357557 Tiller Handle Kit Non Touch Troll 40-60 HP · PDF filethe Engine Management Module...

Transcript of 357557 Tiller Handle Kit Non Touch Troll 40-60 HP · PDF filethe Engine Management Module...

Outboard Engines

TILLER HANDLE KITS - P/N’s 5009249 & 5009251INSTALLATION INSTRUCTIONS

SAFETY INFORMATIONThe following symbols and/or signal words maybe used in this document:

These safety alert signal words mean:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

For safety reasons, this kit must be installed byan authorized Evinrude® dealer. This instructionsheet is not a substitute for work experience. Ad-ditional helpful information may be found in otherservice literature.

DO NOT perform any work until you have readand understood these instructions completely.

Torque wrench tightening specifications muststrictly be adhered to.

Should removal of any locking fastener (locktabs, locknuts, or patch screws) be required, al-ways replace with a new one.

When replacement parts are required, use Evin-rude/Johnson® Genuine Parts or parts withequivalent characteristics, including type,strength and material. Use of substandard partscould result in injury or product malfunction.

Always wear EYE PROTECTION AND APPRO-PRIATE GLOVES when using power tools.

Unless otherwise specified, engine must be OFF(not running) when performing this work.

Always be aware of parts that can move, such asflywheels, propellers, etc.

Some components may be HOT. Always wait forengine to cool down before performing work.

If you use procedures or service tools that arenot recommended in this instruction sheet, YOUALONE must decide if your actions might injurepeople or damage the outboard.

This instruction sheet may be translated into oth-er languages. In the event of any discrepancy,the English version shall prevail.

TO THE INSTALLER: Give this sheet and theoperating instructions to the owner. Advise theowner of any special operation or maintenanceinformation contained in the instructions.

TO THE OWNER: Save these instructions inyour owner’s kit. This sheet contains informationimportant for the use and maintenance of yourengine.

� DANGERIndicates a hazardous situation which, if notavoided, will result in death or seriousinjury.

� WARNINGIndicates a hazardous situation which, if notavoided, could result in death or seriousinjury

� CAUTIONIndicates a hazardous situation which, if notavoided, could result in minor or moderatepersonal injury.

NOTICEIndicates an instruction which, if not fol-lowed, could severely damage engine com-ponents or other property.

1 of 14

*357557*Printed in the United States.© 2014 BRP US Inc. All rights reserved.TM, ® and the BRP logo are registered trademarks of Bombardier Recreational Products Inc. or its affiliates.

2 o

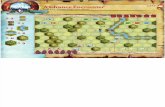

APPLICATIONUse this instruction sheet when installing the tiller handle kits on Evinrude E-TEC 40 – 60 HP AFAor prior model outboards. Do NOT install on any other models.

� WARNINGDo not install this kit unless you have the ability to communicate with the engine using Evin-rude E-TEC® Diagnostics Software. Complete installation of this kit requires reprogrammingthe Engine Management Module (EMM) to provide start-in-gear protection.

