35 Metal Matters Issue 35.pdfCOLD ROLLED The Cold Rolled Process Handbook 19 Confederation of...

Transcript of 35 Metal Matters Issue 35.pdfCOLD ROLLED The Cold Rolled Process Handbook 19 Confederation of...

COLD ROLLED

The Cold Rolled

Process Handbook

19

C o n f e d e r a t i o n o f B r i t i s h M e t a l f o r m i n g

35

35

ISSUE

2014£7.50

ISSN 1759-5975

FASTENERS

FORGING

SHEET METAL

Fasteners with benefits

Supplying lubricant technologies

to the forging industry

New dedicated manufacturing unit established

for vacuum brazing

17

19

22

New dedicated manufacturing unit established

for vacuum brazing

Fasteners with benefits

The figures speakfor themselves……

THE PROVEN ROUTE TOYOUR MAXIMUM REFUND

Landmine Seeking TechnologyStaffordshire:

£125,854 tax refund secured

Precision EDM MachiningSmethwick:

£147,269 tax refund secured

Precision & Small Machined PartsWorcestershire:

£146,677 tax refund secured

Precision Aluminium ComponentsBirmingham:

£72,179 tax refund secured

Precision Components EngineersBirmingham:

£21,423 tax refund secured

Specialist Gears ManufacturerStockport:

£181,281 tax refund secured

01902 783 [email protected]/@RandDtaxrefunds

www.rdtaxclaims.co.uk for more examples……

I must admit, I haven’t been a great watcher of TV news bulletins for the last couple

of years, as everything related to the world of business just seemed so negative.

However, I’m back in front of the screens now, because there is so much upbeat information, concerning the general economy, and the manufacturing sector in particular.Discovering that the closely-watched Purchasing Managers’ Index (PMI) for March had been revised upward was good news, but hearing that the upward trend had continued into April was even better.Of course, we should never read too much into a single survey or solitary statistic, but the underlying data really is impressive.Markit, the people who carry out the PMI, say manufacturers are now creating around 10,000 jobs every month, and their data shows employment in our sector has now risen for twelve successive months.As we moved into May, there was more optimism from the Engineering Employers Federation (EEF) which reported manufacturing productivity was up, and saw above-average wage rises being awarded throughout the country.The EEF even thinks the gradual increase in demand from the Eurozone is beginning to feed through to order-books, which could be the start of a very welcome trend.It’s good to see the economy continuing to improve, and the manufacturing sector playing a major role in the recovery process.However, we also have a duty to act quickly and responsibly, to ensure a future that is built on firm foundations and has sustainability at its core. We must continue to bolster our investment in training to ensure genuine sustainability, and adopt a more robust approach to erode the impact that skill shortages have on our sector. Of course, as individual companies, there is very little we can do to influence the recovery, but a trade organisation which is genuinely committed to its members really can make a difference, and I’m impressed by what the CBM has achieved during the last year.As you know, the Climate Change Levy system has undergone major changes, and the exemption system has been amended and extended. This has, in no small way, been as a result of the CBM working closely with the Department of Business, Innovation & Skills and HMRC to achieve a fairer and more equitable system, ensuring the inclusion of previously exempt companies and procedures. Our strengthening relationship with the Advanced Forming Research Centre will be important in the development of new processes and products to maintain, or gain, an edge for UK manufacturing, and be an increasingly valuable resource for members.I am confident that the coming years will provide major opportunities for UK manufacturing to continue to expand, and a bright future is there for those ready to embrace the changes required.I am equally certain that the CBM will be there to support its members, and to play an important role in the advancement of our sector - and of every element within UK industry

Barry YeomansCBM President

www.britishmetalforming.com 1

CBM STAFF

THE PRESIDENT’S REVIEW

Good news just keeps on coming

ONLINENOW!for the latest news, events & features.

METAL MATTERS 35

PresidentBarry Yeomans [email protected]

Operations DirectorGeraldine Bolton MCMI, Dip.OCR, MAAT, M.IIM [email protected]

Energy & Forging Sector SpecialistDr Ken Campbell F.Inst.F.T [email protected]

Sheet Metal, Cold Rolled & Fastener SpecialistAdrian Nicklin ISME [email protected]

AccountsChris Smith MAAT [email protected]

Marketing & Communications ManagerKirsi Lintula BA(Hons), LBIPP [email protected]

Sales & Marketing AssistantRohima Begum BSc(Hons) [email protected]

Project ManagerPaul Denning [email protected]

Energy ConsultantKevin Kirk [email protected]

AdministratorDebbie York [email protected]

AdministratorLouise Campbell [email protected]

ReceptionistJan Taylor Lynette Mand [email protected]

Confederation of British Metalforming 0121 601 6350

www.britishmetalforming.com

t: 0121 601 6350 • e: [email protected] • www.britishmetalforming.com Confederation of British Metalforming • National Metalforming Centre • 47 Birmingham Road • West Bromwich • West Midlands B70 6PY

DIARY

DATES• Materials Characterisation

seminar

29 May 2014

Materials Characterisation

seminar at the AFRC (Advanced

Forming Research Centre)

University of Strathclyde.

www.britishmetalforming.com2

CBM MEMBERSHIP/DIARY DATES

CBM members provide high quality components to key industry sectors; indeed virtually every manufacturing sector buys components from a CBM member company.Working with members, and the UK government CBM creates a world class metalforming supply base for UK manufacturing.Maintaining close links with UK Department for Business, Innovation and Skills (BIS), Transport and the Regions, and the Health & Safety Executive, CBM ensures that the members’ interests are represented in the consultative processes which precede legislative or regulatory initiatives.Membership is available to companies who manufacture products in the UK, by Metalforming processes, particularly those who are engaged in hot and cold forging, and the shaping, cutting and forming of sheet metal. Associate membership is available to companies and institutions allied to the manufacture of metalformed products.Membership of the CBM includes a wide and growing range of free and discounted services, designed to save you money and help your business operate more efficiently:

For further information or to book a place please visit:

www.britishmetalforming.com/events.aspx

• REBATES on your Climate Change Levy: More than 100 member companies received rebates averaging £20,000 per year, and didn’t even have the time-consuming burden of administration.• FREE employment law helpline: In today’s litigious climate, access to professional help is vital from the outset. Members have unlimited access to a genuine 24/7 service designed to help managers achieve their aims, whilst minimising risks.• FREE Technical Helpline: From hot-forging to sheet metal processing, we can solve your problems, either via the staff at our National Metalforming Centre, or through their wide network of contacts across our industry.• FREE Publications: Not everyone can attend our seminars and meetings, so we circulate newsletters and magazines highlighting important issues and celebrating members’ achievements.• FREE Health & Safety Helpline: Whether you need an instant response, or advice about long-term issues, this service will provide cost-effective answers whenever you need them.• MONTHLY Market Reports: Our new Industrial Market Report provides valuable information on potential sales opportunities and has been particularly well received.• DISCOUNTED Hearing and Noise Assessments: Our partner organisations who offer occupational healthcare will save you money whether you use the CBM’s mobile hearing assessment vehicle, or attend an associate member’s clinic.• DISCOUNTED Training Packages: Regular courses on such issues as lean management and Six Sigma are provided for management and shop-floor employees, either at your premises or at the NMC. All are heavily subsidised, some are free.• DISCOUNTED Insurance Premiums: The ever-rising cost of insurance can now jeopardise the survival of your business. Our specialist providers though will save you money without reducing essential cover.

• BRIEFINGS and Seminars: Our staff and outside experts keep members abreast of such vital topics as steel prices, the latest H&S legislation and upcoming employment law changes.• REGULAR Meetings: Workshops and sector group meetings allow you to meet delegates from other companies and associate members who supply products and services to the industry.• HEALTH and Safety Officer Service : The availability of a health and safety professional to carry out risk assessments and ensure the company is compliant with the latest legislation is an important addition to the CBM services to members.• PRIVATE Healthcare Scheme: Like any industry, your business is reliant on your employees and if they become ill, you need them back as quickly as possible. Some of the CBM Private Healthcare Scheme benefits are: premiums up to 20% less than comparable First Assist schemes, a ‘full refund’ policy meaning there are no financial limits for hospital treatment, specialist treatment and diagnostic tests, and an optional Employee Assistance Programme offering 24/7 access to telephone legal advice and counselling.

• Subcon Show

3-5 June 2014

Hall 3, NEC, Birmingham.

• Metallurgy for non metallurgists

09 June 2014

Two day course designed for anyone

who needs to know more about metals

and processes used in their company.

• CBM Sheet Metal & Cold

Rolled Sector Meeting

10 June 2014 The next meeting will take

place at Rhodes Group.

• Manual Handling ‘Train the Trainer’ 19 June 2014

The course provides delegates with the skills, knowledge and materials to enable them to deliver a short manual handling course.

WHAT’S IN IT FOR YOU?CBM MEMBERSHIP...

Contact CBM now for a free subscription to our membership magazineMETAL MATTERS

WELCOME TO OUR NEW MEMBER

BGSteels

www.bgsteels.co.uk

TO BE PART OF THE WIDER PICTURE AND BE MASTERS OF YOUR OWN IDENTITY… CONTACT CBM NOW!

