30C/CA COMPACT - azreinigungstechnik.de · e-mail: [email protected] GREA T BRIT AIN ALTO...

Transcript of 30C/CA COMPACT - azreinigungstechnik.de · e-mail: [email protected] GREA T BRIT AIN ALTO...

Instruction manual ..................... 2 - 13Betriebsanweisung...................... 14 - 25Manuel d’Instructions ................ 26 - 37Gebruikershandleiding................ 38 - 49Manual de Instrucciones ............. 50 - 61Manuale di istruzioni .................. 62 - 73Manual de Instruções .................. 74 - 85ã÷åéñéäéï ïäçãéùí ......................... 86 - 97

30CA COMPACT30C/CA COMPACT �

GB

P

NL

F

D

I

E

GR

ALTO HEADQUARTERSALTO U.S. Inc.390 South Woods Mill RoadSuite 300ChesterfieldUSA-Missouri 63017-3433Tel.: (+1) 31 42 05 12 20Fax: (+1) 31 42 05 15 44

SUBSIDIARIES/DIVISIONS

AUSTRALIAALTO Overseas Inc.1B/8 Resolution DriveP.O.Box 797AUS-Caringbah, N.S.W. 2229Tel: (++61) 295 24 61 22Fax: (++61) 295 24 52 56

AUSTRIAWap Reinigungssysteme GmbHMetzgerstr. 68A-5101 Bergheim/SalzburgPhone: (+43) 662 45 64 00-14Fax: ( +43) 662 45 64 00-55Mobil: (+43) 664 12 49 55 0

BRASILWap do Brasil Ltda.Rua 25 de Agosto, 608Jardim PinhaisCEP 83323-260 Pinhais/ParanáBR-BrasilTel./Fax (+55) 41 86 74 02 6

CANADAALTO Canada24 Constellation RoadRexdaleC-Ontario M9W 1K1Tel: 1 41 66 75 58 30Fax: 1 41 66 75 69 89

CZECHIAWap čistící systémy s.r.o.Zateckých 9CZ-140 00 Praha 4Tel. (++420) 02 / 42 78 38Fax (++420) 02 / 42 19 25

Wap čistící systémy s.r.o.Mucednícka 3CZ-61600 BrnoTel. (++420) 05 / 41 21 48 85Fax (++420) 05 / 41 21 48 87

DENMARKALTO Danmark A/SIndustrikvarteretDK-9560 HadsundTel: (++45) 72 18 21 00Fax: (++45) 72 18 21 05

ALTO Danmark A/S(food division)Blytækkervej 2,DK-9000 Aalborg 10Tel: (++45) 72 18 21 00Fax: (++45) 72 18 20 99

FRANCEALTO France S.A.B.P. 44, 4 Place d’OstwaldF-67036 Strasbourg Cedex 2Tel: (++33) 3 88 28 84 00Fax: (++33) 3 88 30 05 00

GERMANYWap KundenCenterTel. (++49) 0180 / 5 37 37 37Fax (++49) 0180 / 5 37 37 38e-mail: [email protected] Sie uns im Internet:http://www.wap-online.com

Wap-Zentrale BellenbergHauptverwaltungWap Reinigungssysteme GmbH & CoD-89287 BellenbergGuido-Oberdorfer-Straße 2-8Tel. (++49) 07306 / 72-0Fax (++49) 07306 / 7 22 00

RegionalCenter FrankfurtD-63452 HanauMoselstraße 2bTel. (++49) 06181 / 18 72-0Fax (++49) 06181 / 18 72-11e-mail: [email protected]

RegionalCenter HannoverD-29227 CelleWernerusstraße 25Tel. (++49) 05141 / 95 55-0Fax (++49) 05141 / 95 55-95e-mail: [email protected]

RegionalCenter KölnD-51145 Köln-PorzKaiserstraße 127Tel. (++49) 02203 / 9 22 99-0Fax (++49) 02203 / 9 22 99-25e-mail: [email protected]

RegionalCenter LeipzigD-04416 MarkkleebergWachau/GewerbegebietSüdring 16Tel. (++49) 034297 / 4 87 25Fax (++49) 034297 / 4 93 57e-mail: [email protected]

RegionalCenter MünchenD-85716 UnterschleißheimFurtweg 11Tel. (++49) 089 / 32 15 02-0Fax (++49) 089 / 32 15 02-40e-mail: [email protected]