1

2

5

17

18

6

7

8

8910

11

12

13 14

41

15

16

19

20,21

22

26

26

3

232930

282930

3132

35

36,37

38

3940

42

4344

4546

47

48

4950 51

25

4

52

5354

55

56

57

58

59

60 61

62

79

81

80

6364,65,66To Remote SystemCheck Harness

64,65,66To Engine Key

Switch Connector

64,65,69Sealing Cap

67,68,69Sealing Plug

67,68,70To Remote Key Switch

67,68,70To Engine SystemCheck

Connector

71,72,70Stop Switch

71,72,70Start Switch

73,74,70Trim Switch

75,76,66To RemoteTrim Gauge

73,74,69Sealing Plug

73,74,70To Engine Trim

Connector

77,78Tiller Key Switch

Switched 12 VFor CANbus

40a

357557-01

f 14

Ref P/N Name of Part Qty Ref P/N Name of Part Qty– 5009249 TILLER HANDLE KIT - Blue 1 42 333774 RETAINER CLIP 1– 5009251 TILLER HANDLE KIT - White 1 43 328702 WASHER 11 N/A STEERING HANDLE 1 44 5006159 CABLE, Throttle 12 329878 STEERING HANDLE, Inner 1 45 334083 ANCHOR, Throttle cable 13 332089 *RETAINER CLIP 1 46 328739 WASHER, Anchor to bracket 14 N/A BRACKET, Steering handle 1 47 329160 SCREW, Anchor to bracket 15 352673 HANDLE, Shift 1 48 334153 CONNECTOR, Throttle cable 16 329885 SCREW, Shift handle mount 1 49 350989 SCREW, Steering handle to bracket 17 313607 LUBE FITTING 1 50 328733 WASHER, Spring 18 327400 WASHER, Shift handle 2 51 307160 LOCKNUT, Steering handle screw 19 334815 BUSHING, Shift handle 1 52 313607 LUBE FITTING 110 318626 BALL 1 53 352295 THUMBSCREW, Height adjustment 111 327178 GUIDE 1 54 203470 RETAINER CLIP 112 309247 SPRING 1 55 325729 SCREW, Bracket to steering arm 213 351932 PIN, Shift handle to cable 1 56 320397 WASHER 214 303049 COTTER PIN 1 57 325452 BUSHING, Steering handle to brkt. 215 351995 RETAINER, Shift cable 1 58 352625 PLATE, Angle adjustment 116 336481 SCREW. Retainer 2 59 315077 NUT, Steering bracket 217 352293 COVER, Steering Handle 1 60 5005800 SWITCH, Ignition & key assy 118 336481 SCREW. Cover 7 61 127251 SPACER 119 333499 CLIP, Emergency stop 1 62 127237 NUT, Keyswitch 120 586936 STOP SWITCH Assy 1 63 587290 HARNESS, Tiller handle 121 514679 *PIN, Terminal 6 64 514688 *CONNECTOR, 6 pin receptacle 3NS 514696 CONNECTOR, 2 pin receptacle 1 65 514684 *LOCKWEDGE 3NS 514697 LOCKWEDGE, 2 pin receptacle 1 66 514679 *PIN, Terminal 1522 336481 SCREW. Stop switch 3 67 514687 *CONNECTOR, 6 Socket plug 323 398602 CLIP & LANYARD Assy 1 68 514683 *LOCKWEDGE 324 336481 SCREW. Inner handle retaining 1 69 514690 *SEAL PLUG 1525 121497 WASHER 1 70 514680 *SOCKET, Terminal 2226 174741 THROTTLE FRICTION CONTROL 1 71 176295 *CONNECTOR, 2 Socket plug 227 339722 HELIX, Twist Grip 2 72 127287 *LOCKWEDGE 228 329880 PIN 1 73 514685 *CONNECTOR, 3 Socket plug 329 329879 GUIDE 2 74 514681 *LOCKWEDGE 330 329881 ROLLER, Helix to cable 2 75 514686 *CONNECTOR, 3 Pin receptacle 131 352104 GUIDE, Wire 1 76 514682 *LOCKWEDGE 132 353409 TWIST GRIP, Assy 1 77 910446 *SOCKET, Terminal 635 352270 SWITCH, Trim & Tilt 1 78 126908 *SEAL PLUG 636 514686 CONNECTOR, Trim & Tilt 1 79 551113 SPRING, Steering friction 137 514682 LOCKWEDGE, 3 pin receptacle 1 80 332945 SCREW, Steering friction 138 586935 START SWITCH Assy 1 81 357491 PLUG, Handle 139 514679 *PIN, Terminal 2 NS 335299 DECAL, Emergency stop clip 1NS 514696 CONNECTOR, 2 pin receptacle 1 NS 333978 DECAL, Start warning (blue) 1NS 514697 LOCKWEDGE, 2 pin receptacle 1 NS 333979 DECAL, Gear shift (blue) 140 327805 NUT, Start switch 1 NS 320107 TIE STRAP 1541 5007627 CABLE, Shift 1 NS 317893 TIE STRAP 242 333774 RETAINER CLIP 1

NS Not Shown

3 of 14

4 o

INSPECTION

Before installation, check boat for obstructionsthat could interfere with free movement of tillerhandle when steering or tilting outboard.

INSTALLATION

IMPORTANT: An optional MWS harness maybe added to this tiller kit to allow installation of re-mote SystemCheck gauges or trim control. Be-fore installing tiller on outboard, refer toOPTIONAL MODULAR WIRING SYSTEM(MWS) HARNESS INSTALLATION on p. 9.