• Simulation of Fasteners Forming Processes Workshop 24 June 2014

Understanding the role of finite element simulation to model bulk metalforming processes.

• Simulation of Hot Metal Forming Processes

Workshop - Forging 25 June 2014

Understanding the role of finite element simulation to model bulk metalforming processes.

• Euroforge: The 21st International Forging Congress 29 June 2014 InterContinental Berlin, Germany.

• CBM Health, Safety & Environment Group Meeting 03 July 2014

www.britishmetalforming.com 3

CONTENTS

Presidents Review1: Good news just keeps on coming1: CBM Staff

CBM Membership/Diary Dates2: CBM Membership What’s in it for you?2: New Members2: Diary Dates

CBM Update4: A year of great progress

CBM Member News6: Ultra STEEL® wins Queen’s award for Enterprise Innovation 20146: Still time to enter the ISME Apprentice Skills Competition at the Morgan Motor Company6: Frank Cooper7: Associate Member, Sound Advice - nationwide Occupational Health service7: Oerlikon Balzers; vacancy for a Sales & Business Development Engineer for Metal Forming & Mould Tool Sector

Industry News8: Regional Growth Fund Round 5 funding announced by Nick Clegg10: BG Steels expand strip range13: Embrace the CAFE society or risk getting left behind13: In-Comm’s £235,000 investment delivers training academy13: Hot topics, top speakers: Siemens, Pratt & Whitney, HS2, Rolls-Royce to speak at Subcon

Fasteners15: Eurostat data for fastener trade 201317: Product Development - The use of Forged Exotic Materials for Weight Reduction17: Fasteners with benefits

Forging19: Supplying lubricant technologies to the forging industry

Cold Rolled19: The Cold Rolled Process Handbook

Sheet Metal21: Metal Forming tool users benefit from CPM steels and Reduce Maintenance Costs22: New dedicated manufacturing unit established for vacuum brazing

Finance23: Are you ready for the New UK Generally Accepted Accounting Principles (UK GAAP)?

Business Support24: Commercial benefits of employing disabled people 25: Automotive manufacturer reclaims over £75,000 in R&D tax credits

Health & Safety27: REACH Substances of Very High Concern - Update, April 201427: CBM Health, Safety and Environment Group Meeting – 3 July 2014

Membership Directory28: Fastener Manufacturer Members28: Forging Manufacturer Members29: Sheet Metal Manufacturer Members30: Cold Rolled Manufacturer Members31: Fastener Supplier Members31: Forging Supplier Members31: Sheet Metal Supplier Members32: Commercial Supplier Members32: Overseas Supplier Members

Contentsissue 35

Confederation of British MetalformingNational Metalforming Centre, 47 Birmingham Road, West Bromwich, West Midlands B70 6PY.

Telephone: 0121 601 6350Enquiries: Kirsi Lintula, Marketing & Communications ManagerEmail: [email protected]: Rohima Begum, Sales and Marketing AssistantEmail: [email protected]: www.britishmetalforming.com

All rights reserved. No part of this publication may be reproduced in any form or by any means, electronic or mechanicalincluding photocopying, recording or any information storage or retrieval system without the express prior written consentof the Publisher. ISSN 1759-5975 Metal Matters Magazine is published by The Confederation of British MetalformingEvery effort has been made to ensure the accuracy and reliability of material published in this magazine. The Confederationof British Metalforming and its agents do not accept any responsibility for the views or claims made by contributors in theadvertising or editorial content.

© The Confederation of British Metalforming 2014

www.britishmetalforming.com4

CBM UPDATE

A s I was penning this report, the media was very animated because wages had edged ahead of inflation, for the first time since recession began.

True, it was only by a decimal point - and we still need to see if it’s the start of a trend, rather than just a blip - but I thought it rounded off the events of the last twelve months very nicely.From a CBM perspective, it was the most challenging, but also the most successful year, which I can recall.A relentless strategy of enhancing existing membership-focused services and devising new ones, which added genuine value, paid off as membership reached a record high.Our relationship with the Glasgow-based Advanced Forming Research Centre (AFRC), one of the UK’s High-Value Manufacturing Catapult R&D sites, blossomed into a genuine partnership, which will benefit many members in the coming months and years.The campaign to raise our organisation’s profile also paid off, and we met both Energy Secretary Michael Fallon - who was very interested in our energy road-map - senior HMRC officials, and influential members of Vince Cable’s team at the Department for Business & Skills.It’s vital to make our collective voice heard in the political corridors of power, and such activity will again be a core focus in the coming year.From a manufacturing perspective, the year was full of great news; not least JLR’s continued investment in its UK supply chains.Production of its best-selling Range Rover Evoque alone has led to £3 billion of supply contracts since its launch in July 2011, which have created some 10,000 jobs in the UK. Output has also increased throughout our motor industry, and this January, it was revealed that 2013 car production had passed 1.5m units, the highest for six years, amid predictions that output could hit 2m by 2017.

It’s also great to see our construction industry on the way back, after several years of struggle, as the government’s Help to Buy scheme drives house-building numbers dramatically upward.From a wider economic perspective, signs that GDP is edging upward are welcome, although the strength of the recovery remains unclear, with February’s exports nosediving sharply to the lowest since November 2010.However, our aerospace sector continues to thrive, and the infrastructure sector is eagerly anticipating the start of work on the once-in-a-generation HS2 project, so we shouldn’t become too concerned by a single statistic. From a personal and professional perspective, the last year brought both highs and lows.I was delighted that our in-house restructuring gave us leeway in our budget to recruit Paul Denning, as a part-time project manager to strengthen our relationship with the AFRC.Many of you will remember him from his time at Barton Cold-Form, and I’m sure you’ll agree that his long experience and boundless enthusiasm will be a significant benefit to our resources.However, February brought the very sad news that Jim Mundell had passed away, after years of fighting bravely against ill-health.He had been a doughty fighter in his working life too, and gave many years of service to the CBM, especially as a member of the finance committee.For me, Jim’s greatest professional achievement was to chair the committee which oversaw the construction of the National Metalforming Centre, bringing it in both on time and on budget.He was a dear friend and mentor, and the successful organisation which the CBM has become today owes a great debt of gratitude to Jim.

Geraldine Bolton CBM Operations Director

update

By: Geraldine Bolton, CBM operations director

A year of great progress

www.britishmetalforming.com 5

CBM NEWS

CBM MEMBER NEWS

www.britishmetalforming.com6

Ultra STEEL® wins Queen’s award for Enterprise Innovation 2014

Patented metal manufacturing process generates new exports of over £44,000,000 in four years with savings to customers of over £4,000,000.

West Midlands based Hadley Group, Europe’s largest privately owned cold rolled steel manufacturer, has been awarded the Queen’s Award for Enterprise Innovation for 2014. The business, headquartered in Smethwick and with seven manufacturing centres worldwide including operations in Germany, Dubai and Thailand, has won the Queen’s Award for the continuous development and innovation of the capabilities of their unique and patented UltraSTEEL® manufacturing process. The UltraSTEEL® process work hardens metal during the rollforming process enabling lighter gauge metals to be utilised in the production of products and components. At the same time UltraSTEEL® products typically improve thermal, fire retardant and screw retention and achieve the same strength of heavier gauges. By utilising a lighter gauge, the Ultra STEEL® process also uses fewer raw materials. The new innovation has enabled the UltraSTEEL® process to be applied to heavier gauge metals and Hadley Group demonstrated three new overseas markets to which they now export as a result of the success of the new UltraSTEEL® process.In Europe, it is used on fruit and vine posts, replacing traditionally wooden stakes with durable steel posts. UltraSTEEL® posts are more stable and require less maintenance and replacement than wooden posts as well as reducing bruising and infection of the fruit compared to wood.

In Thailand UltraSTEEL® is being used for roof truss systems which are helping the region to move away from timber frame roofs to fire retardant steel frames, thereby helping to address the significant issue of building loss due to fire in the country.In the Middle East UltraSTEEL® is enhancing construction sections and dry lining components. The process ensures profiles are lighter which reduces installation costs and saves time for construction projects. Commenting on the Queen’s Award, Hadley Group CEO, Stewart Towe, CBE said,“It is evident of the global application of the Ultra STEEL® process that it contributes to so many diverse performance benefits for metal profiles and sections across so many sectors. It has helped us deliver growth to the business, trade internationally and invest in the futures of our global workforce.2014 is the Hadley Group’s fiftieth year in business and to win this prestigious award for a second time is recognition of the experience, knowledge and quality of our in-house research, development and manufacturing capabilities. This expertise directly impacts on the solutions we provide to our customers and helps them save costs and gain competitive product advantages in their markets.”

www.hadleygroup.co.uk

Still time to enter the ISME Apprentice Skills Competition at the Morgan Motor CompanyThe Institute of Sheet Metal Engineering still have spaces available at our appren-tice skills competition being held at Morgan Plant in Malvern on Thursday 12th June. This competition is open to apprentices from all over the UK. If you are interested please go to the new ISME web site for an entry form which gives full detail; www.isme.btck.co.uk.

