/W

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

26 CK.40.B6.02 August 2001

June 2001 CG.42.B2.02 1

Application LBP

Evaporating temperature range °C -35 to -10

Voltage range V/Hz 198 - 254 /50

Motor type RSIR/CSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor TL5F

Code number 102G4501

Displacement cm3 5.08

Oil quantity cm3 180

Maximum refrigerant charge g 400

Free gas vol. in compressor cm3 1790

Weight without electrical equipment kg 7.5

Data Sheet (Replaces CG.42.B1.02)

General

Application

Design

Motor

DimensionsHeight mm A 173

B 169

Suction connector location/I.D. mm C 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Compressors on a pallet pcs. 125

TL5FStandard CompressorR134a220-240V 50Hz

157

6660

.5

102 96117

297151

°20

°

45°

170178

70 100

ø16

186204

ø9

3510

5

107

105

BA

30°

31.5°28°

176222

E

8263

Cor

DD

orC

102G

4501

TL5F

8271

DANFOSS COMPRESSORS

Barcode onwhite background

Yellow background

Blue stripe

Application

Approvals

R134a

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

Motor size watt 110

alternative motor 125

LRA (rated after 4 sec. UL984) LST/HST A 4.3/5.1

alternative motor 4.7/5.8

Cut-in current LST/HST A 8.6/5.1

alternative motor 8.7/5.8

Resistance, main and start winding (25°C) Ω 18.2/15.1

alternative motor 16.0/17.0

Approvals EN 60335-2-34 with Annex AA, CCIB

August 2001 CK.40.B6.02 27

2 CG.42.B2.02 June 2001

8217

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

8219

10 11

131214

b

d

a2

c

c

Main winding Start windingWinding protector

Accessories

Power consumption watt

Current consumption A

COP (ASHRAE) W/W

Capacity (ASHRAE) watt

LST

HST

seciveD .giF F5LT

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a1100N3018100N301

yalergnitratS 2a 4006U711

revoC b 0102N301

06roticapacgnitratS µF c 4105U711

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F5LT 34 06 28 19 011 441 381

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F5LT 35 47 101 211 631 771 622

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F5LT 07 58 101 701 811 631 451

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F5LT 57.0 87.0 18.0 38.0 68.0 19.0 79.0

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F5LT 16.0 07.0 18.0 58.0 39.0 60.1 91.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F5LT 57.0 68.0 00.1 50.1 51.1 03.1 74.1

Capacity (EN 12900/CECOMAF) watt

COP (EN 12900/CECOMAF) W/W

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

28 CK.40.B6.02 August 2001

May 2001 CG.42.J4.02 1

Application LBP

Evaporating temperature range °C -35 to -10

Voltage range V/Hz 198 - 254 /50

Motor type RSIR/CSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor TLS4F

Code number 102G4425

Displacement cm3 3.86

Oil quantity cm3 180

Maximum refrigerant charge g 400

Free gas vol. in compressor cm3 1600

Weight without electrical equipment kg 6.7

Data Sheet (Replaces CG.42.J3.02)

General

Application

Design

Motor

Dimensions

Height mm A 163

B 159

Suction connector location/I.D. mm C 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Compressors on a pallet pcs. 125

TLS4FStandard CompressorR134a220-240V 50Hz

157

6660

.5

102 96117

297151

°20

°

45°

170178

70 100

ø16

186204

ø9

3510

5

107

105

BA

30°

31.5°28°

176222C D

E

8244

102G

4425

TLS4F

8272

-4

DANFOSS COMPRESSORS

Barcode onwhite background

Yellow background

Blue stripe

Approvals

Application

R134aSUCTIONCONNECTOR

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

Motor size watt 85

alternative motor 80

LRA (rated after 4 sec. UL984) LST/HST A 3.2/4.8

alternative motor 3.2/4.6

Cut-in current LST/HST A 7.5/4.8

alternative motor 7.8/4.6

Resistance, main and start winding (25°C) Ω 25.7/16.3

alternative motor 26.8/13.5

Approvals EN 60335-2-34 with Annex AA

August 2001 CK.40.B6.02 29

2 CG.42.J4.02 May 2001

8217

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

8219

10 11

131214

b

d

a2

c

c

Main winding Start windingWinding protector

Accessories

LST

HST

Power consumption watt

Current consumption A

COP (EN 12900/CECOMAF) W/W

COP (ASHRAE) W/W

Capacity (ASHRAE) watt

Capacity (EN 12900/CECOMAF) wattC°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-

F4SLT 6.43 5.15 0.27 9.97 8.69 621 261

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F4SLT 6.24 5.36 9.88 6.89 911 651 002