Disconnect the battery cables at the battery.

Remove any screws from steering arm holes.Make sure all paint or locking material is cleanedfrom threads.

Place angle adjustment plate in pocket ofsteering arm bracket.

The steering arm can be positioned straight, orangled 15° port or starboard by moving theadjustment plate.

� WARNINGImproper installation of this kit could resultin personal injury due to loss of boat con-trol.

A boat designed for remote steering mighthave a lower maximum rated horsepowerfor a tiller-steered outboard than shown onthe certification plate. To avoid overpower-ing a boat designed and rated for remotesteering, contact boat manufacturer for til-ler-steered maximum rated horsepower.

To prevent accidental starting while servic-ing, disconnect battery leads from battery.Twist and remove all spark plug leads.

To prevent injury from contact with a rotat-ing propeller, remove propeller before ser-vicing and when running outboard on aflushing device

Nautical Orientation

� CAUTIONTo avoid damaging the tiller handle whentilting the outboard up, position the out-board to clear obstacles in the motor welland boat.

1. Plate adjustment for tiller in CENTER position. 005083

1. Plate adjustment for tiller in PORT position. 005084

1. Plate adjustment for tiller in STARBOARD position. 005085

1

1

1

f 14

Insert steering arm screws, with washers,through plate and bracket.

Place tiller bracket on steering arm from thebottom. Thread steering arm screws intosteering arm and tighten to a torque of 18 to 20ft. lbs. (25 to 27 N·m).

IMPORTANT: Be sure that wires are notpinched.

Install locknuts on screws on top of steering arm.Hold screws with a wrench and tighten locknutsto 18 to 20 ft. lbs. (25 to 27 N·m).

CONTROL CABLE INSTALLATION

IMPORTANT: DO NOT complete final attach-ment of cables to shift and throttle levers until allcables, wires, and hoses have been routed andgrommet has been placed into the lower enginecover.

Remove cable retainer from anchor block.

Remove grommet from lower engine cover andinsert shift cable through opening.

Pull firmly on shift cable casing to removebacklash. With outboard and tiller handle shiftlever in NEUTRAL, place the cable trunnion intothe lower anchor pocket. Adjust the trunnion nutso the casing fits onto the shift lever pin.

Use Ball Socket Installer tool, P/N 342225, tosnap throttle cable connector onto throttle campin. (Use Remover tool, P/N 342226, to removecable.)

1. Steering arm screws and washers 006361

1. Locknuts 006362

1

1

1. Cable retainer 002099

1. Shift lever pin2. Trunnion nut

002100

1. Installer tool 005106

1

21

1

5 of 14

6 o

Place throttle cable in upper anchor pocket.Install cable retainer on anchor block.

Hold twist grip in full SLOW position. Pull firmlyon cable to remove backlash.

Adjust cable anchor so throttle cam is againstidle stop when anchor screw aligns with throttlebody boss. Then, rotate anchor four turns towardthe end of the cable.

Install washer, cable anchor, and cable anchorscrew on throttle body boss. Tighten screwsecurely.

IMPORTANT: Rotate twist grip. Make surethrottle cam goes to full throttle without overload-ing cable, and still returns to IDLE stop.

Apply soapy water to the inside surfaces ofgrommet and install cables and fuel line asshown:

Place the grommet into position in the lowermotor cover.

When grommet is in place and all cables havebeen installed, tighten a tie strap, P/N 500081,around the outside of the grommet to form a sealaround the cables.

1. Cable anchor2. Boss3. Cable retainer

006312

1. Idle stop 005114

1. Turn anchor four turns toward cable end. 006564

1

2

3

1

1

1. Throttle cable2. Shift cable3. Wiring harness4. Battery cable5. Fuel line

001998

1. Tie strap 006563

3

4

5

1

2

1

f 14

Secure shift cable to the shift lever pin. Forproper installation, review the following steps:• Place washer on pin.• Position retainer clip with straight section on

the bottom and angled section on the top.• Use long nose pliers to insert straight section

of clip into linkage pin hole.

• Push the clip towards the hole while lifting onthe curved end with the pliers.

• Be sure retainer clip fully engages the pin.• Lock the retainer by moving the angled sec-

tion behind the straight section.

ELECTRICAL CONNECTIONS

Remove electrical cover.

