330C Electrical Schematic

-

Upload

john-simmonds -

Category

Documents

-

view

227 -

download

0

Transcript of 330C Electrical Schematic

-

8/9/2019 330C Electrical Schematic

1/2

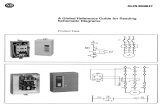

Machine Harness Connector And Component Locations

1010

66

AA

BB

CC

DD

GG

66

1

44

1111

1010

1717

FF

1212

1313

11

1111

1515

1414

HH

1313

1212

EE

44

77

7

88

88

88

99

99

99

1717

1515

2424

2424

2525

2525

2828

2828

3636

3636

3737

3737

3838

3838

3939

3939

4040

4040

4141

4141

4242

4242

4444

4444

4545

4545

4646

4646

4747

4747

4848

4848

4949

4949

5050

5050

1818

1818

1919

1919

22

22

14141616

1616

2626

2626

2727

2727

2929

2929

2121

2121

3030

3030

3131

3131

3333

3333

3434

3434

3232

3232

3535

3535

2020

2020

5151

5151

5252

5252

2222

2222

5353

5353

5454

5454

2323

2323

F

A

B

C

E

J

J

43

43

Wire

Number

Wire

ColorDescript ion

Wire

Number

Wire

ColorDescript ion

1 01 R D B at te ry + 7 63 B U T ra ve l S pe ed C ha ng e S ol en oi d

1 03 R D D om e L a mp / M em or y 7 7 9 W H L ow P re ss ur e Q ui ck C ou pl er S ol en o id

1 05 R D K ey S wi tc h 7 80 P U At ch Q ui ck C ou pl er S wi tc h

108 R D Heater 788 Y L Spped Sensor (-)

1 09 R D A l te rn at or B + T er mi na l A 74 6 P K B o os t P re ss ur e

1 10 R D Time r R el ay A7 47 GY AT M Pr es su re

1 12 P U Ma in R ela y A7 55 PK T hro tt le Po sit io n 1

1 13 O R S w i tc h P an el / R ad io A 75 6 B U T hr ot t le P os it io n 2

114 R D Horn A757 GY Thro ttle Po sit ion 3

1 15 R D C ab L am p R el ay A 75 8 B R T hr ot tl e P os it io n 4

1 18 G Y Wip er /Wa sh er A7 62 P U S pe ed Se ns or ( +)

1 19 OR N o t u se d A7 68 BU Po we r Sh if t C on t S ole no id

1 20 Y L 1 2V 1 0A C on ve rt er 1 A 76 9 G Y P ow er S hi ft C on t S ol en oi d

1 23 W H S ea t H ea te r A 77 0 P K B ac ku p R es is to r T o B ac ku p E PR V al ve S wi tc h

124 GN A/C E795 YL Oil Temperature

1 29 B U C ig ar L ig ht er F 71 6 W H S ec on da ry S hu td ow n S wi tc h

1 30 R D E ng in e C on t ro l F 77 3 O R B ac ku p G ov S w A /D T o E ng G ov A ct ua to r ( Ac ce l)

1 35 B U 1 2V M em or y O ut F 77 4 W H B ac ku p G ov S w A /D T o E ng G ov A ct ua to r ( De ce l)

1 39 O R R ad io 1 2V M em or y H 70 5 B R F u el P um p R el ay

1 4 3 B R A t ch B o om F l oa t D i sa b le R e la y H 7 9 2 B R A t ch M a rt B o om U p /D o wn R e la y 2

1 47 P U At ch S ole no id J7 02 BK A ir H ea te r R el ay

1 49 R D Bo om L amp M7 34 B R T ra ve l M od e Sw it ch

1 50 O R Q ui ck C ou pl er M 73 6 BU G ov er no r C om ma nd

1 51 G N H yd L oc k S ol en oi d R el ay M 73 7 W H F lo w L im it P re ss ur e P RV

1 52 B U L ow er W ip er / W as he r M 73 8 O R P ri ma ry N FC P re ss ur e P RV

1 54 R D N e ut ra l S ta rt R el ay M 73 9 Y L P R V R et ur n ( 2)

1 60 P U C ha ss is L am p M 74 0 P K T r av el S tr ai gh t S ol en oi d

1 68 R D A ux C kt M7 41 GY T ra ve l A la rm C an ce l S wi tch

1 69 P K B ac ku p / M on it or C on t ro l M 74 2 P U A EC M od e S wi tc h

1 72 G N P r od uc t L in k M 74 3 G N A t ch B oo m F lo at D is ab le R el ay

1 75 R D A / C B lo we r M 74 4 P K A t ch S ma rt B oo m S el ec t S wi tc h

1 79 B U 1 2V 1 0A C on ve rt er 2 M 74 5 B U A tc h B oo m C he ck S ol en oi d 1