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F4SLT 5.76 8.77 0.98 0.39 101 511 031

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F4SLT 95.0 26.0 66.0 86.0 17.0 67.0 18.0

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F4SLT 15.0 66.0 18.0 68.0 69.0 01.1 52.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F4SLT 36.0 28.0 00.1 60.1 81.1 63.1 45.1

seciveD .giF F4SLT

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a1100N3018100N301

yalergnitratS 2a 9006U711

revoC b 0102N301

06roticapacgnitratS µF c 4105U711

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz

30 CK.40.B6.02 August 2001

May 2001 CD.42.K6.02 1

Application LBP

Evaporating temperature range °C -35 to -10

Voltage range V/Hz 198 - 254 /50

Motor type RSIR/CSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor TLS5F

Code number 102G4520

Code number 102G4526

Displacement cm3 5.08

Oil quantity cm3 180

Maximum refrigerant charge g 400

Free gas vol. in compressor cm3 1790

Weight without electrical equipment kg 7.3

Data Sheet (Replaces CD.42.K5.02)

General

Application

Design

Motor size watt 125

alternative motor 110

LRA (rated after 4 sec. UL984) LST/HST A 4.7/5.8

alternative motor 4.3/5.1

Cut-in current LST/HST A 8.7/5.8

alternative motor 8.6/5.1

Resistance, main and start winding (25°C) Ω 16.0/17.0

alternative motor 18.2/15.1

Approvals EN 60335-2-34 with Annex AA

Motor

TLS5FStandard CompressorR134a220-240V 50Hz

157

6660

.5

102 96117

297151

°20

°

45°

170178

70 100

ø16

186204

ø9

3510

5

107

105

BA

30°

31.5°28°

176222C D

E

8244

102G

4520

TLS5FR134a

SUCTIONCONNECTOR

8272

DANFOSS COMPRESSORS

Barcode onwhite background

Yellow background

Blue stripe

Approvals

Application

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

Dimensions 102G4520 102G4526

Height mm A 173

B 169

Suction connector location/I.D. mm C 6.2 ±0.09 6.5 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09 6.5 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20 5.0 +0.12/+0.20

Compressors on a pallet pcs. 125

August 2001 CK.40.B6.02 31

2 CD.42.K6.02 May 2001

8219

10 11

131214

b

d

a2

c

c

Main winding Start windingWinding protector

8217

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

Capacity (ASHRAE) watt

Power consumption watt

Current consumption A

COP (ASHRAE) W/W

Accessories

HST

LST

seciveD .giF F5SLT

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a 1100N3018100N301

yalergnitratS 2a 4006U711

revoC b 0102N301

06roticapacgnitratS µF c 4105U711

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F5SLT 8.74 7.07 0.89 901 131 071 612

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F5SLT 9.85 2.78 121 431 161 902 762

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F5SLT 7.28 1.79 211 711 821 441 261

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F5SLT 69.0 89.0 10.1 20.1 50.1 01.1 51.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F5SLT 85.0 37.0 88.0 39.0 20.1 81.1 33.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F5SLT 17.0 09.0 80.1 41.1 62.1 54.1 56.1

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

COP (EN 12900/CECOMAF) W/W

Capacity (EN 12900/CECOMAF) watt

32 CK.40.B6.02 August 2001

June 2001 CG.42.G2.02 1

Application LBP

Evaporating temperature range °C -35 to -10

Voltage range V/Hz 198 - 254 /50

Motor type RSIR/CSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor TLS6F

Code number 102G4620

Displacement cm3 5.70

Oil quantity cm3 180

Maximum refrigerant charge g 400

Free gas vol. in compressor cm3 1790

Weight without electrical equipment kg 7.3

Data Sheet (Replaces CG.42.G1.02)

General

Application

Design

Motor

DimensionsHeight mm A 173

B 169

Suction connector location/I.D. mm C 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Compressors on a pallet pcs. 125