We are sad to report the death of ISME Honorary member Frank Cooper in March at the age of 75.Frank was well known to members through his job at Ortlinghaus UK Ltd where for 21 years until his retirement in 2005 he was their Technical Sales Engineer specialising in clutches and brakes for Power Presses and metal forming equipment. However he had spent 52 years in the industry from his apprenticeship at John Thompson and as a design draughtsman at Ductile Engineering. He first attended ISME meetings in the 70s becoming a full member in 1993. In 1997 he was elected as Hon. Secretary, a position he occupied until 2007.

Bill Pinfold, ISME Hon. Secretary

• StewartTowe CEO Hadley Group CBE

Any questions or further information needed please contact Adrian Nicklin by telephone 07774 260126 or by email; [email protected].

FRANKCOOPER

The My Health card folds in to a convenient credit card size for easy storage in a wallet or purse. This is given to every employee after a Well being or Health Promotion day.We carry out over 50,000 individual health surveillance checks each year in our fleet of air conditioned mobile health surveillance units.

For further Information please contact;

Liz McGuinness Business Relationship Manager

M: 07880504519 LL: 01925 838350 E: [email protected]

www.soundadviceltd.co.uk

www.britishmetalforming.com 7

CBM MEMBER NEWS

company profile

Sound Advice was established over twenty years ago and provides a nationwide Occupational Health service to over 2500 employers in the UK via our 8 Mobile Occupational Health Units or on your own premises. Sound Advice offer a wide range of Occupational Health and Health Surveillance services. We believe our flexible service approach will enable us to meet your Occupational Health and Health Surveillance requirements.

We have various service options including Mobile Health Units, onsite services and remote case management. We feel that this flexible approach ensures we provide the most cost effective service for your company.All health surveillance is carried out to meet the requirements of Health and Safety legislation. Our network of occupational health nurses and occupational health phy-sicians can deliver the full range of services wherever you are located.We also provide a wide range of other Occupational Health services including but not limited to;

•Lung Function Assessments•Hand Arm Vibration Assessments•Hearing Test•Skin Surveillance•Sickness Absence Management•Health Promotion•Pre-Placement Assessments•Working at Heights Medicals•Lift Truck Medicals•Confined Space Medicals•Night Worker Medicals•Stress Management

We believe we can demonstrate

key deliverables that will meet

your needs

Sales & Business Development Engineer for

Metal Forming & Mould Tool Sectorto £35k plus car and generous benefits

(negotiable dependant upon experience)

Oerlikon Balzers is seeking to recruit a dynamic, proactive and highly self motivated Sales and Business Development professional to grow the metal forming, mould and die-casting sector.You will be an articulate and confident communicator and both tenacious and resilient, and ideally qualified to at least HND or degree level in a mechanical engineering or similarly relevant technical discipline, and will be tasked with the promotion of our clients’ solutions and capabilities within a diverse range of technical sectors, with previous business development or technical experience gained in the steel industry, metal forming, moulding or die-casting sectors proving distinctly advantageous.With full product training available, you will develop strong and commercially attractive client relationships and proactively identify business opportunities before delivering presentations and introductions in order to secure inclusion onto client vendor lists or shortlists for projects and secure enquiries for suitable business opportunities as well as being instrumental in the creation of winning proposal generation.In return, an attractive salary is available (negotiable dependant upon experience) and achievable commission structure as well as a company vehicle, Pension scheme, Private Medical Insurance, Permanent Health Insurance and Life Assurance schemes.

Please apply in writing with a CV to HR Manager, Oerlikon Balzers Coating UK Ltd,

Bradbourne Drive, Tilbrook, Milton Keynes, Buckinghamshire, MK7 8AT

• LiftTruckMedicals

• HandArm Vibration Assessments

• Ourairconditioned mobile health surveillance units

ASSOCIATE MEMBER

Regional Growth Fund Round 5 funding announced by Nick CleggThe government’s Regional Growth Fund will invest £300 million in 50 projects across the country to create jobs and fuel business expansion.

The 50 projects will create tens of thousands of jobs and fuel business expansion, the Deputy Prime Minister, Nick Clegg announced today.Today’s funding from Round 5 of the Regional Growth Fund (RGF) is expected to unlock £1.9 billion of additional private sector investment and create or safeguard thousands of jobs, while also generating thousands of jobs in the supply chains. The RGF is a government pot to create sustainable employment and growth in a wide range of sectors across the country.The fund supports areas that are traditionally more reliant on the public sector to increase private sector investment and encourage businesses to expand. This type of targeted investment helps to boost growth throughout the country and rebalance our economy.Deputy Prime Minister Nick Clegg said:“Today we are investing more than £300 million to create thousands of jobs through the Regional Growth Fund. This is a vital fund that has already helped over 400 projects and 3,500 small and medium sized enterprises.This money will help unlock nearly £2 billion of additional private sector investment that will create sustainable and long-term jobs.We’re seeing very encouraging signs that the British economy is on the road to recovery. Home-grown and British-based businesses are leading that charge for a stronger economy. The Regional Growth Fund gives businesses a helping hand from government to fuel business expansion and create sustainable employment.When this coalition government took office in 2010, the economy was on its knees. I’ve made it a priority to ensure that as the economy recovered, all the regions benefited too.I pay tribute to the ambitious companies who are using the Regional Growth Fund to create jobs locally, helping to build a stronger economy and doing it fairly.”Ministers will be visiting RGF projects across England today (10 April) to see how the fund is helping to rebalance the economy. The Deputy Prime Minister will be in Merseyside where he will visit 2 companies who have been awarded funding from the RGF:At cooker manufacturer Glen Dimplex he will talk to staff about how the company will use their £3 million Round 5 RGF investment to expand their business, creating hundreds of jobs and boost the local economy.He will also visit electrical cable manufacturer Tratos to talk to staff about how their RGF Round 4 investment of nearly £3 million is being used to expand the business and create and safeguard about 100 jobs for local people.

Business Secretary Vince Cable will visit automotive specialist Millbrook later today, a successful bidder in Round 5. He said:“Our Industrial Strategy is creating stable foundations for a sustainable, long-term recovery in which opportunity and growth is fairly spread across the country. The Regional Growth Fund will help increase our exports, expand our capacity for innovation and drive up the quality and range of our skills base and supply chain.The awards we’re announcing today like that of Millbrook see every £1 of government funding leveraging in £6 of private capital. They will support sectors from aerospace and automotive to tourism, and the benefits will be felt into the mid 2020s and beyond.”Business Minister Michael Fallon added: “As we work to secure the recovery, every new job and every new pay-packet counts. The Regional Growth Fund is about backing companies and sectors that have the vision and capability to create long-term growth, but need extra support to realise this potential.We have fine-tuned the fund - improving its governance and getting money into the hands of businesses more quickly - and I’d strongly encourage any firms that can generate significant private sector investment and sustainable jobs to bid for a share of the next round we’re launching this summer.”

List of bidders with conditional offers:

•AbsynthBiologicsLtd•AngliaMetalLimited•AstonMartinLagondaLtd•AvantiCommunications Group plc•BectonDickinsonU.K.Limited•BournvilleCollege/TrinityMirror Midands •ClevelandPotashLimited(CPL)•CloseBrothersLtd•CompassBusiness Finance Limited•CornwallMarine Network Limited•CumminsLtd•DalepakLimited•DysonTechnologyLimited•ElektaLtd•Farnborough International Limited (FIL)•FinanceForIndustryLimited•FineIndustriesLimited•FineTubesLimited•GestampTallentLimited•GlenDimplex Home Appliances Ltd.•GoochandHousego (Torquay) Ltd•GTEnergyUKLimited•HaywardTylerLimited(HTL)•HuntsmanPolyurethanes( UK) Ltd•HydraForceHydraulicsLtd•HydramEngineeringLimited

•JDRCableSystemsLimited•JohnsonMattheyDavy Technologies Limited (JM Davy)•KEWSKentWoodland Employment Scheme•Let’sGrow•LincolnshireChamber of Commerce & Industry•MaierUKLtd•MillbrookProving Ground Limited•MTCELtd•Nice-PakInternationalLtd•NorthDevon+•NorthWestLogisticsLimited (“NWL”)•ReallyUsefulProductsLimited•ReckittBenckiser (Brands) Limited•RedxPharmaLtd•SenseandSenseInternational•Sertec•SPPPumpsLimited•StaffordshireChamber of Commerce•TheRoyalBankofScotland Group plc•TinsleySpecialProductsLimited•TRWSystemsLtd•UKSteelEnterpriseLtd•UnileverUKCentral Resources Limited•UniversityofDerby

Contains public sector information licensed under the Open Government Licence v2.0

INDUSTRY NEWS

www.britishmetalforming.com8

• NickClegg Deputy Prime Minister.

continued on page 11 .....>

BG STEELS Ltd, since its establishment in 2005, has served the UK and Ireland markets for drawn wire in coils, speciality bright bar and harden and tempered cold rolled strip, with Agencies for Lueling GmbH and Stahlwerk Unna GmbH & Co. KG. They have now been asked to cover the Theis product range of pre-cision cold rolled strip, flat wire and solid sections, as well as Titanium.