1 80 G N A ux C kt M 74 6 Y L A t ch S ma rt B oo m U p/ Do wn R el ay 1

1 84 R D E / P C on tr ol M 74 7 P U A t ch S ma rt B oo m S w T o R el ay

1 88 W H F u e l P um p M 74 8 O R A t c h S ma rt B oo m U p/ Do wn R el ay O ut pu t

1 89 R D T im er R el ay O ut M 74 9 W H A t c h U p/ Do wn P re ss ur e S wi tc h1 96 B U I NSP L amp S ock et 8 92 BR C at D at a L in k -

199 OR B eacon L amp 8 93 GN C at Data Link +

A893 OR Atch Fuel Pump

2 00 B K Ch as si s G ro un d F 88 9 WH G ov C omma nd

2 01 B K Mo nit or Gr ou nd G 82 6 BR O il P re ssu re

2 10 B K C o nv er te r 1 G ro un d G 82 7 B U O il P re su re -

2 11 B K C on ve rt er 2 G ro un d G 82 8 W H 5 + F ro m E ng in e C on tr ol T o S en so rs

2 29 B K C on ve rt er 2 G ro un d G 82 9 G N S e ns or C om mo n

2 35 B K E /P C on tr ol G ro un d G 83 1 G Y O i l T em p + 5

A278 BK Fuel Pump Ground G833 PK Sensor Common

G849 B R HE UI Rai l P r es sur e

3 04 W H S ta rt R el ay T o M ot or S ta rt e r G 85 0 B U A ir H ea t er R el ay

3 06 G N N eu tr al S ta rt R el ay T o S ta rt R el ay G 85 4 P K C on n H EP

3 07 O R K ey S wi tc h T o N eu tr al S ta rt R el ay G 85 5 P U C on n H EP

308 YL K ey Switch ON G856 W H TDC Probe

3 10 P U S ta rt A id S w T o S ta rt A id S ol en o id G 85 7 Y L T DC P ro b e

3 20 R D H or n S w T o H or n R el ay K 84 3 G N R ig ht J oy st ic k S wi tc h 1

3 21 B R T ra ve l A la rm K 84 4 G Y L e ft J oy st ic k S wi tc h 1

3 22 G Y H or n R el ay T o H or ns K 84 7 P U R ig ht J oy st ic k S wi tc h 2

3 23 W H A tc h R ef ue li ng P um p K 84 8 W H L ef t J oy st ic k S wi tc h 1

3 25 P K A tc h R ef ue li ng S to p S wi tc h K 84 9 Y L A tc h S te m 1

3 26 R D Ke y Sw it ch O ff K8 50 BR A tc h St em 2

329 Y L A tc h Refueli ng S top Rl y To Refueli ng P ower Rl y K 851 B U A tc h S tem 3

3 6 5 Y L A t ch R e fu e li n g S t op S w T o R e fu e li n g R e la y s K 8 52 G N A t ch S t em 4

K 853 GY A tc h P um p1 Fl ow Contr ol Sol enoi d

403 GN A l t R Ter m To S er v ic e M eter A nd E /P Contr ol K 854 OR A tc h P um p2 Fl ow Contr ol S ol enoi d

4 0 5 G N E n g O i l P r es s ur e S w it c h K 8 55 P K A t ch S e pa r at e V a lv e S o le n oi d

4 0 5 G Y L o w O i l P r es s ur e O u tp u t K 8 56 P U A t ch S t em 1 C o nt r ol S o le n oi d ( A )

4 10 W H A c ti on A la rm K 85 7 W H A tc h S te m2 C on tr ol S ol en oi d ( A)

4 12 B U C oo la nt L ev el S wi tc h K 85 8 Y L A tc h S te m3 C on tr ol S ol en oi d ( A)

4 30 B U A ir C le an er S wi tc h K 85 9 B R A tc h S te m4 C on tr ol S ol en oi d ( A)

4 8 7 O R H y dr a ul ic O i l F i lt e r S w it c h K 8 60 B U A t ch S t em 1 C o nt r ol S o le n oi d ( B )

4 9 1 P K H y dr a ul ic O i l T e mp S e ns o r K 8 61 G N A t ch S t em 2 C o nt r ol S o le n oi d ( B )

4 95 G N F u el L ev el K 86 2 G Y A tc h S te m3 C on tr ol S ol en oi d ( B)

4 9 6 W H H y dr a ul ic O i l L e ve l S w it c h K 8 63 O R A t ch S t em 4 C o nt r ol S o le n oi d ( B )

A499 BU Hydraulic Tank Pressure Switch K864 PK Atch Relief 1 Solenoid

C 46 8 B U E ng O il L ev el S wi tc h K 86 5 P U A tc h R el ie f 2 S ol en oi d

E 46 9 Y L T oo l P re ss ur e S en so r K 86 6 W H A tc h 1 w ay / 2 w ay C on tr ol S ol en oi d

