3D Heterogeneous Integration for e-BRAINS · Pict1_532_d1_600_100x_3-15-3...

Transcript of 3D Heterogeneous Integration for e-BRAINS · Pict1_532_d1_600_100x_3-15-3...

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 1 IC Device 1 (Technology 1)

MetallisationSystem 1

IC Device 2 (Technology 2) with TSV

MetallisationSystem 2

IC Device 2 (Technology 2) with TSV

MetallisationSystem 2Metallisation

MEMS/NEMS Device

possibly with TSV

Cap -Chip (Wafer)

MEMS/NEMS Device

possibly with TSV

Cap -Chip (Wafer)

MEMS/NEMS Device

possibly with TSV

Cap -Chip (Wafer)

e-BRAINS

1 Nanolab, École Polytechnique Fédérale de Lausanne Switzerland (*at present in IBM

Research Zurich, Switzerland), 2 Fraunhofer EMFT Germany, 3 Infineon

Technologies AG Germany, 4 Magna Diagnostics GmbH Germany,

5 LITEN/DTNM/LCH France, 6 SIEMENS AG Germany

http://e-brains.org

3D Heterogeneous Integration for

Nanosensor Systems - the EU-Project

e-BRAINS

Montserrat Fernández-Bolaños1*, Peter Ramm2, Reinhard Pufall3, Elizabeth

Buitrago1, Christian Zilch4, Hoël Guerin1, Hélène Le Poche5, Roland Pohle6,

Alexandru Popescu6 and Adrian M. Ionescu1

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 2

• e-BRAINS EU-project

Objectives, consortium and project structure

• Introduction: Evading Moore’s law

From 2D IC to 3D Extended CMOS

• Nanosensors: Novel functionality enabled by 3D

Motivation

NanoSensor for gas detection

o CNT gas sensor

o Smart optical gas sensor

NanoSensors for biofluidic applications

o 3D vertically stacked Si-NWs FET

o Smart biosensor grain

Outline

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 3

Main objective: creation of a new generation of nanosensors and complex

advanced microsystems with

• leverage integration of heterogeneous technologies,

• high-performance devices (increased sensitivity, reduced cost)

• miniaturization,

• smart wireless communication

• and best-reliability (highly reliable and robust)

IC Device 1 (Technology 1)

MetallisationSystem 1

IC Device 2 (Technology 2) with TSV

MetallisationSystem 2

IC Device 2 (Technology 2) with TSV

MetallisationSystem 2Metallisation

MEMS/NEMS Device

possibly with TSV

Cap -Chip (Wafer)

MEMS/NEMS Device

possibly with TSV

Cap -Chip (Wafer)

MEMS/NEMS Device

possibly with TSV

Cap -Chip (Wafer)

e-BRAINS

supported by the European Commission

under support-no. ICT-257488

E-BRAINS European Integrated Project

Best-Reliable Ambient Intelligent Nanosensor Systems

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 4

Consortium

A few numbers…

o 20 partners (9 countries)

9 public research

5 large industry

6 SME’s

o 15.25 million euro

o 3 years (2010-2013)

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 5

Project structure & co-operation

Applications

Smart optical

gas sensor

(SIEMENS)

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 6

The increasing demand for high speed and powerful

electronic devices such as smart-phones, PDA or GPS has

to deal with major design issues:

- RC delay (long signal interconnections)

- Thermal heating

- Power consumption

3D integration is a key technology for

heterogeneous products allowing:

- Improved IC performance at lower cost

- Smart system integration

- Faster signal transmission

- Lower power consumption

Evading Moore’s Law by 3D

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 7

Adapted after: ERD-WG, Japan, December 2007.

3D Extended CMOS

2D SoC

3D heterogeneous

Sytem in Package:

TSV Flip chip

Wire

bonding

Stacked

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 8

Moore’s Law & More

Semiconductor Industry

Association, SEMATECH:

Austin, TX, 2009 (2010 update).

