3d consolidation test

-

Upload

pankaj-dhangare -

Category

Engineering

-

view

473 -

download

1

Transcript of 3d consolidation test

05/01/2023

1

PRESENTATION ON

3-Dimensional Consolidation Test on Soft Marine Clay under Vacuum Preloading With PVD

By

Pankaj Dhangare

Roll No. 142040013

S.Y. M.-Tech Structures,

VJTI, Mumbai

Under the guidance of Prof. Dr. V. B. Deshmukh

05/01/2023

2

INTRODUCTION

Infrastructure development Basic need Costal roads Airports, Bus Terminals, Housing Projects, Landfills

Major Problems with the construction Existence of soft marine clay along the coastal region Low SBC, Low permeability, High Magnitude of Settlement Time Environment

05/01/2023

3

DEVELOPMENT OF VERTICAL DRAIN THEORY

Barron (1948) presented the first exhaustive solution - based on simplifying assumptions of one-dimensional consolidation theory for radial consolidation,

Where “n” is ratio of diameter of equivalent soil cylinder to equivalent diameter of drain (Spacing ratio)

rU

rrUC

tU

h1

2

2

(4.1)

)(8exp1nFTU h

h

2

2 143

)()1(

)(n

nnn

nnF (4.4)

…….Differential Equation

…….Solution of Above Differential equation

05/01/2023

4Modification by Hansbo 1979

For , Smear

For , well resistance factor

F = F(n) + Fs + Fr

43ln)(

w

e

dDnF For , n >20

w

s

s

hs d

dkk

F ln1

w

hr q

kzLzF )(

hrs

h

e

UFFnF

CD

t1

1ln))((

8

2

05/01/2023

5

VACUUM PRELOADING SYSTEMS

Vacuum-assisted preloading system: a) membrane system

(b) membrane-less system (Cap Drain) (Indraratna et al. 2005c)

05/01/2023

6

Comparison: Fill Preload and Vacuum PreloadConventional Preload Vacuum Preload

Soft Clay

VerticalDrain

Surcharge

Sand Blanket Berm

Soft Clay

VerticalDrain

Surcharge

Berm

• Need Counterweight Berm & Wider ROW

• Higher Surcharge• Need Sand Blanket/Sub-drain• Lower Stability• Greater Lateral Movement• Longer Construction Time

• No Counterweight Berm & Smaller ROW

• Lower Surcharge• No Need Clean Sand• Better Control of Stability• Lesser Lateral Movement• Shorter Construction Time

05/01/2023

7

REVIEW OF LITERATURE

1. Settlements due to vacuum preloadingMohamedelhassan and Shang (2002)

Combined application of vacuum and fill loads resulted in an increase in rate and magnitude of settlement. Under similar loading conditions, both vacuum and equivalent fill preload generate a similar settlement responsePrincipal of superposition valid and justifies use of available consolidation theories for designing the preloading projects involving vacuum as a preload

05/01/2023

8

Chai et al. (2005)Settlement induced by vacuum preload will be the same as that produced by fill preload. If inward lateral movements take place, then the magnitude of settlement with vacuum preloading will be less than that of an equivalent fill preload.

Laboratory measurement of settlements due to vacuum and fill loads for specimens with different preconsolidation pressures

05/01/2023

9

2. Increases in Shear Strength due to Vacuum Preloading

Mesri and Khan (2012)All empirical concepts concerning undrained shear strength of soft clay and silt deposits developed based on fill loading equally applicable to vacuum loading. The increases in undrained shear strength of soft clay and silt deposits resulting from consolidation under a vacuum load and equivalent fill load, for all practical purposes, are identical.

3. Vacuum Preloading Techniques- Experimental Contribution

Indraratna (2004) and Rujiakiatkamjorn (2007) Intensity of vacuum linearly decreases with depth.

Schematic Diagram of large scale oedometer(Rujiakiatkamjorn)

05/01/2023

10Saowapakpiboon and Bergado (2010)

Schematic of large scale consolidometer. (Saowapakpiboon and Bergado, 2010)

The settlement of the specimen with the vacuum-PVD was considerably faster in consolidation rate than the specimen with only PVD. But the final settlement of both specimens was same.