E 47 0 B R N eg C on t P re ss ur e S en so r 1 K 86 7 Y L P RV R et ur n ( 1)

E 47 1 B U N eg C on t P re ss ur e S en so r 2 K 86 8 B R S ol en oi d G nd 2

E 47 2 G N R o ta te S wi tc h ( CW ) K 86 9 B U S o le no id G nd 3

E 47 3 G Y A tc h S te m 1 M od ul at io n K 87 0 G N S ol en oi d G nd 4

E 47 4 O R A tc h S te m 2 M od ul at io n K 87 6 B R A tc h R el ie f C he ck 1 S ol en oi d

E 47 5 P K A tc h S te m 3 M od ul at io n K 87 7 B U A tc h R el ie f C he ck 2 S ol en oi d

E 47 6 P U A tc h S te m 4 M od ul at io n 9 94 G Y O il P re ss ur e

E 4 80 W H O v er L o ad A l ar m C a nc e l S w it c h 9 9 5 B U C o ol a nt T e mp e ra t u re

H 44 6 P K O L W D P re ss ur e S en so r 9 9 8 B R B a c ku p G ov S wi tc h

H 4 65 G N T r av e l A la r m C a nc e l I n d ic a to r C 9 6 7 B U I n ta k e A i r T e mp e ra t ur e

H 46 6 B U A EC M od e I nd ic at o r C 98 7 R D P ow er T o A tc h V al ve C on tr ol

H 46 7 W H T r av el M od e I nd ic at o r C 99 1 P K F ue l P re ss ur e

H 4 73 B R S t ra i gh t T r av e l P r es su r e S w it c h E 9 63 B K D u al C a m S p ee d /T i mi n g ( R un )

H 4 74 G N T r av e l R i gh t P r es s ur e S w it c h E 9 64 W H D u al C a m S p ee d /T i mi n g ( R un )

H 4 75 B U T r av e l L e ft P r es s ur e S w it c h E 9 65 B U D u al C a m S p ee d /T i mi n g ( C ra n k)

H 4 76 W H J o ys t ic k P r es s ur e S w it c h E 9 66 Y L D u al C a m S p ee d /T i mi n g ( C ra n k)

G976 B U Water S eparator Lev el S wi tc h

5 01 G N W ip er L ow K 90 4 G N P u mp D is ch ar ge 1 P re ss ur e S en so r

5 0 6 P U W i pe r C o nt r ol T o W a sh e r M o to r K 9 06 G N S w in g B r ak e S o le n o id

5 08 P U L H S pe ak er ( +) K 90 7 B U S wi ng B ra ke C an ce l S ol en oi d

5 09 W H L H S pe ake r ( -) L 96 8 O R P RV Re tu rn ( 1)

5 11 B R R H Sp ea ke r ( +) L 96 9 W H P S C on tro l PR V

5 12 G N R H S pe ak er ( -) L 97 2 B U O ne T ou ch L ow I dl e S wi tc h

5 3 0 O R W a sh S i gn a l ( S w P a ne l T o W ip e r C o nt ) L 9 7 3 G N F r ee S w in g

5 35 B U L ow er W ip er M ot or ( +) L 9 76 G N A tc h R ef ue li ng S ta rt S wi tc h

5 86 B R N o t U se d M 90 6 B U S te m 1 ( Sq ue ez e) P re ss ur e S en so r

5 9 0 G Y W i pe r I N T ( 3 ) ( S w P a ne l T o W i pe r C o n t) T 9 51 Y L I n je c to r 1 S o le n oi d

A537 PK Seat With Seat Heater T952 BR Injector 2 Solenoid

A579 OR Wiper CCW (Wiper Cont To Wiper Motor) T953 BU Injector 3 Solenoid

A580 BR Wiper CW (Wiper Cont To Wiper Motor) T954 GY Injector 4 Solenoid

A584 BU Wiper Cut (Wiper Cont To Window Limit Sw) T955 GN Injector 5 Solenoid

A586 OR Wiper INT (6) (Sw Panel To Wiper Cont) T956 GY Injector 6 Solenoid

A588 GN Hyd Lock Sol Relay To Solenoid T957 PU Injector 1 Solenoid

C537 GN A /C P hoto S ens or ( Y /W) To S w P anel A /C + Heater T958 Y L Inj ector 2 S ol enoi d

C538 OR A /C P hoto S ens or ( Y /G) To S w P anel A /C + Heater T959 B R Inj ector 3 S ol enoi d

C 56 9 Y L C on ve rt er T o 1 2V 1 0A S oc ke t T 96 0 B U I nj ec to r 4 S ol en oi d

E 5 54 P K A / C U n it T o A / C C l ut c h S o le n oi d T 9 61 G N I n je c to r 5 S o le n oi d

E 56 2 P U R ot ar y S wi tc h T 96 2 W H In je ct or 6 S ol en oi d

E 5 64 P K Q u ic k C o up l er S a fe t y L e ve r R e la y s T 9 67 Y L P u mp D i sc h ar g e 2 P r es s ur e S e ns o r