TLS6FStandard CompressorR134a220-240V 50Hz

157

6660

.5

102 96117

297151

°20

°

45°

170178

70 100

ø16

186204

ø9

3510

5

107

105

BA

30°

31.5°28°

176222C D

E

8244

102G

4620

TLS6F

8272

-2

DANFOSS COMPRESSORS

Barcode onwhite background

Yellow background

Blue stripe

Approvals

Application

R134aSUCTIONCONNECTOR

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

Motor size watt 125

alternative motor 110

LRA (rated after 4 sec. UL984) LST/HST A 4.7/5.8

alternative motor 4.3/5.1

Cut-in current LST/HST A 8.7/5.8

alternative motor 8.6/5.1

Resistance, main and start winding (25°C) Ω 16.0/17.0

alternative motor 18.2/15.1

Approvals EN 60335-2-34 with Annex AA

August 2001 CK.40.B6.02 33

2 CG.42.G2.02 June 2001

8219

10 11

131214

b

d

a2

c

c

Main winding Start windingWinding protector

8217

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

Accessories

HST

LST

seciveD .giF F6SLT

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a 1100N3018100N301

yalergnitratS 2a 4006U711

revoC b 0102N301

06roticapacgnitratS µF c 4105U711

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

Capacity (ASHRAE) watt

Power consumption watt

Current consumption A

COP (ASHRAE) W/W

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F6SLT 85 77 401 511 931 381 532

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F6SLT 17 59 821 241 271 622 092

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F6SLT 48 101 911 521 831 951 181

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F6SLT 87.0 28.0 68.0 88.0 29.0 99.0 80.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F6SLT 96.0 67.0 78.0 29.0 10.1 51.1 03.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F6SLT 58.0 49.0 80.1 31.1 42.1 24.1 06.1

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

COP (EN 12900/CECOMAF) W/W

Capacity (EN 12900/CECOMAF) watt

34 CK.40.B6.02 August 2001

June 2001 CG.42.H2.02 1

Application LBP

Evaporating temperature range °C -35 to -10

Voltage range V/Hz 198 - 254 /50

Motor type RSIR/CSIR

Max. ambient temperature °C 38*

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor TLS7F

Code number 102G4720

Displacement cm3 6.49

Oil quantity cm3 180

Maximum refrigerant charge g 400

Free gas vol. in compressor cm3 1790

Weight without electrical equipment kg 7.5

Data Sheet (Replaces CG.42.H1.02)

General

Application

Design

Motor size watt 140

LRA (rated after 4 sec. UL984) LST/HST A 5.4/5.7

Cut-in current LST/HST A 9.7/5.7

Resistance, main and start winding (25°C) Ω 14.5/14.8

Approvals EN 60335-2-34 with Annex AA

Motor

DimensionsHeight mm A 173

B 169

Suction connector location/I.D. mm C 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Compressors on a pallet pcs. 125

TLS7FStandard CompressorR134a220-240V 50Hz

157

6660

.5

102 96117

297151

°20

°

45°

170178

70 100

ø16

186204

ø9

3510

5

107

105

BA

30°

31.5°28°

176222C D

E

8244

102G

4720

TLS7F

8272

-3

DANFOSS COMPRESSORS

Barcode onwhite background

Yellow background

Blue stripe

Approvals

Application

SUCTIONCONNECTOR

R134a

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary* run capacitor 4 µF compulsory in 38°C ambient temperature

August 2001 CK.40.B6.02 35

2 CG.42.H2.02 June 2001

8219

10 11

131214

b

d

a2

c

c

Main winding Start windingWinding protector

8217

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

Accessories

HST

LST

Capacity (ASHRAE) watt

Power consumption watt

Current consumption A

COP (ASHRAE) W/W

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F7SLT 66 98 021 331 061 802 462

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F7SLT 18 901 841 361 791 652 623

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F7SLT 79 611 631 341 851 281 702

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F7SLT 78.0 19.0 69.0 89.0 30.1 11.1 02.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F7SLT 86.0 77.0 88.0 29.0 10.1 41.1 82.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F7SLT 48.0 49.0 90.1 41.1 42.1 14.1 75.1

seciveD .giF F7SLT

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a 1100N3018100N301

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a **6100N301 *1200N301 *

yalergnitratS 2a 0006U711

revoC b 0102N301

06roticapacgnitratS µF c 4105U711

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

4roticapacnuR µ sedapsmm3.6Fsedapsmm8.4

7117-711 *9117-711 *

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

* run capacitor 4 µF compulsory in 38°C ambient

temperature

** with connector for RC

Capacity (EN 12900/CECOMAF) watt

COP (EN 12900/CECOMAF) W/W

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

36 CK.40.B6.02 August 2001

July 2001 CD.43.P5.02 1

Application LBP

Evaporating temperature range °C -35 to -10

Voltage range V/Hz 198 - 254 /50

Motor type RSIR/CSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor NL6F

Code number 105G6606

Displacement cm3 6.13

Oil quantity cm3 320

Maximum refrigerant charge g 400

Free gas vol. in compressor cm3 2130

Weight without electrical equipment kg 9.3

Data Sheet (Replaces CD.43.P4.02)

General

Application

Design

Motor size watt 125

LRA (rated after 4 sec. UL984) LST/HST A 5.0/5.0

Cut-in current LST/HST A 9.6/5.0

Resistance, main and start winding (25°C) Ω 16.0/13.6

Approvals EN 60335-2-34 with Annex AA

Motor

DimensionsHeight mm A 190

B 183

Suction connector location/I.D. mm C 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Compressors on a pallet pcs. 80

NL6FStandard CompressorR134a220-240V 50Hz

70

ø16

254

170

A B

C

ED

166

8248

7854

113127

47°27°51°

119

7260

.525

° 35° 15°

93.5

75.5

102.