By 2020… it is likely that MEMS fabs will have developed internal

standard process blocks but it will be fab-specific standard tools

(Yole Developpement predicted)

3D heterogeneous

integration with

TSVs and wafer

bonding

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 9

SoC versus SiP

System on Chip (SoC) System in Package (SiP)

Conventional CMOS integration

“More Moore”

Heterogeneous integration

“More than Moore”

Advanced integration based

on the size reduction

Cost reduction

Flexiblility

More functionalities

High integration density

× Technological compatibility

× Complex design of the system,

circuit, package and board

designers

Digital, analog, mixed signal

into a single chip

Planar or stacked

CMOS, RFICs, MEMS, Optics, Energy

in a single package

Wire bonding and flip chip

3D IC stacked with TSVs

System on System (SoS)

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 10

Each die can be designed and fabricated with dedicated and

optimized technology to efficiently:

o Enhance the performance

o Optimize individual functions

o Reduce power consumption

System on System (SoS)

S.-J. Lee, IEEE

SOC Conf 2009

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 11

Biosensors

The application area of biosensors has experience

substantial growth with the global biosensor market

estimated to exceed $14.42 billion by 2016

1. Determination of ultra-low concentrations of specific DNA

sequences can lead to a early detection of

Infectious

Inherited diseases

Genetic disorder

Cancer

2.- Point-of-care instrumentation:

Miniaturized

Reliable

Rapid quantification

Wide range of testing parameters

Enhanced sensitivity of 3D

vertically stacked SiNWs FET

In-situ fast analysis wireless

Smart biosensor grain

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 12

(+) High utilization of bulk silicon substrate.

(+) High output currents Id with number of

channels N in two directions (y, z).

(+) High chances for biomolecule interactions

for sensing:

• Suspended structures entire SiNW

surface area available for sensing.

• High number of sensing channels in 3D.

Ultimate SiNW-based biosensor

3D structures for sensing – The vertically stacked SiNW FET sensor

y

z

x

MOSFET ISFET

Gated through the liquid Metal gate

3D Si-nanostructure for sensing

From planar

ISFET

(+) High Sensitivity:

S/V and cross section

(+) High Selectivity: Si functionalization DNA

molecules, proteins, viruses

(+) Direct monitoring of

biological activities: Low

cost, home care, label free

detection, fast response

• 7x20-array

• Functionalized

for streptavidin

sensing

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 13

o Gate all around (GAA) configuration

o Symmetric/asymmetric gating VBG, VSG

o Excellent SS ~ 75 mV/dec, Vth shifts with VBG

o High gate coupling α’= SS60mV/dec/SSmeasured = 0.8

Electrical Characterization

Ultra thin released NWs, liquid-gated experiments: IPA droplet + glass slide

o SS ~ 100 mV/dec

excellent electrostatic

control through liquid by Vd

o High Ion highly dense

array of NWs

o Low Ioff low doped SOI

substrate.

o Gate all around (GAA) configuration

o Symmetric/asymmetric gating VBG, VSG

o Excellent SS ~ 75 mV/dec, Vth shifts with VBG

o High gate coupling α’= SS60mV/dec/SSmeasured = 0.8

o S = (IdΨ1 - IdΨ0)/ IdΨ0, relative variation of current due to

difference of applied external potential, ΔΨ0: 100 mV

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 14

Electrical Characterization

Ultra thin released NWs, liquid-gated experiments: IPA droplet + glass slide

o HfO2 (εr = 15.6) atomic layer

deposition (ALD) around the NWs

o Prevent charge penetration through

oxide to the SiNWs.

o Reduce Ileaky through the liquid

o Vth shift to high VSG values

o Ion increases with number of NWs

o gm=dId/dVSG sensitivity to surface QS

o High gm larger Id for a given QS

thus, higher S when measuring as Vth.

(+) high gain inverter-based sensing

schemes, where dVout/dVin ~ gm_sensor x Rload.

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 15

7x20 SiNWs, biotin terminated devices: VSG = 1.6 V, Vd = 50 mV, VBG = 0 V, oxide surface

o PDMS microfluidic channel.

o Operated in subthreshold region.

o Current drops several orders of

magnitude after streptavidin shot.

o Successful surface modification,

current drops again after PBS

(phosphate buffer saline) wash.