E 56 5 B U R ot ar y S wi tc h 8 63 0 B U At ch B ea co n R el ay

607 P K Chas si s Lam p Rel ay Output

6 15 Y L C ab L a mp

6 16 B U B oo m L am p

638 WH A tc h B eac on Rel ay Output

645 RD B oom Lam p ( S w P anel To Boom Lam p Rel ay)

646 RD Cab Lam p (S w Panel To Cab Lamp Relay )

A623 BU Chassis Lamp Relay To Diode

Accessory Circuits

Lighting Circuits

Wire Description

Ground Circuits

Basic Machine Circuits

Monitoring Circuits

Control CircuitsPower Circuits

Component Schematic

L o ca t io n

Machine

L o ca t io n Component

Schematic

L o ca t io n

M a ch in e

L o ca t io n

S en so r - O il P re ss ur e C -1 1 H

Sensor - Oi l T emp B-11 49

S e ns o r - P u mp D i sc h ar g e P r es s 1 A - 11 F

S e ns o r - P u mp D i sc h ar g e P r es s 2 A - 10 F

S en so r - T u rb O ut le t P re ss ur e B -1 1 4 5

Service Meter F-2 A

S ol en oi d - A /C C lu tc h D -1 1 5 0

S o le n oi d - A t ch 1 W ay / 2W a y C o nt r ol A - 5 3 5

S ol en oi d - A tc h B oo m C he c k 1 B -5 D

S ol en oi d - A tc h B oo m C he c k 2 B -5 D

S o le n oi d - At c h B o om Do w n L i ne Cu t O f f C - 9 D

S ol en oi d - A tc h F i ne S wi n g C -3 3 0

S ol en oi d - A tc h F l ow L i mi t A -1 2 F

S ol en oi d - A tc h P ri ma ry N FC A -1 2 F

S o le n oi d - A t ch P u mp 1 F l ow C o nt r ol A - 12 F

S o le n oi d - A t ch P u mp 2 F l ow C o nt r ol A - 12 F

S o le n oi d - A t ch Q . C. H i gh P r es s u re 1 B - 2 F

S o le n oi d - A t ch Q . C. H i gh P r es s u re 2 B - 2 F

S o le n oi d - A t ch Q . C. L ow P r es s ur e B - 2 F

S ol en oi d - A tc h R el ie f 1 B -5 3 1

S ol en oi d - A tc h R el ie f 2 B -5 3 2

S ol en oi d - A tc h R el ie f C he ck 1 A -5 3 3

S ol en oi d - A tc h R el ie f C he ck 2 B -5 3 4

Action Alarm F-2 A

S ol en oi d - A tc h S ep ar at e V al v e C -7 G

Fus e I-7,9 E Solenoi d - Atch Stem 1 Control (A) A-9 J

Horn C-2 7 Solenoi d - Atch Stem 1 Control (B) A-9 J

I nd ic at or U ni t H -1 B S ol en oi d - A tc h S te m 2 Co nt ro l (A ) A -9 J

L am p - A tc h B oo m C -2 8 S ol en oi d - A tc h S te m 2 C on tr ol ( B) A -9 J

L am p - A tc h C ab G -1 9 S ol en oi d - A tc h S te m 3 C on tr ol ( A) B -9 J

L am p - C ha ss is C -2 1 0 S ol en oi d - A tc h S te m 3 C on tr ol ( B) B -9 J

L amp - Do me G -2 A S ol en oi d - A tc h S te m 4 Co nt ro l (A ) B -9 J

M oni to r F -1 A S ol en oi d - A tc h S te m 4 Co nt ro l (B ) B -9 J

M ot or - A tc h F ue l P um p H -7 4 6 S ol en oi d - H yd L oc k C- 8 G

Motor - Starter D-11 12 Solenoi d - Injector 1 C-10 36

Motor - Was her G-7 13 Solenoi d - Injector 2 C-10 37

Motor - Wi per I-1 A Solenoi d - Injector 3 C-10 38

Panel - A/C Switch D-1 A Solenoi d - Injector 4 C-10 39

P an el - A tc h H ea te r S wi tc h D -1 A S ol en oi d - I nj ec to r 5 C -1 0 4 0

P um p - A tc h R ef ue li ng A -2 2 1 S ol en oi d - I nj ec to r 6 C- 10 4 1

R el ay - A ir H ea te r E -1 1 H S ol en oi d - P ow er S hi ft C on tr ol A -1 1 F

Re la y - A tc h B eac on G -8 E S ol en oi d - S wi ng B ra ke C- 9 G

R el ay - A tc h B oo m F lo at D is ab le I -1 2 E S ol en oi d - T ra ve l S pe ed C -9 GR el a y - A tc h Q .C . S af et y L ev er O n I -1 0 E S ol en oi d - T ra ve l S tr ai gh t C -9 G