Route wiring harness from tiller handle throughchannel in flywheel cover.

Apply Electrical Grease to connector seals, thenconnect tiller handle wiring harness to engineharness.

Arrange connectors in flywheel cover as shown.

Use tie strap to secure harness to throttle bodybracket.

IMPORTANT: Route and secure all wires toavoid contact with moving parts.

1. Straight section2. Angled section

DP0818DP0817

Locked Retainer Clip1. Angled section behind straight section

DP0817a

1. Electrical cover 002421

12

1

1

1. Seal 42079a

1. Trim and tilt harness2. SystemCheck™ connector3. Start/stop harness

001999

1. Bracket 006314

1

1

2

3

1

7 of 14

8 o

Use Evinrude E-TEC Diagnostics Software toreprogram Engine Management Module (EMM)for Tiller Model start-in-gear protection.

STEERING FRICTION

Remove plug from port side of swivel bracket.

Apply Triple-Guard® grease to threads ofsteering friction adjustment screw. Install springand screw.

Steer outboard from side to side. Adjust steeringfriction screw until steering effort is comfortablystiff with only slight drag.

CHECK INSTALLATION

Make sure the following operate properly beforereturning outboard to customer:• Engine stop circuit• Emergency stop switch and lanyard• Steering movement and friction control• Throttle control (IDLE to WIDE OPEN)• Shift control and proper gear engagement• Start-in-gear protection• Trim and tilt control• Touch-Troll switch operation

1. Tiller mode setting 008564

� WARNINGDealer must use Evinrude E-TEC Diagnos-tics Software to reprogram Engine Manage-ment Module (EMM) to provide start-in-gearprotection. Failure to provide start-in-gearprotection could create a risk of personalinjury or property damage.

1. Plug 005116

1

1

1. Steering friction screw 005117

� WARNINGSteering friction device is not intended tohold boat on a set course. DO NOT overtighten steering friction screw for“hands-off” steering. Reduced control ofthe boat could result in loss of control bythe operator, creating a risk of personalinjury or property damage.

� WARNINGOnly shift outboard with throttle in IDLEposition. If outboard is shifted into gear withthrottle setting above IDLE speed, the boatcould accelerate suddenly, injuring boatoccupants and bystanders.

1

f 14

OPTIONAL MODULAR WIRING SYSTEM

(MWS) HARNESS INSTALLATION

Remove seven screws and bottom cover of tillerhandle.

Remove tie straps, disconnect tiller handle wiringharness connections, and remove sealing caps.

Insert MWS Harness through the top of the tillerhandle, to the port side of the existing cables.

Install harness trim/tilt and SystemCheckconnectors. First, place trim/tilt connector under

shift cable. Then, place SystemCheck connectorinto handle as shown.

Install harness key switch connector and tillerhandle trim/tilt connector. Place connectors asshown.

Install tiller handle stop switch connector andstart button connector.

Route cables and install tie straps as shown.Make sure that wiring cannot interfere withmoving parts of shift cable.

Install bottom cover. Tighten screws 24 to 36 in.lbs (2.7 to 2.9 N·m).

1. Cover screw 006566

006567

1. MWS Harness 006568

1

1

1. Trim/Tilt connector2. SystemCheck connector

006569

1. Harness key switch connector2. Tiller handle trim/tilt connector

006570

1. Tie straps 006571

1

2

1

2

11

9 of 14

10

OPERATING INSTRUCTIONSIMPORTANT: Store these instructions onboardthe boat with the operator’s guide.

SAFETY INFORMATION

ENGINE STARTING

Refer to the Routine Inspection Checklist inthe Evinrude E-TEC Operator’s Guide forpre-launch checks before using your outboard.

You MUST supply water to the engine beforestarting. Engine damage can occur quickly.

Connect the clip to the emergency stop switch.Snap the lanyard to a secure place on theoperator’s clothing or life vest — not where itmight tear away instead of activating the stopswitch.

IMPORTANT: The operator should always usethe clip and lanyard anytime the engine is run-ning.

� DANGERDO NOT run the engine indoors or withoutadequate ventilation or permit exhaustfumes to accumulate in confined areas.Engine exhaust contains carbon monoxidewhich, if inhaled, can cause serious braindamage or death.