5

100

204

178

205

105G

6606

NL6F

8273

-2

DANFOSS COMPRESSORS

Barcode onwhite background

Yellow background

Blue stripe

Application

Approvals

R134a

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

August 2001 CK.40.B6.02 37

2 CD.43.P5.02 July 2001

Power consumption watt

Current consumption A

Capacity (ASHRAE) watt

Accessories

COP (ASHRAE) W/W

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F6LN 25 77 011 321 151 002 852

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F6LN 46 59 531 151 681 742 813

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F6LN 08 89 811 521 931 161 581

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F6LN 87.0 18.0 68.0 88.0 29.0 99.0 80.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F6LN 56.0 87.0 39.0 99.0 90.1 42.1 93.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F6LN 08.0 69.0 51.1 12.1 43.1 35.1 27.1

8219

10 11

131214

b

d

a2

c

c

Main winding Start windingWinding protector

8217

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

LST

HST

seciveD .giF F6LN

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a1100N3018100N301

yalergnitratS 2a 4006U711

revoC b 0102N301

08roticapacgnitratS µF c 5105U711

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

Capacity (EN 12900/CECOMAF) watt

COP (EN 12900/CECOMAF) W/W

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

38 CK.40.B6.02 August 2001

August 2001 CG.43.K2.02 1

Application LBP

Evaporating temperature range °C -35 to -10

Voltage range V/Hz 198 - 254 /50

Motor type RSIR/CSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor NL7F

Code number 105G6706

Code number compressor with oil cooler 105G6716

Displacement cm3 7.27

Oil quantity cm3 320

Maximum refrigerant charge g 400

Free gas vol. in compressor cm3 2180

Weight without electrical equipment kg 9.6

Data Sheet (Replaces CG.43.K1.02)

General

Application

Design

Motor size watt 150

LRA (rated after 4 sec. UL984) LST/HST A 5.9/5.9

Cut-in current LST/HST A 10.4/5.9

Resistance, main and start winding (25°C) Ω 13.3/14.1

Approvals EN 60335-2-34 with Annex AA, CCIB

Motor

Dimensions

Height mm A 190

B 183

Suction connector location/I.D. mm C 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Oil cooler location/I.D. mm F 5.0 +0.12/+0.20

Compressors on a pallet pcs. 80

NL7FStandard CompressorR134a220-240V 50Hz

70

ø16

254

170

A B

C

E

F

D

166

8249

7854

113127

47°27°51°

119

7260

.525

° 35°15°

93.5

75.5

102.

5

100

204

178205

4040

105G

6706

NL7F

8273

-4

DANFOSS COMPRESSORS

Barcode onwhite background

Yellow background

Blue stripe

Application

Approvals

R134a

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

August 2001 CK.40.B6.02 39

2 CG.43.K2.02 August 2001

Power consumption watt

Current consumption A

Capacity (ASHRAE) watt

Accessories

COP (ASHRAE) W/W

8219

10 11

131214

b

d

a2

c

c

Main winding Start windingWinding protector

8217

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

LST

HST

seciveD .giF F7LN

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a1100N3018100N301

yalergnitratS 2a 0006U711

revoC b 0102N301

08roticapacgnitratS µF c 5105U711

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F7LN 17 99 631 151 281 832 303

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F7LN 79 121 641 551 371 102 232

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F7LN 78 221 761 681 522 392 473

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F7LN 29.0 69.0 20.1 40.1 01.1 02.1 33.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F7LN 37.0 28.0 39.0 79.0 60.1 81.1 13.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F7LN 09.0 10.1 51.1 02.1 03.1 64.1 16.1

Capacity (EN 12900/CECOMAF) watt

COP (EN 12900/CECOMAF) W/W

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

40 CK.40.B6.02 August 2001

June 2001 CD.43.J6.02 1

Application LBP

Evaporating temperature range °C -35 to -10

Voltage range V/Hz 198 - 254 /50

Motor type RSIR/CSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor NL8F

Code number 105G6822

Displacement cm3 7.95

Oil quantity cm3 320

Maximum refrigerant charge g 400

Free gas vol. in compressor cm3 2230

Weight without electrical equipment kg 9.8

Data Sheet (Replaces CD.43.J5.02)