LUELING GmbH&Co.KG, established in 1857, produces high quality cold forming wire from its manufacturing facilities in Altena and Iserlohn. The company’s size range is from 1mm to 36mm and in rings and coils up to 3 tonnes in weight. Total production amounts to some 65k tonnes per year, 50% of which serves the German domestic market. A further 40% of the sales are to European counties and are achieved through agents such as BGSteels. Investment in manufacturing and product development has always had a high profile at Lueling and this continues with a major invest-ment of 10M euros in a new fully automated surface treatment facility at Altena. This facility is nearing completion and should be in full production by April / May. Product development has always been in tune with customer

requirements and demands. The latest innovation to emerge is Zero-PTM coating which eliminates the need for phosphate coating in many appli-cations. The product has been greatly welcomed by their customers who have been able to achieve significant cost savings over conventional wire. …“Taking wire to a new level”.

INDUSTRY NEWS

www.britishmetalforming.com10

BG Steels expand strip rangeIn their quest to keep themselves globally competitive, most German industrial companies

consider the EU their home market.

www.britishmetalforming.com 11

INDUSTRY NEWS

This expansion also coincides with exciting developments at STAHLW-ERK UNNA as they have just moved into a new purpose built factory at Böenen, some 12 km north of Unna. The company currently has a turnover of 30 million euro’s with a workforce of 100 people and celebrates its’ 100th anniversary in May last year. A total production of 16 kt is produced by the company and steel strip accounts for 60% of the output, the balance being wire and bright bar. Main markets for 90% of the company’s products are automotive, tool and saw industries in equal proportion. The construc-tion, spring, paper and textile industries account for the remaining 10%. Geographically, the home market of Germany is their strongest followed by other countries within the E.E.C. and around 16% going to other parts of the World. Stahlwerk Unna supplies many leading names with steel products, amongst which are LUK, Robert Bosch and Husqvana. The company sees its’ self very much as the market leader for special steel wire and harden and tempered strip products, always meeting the demands of their customers.

The Böenen factory has a new “state of the art” Ebner furnace for the hard-ening and tempering of steel strip in high quality engineering and tool steels as well as martensitic stainless steels. The thickness range for strip is 0.10-3.0mm with a width of 5.0-540mm. A range of surfaces are avail-able which include grey-blue, bright, sliver bright, white-polished, yellow polished and blue-polished. Edges can be slit, rounded (up to 2.7mm), deburred or bevelled.

BG Steels Ltd. now widens its’ steel market to cover the U.K. and Ireland’s demands for strip products. They are delighted to have been selected by THEIS GmbH (www.Theis.de) to be their agents for cold rolled strip prod-ucts which will sit alongside Stahlwerk Unna’s hardened and tempered strip already being supplied into the U.K. market. Theis, based in Hagen Germany, are a major player in the cold rolled steel strip market with sales of this product totalling 120 million euros and producing 100,000t/year in three main product groups. These groups being annealed cold rolled strip, stainless strip and flat rolled/narrow strip and profiles as solid sections. The main industry sector served by Theis products is automotive which accounts for approximately 50% with mechanical and power tools, textile, aerospace, medical, fastener, electric and electronic and furniture providing the balance. Europe provides the main market for Theis products accounting

for 85% of sales. Theis can boast many prestige names, as customers, like Gillette, Delphi, Renault, Bosch, Airbus and Stihl being just a few.

Theis cold rolled strip is available in thicknesses of 0.2–4,75mm and width of 6.0mm-650mm in low carbon-, IF-, high carbon-, micro-alloyed-, alloyed-, high and ultra high strength- and boron steels. This product is annealed in HLW (high efficiency H 2) – furnaces of state of the art suppliers like Ebner or LOI (or others) under a protective atmosphere of 100% hydrogen. Each furnace can accommodate a charge weight of up to 60t of strip coils. Material is rolled using a 4 Hi four stand tandem rolling mill or a 20 Hi reversing cluster mill. Both lines are manufactured as state of the art machines by famous suppliers like Sundwig, SMS (or others).

After final annealing either as soft annealing or with carbon steels as hundred percent spheroidisation the strips are (is then) finished through either a CVC (continuous variable crown) skin passing or tempering mill or a 4Hi skin passing mill for higher cold reduction. For extreme flatness and dead softening also the stretch-leveller can be used. From here the material moves (travels) to the confectioning centre, where the wider steel coils can be slit on modern precision slitters to cuts of a dimension to any customer request. Oscillated bundled coils out of the single cuts are also possible up to a weight of five metric tonnes. On request edges can be also be delivered in an either deburred or filed condition for parts, which need an extreme fatigue strength or low roughness for the textile industry.

The Theis high-precision stainless steel strip, Thenox ®, rolled on the state of the art 20 Hi cluster mill, gives consistent quality, tailored to re-spective applications and purposes. Heat treatment of this product is in a purpose built, atmosphere (H2) controlled, vertical CAL annealing furnace. The product can then be finally rolled / stretcher - levelled before shearing and packaging. Specials are here also a deburred edge on request or an almost burr free slitted edge. Oscillated bundled coils of max. 1,5 ton out of several single cuts are also possible. The size range available for the Thenox® product is 0.05mm-1.5mm with widths of 3.0-650mm.

Flat wire, profiles (solid sections) and narrow strip produced by Theis are manufactured by annealing and rolling of wire rod feedstock or our of

<..... continued from page 10

continued on page 12 .....>

INDUSTRY NEWS

www.britishmetalforming.com12

narrow slitted cuts. For flat wire thicknesses of 0.15-5.0mm with a width of 1-20mm, whilst narrow strip is available in thicknesses of 0.05-5.00mm and widths of 4-50mm. Many profiles are available from simple regular shapes to quite high sophisticated and intricate designs. Products can be supplied as hard rolled, annealed and finally rolled, and as hardened and tempered material. A number of surface finishes can also be specified such as polished bright, yellow, brown or blue. These products find many and diverse applications.

As one would expect of a leading manufacturer, the Theis factory has the approval to international standards for its quality and environmental procedures, processes and products. All processes are based on a qual-ity management system and are certified after TS 16949, EN 14001 and EN 50001. Theis is a company that truly aspires to its vision of “Steel. Excellence. Passion.”

BGS TEELS LTD., based at Eyam in Derbyshire, bring a wealth of ex-perience gained in the steel industry and serving the metal forming industry. Commercially they are second to none and are known for their business approach in providing customer service and care. BGSteels

have recently strengthened their team with a combination of youth a nd experience to further reinforce the founders Bryan Hague and Graham Aldrich. The youth comes in the form of Hague’s son “BJ” who brings I.T. knowledge and marketing support to the company. The ex-perience is from David Thorpe who is responsible for developing the technical arm of the business. These changes coincide with the launch of a new website www.bgsteels.co.uk which gives details of all the prod-ucts that are available from the companies that BG Steels represent in U.K. and Ireland. The website gives details of a free technical consultancy service which is now available to customers and potential customers.

BG Steels look forward to continue to serve their customers as the U.K. and its manufacturing industry embarks on a brighter future with growth being very much a reality after the dark years of recession.

<..... continued from page 11

www.britishmetalforming.com 13

INDUSTRY NEWS

• PaulDenning

In-Comm's£235,000investmentdeliverstrainingacademyIn-CommTrainingandBusinessServiceshasspentover£235,000oninst-allinganewhydraulicsandpneumaticssectionandalivecomponentsboardthatprovidesreal-lifescenariosforbuddingmaintenanceandsectorspecificengineers.IthasinstalledasixbayweldingsectionandacquiredCNCandCAD/CAMtrainingsimulationpackages.Thefirmhasalsobuiltadedicated150squaremetreForkliftTruckCentreacrosstheroadfromitsacademyinAldridge.ThiswillprovideRTITBaccreditedtrainingformorethan250peopleeveryyearincounterbalance,narrowaisle,reachandmobileelevatedworkplatforms.“Ourworkshopisnowoneofthebestequippedintheregion,”saidGarethJones, operations director for In-Comm Training and Business Services.“Industryknowledgeandtheprofessionalsweemployhavealwaysbeenbigsellingpointswithclientsandwegenuinelybelievethesenewfacilitieswillstrengthenexistingrelationshipsandhopefullyleadtonewopportunities.“Thisinvestment–believedtothebiggestinmorethanadecade–willhelpusoffertrainingtomoreapprenticesandadultlearnersthaneverbeforeandputsusinaperfectpositiontodevelopindividualsforworkintheautomotive,aerospace,highvaluemanufacturingandmedicalsectors.”Headded:“Thisisalreadyworking,with£250,000ofnewcontractssecured.”

www.in-comm.co.uk

Embrace the CAFE society or risk getting left behindBy PaulDenning,CBMProjectManager