Contact with a rotating propeller is likely toresult in serious injury or death. Assure theengine and prop area is clear of people andobjects before starting engine or operatingboat. Do not allow anyone near a propeller,even when the engine is off. Blades can besharp and the propeller can continue to turneven after the engine is off. Always shut offthe engine when near people in the water.

� WARNINGThe engine cover is a machinery guard. DONOT operate your outboard with the coveroff unless you are performing maintenanceor emergency starting, and then be carefulto keep hands, hair, and clothing clear of allmoving parts. Contact with moving partscould cause injury.

Always shut off the outboard when yourboat is near people who are in the water.

Be familiar with the waters you areoperating in. The gearcase of this outboardextends below the water surface and couldpotentially come in contact with underwaterobstructions. Contact with underwaterobstructions may result in loss of controland personal injury.

1. Clip2. Emergency stop switch3. Lanyard

005099

� WARNINGThe engine cover is a machinery guard. DONOT operate your outboard with the coveroff unless you are performing maintenanceor emergency starting, and then be carefulto keep hands, hair, and clothing clear of allmoving parts. Contact with moving partscould cause injury.

21

3

of 14

If clip and lanyard should be lost overboard, aspare clip can be found on the bottom of the tillerhandle.

IMPORTANT: Spare clip is for emergency useonly. Clip with lanyard should always be at-tached to operator during normal operation.

Move the shift lever to NEUTRAL. Refer toShifting and Speed Control.

Twist throttle grip to slowest IDLE position. Referto Speed Control.

� WARNINGAlways use the safety lanyard when operat-ing your boat to help prevent a runawayboat and reduce the risk of personal injuryor death.

Avoid knocking or pulling the clip off thestop switch during normal boating. Theresulting unexpected loss of forwardmotion can throw occupants forward, caus-ing injury.

Your emergency stop switch can be effec-tive only when in good working condition.At each outing, inspect clip and lanyard forcuts, breaks, or wear. Replace worn or dam-aged parts.

Keep the lanyard free from obstructions andentanglements.

� WARNINGAt each outing, test the system’s operation.With the engine running, remove the clipfrom the switch by pulling the lanyard. If theengine does not stop running, see yourDealer.

1. Spare emergency clip 005105

1

1. NEUTRAL 005100

� WARNINGAlways shift to NEUTRAL before startingthe outboard to prevent sudden boat move-ment, which can cause injury.

1. SHIFT position 005101

DO NOT advance the throttle before start-up.Advancing the throttle overrides the electronicidle control system. After the engine starts, theengine management module (EMM) willautomatically increase idle speed slightly. Idlespeed will decrease as the engine warms up.

If the outboard is started at wide open throttle,twist the throttle grip back to IDLE beforeshifting.

1

1

11 of 14

12

Key Switch

While seated, turn the key switch fully clockwiseto the START position. Crank the engine nolonger than 20 seconds.

IMPORTANT: The starter motor can be dam-aged if operated continuously for more than 20seconds.

Upon start-up, release the key.

If the engine did not start, release the keymomentarily, then try again.

IMPORTANT: Engine will not start if outboard isin gear.

Start Button

While seated, press the start button. (Key switchmust be in the ON position.) Crank the engine nolonger than 20 seconds.

IMPORTANT: The starter motor can be dam-aged if operated continuously for more than 20seconds.

Upon start-up, release the start button.

If the engine did not start, release the start buttonmomentarily, then try again.

IMPORTANT: Engine will not start if outboard isin gear, if lanyard is not in place, or if key switchis in OFF position.

After Engine Starts

Check the water pump indicator. A steadystream of water indicates the water pump isworking. If a steady stream of water from thewater pump indicator is not visible, stop theengine. Refer to Engine Overheating in theEvinrude E-TEC Operator’s Guide.

ENGINE STOPPING

Twist the throttle grip to IDLE position.

Move shift lever to NEUTRAL.

Outboard may be stopped by turning the keyswitch to the OFF position, or by pressing theSTOP button until the outboard stops running.

IMPORTANT: Be sure to turn key OFF whenoutboard is not in use to avoid discharging thebattery.

005118

1. Start button2. NEUTRAL

005104

1

Water Pump Indicator drc4952a

1. STOP button 005099

1

of 14

SHIFTING AND SPEED CONTROL

IMPORTANT: Carefully check the function of allcontrol and engine systems before leaving thedock. DO NOT shift the outboard into FOR-WARD or REVERSE while it is shut OFF.