RegionalCenter StuttgartD-71069 SindelfingenOT DarmsheimDornierstraße 7Tel. (++49) 07031 / 76 70-0Fax (++49) 07031 / 76 70-20e-mail: [email protected]

RegionalCenter UlmD-89287 BellenbergGuido-Oberdorfer-Straße 2-8Tel. (++49) 07306 / 72-195Fax (++49) 07306 / 3 41 29e-mail: [email protected]

GREAT BRITAINALTO Cleaning Systems(UK)Ltd.Gilwilly Industrial EstateGB-Penrith, Cumbria CA11 9BNTel: (+44) 1 7 68 86 89 95Fax: (+44) 1 7 68 86 47 13Telex: 64309 kewg

ASIAAlto Hong KongRepresentative OfficeRM 602, Tower B, Regent Ctr.70, Ta Chuen Ping StreetKwai chungHK-Hong KongTel. (++852) 26 10 10 42Fax (++852) 26 10 10 47

JAPANALTO Danmark A/S JapanRepresentative OfficeNaruse-build 4F7-2 Shinbashi 1-Chome, Minato-KuJ-Tokyo 105-004Tel: (+81) 3 35 69 38 07Fax: (+81) 3 35 69 38 08

Wap Representative Office Japan25-6, Honode ChoAdachi-KuJ-Tokyo - 120-0021Tel. (+81) 3 / 52 44 07 82Fax (+81) 3 / 52 44 07 83

KROATIAWap sistemi za čišćenje, d.o.o.HR-10000 ZagrebFlorijana Andrašeca 14Tel. (++385) 01 / 3 09 49 07 (++385) 01 / 3 09 49 09Fax (++385) 01 / 3 09 49 06

NETHERLANDSWAP/ALTO Nederland B.V.Stuartweg 4C,NL-4131 NJ VianenTel: (+31) (0) 3 47 32 40 00Fax: (+31) (0) 3 47 32 40 01

Wap (NL) B.V.NL-3371 MA Hardinxveld-GiessendamTransportweg 53-57Postbus 65Tel. (+31) 01846 / 1 81 44Fax (+31) 01846 / 1 41 13e-mail: [email protected]

NORWAYALTO Norge ASBjørnerudveien 24Postboks 64, Bjørndal,N-1266 OsloTel: (+47) 22 75 17 70Fax: (+47) 22 75 17 71

SINGAPOREALTO Danmark A/SRepresentative Office271 Bukit Timah Road#04-11 Balmoral PlazaSG-Singapore 259708Tel: (+65) 8 36 64 55Fax: (+65) 8 36 64 56

SLOWAKIAWap čistiace systémy spol. s.r.o.SK-83237 BratislavaVajnorská 135Tel. (++421) 7 44 25 96 64Fax (++421) 7 44 25 79 44

SLOWENIAWap čistilni sistemi, d.o.o.SLO-1110 LjubljanaLetališka 33Tel. (++0368) 61 44 23 42Fax (++0368) 61 1 40 42 94

SOUTH AFRICAWap South Africa (Pty) Ltd.ZA-Kempteon Park (T) 1620P.O. Box 2122Tel. (++27) 11 97 57 06 0Fax (++27) 11 39 43 08 1

SPAINHidrolimpia, S.L.E-28760 Tres Cantos - MadridRonda de Valdecarrizo 9– Modulo 5 –Tel. (++34) 091 / 804 62 56Fax (++34) 091 / 804 64 63

SWEDENALTO Sverige ABAminogatan 18, Box 40 29S-431 04 MölndalTel: (+46) 31 27 16 00Fax: (+46) 31 87 24 19

SWITZERLANDWap Reinigungssysteme(Schweiz) AGCH-5042 Hirschthal / AGHolzikerstraße 488Tel. (++041) 062 / 7 39 32 50Fax (++041) 062 / 7 39 32 51

Wap Reinigungssysteme(Schweiz) AGCH-1029 Villars-Ste-CroixZone industrielleCroix du PéageTel. (++041) 021 / 6 35 32 74Fax (++041) 021 / 6 35 32 75

USAALTO U.S.Inc2100 Highway 265SpringdaleUSA-Arkansas 72764Tel: (+1) 50 17 50 10 00Fax: (+1) 50 17 56 07 19

ALTO U.S.Inc1100 Haskins RoadBowling GreenUSA-Ohio 43402Tel: (+1) 41 93 52 75 11Fax: (+1) 41 93 53 71 87

ALTO U.S.IncP.O.Box 43691500 North Belcher RoadClearwaterUSA-Florida 33765Tel: (+1) 72 74 61 45 55Fax: (+1) 72 74 61 51 93

718 90 11 i (00.03)Printed in GermanyCopyright © 2000ALTO/Wap Bellenberg

T E C H N O L O G I E S

2

1

43

5

6

89

7

10

12

13

11

18

14

17

16

20

15

19

2

WARNING: Read this instruction manualbefore you start up your high pressure washerfor the first time.This machine is a high pressure washer producing a waterjet under high pressure which is why severe injuries canoccur if the safety precautions are not observed.Therefore a complete understanding of the contents of thisinstruction manual is required in order to prevent injuries toyourself, objects and persons nearby, and the machineitself.