I recentlyattendeda fascinatingconference focusingon theuseof light-weightmaterialsbytheglobalautomotivesector.Companiespresentforthetwo-dayeventincludedAstonMartin,Ford,GM,Honda,JLR,Lotus,McLaren,MercedesBenz,PSAPeugeotandTesla,sothediscussionsofferedacomprehensiveandintriguinginsightintothecur-rentandfutureactivitiesoftheworldofcarmakers.IknowthatmanyCBMmembersarealreadyengagingwiththeOEMsand1stTiersuppliers,literallyformingthefutureofourindustry.There are challenging targets ahead though, not least the new fuel con-sumptionstandardstoreduceCO2emissions,knownasCAFE(CorporateAverageFuelEconomy).IntheUS,thebenchmarkwillbeatleast54.5mpg(USgallons)by2025,whilstinEuropethetargetis45MPGBY2018.Already,OEMsareresearch-ing-andinmanycasesputtingintopractice- lightweightalternativestoconventionalmaterials,toreducevehicleweightandimproveperformance.Theoverridingmessagefromtheeventwasthatifyouareaconventionalformingcompany,workingintraditionalways,youmustrealisetheworldischangingandunlessyouchangewithit,youwillbeleftbehind-awarningwhichappliesnotjusttotheautomotivesector,buttoallindustries.Theseminarwasheavilybiasedtowardsbodyshells,andmostpresenta-tionswere about alternatives to steel body panels, including aluminium,magnesiumandcomposites.Equally, there were also presentations by steel producers, determined toprovesteel isnotdestined for thescrapheap,andpointingout that theycanalsoofferlightweightsolutions,withhighergradeoptionsandthinnergauges,atmuchlowercosttothemoreexoticmaterials.Historically,whencompaniesreceiveddrawingsfromcustomerstheauto-maticreactionwastoconsiderthecheapestsolution,includingthecostofnewpartsonmachinesfromtheirownproductionfacilities.Today though, the first thought should be to think how the componentcould be made lighter, yet still perform to the spec, which means both

Top executives from some of the world’s leading companies – including Rolls-Royce, Siemens and Pratt & Whitney – will be giving keynote presentations at this year’s Subcon exhibition.Following on from its very successful launch at last year’s show, thisyear’sconference,whichisfreetoattendandorganisedbyTheEngineer,takesacloselookatthehottopics,bigideasanddisruptivetrendsthataredrivingtheengineeringandmanufacturingagenda.These include Industry 4.0, energy storage, advanced manufacturingtechniquesforjetengines,andtheUK’smostambitious,game-changing,and possibly most controversial infrastructure project, the HS2 high-speedrailline.Subcon,which runs from3 to5 June at theNEC,Birmingham, is theUK’s national subcontracting, advancedmanufacturing and technologyexhibition.Itcoverseveryaspectofoutsourcedmanufacturingservicesandtechnologyfromdesignandprototyping,machining,moulding,3Dprinting, fabrication, composites, electronic assembly and finishing tosoftware,testing,inspectionandmetrology.Thisyear’seventissettobethebiggestyet,withover300subcontractorsexhibitingandastrongerthaneverparticipationbyUKexhibitors.ThelatestspeakertobeconfirmedattheconferenceisDrAlanEpstein,Pratt&Whitney’sVice-President,Technology&Environment,whowillbeflyinginfromtheUStospeakonnewtechnologiesfortoday’scutting-edgejetengines.Other keynotes include: Siemens’ Divisional Director for IndustrialAutomation,BrianHolliday,explainingthewhat,whyandhowofIndustry4.0;DavidClarke,ChiefExecutiveoftheEnergyTechnologiesInstitute,lookingattheoptions,challengesandprizeofenergystorage;StephenBarr,HeadoftheManufacturingAdvisoryServiceonReshoreUK,andtheTechnicalDirectorofHS2Ltd,AndrewMcNaughton.Tofinishonaparticularlyhighnote,thefinalkeynotespeakerisHamidMughal,HeadofGlobalManufacturingatRolls-Royce.Alongside the keynotes, ‘show and tell sessions’ focus on inspiringprojects, includingthedesignofanewlifeboat, theapplicationofhightechnology to performance sport and the recreation of a lost iconicaeroplane, the Bugatti 100p.More details will be released in the nextfewweeks.

buyers and manufactures thinking differently.Excitingisn’tit?The challenge for all companies is to innovate,and to minimise the use of natural resources.Thosewhocandemonstratewaystosaveenergyandweightfortheircustomerswillbethedriversinindustry.TheCBMwill,ofcourse,continuetoguidemem-berstowardnewtechniquesandprocesseswhichcancuttheirenergycosts,anddeliverbenefitsfortheir customers, not least through our evolvingpartnershipwiththeAdvancedFormingResearchCentre.

Hot topics,top speakersSiemens, Pratt & Whitney, HS2, Rolls-Royce to speak at Subcon

To register for the Subcon 2014 exhibition and to book your free places for conference sessions of your choice please visit

www.subconshow.co.uk

www.britishmetalforming.com 15

FASTENER

EurostatdataforfastenertradeEurostat has recently published the full year trade data for 2013, which gives details of imports into and exports from the EU 27 nations. The data that relates to fastener trade has been extracted in the chart below. Data for CN code 7318 was extracted, and this includes threaded parts such as bolts, screws, studs, nuts, screw hooks and screw rings, and non-threaded fasteners such as washers, rivets, cotters and multi-component parts. Only steel and stainless steel parts are included, and the data below applies to the six national trade association members of EIFI.

2013 France Germany Italy Poland Spain UK TotalNational production 220 871 643 125 106 86 2,051National Imports 295 732 181 186 164 274 1,832Imports from China 19 57 34 31 20 36 197National Exports 161 723 399 68 101 63 1,515Domestic Demand 354 880 425 243 169 297 2,368

All figures in thousands of tonnesDemand = production + imports - exports

Although data for national production is not yet available, an estimate of domestic demand has been made using 2012 pro-duction figures, to give some impression of the size of the fastener market in each country. While the UK is fourth in terms of market size, the market demand is mostly satisfied from imports. This contrasts with Italy, where they produce far more than their domestic demand, and Germany, the biggest market, where they manufacture about ten times more fasteners than the UK.

Comparing the change in market size between 2012 and 2013, the UK appears to have experienced the greatest increase, at 9%, while Spain’s market showed a 12% reduction.

2013 France Germany Italy Poland Spain UKDemand -2% 0% -1% +4% -12% +9%Total imports +1% +2% +7% +5% -3% +10%China imports 0% -4% +1% +5% +4% +2%

Much of the UK market’s increase in demand was satisfied by an increase in imports, with total imports rising by 10%. Imports from China rose only a small amount (2%), which shows the continuing effect of the EU tariffs that have been applied to selected products from China over the last five years. These tariffs are currently under review, and it may be expected that there will be a change in the supply market if the tariffs are cancelled.

2013

www.britishmetalforming.com16

FASTENER

www.britishmetalforming.com 17

FASTENER

For more informa on please contact Brooks Forgings LtdTel: 01384 563356 or Fax. 01384 563357Email: [email protected]: www.brooksforgings.co.uk

Product Development - The use of ForgedExo c Materials for Weight Reduc on

Many industries worldwide demand the use of exo c materials, carefullyselected and used to manufacture components requiring reducedweight, increased strength or resistance to both chemicals and extremetemperatures.

The forging of these materials requires a refined and temperaturecontrolled manufacturing process, something Brooks Forgings are in theprocess of tes ng and implemen ng into thier in-house forgingprocesses.

The product development department prepared a trial scenario, toinves gate the suitability of exo c materials to achieve an overall weightreduc on of an exis ng assembly. A component commonly forged insteel was selected and trials were conducted using tanium andaluminium.

Forged from steel, the component weighs 1313.5g and accounts for 55%of the total assembly weight. Steel is used where there is a need for ahardened material and strength is more important than weight, howeverit rusts, stains and is heavy.

Titanium offers high strength, low weight and has high resistance to arange of industrial chemicals including acids, alkalis and water. It alsooffers the same strength and is more thermally stable than steel. In

tanium the component weighs 798.5g, offering a weight saving of 40%.

Aluminium is extremely lightweight and like tanium is resistant to rustand numerous chemicals. Three mes weaker than steel, its suitabilitywithin its final applica on must be seriously considered. In this materialthe component weighs 512g, a weight saving of 36% over tanium andis 61% lighter than steel.

In conclusion, a er successfully forging the component we were able toestablish that tanium would safely offer a superior product with a 40%reduc on in weight. Aluminium, although offering a 61% weightreduc on, wouldn’t be a suitable material for the final applica on.

FastenerswithbenefitsGESIPA® says that its blind rivet nut studs with coarse threads create the basis for fast and easy assembly pro-cesses with the benefit of being able to be used again and again.Industriallarge-scaleproductionrequiresshortprocesscyclesandahighlevel of efficiency. For fast and easy assembly of plastic parts withouttoolingequipment, the industryusesspecial threads in fir-tree form forfixing.Thistechnique-fir-treeclipassembly-hastheaddedprotectionofstoppingturningandthebenefitofrepeatableuse.GESIPA®pointsoutthatitsblindrivetnutsstudswithcoarsethreadhavetheadvantagesof aneasyand fast assemblybyone-wayaccess to theposition, no thermal influences to the parts as well as no emission ofheatandweldinggasreleasedintotheenvironment.Thismeansthatthereisno reworkoperation requiredafter thesettingof thespecial fastener.

TheGESIPA®fastenerisalsotheidealsolutionifrepairisneededbecausetheappliedpartissurfacefinished.TheGESIPA®blindrivetnutsstudswithcoarsethreadcanbesetwiththeestablishedGESIPA®toolsforblindrivetnutsandstudsusingaconversionkitmakingthissystemveryflexibleandefficient.Typicalapplicationsattheautomotivesectorarethefixingofplasticnuts,plasticcableholderorholderforpipes,hosesandwires,theautomotivecarpetandsmallorlightassemblypartslikethefusebox.