05/01/2023

11

4. Porewater pressure generation and dissipationMohamedelhassan and Shang (2002)

Excess porewater pressure in a soil mass, subjected to a vacuum or a combined vacuum-fill preload, can also be evaluated using the principal of superposition.

05/01/2023

12

CRITICAL COMMENTS

Mohammedalhassan and Shang (2002) suggested that, Magnitude of settlement and its rate under one-dimensional condition surcharge and vacuum of the same magnitude produce almost identical settlements whereas Chai et al. (2005a) found that even under one- dimensional condition, the higher the initial vertical effective stress is, the smaller the settlement will be in the case of vacuum 3 D consolidation

No one tested the undisturbed sample till nowMost of the work has been done in the abroad

05/01/2023

13

OBJECTIVES

To evaluate engineering properties of reconstituted sample of soft marine clay.

To test reconstituted sample to evaluate 3-Dimensional consolidation parameters and draw isochrones accurately by measuring pore pressure with pressure cell.

To check predominated laboratory undrained shear strength along with vacuum preloading using PVD.

To evaluate compressibility parameters under 3-D flow due to vacuum consolidation with prefabricated vertical drains (PVD).

05/01/2023

14

Actual Experimental Setup

05/01/2023

15

Experimental Setup Elevation

1. Dial gauge 2. Hollow pipe 3. Vacuum Chamber 4. Piston plate 5. PVC Pipe 8 mm Dia. 6. Vacuum gauge 7. (PVD 45 mmX3 mm) 8. Air Water Separator Tank (Vacuum Chamber) 9. Vacuum chamber 10. Motor 11. Base 12. 2 mm Thick Geotextile 13. Standard Sand 25 mm Thick 14. Bottom Plate 15. 10 mm Bolt 16. Soil 17. Piezometer Points 18. Hook 19. 5mm Bolt 20. Hydraulic Chamber 21. 10mm Bolt 22. Pressure gauge 23. Air Water Pressure Chamber 24. Air Controller valve 25. Pressure gauge 26. Engine 27. Motor 28. Pressure gauge 29. Air tank 30. Stand

05/01/2023

16

Experimental Work

Reconstitute sample1. Sample preparation2. Test3. Observation1. Settlement, PWP at regular interval4. Results are plotted as1. Time vs settlement2. Time vs effective PWP3. Discharge capacity4. Increase in undrained shear

strength

Undisturbed sample1. Sample preparation2. Test3. Observation1. Settlement, PWP at regular

interval4. Results are plotted as1. Time vs settlement2. Time vs effective PWP3. Discharge capacity4. Increase in undrained shear

strength

05/01/2023

17

Source of Soft Marine Clay

Road over Bridge at crossing LC No. 06 Km 91/1-2” Sonari village, Uran area of Navi Mumbai.

05/01/2023

18

Physical and Engineering Properties Soft Marine Clay

Property UNIT VALUENatural moisture Content

(%) 71.08

Liquid Limit (%) 75.18Plastic Limit (%) 32.64Specific gravity 2.57Silt content (%) 35Clay content (%) (%) 65Plasticity Index 40Bulk Density gm/cc 1.57Compression Index, cc 0.71

Classification CI

Property Load UNIT VALUE

Coefficient of Vertical Consolidation, (Cv ) at

0 – 0.2 (kg/sq.cm) (m²/year) 1.34

0.2 – 0.5(kg/sq.cm) (m²/year) 1.81

0.5 – 1.0(kg/sq.cm) (m²/year) 1.14

1.0 – 2.0(kg/sq.cm) (m²/year) 1.58

2.0 – 4.0(kg/sq.cm) (m²/year) 1.42

Undrained Cohesion, c kg/cm2 0.02Undrained Angle of Internal Friction, ø Degree 2

05/01/2023

19

Reconstitute Sample

1. Sampling Process2. Test

i) Surcharge 0.6 kg/sq.cm and Vacuum 1.0 kg/sq.cm(Test 1)

ii) Surcharge 1.0 kg/sq.cm and Vacuum 1.0 kg/sq.cm(Test 2)