Contents 2 - 13 GB1.0 Survey of models ............................................ 3

1.1 Model tag .................................................... 31.2 Technical data ............................................. 3

2.0 Instructions for use ...........................................Safety precautions and warnings .................. 42.1 Starting-up .................................................. 42.2 Operation .................................................... 42.3 Safety devices on the machine ................... 52.4 General ....................................................... 5

3.0 Operating instructions .................................... 63.1 Connections ................................................ 6

1. High pressure hose ................................ 62. Water connection .................................... 63. Mains power connection ......................... 64. Spray handle - accessories .................... 75. Detergents - dosing unit ......................... 7

3.2 Starting-up .................................................. 73.3 Operation .................................................... 83.4 Spray lance, pressure regulation ................ 83.5 End of operation ......................................... 83.6 Placement of accessories, hose and cable 93.7 Transport directions - transport handle ....... 93.8 Storage ....................................................... 9

4.0 Fields of application andworking methods ........................................... 104.1 Fields of application .................................. 104.2 Working pressure ..................................... 104.3 Detergents ................................................ 104.4 Dosing of detergent .................................. 104.5 Working methods ...................................... 11

5.0 Pre-priming .................................................... 116.0 Maintenance ................................................... 12

6.1 Cleaning of high pressure nozzle ............. 126.2 Cleaning of water inlet filter ...................... 126.3 Cleaning of vents ...................................... 12

7.0 Troubleshooting and correction .................. 138.0 Functional description ............................. 98-99

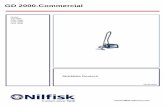

Designations GB(see drawing on the back cover)

1. Start/stop button2. Pressure gauge3. Connection for high pressure hose4. High pressure hose with quick coupling5. Nipple for water inlet hose6. Water connection (water inlet filter)7. Electric cable8. Dosing unit for detergents9. Suction hose for detergents

10. Lifting handle11. Transport handle12. Driving wheel13. Support for spray lance14. Tipping plate15. Model tag, placement16. Release for transport handle17. Vents18. Support for container19. Spray handle20. Spray lance

The environmental policy of ALTOALTO has made it a natural part of the concept of the com-

pany to reduce the effect on our environment as much aspossible. This plan is effected through a constant developmentin all branches of the company so that the greatest number ofelements in our high pressure washers affects the environmentto a minimum.

This product too is characterised by the attitude of ALTOtowards the environment.

The majority of the incorporated plastic components and firstand foremost, the cabinet, is made of the environmentallydesirable polypropylene plastic material. The applied form ofthe substance can be regranulated, which means that thesubstance can be reused upon discarding.

To ensure the possibilities of recycling theplastic materials of the product, they have beenmarked with a recycling symbol and the type ofmaterial.

It is also a part of our concern for environmen-tal problems that the high pressure washer ismaintenance-free, meaning that the oil in the high pressurepump will not have to be changed. The oil is in a closed systemand is only changed by an eventual servicing.

For the production of this high pressure washer the latesttechniques and technology have been applied. The consump-tion of unnecessary subsidiary materials has been minimized,and during the final test of the product the test water is recy-cled.

United Kingdom: Health and safety at Work Act 1974 Guidance Note P.M. 29It has always been the ALTO policy to ensure that all ALTO products are safe and without risk to health or safetywhen properly used.ALTO always endeavour to provide customers with every available item of information on the product they areusing by the issue of descriptive instruction manuals, literature and brochures which are constantly beingupdated and reviewed.If you have any doubts or problems please do not hesitate to contact ALTO Customer Services on01768 868995 or write to ALTO Consumer Products, Gilwilly Industrial Estate, Penrith, Cumbria, CA11 9BN.