R el a y - A tc h Q .C . S af et y L ev er P ri or it y I -1 1 E S wi tc h - A ir C le an er F -9 2 4

R el a y - A tc h Q .C . S af et y L oc k 1 I -1 0 E S wi tc h - A tc h B oo m D ow n P re s su re C -8 D

R el a y - A tc h Q .C . S af et y L oc k 2 I -1 0 E S wi tc h - A tc h B oo m F l oa t E x ch an ge D -2 A

R el a y - A tc h R ef ue li n g P ow er A -2 2 6 S wi tc h - A tc h F i ne S wi n g C on tr ol D -2 A

R el a y - A tc h R ef ue li n g S ta rt A -3 2 9 S wi tc h - A tc h O LW D A la rm C an ce l D -3 A

R el a y - A tc h R ef ue li n g S to p A -2 2 7

S wi tc h - A tc h R ef ue li ng A -4 2 0

S w it c h - A t ch F u el Pr i mi n g P u mp M o to r H - 7 4 6

R e la y - A t c h S m ar t B o om U p /D o wn 1 I - 12 ES w it c h - A t ch R e fu e li n g S t ar t ( N O) A - 3 1 8R e la y - A t c h S m ar t B o om U p /D o wn 2 I - 11 ES w it c h - A t ch R e fu e li n g S t op ( N C) A - 3 1 9Rel ay - Boom Lamp I-8 E

S wi tc h - A tc h S ea t H ea te r D -2 ARelay - Cab Lamp I-8 E

S w it c h - A t ch S t ra g ht T r av e l P r es s u re I - 1 DRe la y - C ha ss is L am p I -8 E

S wi tc h - A tc h U p/ Do wn P re ss u re B -8 DRel ay - F uel Pump G-8 E

S wi tc h - B ac ku p E PR V al ve G -2 BRelay - Horn H-8 ES wi tc h - B ac ku p G ov H- 2 BRelay - Hyd Lock H-8 E

S wi tc h - C oo la nt L ev el H -7 2 5Relay - Main H-11 E

S wi tc h - D is co nn ec t G -9 ERe la y - N eu tra l S ta rt H -8 E

S wi tc h - E ng in e O il L ev el D -1 1 HRelay - Start H-11 E

Switch - Horn I-3 CRelay - Timer I-9 ES wi tc h - H yd O il F il te r A -5 FResistor I-9 ES wi tc h - H yd O il L ev el A -4 FS en der - H yd O il T emp A -5 F

S wi tc h - H yd T an k P re ss ur e B -3 4 3Sensor - A/C Photo F-1 A

S wi tc h - J oy s ti ck P re ss u re H -3 DS e ns o r - A t ch N e ga t iv e C o nt r ol P r es s 1 A - 12 F

Switch - Key G-1 BS e ns o r - A t ch N e ga t iv e C o nt r ol P r es s 2 A - 12 F

S wi tc h - N eu tr al S ta rt L i mi t I -3 DS en so r - A tc h O LW D P re ss ur e B -2 2 1S wi tc h - O ne T ou ch L ow I dl e H -1 BS e ns o r - A t ch S q ue e ze P r es s u re B - 5 1 6

Switch - Rotary D-3 47S en so r - A tc h T oo l P re s su re C -7 G

S wi tc h - S ec on da ry S hu td ow n F -6 1 1S e ns o r - A t ch W a te r S e pa r at o r L e ve l H - 7 1 5

S wi tc h - T hr ot tl e P os H- 1 BS e ns o r - A t mo s tp h er i c P r es s u re C - 11 4 4

S wi tc h - T ra ve l L ef t P re ss ur e H -1 DS en so r - E ng in e C oo l an t T e mp B -1 1 HS wi tc h - T ra ve l R ig ht P re ss ur e H -1 DS en so r - F ue l Le ve l A -4 1 7S wi tc h - W in do w Li mi t G -1 AS en so r - F ue l P re ss ur e B -1 1 H

Switch Panel F-1 AS en so r - H EU I R ai l P re ss ur e B -1 1 4 2

TDC Probe B-11 HS en so r - I nt ak e A ir T em p B -1 1 H

Machine locations are repeated for components located close together.

A = Located inside of cab. F = Located inside of pump compartment

B = L o ca t ed i n s id e o f r i gh t c o ns o l e. G = L o ca t ed a r ou n d c o nt r ol v a l ve

C = L oc at ed i ns i de o f l ef t c on s ol e. H = B eh in d e ng in e

D = L o ca t ed u n de r p l at f or m . J = S o le n oi d b l oc k i n s id e o f p u mp c o mp a rt m en t

E = Located around relay panel.