05/01/2023

20

Test Procedure

Slurry preparation

Pouring of Slurry into cell

PVD of required size (45 X3) mm

PVD Installation in sample

05/01/2023

21

Test Procedure

Filter geotextile is placed

Placing of Piston Plate

Cut PVD of required size

Placing Of Vacuum lid

Top plate is placed

05/01/2023

22

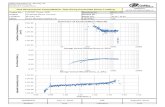

Results

0 5000 10000 15000 20000 250000.00

20.00

40.00

60.00

80.00

100.00

120.00

140.00

160.00

∆P = 0.60 kg/cm² and σvc = 1.00 kg/cm²∆P = 1.00 kg/cm² and σvc = 1.00 kg/cm²

Time in mins

Settl

emen

t in

mm

0 20 40 60 80 100 120 140 1600.00

20.0040.0060.0080.00

100.00120.00140.00160.00

∆P = 0.60 kg/cm² and σvc = 1.00 kg/cm²

∆P = 1.00 kg/cm² and σvc = 1.00 kg/cm²

Square Root of Time in mins

Settl

emen

t in

mm

Increasing surcharge load from 60kPa to 100kPa and constant vacuum of 100 kPa the rate of settlement is increased drastically and magnitude also increase reasonably

Time Settlement profile Time settlement profile plotted as settlement vs square root of time

1. Settlement variation with Time result

05/01/2023

232. Discharge Capacity with Time result

0 2 4 6 8 10 12 14 160

0.01

0.02

0.03

0.04∆P = 0.60 kg/cm² and σvc = 1.00 kg/cm²∆P = 1.00 kg/cm² and σvc = 1.00 kg/cm²

Time in days

Wat

er d

isch

arge

in

cm3/

sec

Discharged capacity with Time

•Similar nature as that of Time settlement curve.•Maximum discharge at early stage•Discharge increases with increase in effective pressure

05/01/2023

24

3. Pore Water Pressure result

0 5000 10000 15000 20000 25000

-150

-50

50

Time (Mins)

Exce

ss P

ore

Wat

er P

ress

ure

( kP

a)

0 5000 10000 15000 20000

-100

-50

0

50

100

Time (Mins)

Exce

ss P

ore

Wat

er P

res-

sure

( k

Pa)

0 5000 10000 15000 20000 250000.00

40.00

80.00

120.00

160.00 Time (Mins)

Sett

lem

ent

(mm

)

0 5000 10000 15000 20000 250000.00

30.00

60.00

90.00

120.00

150.00 Time (Mins)Se

ttle

men

t (m

m)

Surcharge of 0.6 kg/cm2 and vacuum of 1.0 kg/ cm2 Surcharge of 1.0 kg/cm2 and vacuum of 1.0 kg/ cm2

05/01/2023

25Geotechnical and Physical properties of improved clay samples

1. Vane Shear test result

0 1 2 3 4 50.000

0.040

0.080

0.120

0.160 Top samples tested after consolidationMiddle samples tested after consolidationBottom sam-ples tested after consoli-dation

Sample numbers

Shea

r St

reng

th

(kg/

cm2)

0 1 2 3 4 50.020

0.060

0.100

0.140

0.180 Top samples tested after consolidationMiddle samples tested after consolidationBottom sam-ples tested after consoli-dation

Sample numbers

Shea

r St

reng

th

(kg/

cm2)

Surcharge of 0.6 kg/cm2 and vacuum of 1.0 kg/ cm2 Surcharge of 1.0 kg/cm2 and vacuum of 1.0 kg/ cm2

05/01/2023

26

% Increase in undrained shear strength

Location Percentage Increase in undrained Shear strength (%)

LoadingsTest 1-∆P = 0.60 kg/cm²

and σvc = 1.00 kg/cm²

Test 2-∆P = 0.80 kg/cm²

and σvc = 1.00 kg/cm²

Top 255.13 334.615

Middle 160.26 280.769

Bottom 66.67 241.025

05/01/2023

27

Geotechnical and Physical properties of improved clay samples

2. Triaxial test result %increase cu %increase Φ

Test 1-∆P = 0.60 kg/cm²

and σvc = 1.00 kg/cm²

Test 2-∆P = 1.0kg/cm² and

σvc = 1.00 kg/cm²

Test 1-∆P = 0.60 kg/cm²

and σvc = 1.00 kg/cm²

Test 2-∆P = 1.0kg/cm² and

σvc = 1.00 kg/cm²

TOP 400 500 59 256.25

MIDDLE 337.5 337.5 256.25 185.5

BOTTOM 25 337.5 43 217

•The strength of top samples is relatively more as compared to the middle and bottom samples.