> PP <

3

1.2 Technical dataModel 30CA

COMPACT

Type P478

Pump pressure bar 160

Water volume, min/max pressure l/min. 11.5 /10.3

Pre-priming, max. suction height m 1

Dosing of detergent % 0-5

Spray lance:Spray angle h.p. / l.p. degrees 15 / 65Nozzle type 035Thrust, max. N/kp 26 / 2.65

1) 1 x 110V, 50 Hz (UK)2) 1 x 100V, 50/60 Hz (J)Data at 3 bar inlet pressure and 10°C inlet water.Sound pressure level LpA measured in accordance with ISO 11202 [DISTANCE 1m] [FULL LOAD]: 83dB(A).We reserve the right to make alterations.

1.1 Model tagThis ALTO high pressure washer has the modeldesignation »30CA COMPACT /30C/CA COMPACT �« and the type designation»P478/P452«.The model designation appears from the text on thecabinet.

The model tag (pos. 15) provides the following details:

1. Model2. Type3. Serial no4. Production year5. Capacity6. Max. pressure, opening pressure for by-pass valve7. Working pressure8. Max. inlet pressure9. Max. temperature of inlet water

1.0 Survey of models GB

10. Rated output of motor11. Mains frequency12. Mains voltage13. Number of phases14. Power consumption of motor15. Number of revolutions16. COS j17. Classification of insulation18. Classification of tightness

13579

2468

1012141618

11131517

DK-9560 HADSUND

TLF . (+45) 7218 2100

MODELTYPESERIAL NOPRODUCTION YEARCAPACITYMAX. PRESSUREWORKING PRESSUREINLET PRESSUREINLET TEMPERATURE

MADE IN DENMARK

POWERFREQUENCYVOLTAGEPHASEPOWER CUNSUMPTIONRPMCOS ϕINSULATION CL.MOISTURE RES. CL.

30CA 30CA 30CA 30CCOMPACT � COMPACT ���� COMPACT ����COMPACT �

P452 P452 P452 P452

150 80 80 150

10 / 9 8.6 / 8.1 7.3 / 6.8 10 / 9

1 1 1 1

0-5 0-5 0-5 0-5

15 / 65 15 / 65 15 / 65 15 / 6503 04 03 0320 / 2.01 23 / 2.35 20 /2.01 20 / 2.01

4

2.0 Instructions for use Safety precautions and warnings GB

Before starting up your high pressure washer for the first time, we advise you to read through the followingsections: 2.0 Instructions for use and 3.0 Operating instructions and to follow all instructions to ensure theprotection of user, surroundings and machine.

2.1 Starting-upUpon the unpacking of your machine please check it for any defects. If you find any, we kindly ask you tocontact your ALTO distributor.Check the electric cable

The insulation of the electric cable should be in a safe condition.Please contact a qualified electrician or the nearest ALTO distributor if any doubts arise.

Check the voltageCheck that the voltage stated on the model tag corresponds to your mains voltage.

Power consumption, fuseCheck the power consumption stated on the model tag and then check correct prefuse.

Mains power connectionFaulty connection of the machine can cause electric shock.

1. Only connect the machine to an installation with earth connection.2. If you are in doubt about connections, please contact a qualified electrician for correct installation.3. We recommend you to connect the machine to a power source with a Residual Current Device (RCD),

which will disconnect the power supply if the leakage current exceeds 30 mA for 30 milli seconds.4. The electric supply connection shall be made by an qualified electrician and comply with the latest edition

of the IEC Wiring Regulations.

Extension cableIf you want a wider radius of action ALTO recommend you to use an extension hose instead of an exten-sion cable. If you want to apply an extension cable when operating a three-phase high pressure washer,we recommend you to use the cable dimensions mentioned below: (The use of the stated cable dimen-sions implies that the mains voltage is stable and corresponding to the voltage stated on the model tag.)

Note: If an extension cable is required it must be earthed and connected through the plug to theearth cable of your supply network in accordance with prescribed safety regulations.

5. Extension cable, plug and socket should be waterproof.6. Always use a cable similar to the one mounted on the machine i.e. with earth connection and for outdoor

use. If you are in doubt, please contact a qualified electrician or the nearest ALTO distributor.7. Cable connections should be kept dry and off the ground.8. Check extension cables before usage. Don’t use damaged cables.