Shifting

With engine running, twist the throttle grip toIDLE position.

Move the shift lever briskly and decisively toFORWARD or REVERSE.

IMPORTANT: When shifting from FORWARDto REVERSE or from REVERSE to FORWARD,pause at NEUTRAL until the engine is at idlespeed and the boat has slowed.

Speed Control

With the outboard running, twist throttle grip:• Clockwise to decrease speed; or• Counterclockwise to increase speed.

Tiller is equipped with a throttle frictionadjustment knob. Tighten the knob to reduce theeffort required to hold a throttle setting.

TRIM CONTROL

Tiller includes a handle mounted trim/tilt switch.

TILLER HEIGHTThe angle of the tiller handle can be raised orlowered by adjusting a thumbscrew under thehandle.

1. Shift lever2. FORWARD3. REVERSE

005100

1. Decrease speed2. Increase speed

005101

3 2

1

1

2

1. Throttle friction knob 005099

� WARNINGTighten knob only enough to hold throttle ata constant engine speed. Over tighteningwill prevent quick throttle change in case ofemergency.

1. Trim/tilt switch 005107

� CAUTIONIf tiller kit is installed on a manual tilt out-board, DO NOT use tiller as a lever to helptilt the outboard. Damage can result.

1

1

13 of 14

14

STORAGE (WINTERIZATION)

You can winterize your outboard either in thewater or on a trailer. DO NOT start the outboardonce winterization is completed.

In the Water

Prepare your outboard for the off-season byfollowing these steps:1) Make sure that the throttle is in NEUTRALand the water intake screens are completelysubmerged.

2) Add 2+4® Fuel Conditioner to the fuel tankand fill it with fuel.

3) Advance the throttle to 1/2 throttle positionand start the outboard. The outboard will run atidle speed.

4) After approximately 15 seconds, move thethrottle to IDLE position. Run the outboard atidle for another 15 seconds, then advance thethrottle again to 1/2 throttle position.

5) The outboard will automatically go to fast idleand fog itself. Allow the outboard to run until itshuts itself off (about one minute).

6) Top off the oil reservoir and inspect the fuelfilter. If there is debris in the fuel filter, it must bereplaced.

IMPORTANT: When finished, leave the out-board in a vertical position long enough to com-pletely drain the water from the powerhead.

7) If equipped, disconnect the speedometerpickup at the upper connection and blow allwater out of the hose using air pressure of 25psi (172 kPa) or less. Reconnect the speedome-ter pickup after all of the water has beenremoved.

On a Trailer

Prepare your outboard for the off-season byfollowing these steps:1) Make sure that the throttle is in NEUTRAL.Remove the propeller.

2) Add 2+4® Fuel Conditioner to the fuel tankand fill it with fuel.

3) Attach a garden hose to the flushing port andturn on the water.

4) Advance the throttle to 1/2 throttle positionand start the outboard. The outboard will run atidle speed.

5) After approximately 15 seconds, move thethrottle to IDLE position. Run the outboard atidle for another 15 seconds, then advance thethrottle again to 1/2 throttle position.

6) The outboard will automatically go to fast idleand fog itself. Allow the outboard to run until itshuts itself off (about one minute).

7) After the outboard shuts itself off, detach gar-den hose.

8) Top off the oil reservoir and inspect the fuelfilter. If there is debris in the fuel filter, it must bereplaced.

9) Apply the recommended lubricant to the pro-peller shaft splines, then install the propeller.

IMPORTANT: When finished, leave the out-board in a vertical position long enough to com-pletely drain the water from the powerhead.

10) If equipped, disconnect the speedometerpickup at the upper connection and blow allwater out of the hose using air pressure of 25psi (172 kPa) or less. Reconnect the speedome-ter pickup after all of the water has beenremoved.

When using this winterization procedure, engineoil may appear on the skeg below the gearcasearea. This is normal. Avoid potential oil stainsby placing a shop towel or suitable containerunder the propeller and skeg for the duration ofthe storage.

1. Height adjustment screw 005108

1

� WARNINGTo prevent injury from contact with rotatingpropeller, remove the propeller before ser-vicing and when running the outboard witha flushing device.

of 14