05/01/2023

28

3. Moisture Content

Geotechnical and Physical properties of improved clay samples

0 2 445.000

60.000

75.000

90.000

105.000 Water content of top samples after consoli-dationWater content of middle samples after consoli-dation

Sample numbers

% W

ater

con

tent

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 545.00060.00075.00090.000

105.000120.000 Water content of top

samples after consoli-dation

Water content of middle samples after consoli-dationSample numbers

% W

ater

con

tent

Test 1-∆P = 0.60 kg/cm² and σvc = 1.00

kg/cm²

Test 2-∆P = 1.00 kg/cm² and σvc =

1.00 kg/cm²

05/01/2023

29

Undisturbed Sample

1. Sampling Process2. Test

i) Surcharge 0.6 kg/sq.cm and Vacuum 1.0 kg/sq.cm(Test 3)

05/01/2023

30

Details of sampler

Total Height of Sampler = 1100mm

Self Weight = 24.6kg Inside clearance = 1.56% Outside clearance = 1.23% Area ratio = 6.34%

05/01/2023

31

1. Extraction of sample

Sampler is tied with ribbon

Sampler tied to Chain pulley

Inserting sampler into cell

Removing sampler from cell

05/01/2023

32

Results1. Settlement variation with Time result

0 5000 10000 150000.00

40.00

80.00

120.00

160.00 Time (min)

Sett

lem

ent

(mm

)

0 20 40 60 80 100 1200.00

40.00

80.00

120.00

160.00 Square root of Time (min)

Sett

lem

ent

(mm

)

Test 3-∆P = 0.60 kg/cm² and σvc = 1.00 kg/cm²

Time Settlement profile Time settlement profile plotted as settlement vs square root of time

•Similar to reconstitute sample

05/01/2023

332. Discharge Capacity with Time result

Discharged capacity with Time

• Similar nature as that of Time settlement curve.• Similar with Reconstitute sample result

0 2 4 6 8 10 120

0.91.82.73.64.55.46.37.28.1

99.9

Time in days

Wat

er d

isch

arge

in

cm3/

sec

05/01/2023

34

3. Pore Water Pressure result

Surcharge of 0.6 kg/cm2 and vacuum of 1.0 kg/ cm2

0 5000 10000 15000-40-20

020406080

100

Time (min)

Exce

ss P

ore

Wat

er P

res-

sure

( k

Pa)

0 5000 10000 150000.00

20.0040.0060.0080.00

100.00120.00140.00 Time (min)Se

ttle

men

t (m

m) Mohamedelhassan and Shang (2002)

05/01/2023

35Geotechnical and Physical properties of improved clay samples

1. Vane Shear test result

Surcharge of 0.6 kg/cm2 and vacuum of 1.0 kg/ cm2

0 1 2 3 4 50.030

0.050

0.070

0.090 Top samples tested after consolidation

Middle samples tested after consol-idation

Sample numbers

Shea

r St

reng

th

(kg/

cm2)

LocationPercentage Increase in undrained Shear strength (%)

Test 3- ∆P = 0.60 kg/cm² and σvc = 1.00 kg/cm² (undisturbed)

Top 334.615

Middle 280.769

Bottom 241.025

05/01/2023

36

Geotechnical and Physical properties of improved clay samples

2. Triaxial test result

%increase in cu %increase Φu

Test 3-∆P = 0.60 kg/cm² and σvc = 1.00 kg/cm²

TOP 900 217

MIDDLE 650 160BOTTOM 650 50.5

•The strength of top samples is relatively more as compared to the middle and bottom samples.

05/01/2023

37

3. Moisture Content

Geotechnical and Physical properties of improved clay samples

Test 3-∆P = 0.60 kg/cm² and σvc = 1.00 kg/cm²

0 2 4 650.000

65.000

80.000

95.000 Water content of top samples after consol-idation

Water content of middle samples after consolidation

Sample numbers

% W

ater

con

tent •Moisture content of

Undisturbed sample was reduced in the range of 30 to 35% .

