31 January 2006A.Ciocio - SCTSG1 Type ii-iii and PP1 Production Timescale for installation Plan...

-

Upload

kelly-ryan -

Category

Documents

-

view

217 -

download

0

description

Transcript of 31 January 2006A.Ciocio - SCTSG1 Type ii-iii and PP1 Production Timescale for installation Plan...

31 January 2006 A.Ciocio - SCTSG 1

Type ii-iii and PP1

• Production• Timescale for installation• Plan• PP1and Testing

31 January 2006 A.Ciocio - SCTSG 2

Type II/III• Production (INEO/St Genis, Thurmelec/Alsace)

– Pippa/Sandra/Pepe Bernabeu/Maarit White (prepare tables of lengths, QA of qualification samples, mapping and labels)

– Martin Postranecky/Pepe Bernabeu (testing samples of double harnesses at CERN)

• TC management: Nicolas Massol, Sigi Wenig and team (Russians, Czechs)

• Installation of dummy PP1 and type II cables– Lars Lindquist (Uppsala) & Neil Fletcher (Liverpool) – new technicians

• are getting familiar with detector in SR1• Lars is installing DCS cables

– Andy Nichols, Janet Fraser, Jason Tarrant, Patrick Werneke to advise on installation/labeling of first examples

• Routine tests after installation– Sandra/Petr and shift crews

31 January 2006 A.Ciocio - SCTSG 3

Timescale for Type II Services• Since calorimeter moved to z=0 (November) access to the cryostat is possible

– ID requests should be via Nicolas Massol

• Sector 5 (top) and Sector 13 (bottom) – heater cables, and DCS cables– Should be finished this week

• Sector 3 – was supposed to follow sector 5, but was held up by problems with arches above detector and muon chamber installation

– likely to follow Sector 9

• Sector 9 – horizontal towards USA15 to be installed next – SCT fibres and SCT power cables (886 cables + spares)– Barrel cables (side A and C) tried last week– a small number of fibres (end cap) should be tried this week

• Sequence in a sector is:– Tubes, fibres, heater cables, SCT cables, (Muon chambers), – TRT cables, pixel cables

31 January 2006 A.Ciocio - SCTSG 4

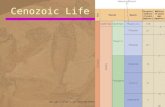

Sectors

31 January 2006 A.Ciocio - SCTSG 5

31 January 2006 A.Ciocio - SCTSG 6

31 January 2006 A.Ciocio - SCTSG 7

Plan for Type II/III cables• INEO/Thurmelec are at present making double length harnesses with type II cable and type II

connectors on both ends. – Work is proceeding to schedule (we are late)– Problems with raw cable quality so far – minor – We needed to order about 4km more type II (sector 9 longer) and 10-20km more type III (cables generally longer than

expected)– Barrel cables (sector 3) will have the type II ends remade to reduce the tolerance on the strip back length to the

JST/FCI connectors to 2mm• Samples of the FCT (type III) connector have been qualified • Almost all cable trays are in place and we could measured lengths of type II/III harnesses with trial

cables before FCT cables are trimmed and FCT mounted on type III ends.• Found extra (more than extra) length to trim off http://www-atlas.lbl.gov/ciocio/SCTcables/TypeII-III/installation_test_cable/• Company will then take 2-3 weeks to do this type III work

– Labels are defined and have been printed for sector 3 (but we don’t need them now) and for sector 9 which is next– Mapping is defined – drawings for installation are being made– First barrel dPP1 are at CERN and have been verified with production cables and the Ljubljana test box– Experts must verify that mapping is transferred to the cryostat bore

• Will install PP3s in racks to which type III cables arrive with highest priority• PPB1 – need small clamps, cable tray covers etc.• PPF1 – more parts needed. Cable clamp redesigned by NIKHEF. Other parts on order via RAL. We just

received a box with parts. Patrick will try to put them together then we can run test cable.

31 January 2006 A.Ciocio - SCTSG 8

PP1 and Testing• Type II-III cables are tested at reception (only samples of delivered batches)

– After installation all tested row by row as they are in the cable tray• Method of testing depends if PP3 and type IV already connected (test at the PP3 or at the PS end• Grounding issues discussed with Ned Spencer, Ljubljana and SCT PS community• Pay attention to ESD suggested by Richard and investigated by Ned

– 1. ESD-protective covering or protective caps on external terminals, interconnecting cables, and connector assemblies shall not be removed until necessary to permit the installation. 2. The cable connector pins and cable shield (connector outer shell) shall be grounded prior to engaging a de-energized connector and cable with a mating receptacle connected to an ESDS item.

• The Type II cable does not have well defined potentials before inserting into PP1 therefore recommended using a shorting plug on the cable connectors before inserting into real PP1, since the cable could be: a) unplugged at PS or PP3, b) be energized, c) have open conductors, d) be experiencing a minor fault to a high potential

• The test fixture (PP1) connectors for the JST are the main problem. PP1 are used to test cables before installation (it could be 1000 plug ins). PP1 are used for both mechanical (check the stripback length) and electrical tests

– Many use cycles on the very thin gold plating of a test fixture could create a surface that is too abrasive for comfort on the Type II cable connector itself.

– David Howell chose 50 cycles as his changeout spec. – The FCI looks more robust -> a changeout at cycles of ~1000

– Either build a mechanically similar adapter or use a DPP1 as a test fixture 20 times, and then swapping it out, and using the part as installed DPP1.