Component Location

Connector Location

Connector Number Schematic

Location

Machine

Location

CONN 1 G-12 E

CONN 2 G-12 E

CONN 3 G-12 E

CONN 4 I-11 E

CONN 5 G-11 E

CONN 6 C-11 H

CONN 7 G-10 E

CONN 8 G-10 E

CONN 9 ET CONN I-9 E

CONN 10 G-9 E

CONN 11 A-6 F

CONN 12 D-6 2

CONN 13 E-6 D

CONN 14 E-6 D

CONN 15 E-6 D

CONN 16 F-6 D

CONN 17 H-6 1 3

CONN 18 H-6 1 3

CONN 19 H-6 1 3

CONN 20 F-5 D

CONN 21 A-4 2 0

CONN 22 B-4 5 2

CONN 23 E-4 A

CONN 24 E-4 A

CONN 25 E-4 A

CONN 26 F-4 A

CONN 27 G-4 A

CONN 28 I-4 D

CONN 29 I-3 D

CONN 30 I-3 D

CONN 31 H-3 D

CONN 32 H-3 D

CONN 33 H-3 D

CONN 34 G-3 D

CONN 35 B-3 5 1

CONN 36 B-3 5 4

CONN 37 A-3 5 3

CONN 38 A-3 2 7

CONN 39 A-3 2 7

CONN 40 C-2 2 2

CONN 41 C-2 2 3

CONN 42 G-1 B

The connectors shown in this chart are for harness to harness connectors.Connectors that join a harness to a component are generally located at or near the

component. See the Component Location Chart.

Part No. Resistance (Ohms)102-8016 Resistor: Backup 47 2.4

1 07 -7 05 6 S ole no id : F in e Sw in g ( AT CH ) 3 4. 0 0 .5

Separate Valve (ATCH)

Stem 4 Control (A) (ATCH)

Stem 4 Control (B) (ATCH)

Stem 1 Control (A) (ATCH)

Stem 1 Control (B) (ATCH)

Stem 2 Control (A) (ATCH)

Stem 2 Control (B) (ATCH)

Stem 3 Control (A) (ATCH)

Stem 3 Control (B) (ATCH)

Power Shift Control

Relief 1 (ATCH)

Relief 2 (ATCH)

Travel Straight

Swing Brake

Travel Speed

Hyd Lock

Low Pressure Quick Coupler (ATCH)

0% = 83.5 1.5

50% = 33.8 2.0

100% = 8.0 +1.0 / -0.5

Primary NFC (ATCH)

Pump 1 Flow Control (ATCH)

Pump 2 Flow Control (ATCH)

1 71 -0 18 8 S ole no id : F lo w L imi t ( AT CH ) 1 1. 5 0 .5

4I-5394 Sender: Hyd Oil Temp 6134 to 7496

Resistor, Sender,Solenoid

111-9916 Solenoid: 11.7 1.2

Component Description

19.5 2

121-1491 Solenoid: 32.0 3.2

1 63 -6 70 0 S en de r: F ue l L ev el

Solenoid:112-0090

At room temperature unless otherwise noted.

Solenoid:171-0114 11.5 0.5

Off Machine Switch Specification

P ar t No . F un ct io n A ct ua te Dea ct uat e C on tac t Po si ti on

154-0498 Air Clean er 6 35 mm H2O Normally Open

167-3466

Boom Down Pressure (ATCH)

Joystick Pressure

Travel Left Pressure

Travel Right Pressure

Straight Travel Pressure (ATCH)

490 49 kPa

(71 7 psi)

290 kPa MIN

(42 psi MIN) Normally Open

168-7557 Up/Down Pressure (ATCH) 13780 kPa MAX

(1998 psi MAX)

10335 689 kPa

(1499 100 psi) Normally Closed

Failure Mode Identifiers (FMI)F M I N o . F a il u r e D e sc r i pt i o n

0 Data v al i d but abov e nor m al oper ational r ange.

1 Data v ali d but below nor m al oper ati onal r ange.

2 Data err ati c, i nterm i ttent, or i nc or r ec t.

3 V ol tage above nor mal or s hor ted hi gh.

4 V ol tage below nor mal or s hor ted l ow.

5 Cur r ent bel ow nor mal or open c ir c ui t.

6 Cur r ent abov e nor m al or gr ounded c ir c ui t.

7 M ec hani c al sy s tem not r es pondi ng pr oper l y.

8 A bnorm al frequenc y, pul se wi dth, or per iod.

9 A bnorm al update.

10 A bnorm al r ate of change.

11 Fai l ur e m ode not i dentifi abl e.

12 B ad dev i ce or c om ponent.

13 Out of c al i br ati on.

14 P ar ameter fai l ur es .

15 P ar ameter fai l ur es .

16 P ar ameter not av ai labl e.

17 M odule not r es pondi ng.

18 S ens or s uppl y faul t.

19 Condi ti on not m et.

20 P ar ameter fai l ur es .

The FMI is a diagnostic code that indicates what type of failure has occurred.