[email protected] www.gesipa.co.uk

FORGING

www.britishmetalforming.com 19

Email: [email protected]

SUPPLYINGLUBRICANT TECHNOLOGIESTO THE FORGING INDUSTRY

UK Agents for James Durrans & Sons Ltdwww.durrans.co.ukwww.durrans.co.ukrans co uk l l d

UK Agents for Jd k

The James Durrans Group has been supplying lubricant technologies to the forging industry for over 15 years and have recently enhanced our in house manufacturing facilities by the commissioning of new ‘start of the art’ equipment.

Backed up by our in house laboratory,research and development facilities, we can offer the forging industry all forms of lubricants.

Furthermore our excellent new facilities and our considerable experience in carbon processing technologies enables us to now offer clients bespoke product solutions to suit their particular needs.

COLD ROLLED

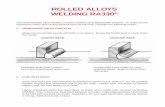

Themain aims of its author, Ray Roberts, are to provide objective adviceaboutoperationalissues,andtoofferpracticalsolutionswhichwork-not

thetheoreticalmumbo-jumboweoftenseefromacademics,whoseemobsessedbytheformulaewhichimpactontheroll-formingprocess.I’msureweallunderstandwhyhedecided towrite this500pagehandbook,because manufacturing cold-rolled products, especially in the constructionindustry,hasforfartoolongbeenabouttrialanderror,wastingmuchtimeandmoney,andcausingconsiderablefrustration.Foryears,itdidn’tmatterifyouwereontheshop-floor,orinmanagement,itwasverydifficulttofindaccurateandtimelyanswerswhenproblemsarose.Itwas equallyhard to find independentopinions about the respectivemeritsof different equipment, because so often the only available detail came frommanufacturers,ortheiragents.Ofcourse,thearrivaloftheinternetmeansmanyarticlesaboutourindustryarenowavailableattheclickofamouse,butalltoooften,Ifindtheylackpracticaldetail.For example, youcan findmuch informationabouthow todesigna formingroll,butwillfinditdifficulttodiscoveranythingabouthowtostopamaterialrippling,markingorstripping.

However, this handbook is based ondecadesofshop-floorexperience,anddesignedtobenefitpeopleatthesharpendofourbusiness;offeringinsightsinto day-to-day challenges facedby everyone, from absolute beginnersto more experienced and knowledgeableindividuals.Itcoverstheverybasicsfornewrecruits,informationforthosefacingeverydayproblems,andthoseindividualsneedingtostartnewprocesses,ornewproducts.Otherfeaturesaredesignedtohelppeopleexpandtheirknowledgeaboutroll-formingprinciples,aswellasaboutdifferenttypesofmaterials,products,andformingmethods-suchascrimpandsmoothcurving.

If you are interested in purchasing the handbook, or would be interested in reading a specific article online, by subscription, please contact me at [email protected]

or ring me on 0121 601 6350.

THE COLD ROLLED PROCESS HANDBOOK by Adrian Nicklin

I’ve been in the metalforming industry for more than 38 years, and I must say, I wish this book had been written a long time ago. It could certainly have prevented me and many others from making basic mistakes, and saved us all much time and wasted effort.

www.britishmetalforming.com 21

SHEET METAL

1. IntroductionMetalformingtoolsuccessreliesonoptimizingasmanyvariableswhichaffectitsperformance.Operatingconditionssuchasappliedloads,abrasiveenvironments,variationinproductionmaterials,andimpactwilldeterminethelifeofatool.Withavarietyandtechnicalvariationofbothproductionmaterialsandtoolsteelsusedinmanufacturing,itcanbecomplicatedtoselectofthebestmatch-ingtoolsteelforacertainapplication(piercing,punching,die,croppingetc).Tool steels (i.e.D21.2379)weredeveloped in the early1920’s andeven todaymany tools forstampingand formingaremadeof1.2379(D2)or1.3343(M2)whichmosttoolmakersarefamiliarwith.Thesesteelshavebeenestablishedovertheyearsandaregenerallygoodmaterials for lowvolume, low tensilestrengthmaterials. However, these older conventionally produced steels sometimescannotprovidethelevelofperformancerequiredforhighvolume,highertensilestrength(difficultsteelsorgeometries)parts, fineandtolerancesensitive.Whenlongerproductionrunsarerequired,lessregrinds(lowermaintenancecosts)andreductionofdowntimethenitistimetolookatthehigheralloyedCPM(CruciblePowderMetallurgy)toolsteels.

2. Properties of tool steelThemostimportantpropertiesofcoldworktoolsteelsarehardness,hardcarbides,carbidestructureandtoughness.It isimportanttohavethecorrecthardnessforresistance to deforming and the tool requires toughness to reduce or eliminatechippedorbrokentools,andofcoursehardcarbidestoofferthetoolwearresistancetoprevent abrasion.Thehardness itself isnotmuchaffectedby theproductionmethodofthetoolsteel,butbothtoughnessandwearresistancearebecausethesepropertiesarerelatedtothecarbidestructure.Typical carbide formers in tool steel are chromium,molybdenum, tungstenandvanadiumwhichdifferinmorphology(form,shapestructure),sizeandhardness.Whilechromiumcarbidesusuallyarerelativelylargeandshowahardnessof65-70HRC,vanadiumcarbidesareverysmallandmuchharder(80-85HRC)[Tarney,E.1997].Thesecarbidesarehardercomparedtothesteelmatrixaroundthemandpreventthematrixtobewornoutinservice.Steelswithahigheramountofcarbidesorhardercarbideshaveabetterwearresistance.Nevertheless,aninhomogeneousdistribution or a disadvantageous morphology of the carbides may impairtoughness.Thisfactlimitstheamountofcarbidesinthetoolsteelandisaffectedbytheproductionmethod.Theconventionalproductionoftoolsteelsisprocessedinlargeingotsandhasaslowsolidificationprocesstendingtohavepoormechanicalqualitieswithahightendencyforthecarbidestogrowandsegregate.On the other handPM-technologymanufacturingmethods compensate for thiseffectandduetotheatomizationofthemelttheingotsizeisextremelyreduced,leading to a very fine and homogenous microstructure which does not onlyimprove wear but shows an improved toughness (no grain flow) comparedto conventional tool steel. Figure 1 shows a comparison of these two typesofmicrostructure.

Figure 1: Comparison of a non-homogeneousmicrostructure (conventional production on the right) anda typical PM-microstructure on the left is very uniform with sperical carbides as well as being extremelyhomogeneous.

3. Reduce maintenace cost by selecting a better tool steel for your applicationToolmakingdesignersortoolmakersneedtoconsiderthestrengthandthicknessof thework (component)material and the compressive strength the toolhas to

Metal Forming tool users benefit from CPM steels and reduce maintenance costsBy: RickLowe,Dr.-Ing.EvelinRatte

endure.Additionally,a thicksteelcomponentmaterialrequiresparticularlygoodtooltoughnessbecauseofhighloadsofthepress.Whenthinkingaboutproductionmaterialswithhighductilitywhichisneededwhencomplexpartsareformedleadtolongformingpaths.Theselongmovementsalongoneflangeof thetoolmayeasilywearoutthesurfaceandrequireabetterwearresistanceofthematerialwhichasfigure1demonstratesbythelargeamountofsphericalandplentifulcarbidestoincreasethewearresistance.Fortoolsrequiringahighresistancetoplasticdeformation,wemustlookatthehardnessasitisthepropertytooptimize.Stampingtoolsusuallyrequireaminimumhardnessof58-60HRC.Incasethathighstrengthmaterialismanufacturedandahigh resistance toplasticdeformation is requiredHSSsuchasCPM®RexT15or CPM® Rex 76® which approach 68 HRC are suitable inmany applicationsandoutperformsoftertoolsteelssuchas1.2379at60to62HRC.Nevertheless,increasingthehardnessofaconventionalsteelisnotgenerallyaneffectivemethodtoincreasethewearlifeoftools.Thereforewhen a higher wear resistance is required the carbide volume needstobeashighaspossiblewithoutimpairingthetoughnesstoavoidchippingandbreakage. In thiscase,all thechoices forupgradingwill involvePMsteelswithhighercarbidecontent[Stasko,o.J.].D2has15,5volume-%ofcarbideswhichbecauseoftheirsizeanddistributiontendtoreducethetoughnessofthesteel.ItcaneasilybeupgradesbyusingCPM®RexM4,CPM®10VorCPM®15VwhichshowahighervolumeoffavourablevanadiumcarbidesandthusaremorewearresistantthanD2(figure2).Whentoolschiporbreak,becauseoffrailgeometriesorsharpnotches,highimpacttoughnessisrequired.SteelsliketheCPM®3Vshowanoutstandingtoughnessadvantageandareusedwhenothersteelsarepronetobreakage.Ingeneral,even those toolsteelswith the lowest impact toughnessare tougherthan carbide. Nevertheless, the toughest tool steel cannot compensate for adisadvantageousgeometrywithnotches,undercuts,sharpcornerswhichalltendtoleadtoastressconcentrationinthisareaandeventuallycrackingorchipping.

Figure 2: Optimizeyourprocessandchoosetherighttoolsteel!