PBS+

streptavidin

PBS

wash

2mg/ml

Proof of Concept – Streptaviding Sensing

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 16

Smart Biosensor Grain

Motivation:

(+) complex biological samples can be

analyzed rapidly on-site

(+) Allows measurements of multiple

biological parameters in parallel

(+) 3D heterogeneous integrated on a

monolithic sensor grain including

CMOS-TMR sensor + RF chip/antenna

(+) Wireless data and energy transfer

between chip and device

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 17

Smart Biosensor Grain

Biochip equipped with arrays of magnetic resistive (TMR) sensors

Biosensor-unit

Working principle:

Fully 3D integration:

Microfluidic card

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 18

Smart Biosensor Grain

Biochip equipped with arrays of magnetic resistive (TMR) sensors

Results:

o First demonstrator completed on a PCB

o TMR-elements processed

o RFID / antenna chip completed and tested

o Immobilization of biomoleculas on chip

surfaces

Application: Sepsis Diagnostics (Bacteria/Fungi)

Next: further integration TSVs / SLID Bonds

(+) miniaturization

(+) speed (+) simplicity

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 19

- Mass sensing (NEM resonator)

Nanotube gas sensors: Motivation

Y. T. Yang, Nano Lett 2006

F. Patolsky, Materials Today 2005

- Conductance sensing

(Si nanowire) - Current and Vt modulation

(SWCNT FET)

o Molecular detection:

o Gas detection: C. Hierold, ETH Zurich

- Capacitive & conductance

sensing

(capacitive

CNT arrays)

I. Heller, Nano Lett 2008

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 20

Gas sensors

Gas sensor can find applications in the field of industrial gas

monitor, environmental, building automation, health care and

safety.

1. Detection of toxic gases even in very low concentrations

such as

CH4, CO, CO2

NO2,

SOX,

NH3, …

2.- Privacy compliant area monitoring via CO2 detection

Small form factor

High selectivity

Integrated with IC

Cost effective

High sensitivity

CNT gas sensor

Wireless data & power supply

smart optical gas sensor

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 21

o Carbon nanotube (CNT) remarkable properties

– Building block for electronic devices

o Integration issues to implement CNT as a alternate material

for commercial, robust devices

o High throughput, in-situ integration of horizontal, dense CNT

arrays at the wafer scale

o Integration of horizontal CNTs into gas sensors via:

(+) All fabrication processes compatible with full wafer processing.

http://blog.pharmaphysic.fr

CNT-based gas sensor

Catalytic chemical

vapor deposition

process

Selective growth

Directional growth

Catalyst support

Designed for

nucleation on

vertical sidewalls

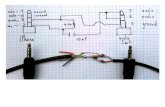

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 22

catalyst support

• Sputtered stack of TiN, Al2O3, TiN and SiO2

– Nitride-oxide-nitride alternation > selective growth

– Top SiO2 > hard mask

• Dry etching of top TiN & Al2O3

– Catalyst support lines

– Vertical profile > horizontal CNTs

• Electrode shaping

• Fe catalyst local deposition

– Tilt angle 45° > on the sidewall

Fabrication Process

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 23

CNT growth process and device integration

• Thermal CVD process (feedstock gas:

acetylene, hydrogen and helium, T°: 580°C,

pressure: 0.4 mbar)

– Dense MWCNT arrays: mean diam. 4-5nm,

3-4 walls.

• Selective: growth activated on Al2O3/Fe

surfaces

• Directional: CNT nucleate orthogonal to

catalyst surface

• IPA flattening and top contact mettalization

Fabrication Process

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 24

Resistive Gas Sensors

o Electrical properties

– Ohmic behavior

– 84µm wide CNT array

resistance = 7 Ω.µm-1

– Contact resistance~18 Ω

– CNT resistivity = 17.9 e-5 Ω.m

1 000

2 000

3 000

4 000

5 000

6 000

7 000

8 000

9 000

10 000

11 000

Inte

nsi

ty

200 400 600 800 1 000 1 200 1 400 1 600 1 800 2 000 2 200 2 400 2 600 2 800 3 000

(a.u.)

