3

description

Transcript of 3

IS Codes Acknowledge the Usage of Precast Elements

Precast technology

Precast building construction is still in its nascent stages

in India and thus there is still a lack of awareness about

it among the builder, developer community. Despite this

Elematic has supplied, installed and successfully commissioned 14

precast plants all across India. As a technology provider we do not

restrict ourselves to supply of precast machines. We provide 360

degree solutions like project consultancy, precast machine supply,

design and installation of precast factories, structural design and

value engineering of precast buildings and training for production

and installation of precast elements”, says Mr. Chander Dutta

Managing Director, Elematic India Private Limited

CE&CR: Tell us about your expertise in precast technology

C.D: Elematic works globally having many long-term

partnerships in all continents. We have completed over 3600

deliveries in more than 100 countries in 6 continents.

We are a one-stop supplier of all precast machines for

production of slabs, columns, beams, walls, staircases and lift

shafts. We have other moulds for specialized precast elements

which can be customized for individual clients. Elematic has the

most advanced Automated Concrete Distribution System and

we have the capability of providing robotic shuttering in our

advanced precast factories.

As a technology provider we do not restrict ourselves to

supply of precast machines. We provide 360 degree solutions

like project consultancy, precast machine supply, design and

installation of precast factories, structural design and value

engineering of precast buildings and training for production and

installation of precast elements. We provide end to end solutions.

Through our Indian and global partners we also provide

consulting services for concrete mix design for Hollow Core Slabs

and SCC for Battery Moulds. Further we also provide training for

site staff for treatment of precast joints on construction sites and

effective waterproofing in precast buildings.

Lately the most vivid areas have been the Middle East, Russia,

India and China. To the United Arab Emirates, Qatar, and Bahrain

alone, Elematic has delivered twenty complete factories.

CE&CR: What is the USP of technology adopted by your

company?

C.D: Elematic has launched three technology levels to suit the

needs of different players in the construction sector. We have

three technology levels, SEMI, PRO and EDGE which differ from

each other in the production capacity and level of automation.

We have specially developed the SEMI Line keeping in mind

developing economics such as India, China, South East Asian and

African countries.

CE&CR: What has been your experience with regard to

awareness, development and growth of precast technology in

India?

C.D: Precast building construction is still in its nascent stages

in India and thus there is still a lack of awareness about it among

the builder, developer community. Despite this Elematic has

supplied, installed and successfully commissioned 14 precast

plants all across India. Our competitors have also supplied roughly

10-15 plants.

CE&CR: What trends do you foresee in the years to come in

this field?

C.D: Due to widespread project delays and consequently huge

cost over runs, the industry is now responding and thinking of

modern techniques of construction. As more and more projects

are completed successfully using precast concrete technology,

the use and awareness of precast is increasing rapidly.

Face-To-Face

122 CE&CR NovEmbER 2014

“

Mr. Chander Dutta

Managing Director,

Elematic India Private Limited

Through our Indian and global partners we also provide

consulting services for concrete mix design for Hollow

Core Slabs and SCC for Battery Moulds. Further we also

provide training for site staff for treatment of precast

joints on construction sites and effective waterproofing in

precast buildings.

Already many big names such as Amrapali Group, B.E.

Billimoria, Jindal Realty, BG Shirke, Janapriya, Tata Housing, BCC

(Bharat City) etc. are constructing many buildings using modern

precast concrete technology.

CE&CR: It seems that this technology can help meet the

requirement of affordable housing in India. Are the authorities in

India duly emphasizing on these technologies in this regard?

C.D: According to data available with Brick Eagle, a financial

services firm for affordable housing in India, the demand for

affordable housing in India is around 18.78 million. The size of

these units is in the range of 30-50 sq.m. Precast technology

is excellent for Speedy construction in the affordable housing

sector. High quality, factory produced elements reduce the

plastering and other on-site work and increases the life span and

reduced lifecycle cost of the buildings.

Recently DDA (Delhi Development Authority) contractor, BG

Shirke, completed 18,000 precast units for affordable housing

in less than two years and has commissioned another project

of 27,000 houses to be constructed using precast concrete

technology in 3 years in Delhi. DDA has approved precast

technology for all their future projects and plan to construct

100,000 units every year.

CE&CR: Do you think IS code doesn’t provide sufficient

provision for precast building design and also doesn’t allow design

of high rise building in precast?

C.D: Precast construction method is extensively being

practiced, for all sorts of buildings, in

countries like New Zealand, Canada, and

USA which fall under high seismic areas.

There has been a lot of research work

done to design precast buildings and

have developed literature for practicing

engineers e.g. precast Concrete Design

Handbook, New Zealand PCI Handbook,

FIB Documents.

In India, we have following codes

for the design of precast buildings; they

have nowhere talked about restriction

on use of precast technology. Since

IS codes are inadequate for precast

connection design, outside codes/

journals are followed for that purpose.

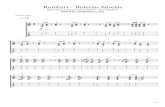

IS codes acknowledge the usage of precast elements.

IS 15916 prefabricated concrete

IS 15917 mixed composite construction

IS 13920 ductile detailing

IS 11447 large panel prefabricates

IS 456 plain and reinforced concrete

IS 1343 pre-stressed concrete

“Precast and/or prestressed concrete members may be used

only if they can provide the same level of ductility as that of a

monolithic reinforced concrete construction during or after an

earthquake” (Cl 1.1.2, IS 13920)

Already, there has been a lot of work going on in India for

developing precast design handbook for structural engineers.

Esteemed colleges like IIT Chennai are involved in this process.

First edition of this handbook is expected to release by end of the

year 2014.

CE&CR: How is use of precast concrete construction a better

idea as compared to pre-fabricated steel structures?

C.D: Precast construction is simply a replacement to

conventional way of constructing buildings. Pre-fabricated

construction has got limitations and is majorly used for industrial

buildings. Constructing a steel structure is always a costly option.

With precast construction one not only saves on time but also on

cost of construction.

Precast technology

124 CE&CR NovEmbER 2014