4. ConclusionsCompared to conventional tool steelsPM-steelshave an advantage to increaseandextendtoollifeespeciallywhenworkingonhigh-strengthcomponentsteelsordifficultgeometries.Dependingonthehardness,toughness,andwearresistancerequiredthereisnormallyaCPM®productcanbeusedtoimproveyourproductivityandsavemoneyonmaintenancecosts.

5. ContactRickLowe Dr.EvelinRatteSalesManagerUK TechnicalManagerToolingAlloys [email protected] [email protected]:+4407979954111 Phone:+4921027107181Fax:+44(0113)3411837SalesOffice(Sven):FREEPHONE0080092774624

References[Tarney, 1997]Tarney,E.;Selectinghighperformancetoolsteelsforcold-formingapplicationsin:ProceedingsofColdForminh,February19-20,1997,Detroit,Michigan.

[Stasko et al.]Stasko,W.;Particlemetallurgycoldworktoolsteelscontaining3-18%Vanadium.

www.britishmetalforming.com22

SHEET METAL

New dedicated manufacturing unit established for vacuum brazingSurface engineering specialist Tecvac has established a dedicated cellforproductionofcomplexcomponentsbyvacuumbrazing.Theunitis

designedtobraze‘one-off’anddevelopmentcomponentsbutalsohasthecapacitytoproducehighvolumesofcommercialpartsusingvacuumfur-nacesofvaryingsize.Tecvaccurrentlyprovidevacuumbrazingservicestokeytechnologysectorssuchasaerospace,motorsport,medicaldevices,instrumentation,vacuumequipmentandtheoilandgassector.“Wehaveahighlyskilledteamwhoareabletoassemblethemostintricatecomponents,comprisingscoresofparts,withprecision.Joiningundervacuumrequiresnofluxandthepro-cessiscontrolledsothatthefinishedassemblesproducedarecleananddi-mensionallyaccurateeverytime,requiringnofurtherfinishingoperations,”explainedsitedirectorSimeonCollins.Mostcommonlyusedforjoiningmetaltometalcomponents,brazingcanalsobeusedtojoinmoreexoticmaterialssuchasceramicsandcarbides.Brazingwillsatisfactorily joindissimilarmetalssuchascopper,stainlesssteelandtitanium.All jointsarefreefromsurfaceoxidationandthereforehave high strength, often greater than that of thematerials being joined.Brazed jointsareductileandsocomponentsperformreliably,evenwhensubjecttoshockandvibration,retainingtheirstrengthandremainingleakproof.Itispossibletocombineheattreatmentssuchassolutiontreatmentorhardeningduringthebrazingprocessleadingtoreducedleadtimesandtotalpartpricereduction.

• Joiningundervacuumrequires noflux.Intricatecomponents, comprisingscoresofparts,are vacuumbrazedwithprecision andneednofurtherfinishing

• Tecvacoperatedmetallurgical laboratorieswithinanISO9100 aerospace-standardquality assurancesystem

EachprojectiscarefullyevaluatedandTecvacselectbrazematerialsandde-velopabespokeprocessforassembly,furnacecontrolandfinaltestingthatareappropriatetotheneedsofthecustomer.Withextensivemetallurgicallaboratoriesandoperatingan ISO9100aerospace-standardqualityassur-ancesystem, thecompanycandeliveraqualityproductevery time.Theyalsowelcomeindividualcompanyinspectionandaccreditation.More InformationSimeonCollins,SalesDirectorTel:+44(0)1617979111E-mail:[email protected]

• Vacuumfurnacesofvaryingsizes areavailabletohandletheneeds ofaerospace,motorsport,medical devices,instrumentation,oiland gasandprecisiontehnologysectors

• Designedtobrazeone-off developmentcomponents, Tecvaccanalsoscaleup toproducelargerquantities ofcommercialparts

www.britishmetalforming.com 23

FINANCE

The FRC has issued three new accounting standards; FRS 100, FRS 101 and FRS 102, that will have an impact on companies reporting in the UK and the Republic

of Ireland who do not choose to adopt EU International Financial Reporting Standards (IFRS) or are not entitled to, or do not choose to follow, the FRSSE (Financial Reporting Standard for Smaller Entities). These three new standards form the basis of the New UK GAAP, moving UK financial reporting towards an IFRS based framework.The effective date for implementation of FRS 100, FRS 101 and FRS 102 is for accounting periods beginning on or after 1 January 2015.An entity applying FRS 102 or the FRSSE will continue to apply a Statement of Recommended Practice (SORP) if required or relevant. The SORPs are currently being revised in light of the New UK GAAP release.

What will the presentation cover? • AnintroductiontoFRS100,101and102• ThenewUKFinancialReportingRegime• Implementationdates• AreviewofeachtheFRSscomparedto current UK GAAP• Applicationandguidance

When: Birmingham, Friday 4 July 2014

For more information please contact the CBM on: 0121 601 6350

AreyoureadyforthenewUK Generally Accepted Accounting Principles (UKGAAP)?The CBM auditors, Chantrey Vellacott, are presenting a series of complimentary seminars that will focus on the three new accounting standards issued by the Financial Reporting Council (FRC). They will go into detail about the standards and how they will affect your current financial statements.

The 18th Congress of the International Council of

Sheet Metal Presswork Associations (ICOSPA)

is taking place

26-30 October 2014 IN STRASBOURG AND PARIS

An opportunity to make valuable contacts for your company and connect with your international counterparts.

For all information please contact Catherine LARROQUE - [email protected]

SHEET METAL

www.britishmetalforming.com24

BUSINESS SUPPORT

In business, as in society, there are many misconceptions about disabled people, mainly driven by the negative image of us in the media. As employers we are all concerned about saving money, and employing disabled people can feel like an expensive luxury. However, the reality is somewhat different, and interestingly, company surveys consistently conclude that organisations who have successfully employed disabled people are keen to employ more.

Let’s look at the commercial side. There are more than eleven million disabled people in the UK with spending power up to £80 billion a year. Employing disabled people, understanding disability and generally having a proactive attitude towards disabled customers could be hugely rewarding to your organ-isation’s bottom line.

Also, it is much, cheaper to retain a staff member who has become disabled than try to recruit someone new. The Post Office estimates that medically retiring an employee can cost around £80,000.

From purely a recruitment point of view, if you positively seek to attract applications from disabled people you will have a much wider choice of potential employees with a good range of skills and a positive attitude towards work. Many studies (sources available on request) show that on average disabled employees are just as productive as their non-disa-

bled colleagues (sometimes more so), have less time off sick, fewer workplace accidents and stay with their employers longer, increasing retention and saving money on recruiting and training new staff. Showing a positive approach towards disability also tends to foster good relations with other staff and generally enhances your reputation as an employer of choice.

So all in all, employing disabled staff is a good commercial de-cision. However, it can be difficult to attract talented disabled people, and that’s where Evenbreak comes in. Evenbreak is an award-winning not-for-profit job board run by disabled people for disabled people. Inclusive employers advertise their roles there confident that they will attract talented disabled candidates they probably won’t attract from any other source. Have a look at us on www.evenbreak.co.uk, call us on 0845 658 5717 or email us at [email protected] to find out more.

Shockingly, some employers still think that disabled people have nothing to offer – perhaps they should try telling that to Stephen Hawking, Albert Einstein, Alexander Graham Bell, Winston Churchill, David Blunkett and Richard Branson.

Author bio:Jane Hatton M.Sc. FCIPD FITOL is the Founder and Director of Evenbreak (www.evenbreak.co.uk) and runs Even-break lying flat with a laptop suspended above her due to a degenerative spinal condition. Evenbreak lives what it pro-motes, and only employs disabled people.

It’s a cliché, but still true that for most businesses their people are not only their most important asset, but also their most expensive. Recruiting and retaining the best people who are equipped with the right skills needed to do the job can take up much time in an employer’s life. As 20% of the working population are disabled, and eight out of 10 disabled people acquired their disability during the course of their working life, the chances are that disability is an issue that you will come across in your company.

Commercial benefits of employing disabled people

• StephenHawking

• JaneHatton

www.britishmetalforming.com 25

BUSINESS SUPPORT

A Redditch based presswork supplier to the automotive sector has won an HMRC tax credit thanks to Wolverhampton R&D tax specialists R&D Tax Claims Ltd.

AEOscroftandSonsLtdreclaimed£75,745undertheR&Dscheme.Thefamily business was started by Arthur Oscroft in Redditch in 1947. Thecompanyspecialises in low tohighvolumemanufacturingandassemblyas well as robotic MIG welding, resistance welding, precision machineprocesses,platingandcoatingforaglobalmarket.“Mygranddadusedtomakeandfixthings”,saysmanagingdirectorChrisOscroft.“ItwastowardstheendofWorldWarTwo,andGranddadusedtodrive a Type35modelBugatti. It belonged to a local vet, andGranddadmadereplacementparts for it inhisgardenshed.Hisday jobwasat theAustinmotorcompanyinLongbridgeandhisshedbecamewhatwewouldnowcallasmallR&DfacilityforAustin.Hestartedtodooddjobsforothercompanies,thenin1947heinstalledapowerpressintheshedandhewasaway,makingpartsforTriumphCoventryandlaterLandRover.“MyfatherChris,nowChairman,andhisbrotherIan,carriedonfromhimandIstartedhere20yearsagototakingthebusinessforwardwithmycousinsTimOscroft andGuyOscroft.Wemakemetalpressings, assemblies andprototypeprojectsinadiverserangeofmaterialsforallkindsofindustriesandofferR&Dassistanceinproductdesignanddevelopment,sharingourknowledgewithcustomersfromconcepttofullproduction.”The company recently relocated to a 53,000+sq ft site in Washwood,Redditch,investingalmost£2minthemove.“OurbiggestclientisSpanishchassismanufacturerGestamp,andmuchofourworkgoesintoHonda,JLR,Nissan,RenaultandToyota”,saysChris.