Pict1_532_d1_600_100x_3-15-3

Pict2_532_d1_600_100x_3-15-3

Pict3_532_d1_600_100x_3-15-3

Pict4_532_d1_600_100x_3-15-3

Pict1_532_d1_600_100x_3-15-3

Evaluation Copy

G D

Si

Si

CNT device characterization

o Raman spectra

– Flat RBM no SWCNTs

– No G-band split MWCNTs

– High D-Band contamination

a-carbon

TEM

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 25

o Detection limit < 5 ppm

– TLV 25 ppm

– Adsorption/desorption (fitted by

double exponential model)

o Reliability device to device

o Long response time > 15 minutes

Proof of Concept – Gas Sensing

o Resistance shift to

– NO2, NH3, H2

– Relative humidity

– Ethanol, Toluene

o Robust CNT arrays

– Tested over 7 months

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 26

Motivation:

(+) Tunable diode laser spectroscopy (TDLS)

combine the small form factor of vertical NWs

with the high selectivity of optical gas detection

(+) Photonic band gap crystals (PhCs) used for

absorption path reduction (strong dependence

in the detection limit and accuracy)

(+) Integration of the entire hardware including temperature and current drivers,

the signal acquisition/evaluation and the communication module

Smart Gas Sensor

Based on photonic light concentrator & integrated electronics hardware

ongoing future (1cm)

Cost reduction

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 27

Working principle: light concentrator.

Fabrication: poly-Si rods (aspect ratio 1:25 2D PhC)

Periodic holes in the m range are defined in Si:

1. photolithography and etch

2. filled with adapted IR-transparent material by

vacuum filling

3. Silicon template is then removed to allow the

generation of a periodic pattern of needles.

Smart Gas Sensor

Based on photonic light concentrator & integrated electronics hardware

Reduced group velocity Enhance

interaction

Increase the

effective path

Detection limit

Accuracy

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 28

Results:

o Power plug-in demonstrator including gas

sensor, microprocessor, wireless and power

supply module

o Gas detection: 50 ppm within 1mm path

length. CO2 strong absorption line at 2.7 m

Applications: Air quality (CO2), industrial gas

monitor (NH3, CO, CO2, HF…)

Smart Gas Sensor

Based on photonic light concentrator & integrated electronics hardware

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 29

• The future of Nanoelectronics could be foreseen as a combination of

More Moore and More than Moore with the heterogeneous integration of

a large variety of technologies, and their exploitation in System-On-Chip

or System-In-Package, combining various discrete subsystems using

different optimized process technologies.

Biosensors:

• 3D vertically stacked SiNWs: TSV-compatible, robust, highly sensitivity and

dense (7x20 array) sensing validated (biotin-streptaviding) in a liquid GAA FET.

• The 1st generation of smart biosensor grain fully integrates the CMOS-TMR

sensor and the RFID chip + antenna mounted on a PCB

Gas sensor:

• CNT-based nanosensors: Wafer-scale, in-situ with high yield, dense has been

characterized as resistive gas sensor showing promising sensing capabilities

• Integration technology has help to combine small form factor with the high

selectivity of optical gas detection by absorption path reduction

Conclusions

© Montserrat F.-Bolaños, Fukuoka - 27th Sept. 2013 30 IC Device 1 (Technology 1)

MetallisationSystem 1

IC Device 2 (Technology 2) with TSV

MetallisationSystem 2

IC Device 2 (Technology 2) with TSV

MetallisationSystem 2Metallisation

MEMS/NEMS Device

possibly with TSV

Cap -Chip (Wafer)

MEMS/NEMS Device

possibly with TSV

Cap -Chip (Wafer)

MEMS/NEMS Device

possibly with TSV

Cap -Chip (Wafer)

e-BRAINS

o FP7 Integrated project e-BRAINS and

NEMIAC European Projects

Acknowledgments

Thank you for your attention!

Questions?