CI D Component

0001 Inj ec tor S ol enoi d 1s t Cy l inder

0002 Inj ec tor S ol enoi d 2nd Cy l i nder

0003 Inj ec tor S ol enoi d 3r d Cy l i nder

0004 Inj ec tor S ol enoi d 4th Cy l i nder

0005 Inj ec tor S ol enoi d 5th Cy l i nder

0006 Inj ec tor S ol enoi d 6th Cy l i nder

0041 8V + P ower S upply

0042 Inj ec tor Ac tuation Contr ol V al v e

0091 Thr ottle P os i ti on S wi tch

0094 Fuel P r es sur e S ens or

0100 E ngi ne Oi l P r es sur e S ens or

0110 E ngi ne Cool ant Tem peratur e S ens or

0164 Inj ec tor P r es sur e S ens or

0168 S y s tem V ol tage

0172 Inl et A i r Tem peratur e S ens or

0175 E ngi ne Oi l Tem peratur e S ens or

0190 E ngi ne S peed S ens or

0253 P er s onal i ty M odule

0261 Ti m ing S ens or Cal i br ati on

0262 A nal og S ens or P ower S upply V oltage

0268 P r ogr am m able P ar ameter s

0273 Tur bochar ger Com pr es s or Outl et Pr es s ur e S ensor

0274 A tm ospher i c P r es sur e S ens or

0 2 86 E M S O i l L a mp

0342 S peed Ti m ing S ens or

0617 A i r Heater Rel ay

1 6 27 F u e l P u mp R e la y

1715 E ngi ne Oi l Tem peratur e S ens or 2

CI D Component

0091 Throttle Position Signal

0096 Fuel Level Sensor

0110 Engine Coolant Temperature Sensor

0167 Alternator

0168 Voltage Of The Power Supply (keyswitch)

0190 Speed Sensor

0286 Signal For Engine Oil Pressure Decrease

0374 Swing Brake Solenoid

0376 Travel Alarm

0581 Proportional Reducing Valve For The Power Shift Pressure

0586 Engine Speed Dial

0587 Feedback s ensor for the govenor actuator

0590 Engine Control

0598 Travel Speed Solenoid

0600 Hydraulic Oil Temperature Sensor

1161 Pump Delivery Pressure Sensor (Drive)

1162 Pump Delivery Pressure Sensor 2 (Idle)

1525 Straight Travel Solenoid

2002 Action Alarm

CI D Component

0145 12V DC P ower S uppl y

1522 Num ber Two Chec k V al v e S ol enoi d

1523 Num ber Two Chec k V al v e S ol enoi d

1593 E x tend S ol enoi d V alv e for Aux i ll ar y Stem 1

1594 E x tend S ol enoi d V alv e for Aux i ll ar y Stem 2

1595 E x tend S ol enoi d V alv e for Aux i ll ar y Stem 3

1596 Retr act S ol enoi d V alv e for Aux i l lar y S tem 1

1597 Retr act S ol enoi d V alv e for Aux i l lar y S tem 2

1598 Retr act S ol enoi d V alv e for Aux i l lar y S tem 3

1609 Cl enc h P r es sur e S ens or

1615 S ol enoi d V alv e for One- Way or Two-Way Flow

1657 Left J oy s ti c k S l i de Contr ol

1658 Ri ght J oy s ti c k S l i de Contr ol

1665 S ol enoi d V alv e for the Num ber One Rel i ef Val v e

1666 S ol enoi d V alv e for the Num ber Two Rel i ef Val v e

The CID is a diagnostic code that indicates which component is faulty.

The MID is a diagnostic code that indicates which electronic control module

diagnosed the fault.

E ngine Cont rol

(MID No. 24)

Component Identifiers (CID)

Module Identifier (MID)

Engine/Pump Control

(MID No. 69)

Tool Cont rol

(MID No. 06A)

E ve nt C od e C on di ti on

E 005 Fuel Fi l ter Restr i c ti on Der ate

E 015 Hi gh Engi ne Cool ant Tem peratur e Der ate

E 017 Hi gh E ngi ne Cool ant Tem per atur e Warni ng

E 025 Hi gh Inl et Ai r Temper ature Der ate

E 027 Hi gh Inl et Ai r Temper ature War ni ng

E 039 Low E ngi ne Oi l P r es sur e Der ate

E 096 Hi gh Fuel P r es sur e

E 100 Low E ngi ne Oil P r es s ur e War ning

E 190 E ngi ne Ov er speed War ning

E 265 Us er Defi ned S hutdown

E ve nt C od e C on di ti on

E 017 Cool ant Ov er heat

E043 Abnormal Battery Charge (Voltage to Power Supply Low)

E050 Abnormal Battery Charge (Voltage to Power Supply High)

