51 MLD STP BY C-TECH

-

Upload

venu-m -

Category

Engineering

-

view

121 -

download

10

Transcript of 51 MLD STP BY C-TECH

51 MLD STP BY SBR

(C - Tech) at

Attapur, Hyderabad.

BY

M.VENU N091918

K.REVATI N100525

B.LALITHA N100671

M.NAGA LAKSHMI N100804

1

Contents

Introduction

Objective

Sewage Treatment Plant (STP)

Special Feature

Conclusion

2

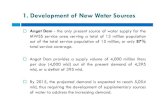

Introduction

Pollution in the Musi River

Current Status

Resolution to the Musi River Pollution

Role of HMWS&SB (Hyderabad Metropolitan Water

Supply & Sewage Board)

3

Objective

Treatment of Wastewater from Defined Places by using

51 MLD STP with C-Tech Basin Technology.

Reducing the BOD, COD, TSS etc.

4

STP Location 5

Courtesy : Google earth

STP 3D View 6

Courtesy : Autocad 3D Drawings

STP Process 7

Inlet chamber: Coarse screened out

raw sewage will be taken by inlet

chamber.

Screening: Particles with the size

will be removed by fine screens.

Courtesy : 51 MLD STP Site

STP Process Cont. 8

Detritor Units : Grit Settling due to

gravity.

Grit Chamber: Grit particles in the

screened water will be settled by

using the classifier mechanism.

Courtesy : 51 MLD STP Site

STP Process Cont. 9

Parshall Flume: Used to calculate

volumetric flow rate.

C-Tech Basins: Raw sewage after

primary treatment is taken by gravity

into the c-tech basins. C-tech basins

present here is six in number.

S.NO FLOW (MLD) NUMBER OF

BASINS

1 1-15 2

2 15-30 4

3 30-100 6

4 100-150 8 Courtesy : 51 MLD STP Site

STP Process Cont. 10

C-Tech Basins: Each basin operates

with sequential phase of filling,

aeration, settling and decating. It

is a cyclic process.

Filling – aeration: During the fill –

aeration sequence mixed liquor

from the aeration zone is recycled

into the selector.

1) Anoxic denitrification of nitrates in the biological selector zone of

c-tech.

2) Bio-degradation of organics including phenol present in the waste water

by extended aeration process.

Courtesy : 51 MLD STP Site

STP Process Cont. 11

3) Oxidation of sulphides in the wastewater.

4) Co-current nitrification and denitrification

of ammonical nitrogen in

the aeration zone.

5) Removal of phosphorous.

Settling: After the aeration phase the

biomass settles under perfect

settling conditions.

Decanting: After settling the supernatant

is removed from the top using

a decanter. Courtesy : 51 MLD STP Site

STP Process Cont.…. 12

Chlorine mixing and contact tank:

Decanted effluent will be carried to

chlorine mixing and contact tank

by RCC Channel.

Treatment Results:

S.NO Parameter Raw Sewage Treated Effluent

Max Min Avg Max Min Avg

1 pH 7.80 6.95 7.33 7.69 7.09 7.28

2 TSS (mg/L) 372 200 256 24 5 12

3 BOD (mg/L) 220 120 144 24 5 13.8

4 COD (mg/L) 372 256 296 44 16 24

5 E.Coliform

(MPN/100 ml)

5.0x10^5 2.1x10^5 2.8x10^5 1000 75 100

Courtesy : 51 MLD STP Site

STP Process Cont. 13

Advantages:

1) PLC based intelligent control in complete Plant.

2) Introducing C-Tech basin technology.

3) Introducing the SCADA (Supervisory Control And Data Acquisition)

4) Economically beneficial.

5) Sludge obtained from STP would be used in agricultural purposes.

Disadvantages:

1) More Power Consumption.

2) Maintenance cost is high.

3) The Parshall flume used here is not giving the accurate outflow.

Case study

Why Parshall flume?

Ans: It is used for the flows that contain suspended solids, as in

wastewater treatment plant.

Flow rate through a parshall flume under free flow conditions is

Q𝑓𝑟𝑒𝑒 = C. Ha

n

14

Case study Cont. 15

From table for throat width

W = 30 cm we get c = 0.6810

n = 1.5225

Q𝑖𝑛𝑓𝑙𝑜𝑤 = 1.3280 𝑚3

𝑠

Q𝑜𝑢𝑡𝑓𝑙𝑜𝑤 = 0.6810 x 1.61.5225

Q𝑜𝑢𝑡𝑓𝑙𝑜𝑤 = 1.3920 𝑚3

𝑠

Courtesy : Open channel flow measurement - Harlon H.Bengston

Case study Cont.

Finally we concluded that for the specified parshall flume

Qinflow ≠ Qoutflow

If we maintain the throat thickness of

parshall flume we can get the accurate

results.

16

Courtesy : Google Images

Special Feature 17

SCADA:

Here the controlling is done by using Automation Control System called

SCADA (Supervisory Control And Data Acquisition).

SCADA was fully PLC (Programmable logic Controller) based intelligent

control resulting in complete plant operation which is a major factor in

reducing operation cost.

All key function like RAS, Sludge wasting, Aeration intensity, Cycle time

control, Decanting rate etc., are automatically controlled as well as

data logged.

The DO Concentration in the basin is continuously monitored using a DO

Sensor.

Special Feature cont. 18

Courtesy : 51 MLD STP Site

Special Feature cont. 19

Courtesy : 51 MLD STP Site

Conclusion 20

As per the data available at site and physical observation a

conclusion that the plant was running smoothly and the required

efficiency of treatment is achieved for safe disposal of sewage into

Musi River as per the norms of river standards.

As we already know that Musi River is highly polluted it is required to

construct so many STP Plants like this to achieve desired conditions.

21