R&DTaxClaimsLtdconsultantPeterRoachhandledthereclaimprocess.“I’veknownPetersincehewasanadviserwithMAS”saysChris.“Iknewaboutthetaxreclaimschemebutweweresobusyworkingonthebusinesswedidn’thavetimetoinvestigateit.PeterwasquicklyabletoidentifytheR&DelementofourworkandtodefinetheR&DstagesofourprocessestodocumentforHMRC.HeisnowhelpingustorecordourR&Dactivitygoingforwardandcontrolitwithinourmanagementsystems,sofuturereclaimingbecomesaseamlessprocess.PeterhasbeeninvaluabletousandpeoplelikeMASandR&DTaxClaimsarepartofthereasonwe’reheretoday.”AEOscroftreclaimed£75,745overtwoyears.“Themoneywillbereinvestedinthebusinessbecauseofincreasingorders”,saysChris.“Manyfirst tiercompaniesrelyheavilyoncompanieslikeAEOtodotheR&Dfor them”,saysMarkEvans,managingdirectorofR&DTaxClaims.“Second tiers takeonmuchof the time,effortandriskand for theUK tocontinuetoberecognisedasaleaderintheautomotivesector,ourSMEsneedsupport.Thisschemeisaperfectexample.”MarkEvanssaysthatSMEsarestillslowtotakeupR&Dtaxcredits.“R&Dis about risk taking and tax creditsgivebusinessowners the confidencetotakethatrisk.Smartbusinessesbuilditintotheirbusinessmodelbecausetheyknowthey’llgetitback,evenforfailures.”

www.rdtaxclaims.co.uk

Automotive manufacturer reclaims over £75,000 in R&D tax credits

• Left to right: ChrisOscroft,managingdirector, AEOscroftandSonsLtd(AEO)MarkEvans,managing directorR&DTaxClaimsLtd

www.britishmetalforming.com 27

HEALTH & SAFETY

SUBSTANCES OF VERY HIGH CONCERNUPDATE APRIL 2014

Authorisation List for SVHCsThere have been no additions to the Authorisation List over the last few months, so it remains at twenty two substances. Also, no chem-icals have been prioritised for inclusion in this list since June 2013.

Sixteen more applications for authorisation to use substances from the Authorisation List were posted by ECHA. The additional sixteen are out for public comment, with a deadline of 8th April 2014. They concern the use of three of the chemicals on the Authorisation List in various different processes.

To date there have been a total of twenty four such applications. The first of these was from Rolls Royce for use of the phthalate DEHP, and ECHA made a positive recommendation to the EC to allow its use. Rolls had analysed alternatives and showed how it plans eventually to substitute the substance. ECHA is now working on the next seven applications, and has received more than 120 comments from third parties during the consultation period.

Candidate List for SVHCsThe Candidate List now contains 151 chemicals, seven additional chemicals having been added in December 2013. These seven include cadmium sulphide and six organic chemicals. Only 13 sub-stances were added to the Candidate List during 2013.

Four new substances have been proposed as SVHCs, and are currently out for comments with a deadline of mid-April. These include cadmium chloride and two types of sodium borate salt.

We only hold these events four times a year; so there will be lots of new information and analysis from the last quarter,

as well as a look at current trends and upcoming legislation.

The most popular element of our sessions is when we get an inside steer about the Health & Safety Executive’s plans for the manufacturing sector, from one of its national inspectors.

Michael Bone is based in Newcastle-upon-Tyne, but has spent the last five years travelling the country working with management teams and safety officers in all industrial sectors, including molten metals, glass, ceramics, foundries and refractories.

The February 27th meeting offers a rare chance not only to hear a senior HSE inspector update you on his work, but to gain confidential access through a Q&A session to his thoughts, opinions and insights, so it’s an opportunity which really shouldn’t be missed.

The event - which starts at 10am and will finish at 2-30pm - is also chaired by Simon Randall, the environmental, health and safety manager for the Stadco Group.

He’s accumulated 25 years of experience working with such world-class corporates as GKN, Johnson Controls, JCB, Molson Coors and Textron, so like Michael, has much knowledge to share with delegates.

There’ll also be a discussion about our industry’s latest safety statistics, where everyone is encouraged to share their stories about challenges, incidents and successes, and an update on progress of the important Safety & Health in the Metalforming Sector (SHIMS) initiative.

For those of you taking a CPD course through the Institution of Occupational Health & Safety, the meeting will be included in your learning module.

Even if you’re not undergoing formal training, these sessions offer great networking opportunities and a chance to discuss best practice in a relaxed and informal atmosphere.

There’s parking right outside the door, the wi-fi is free and reliable, and the catering’s pretty good too, so we hope you agree there are lots of reasons for this to be a ‘must’ event.

For more information about this, or future meetings, or our H&S work in general, do please contact me via [email protected], or ring myself or my colleagues on 0121-601-6350.

I look forward to seeing you on the 3rd.

KirsiLintulaMarketing&CommunicationsManager

CBM Health, Safety and Environment Group Meeting - 3 July 2014

There is no more important day-to-day issue than ensuring a safe workplace, so I do hope you - or someone from your company - will be able to join us at our latest health and safety meeting on 3rd July.

www.britishmetalforming.com28

MANUFACTURER MEMBERS

A.M.C. UK Fasteners Ltd (: 01536 271 920 Northamptonshire NN17 5XZ www.amcukfasteners.co.uk

Alcoa Fastening Systems (: 01952 290011 Shropshire TF3 3BQ www.alcoa.com

Alcoa Fastening Systems (: 01527 525 719 Worcestershire B98 7TD www.alcoa.com

Avdel UK Ltd (: 01925 856 526 Cheshire WA1 4RF www.acument.com

Barton Cold-Form (UK) Ltd (: 01905 772 021 Worcestershire WR9 0LP www.coldform.it

Caparo Atlas Fastenings Ltd (: 0121 224 2000 West Midlands WS10 8XL www.caparoatlasfastenings.com

Cirteq Ltd (: 01535 633 333 West Yorkshire BD20 8QP www.cirteq.com

Clyde Fasteners Ltd (: 01355 225 451 Lanarkshire G74 5ET www.clydefasteners.com

Cooper & Turner Ltd (: 01142 560 057 Yorkshire S9 1RS www.cooperandturner.com

DSL Ltd (Stride Supplies Ltd Div.) (: 01902 609 004 West Midlands WV14 2JS www.designscrews.com

Griff Chains Ltd (: 01384 569 415 West Midlands DY2 0ED www.griffchains.co.uk

Henrob Ltd (: 01244 837 220 Flintshire CH5 2NX www.henrob.com

Leggett & Platt Components Europe Ltd (: 01226 707 550 South Yorkshire S27 7GH www.leggetteurope.com

Leggett & Platt Components Europe Ltd (: 01282 811 232 Lancashire BB18 6JA www.leggetteurope.com

PSM International Limited (: 01646 623 569 Pembrokeshire SA71 4RE www.psminternational.com

RCF Bolt + Nut Ltd (: 0121 522 2353 West Midlands DY4 8RF www.rcfboltnut.co.uk

Smith Bullough (: 01942 520 250 Lancashire WN2 4HD www.smithbullough.com

SPS Technologies (T.J. Brooks Div.) (: 0116 276 8261 Leicestershire LE4 9HX www.spstech.com

FASTENERS

Gesipa Blind Riveting Systems LtdWest Yorkshire BD21 4JU

• Special designed blind rivets• Rivet nut and rivet nut studs • Tooling with process control (fully automatic or manual)

: 01535 212 200 E: [email protected]

www.gesipa.co.uk

Abbey Forged Products Ltd (: 0114 231 2271 Yorkshire S6 1ND www.theabbeygroupuk.com

AKS Precision Ball Europe Ltd (: 0191 587 0000 Co Durham SR8 2PP www.aksball.com

Bedford Steels (: 0114 276 9643 Yorkshire S4 7YS www.bedfordsteels.co.uk

Bifrangi UK Ltd (: 01522 585 800 Lincolnshire LN2 5DT

Brockhouse Group Ltd (: 0121 556 1241 West Midlands B70 0SN www.brockhouse.co.uk

Caparo Forging: Europe (: 01384 252 587 West Midlands DY2 0LA www.caparo.com

Cascade (UK) Ltd (: 0161 438 4021 Greater Manchester M11 2DD www.cascorp.com

Cerro EMS (: 0121 772 6515 West Midlands B9 4DS www.cerro-ems.com

Chapmans Agricultural Ltd (: 0114 285 6000 Yorkshire S6 2FH www.chapmans-uk.com

Cramlington Precision Forge Ltd (: 01670 716 811 Northumberland NE23 1WA www.cpfl-tvs.com