E 059 Ins uffic i ent Lev el of Cool ant

E 095 Fuel Fi l ter is Cl ogged

E 100 E ngi ne Oi l P r es sur e is LowE 119 Fuel Lev el i s Low

E 171 E ngi ne Oi l Lev el i s Low

E 179 A bnor mal B attery Char ge

E 232 Water S epar ator Drai ni ng Dem and

E 235 Hy dr aul i c Oi l Lev el i s Low

E 236 Hy dr aul i c Oi l Fil ter is Cl ogged

E 237 Ov er load War ning

E 272 A i r Fi l ter is Cl ogged

E 600 Hy dr aul i c Oi l Ov er heat

E 862 S pec ial Fi l ter i s Cl ogged

E 863 A utom ati c Gr eas e Fai l ur e

Event Codes For Engine ECM

Event Codes For Engine/Pump Control

Related Electrical Service Manuals

Form Number

Alternator: 185-5294 SENR4130

Electric Starting Motor: 10 4-7040

Cons is t: 106- 8557 SENR3859

Cons is t: 6V - 5720 SENR3581

Engine/Pump Control: RENR3814

Engine Control: SENR9506

Tool Control: RENR5389

Title

Air Heater E-10 H

Alternator E-10 4

Atch A/C Unit D-5 28

Atch Battery E-12 6

Atch Converter F-3 A

Atch Converter 12V 7A F-3 D

Atch Heater Unit D-5 28

Atch Joystick (LH) I-3 C

Atch Joystick (RH) H-1 B

Atch Seat With Seat Heater H-2 14

Battery F-11 6

Block As. G-11 E

B re ak er - A lt ern at or H -9 E

B re ak er - H ea te r R el ay H -9 E

Cigar Lighter F-2 A

Connector HEP A-11 48

Co nt ro l - A tc h V al ve C -8 2

Control - E ngi ne F-12 H

C on tr ol - E ng in e/ Pu mp E -8 1

Control - Wiper F-2 A

D u al C a m S p ee d /T i mi n g ( C ra n k) B - 11 H

D ua l C am S pe ed /T im i ng ( Ca m) B -1 1 H

E ng in e S pe ed P ic kup D -1 1 H

1

2

200-BK-14

LC

9X-1123ComponentPart Number

Single WireConnector

SocketPin

AG

Pin or SocketNumber

Harness Identification Letter(s):(A, B, C, ..., AA, AB, AC, ...)

Plug

GroundConnection

325-PK-14

Circuit IdentificationNumber Wire Color

Wire Gauge

T

Ground (Case):This indicates that the component does not have a wire connected to ground.It is grounded by being fastened to the machine.

Ground (Wired):This indicates that the component is connected to a grounded wire. Thegrounded wire is fastened to the machine.

T

Switch (Normally Open): A switch that will close at a specified point (temp, press, etc.). Thecircle indicates that the component has screw terminals and a wire can be disconnected from it.

Receptacle

Switch (Normally Closed):A switch that will open at a specified point (temp, press, etc.).No circle indicates that the wire cannot be disconnected from the component.

PressureSymbol

TemperatureSymbol

LevelSymbol

FlowSymbol

Circuit BreakerSymbol

Reed Switch: A switch whose contacts are controlled by a magnet. A magnet closes thecontacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

Sender: A component that is used with a temperature or pressure gauge. The sendermeasures the temperature or pressure. Its resistance changes to give an indication tothe gauge of the temperature or pressure.

Relay (Magnetic Switch): A relay is an electrical component that is activated by electricity.It has a coil that makes an electromagnet when current flows through it. The

electromagnet can open or close the switch part of the relay.

Solenoid: A solenoid is an electrical component that is activated by electricity. It has acoil that makes an electromagnet when current flows through it. The electromagnetcan open or close a valve or move a piece of metal that can do work.

Harness and Wire Symbols

1 12 2

Sure-Seal connector: Typical representationof a Sure-Seal connector. The plug and receptaclecontain both pins and sockets.

Deutsch connector: Typical representationof a Deutsch connector. The plug contains allsockets and the receptacle contains all pins.

Symbols

Symbols and Definitions

Fuse - A component in an electrical circuit that will open the circuit if too much current flowsthrough it.

MAGNETIC LATCH SOLENOID - A magnetic latch solenoid is an electrical component that is

activated by electricity and held latched by a permanent magnet. It has two coils (latch and unlatch)

that make electromagnet when current flows through them. It also has an internal switch that places

the latch coil circuit open at the time the coil latches.

Harness And Wire Electrical Schematic Symbols

Fuse(5 Amps)

5A

AG

RENR5456-03

30Page,

(Dimensions:39inchesx28inches)

RENR5456-03June 2007

330C Excavator

Electrical System

JCD1-UPJNK1-UP

MKM1-UPCAP1-UPCGZ1-UP

2007 Caterpillar

All Rights Reserved

Printed in U.S.A.

-

8/9/2019 330C Electrical Schematic

2/2