05/01/2023

38

Conclusion

Increase in surcharge load increases the rate of consolidation.Gain in shear strength and reduction in moisture content are

significant especially when specimen consolidated under higher vacuum pressure.

Pore pressure variation with time is in good agreement with settlement profile but having slower rate.

Results obtained for reconstituted sample and undisturbed sample are similar so, there is no need of testing undisturbed sample. Results of reconstituted samples can be used for determine consolidation parameters.

05/01/2023

39

References Barron, R.A. (1948), Consolidation of fine-grained soils by drain wells, Trans. ASCE No. 2346, pp. 718-

754. Mohamedelhassan, E. and Shang, J.Q. (2002). “Vacuum and surcharge combined one dimensional

consolidation of clay soils”. Can. Geotechnique, J 39, 1126 -1138 Saowapakpiboon, J., Bergado, D.T., Chai, J.C., Kovittayanon, N. and Zwart, T.P. (2010). “Vacuum –PVD

combination with embankment loading consolidation in soft Bangkok clay: A case study of the Suvarnabhumi airport project”. Proc.Of the 4thAsian Regional Conference on Geosynthetics, Shanghai – China. 440 – 449

Kjellman.(1952). “Consolidation of clay soil by means of Atmospheric pressure”. Proc., Conference on soil stabilization, MIT, 258 – 263

Bergado, D.T., Miura, N., Singh, N., and Panichayatum, B. (1988), Improvement of soft Bangkok clay using vertical band drains based on full-scale test, Proc. Int. Conf. Eng'g. Problems of Reg. Soils, Beijing, China, pp. 379-384.

Leong, E.C., Soemitro, R.A.A. and Rahardjo, H. (2000).“Soil improvement by surcharge and vacuum preloading”. Geotechnique 50, No. 5, 601 – 605

Bergado, D.T., Alfaro, M.C., and Balasubramaniam, A.S. (1993a), Improvement of soft Bangkok clay using vertical drains, Geotextiles and Geomembranes J., Vol. 12, No. 7, pp. 615-664.

Hansbo, S. (1979), Consolidation of fine-grained soils by prefabricated drains, Proc. 10th Intl. Conf. Soil Mech. and Found. Eng'g., Stockholm, Vol. 3, pp. 12-22.

Mesri, G. (1973), Coefficient of secondary compression, J. Soil Mech. and Found. Div., ASCE, Vol. 99, No. SMI, pp. 123-147.

05/01/2023

40

References Bergado, D.T., Balasubramaniam, A.S., Fannin, R.J. and Holtz, R.D. (2002). “PVD in soft

Bangkok clay; A case study of New Bangkok International Airport Project”. Can. Geotechnique, J 39, 304 – 315

Rujikiatkamjorn.C. and Indraratna, B. (2005). “Soft ground improvement by vacuum assisted preloading”. University of Wollongong

Chai, J.C., Carter, J.P. and Hayashi, S. (2005). “Ground deformation induced by vacuum consolidation” Journal of Geotechnical and Geoenvironmental Engineering, ASCE. 1552 – 1561

Shang J.Q., Tang, M. and Miao, Z. (1998). “Vacuum preloading consolidation of reclaimed land: a case study”. Can. Geotechnique, J 35, 740 – 749

Yan, S.W. and Chu, J. (2005).“Soil improvement for a storage yard using the combined vacuum and fill preloading method”. Canadian Geotechnique, J 42, 1094 – 1104

Rujikiatkamjorn.C. and Indraratna, B. (2007).“Analysis of Radial Vacuum-Assisted Consolidation Using 3D Finite Element Method”. University of Wollongong

Chu, J., Yan, S.W. and Yang, H (2000).“Soil improvement by the vacuum preloading method for an oil storage station”. Geotechnique 50, No. 6, 625 - 632

Terzaghi, K. (1943), Theoretical soil mechanics, John Wiley and Sons, New York. Advanced Foundation Engineering by B. M. Das IS 1892-1979 Code of practice for subsurface investigation for foundation.

05/01/2023

41

Thank You