General

Application

Design

Motor size watt 175

LRA (rated after 4 sec. UL984) LST/HST A 6.6/7.9

Cut-in current LST/HST A 10.9/7.9

Resistance, main and start winding (25°C) Ω 10.7/13.0

Approvals EN 60335-2-34 with Annex AA

Motor

DimensionsHeight mm A 197

B 191

Suction connector location/I.D. mm C 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Compressors on a pallet pcs. 80

NL8FStandard CompressorR134a220-240V 50Hz

70

ø16

254

170

A B

C

ED

166

8248

7854

113127

47°27°51°

119

7260

.525

° 35° 15°

93.5

75.5

102.

5

100

204

178

205

105G

6822

NL8F

8273

-5

DANFOSS COMPRESSORS

Barcode onwhite background

Yellow background

Blue stripe

Application

Approvals

R134a

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

August 2001 CK.40.B6.02 41

2 CD.43.J6.02 June 2001

Power consumption watt

Current consumption A

Capacity (ASHRAE) watt

Accessories

COP (ASHRAE) W/W

8219

10 11

131214

b

d

a2

c

c

Main winding Start windingWinding protector

8217

N

N LC

b

d

a1

a1

Winding protector

Start windingMain winding

g

LST

HST

seciveD .giF F8LN

sedapsmm3.6ecivedgnitratsCTPsedapsmm8.4

1a1100N3018100N301

yalergnitratS 2a 1006U711

revoC b 0102N301

08roticapacgnitratS µF c 5105U711

feilerdroC d 0101N301

CTProfneercsnoitcetorP g 6740N301

seirosseccagnitnuoMrosserpmocenoroftniojtloB

seititnauqnitniojtloBseititnauqnino-panS

7191-8118191-8119191-811

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F8LN 28 211 941 361 491 942 713

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F8LN 101 931 481 102 042 803 293

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F8LN 611 431 451 261 771 302 232

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F8LN 29.0 89.0 40.1 70.1 31.1 22.1 43.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F8LN 07.0 48.0 79.0 10.1 90.1 32.1 73.1

C°\.pmoC 53- 03- 52- 3.32- 02- 51- 01-F8LN 78.0 40.1 91.1 52.1 53.1 25.1 96.1

Capacity (EN 12900/CECOMAF) watt

COP (EN 12900/CECOMAF) W/W

Test conditions EN 12900/CECOMAF ASHRAECondensing temperature 55°C 55°CAmbient and suction gas temp. 32°C 32°CLiquid temperature 55°C 32°CStatic cooling, 220V 50Hz,PTC consumption incl.

42 CK.40.B6.02 August 2001

August 2001 CG.43.M2.02 1

Application LBP

Evaporating temperature range °C -35 to -10

Voltage range V/Hz 198 - 254 /50

Motor type RSIR/CSIR

Max. ambient temperature °C 38

Comp. cooling at ambient temp. 32°C S

38°C S

Compressor NL9F

Code number 105G6802

Code number 105G6804*)

Code number compressor with oil cooler 105G6812

Displacement cm3 8.35

Oil quantity cm3 320

Maximum refrigerant charge g 400

Free gas vol. in compressor cm3 2280

Weight without electrical equipment kg 10.0

Data Sheet (Replaces CG.43.M1.02)

General

Application

Design

Motor size watt 175

LRA (rated after 4 sec. UL984) LST/HST A 6.6/7.9

Cut-in current LST/HST A 10.9/7.9

Resistance, main and start winding (25°C) Ω 10.7/13.0

Approvals EN 60335-2-34 with Annex AA

Motor

NL9FStandard CompressorR134a220-240V 50Hz

70

ø16

254

170

A B

C

E

F

D

166

8249

7854

113127

47°27°51°

119

7260

.525

° 35°15°

93.5

75.5

102.

5

100

204

178205

4040

105G

6802

NL9F

8273

DANFOSS COMPRESSORS

Barcode onwhite background

Yellow background

Blue stripe

Application

Approvals

R134a

S = Static cooling normally sufficientO = Oil coolingF1 = Fan cooling 1.5 m/s

(compressor compartment temperatureequal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

Height mm A 197

B 191

Suction connector location/I.D. mm C 8.2 ±0.09 8.2 ±0.09 6.2 ±0.09

Process connector location/I.D. mm D 6.2 ±0.09 6.2 ±0.09 6.2 ±0.09