2.2 OperationThis machine produces a high pressure jet and operation contrary to the instructions can cause severe injury!For your own and the safety of others the following precautions should always be observed:

1. WARNING! Never direct the water jet towards people, pets, electric wiring, or the machine itself.2. WARNING! Never try to clean clothes or footwear on yourself or other persons.3. We recommend you to wear goggles during operation.4. Never work barefoot or with sandals.5. Operator and anyone in immediate vicinity of the site of cleaning should take

action to protect himself from being struck by debris dislodged during operation.6. According to regulations persons under the age of 18 must not operate cleaning machines with a working

pressure above 70 bar (applies to this machine).7. The machine should be placed as far away from the cleaning site as possible.8. Only let instructed personnel operate the machine.9. Don’t start the machine until the high pressure hose has been correctly mounted.

10. Spray handle and lance are affected by a backward force (thrust) during operation - thereforealways hold the spray lance firmly with both hands.

I 0<I<10 Amp 10<I<16 Amp 16<I<25 Amp 25<I<32 Ampm mm² mm² mm² mm²

0-50 1,5 1,5 2,5 4,051-75 1,5 2,5 2,5 4,076-100 1,5 2,5 4,0 6,0

5

Safety precautions and warnings GB

11. When pausing during operation, stop the machine by turning the start/stop button to pos. O and securethe spray handle against inadvertent use by locking the trigger with the locking device.

12. Only activate the trigger by hand. Never tie it up or fix it in any other way.13. Avoid damage to the high pressure hose such as running over by a car, squeezing, pulling, knotting/

kinking etc. and keep it away from oil and sharp or hot objects, as such may cause the hose to burst.14. Danger of scalding! Never dismount the high pressure hose or the water inlet hose while the machine is

in operation. Disconnect the cleaner, shut off the water supply and activate the spray handle beforedismounting the high pressure hose or the water inlet hose.

15. Never jerk the cable to disconnect the plug from socket.16. Always disconnect the plug from socket prior to disconnecting any extension cables.17. Avoid damage to the electric cables such as running over by a car, squeezing, pulling, knotting etc. and

keep them away from sharp or hot objects.18. According to the legislation in many countries it is forbidden to use the machine in an environment where

there could be a danger of explosion. If any doubt arises, please contact your local authorities.Important! OFFSHORE: Never use the machine in an environment where there could be a danger of

explosion (according to EN-50014).19. WARNING! High pressure hoses, nozzles and connections are important for safety when operating the

machine. Only use the high pressure hoses, nozzles and connections prescribed by ALTO.20. For safety reasons only use original ALTO accessories and spare parts.21. In icy conditions never start the cleaner until machine, hoses and accessories have thawed. Otherwise

the machine could be damaged.22. The cleaner should not be covered during operation.

2.3 Safety devices on the machineAutomatic start/stop (only 30CA)The machine is fitted with a start/stop function, which automatically switches off the machine when thespray handle is closed or if a nozzle is blocked. The start/stop function ensures that the pressure will neverexceed the working pressure by more than 20 bar. At this pressure the machine will automatically stop.

Circulation valve (safety valve) (only 30C COMPACT �)The pressure side of the high pressure pump is fitted with a circulation valve (safety valve). This valvecirculates the water back to the suction side of the pump when the spray handle is closed or if a nozzle isblocked. The circulation valve has been constructed as a safety function ensuring that the pressure willnever exceed the working pressure by more than 20 bar. At this pressure the circulation valve will auto-matically switch from high pressure to circulation mode.The pump will overheat if it is not disconnected within 5 min. and thus it may be damaged (only 3 min. at50°C). The circulation valve ensures that the machine becomes devoid of pressure when it is stopped.

Motor protectionThe electric motor features an overcurrent release for protection of motor against overloading. In the caseof increased power consumption (maloperation) the power for the motor will automatically be disconnected.

2.4 General1. It is not allowed to clean asbestos-containing surfaces with high pressure, unless using special equipment.2. Persons under the influence of alcohol, drugs and medicine should not operate the machine.3. Never touch plug and socket with wet hands.4. WARNING! This machine has been constructed for use with ALTO detergents. The use of other

detergents or chemicals may cause problems as to the operation and the safety.5. When using detergents the instructions should always be strictly observed.6. Always unplug when cleaning and maintaining the machine.7. If the electric cable is damaged, it must be replaced by ALTO trained service personnel or a similarly

trained person to avoid a dangerous situation (NB! Type Y connection: A special tool is required for thedisassemblance of the machine).

8. Don’t use the machine if the electric cable or important parts of the equipment are damaged - i.e. safetydevices, high pressure hoses, spray handles, cabinet.

9. The user is obliged to observe all national working environment and working safety regulationsconcerning the "operation of high pressure washers".

10. The most efficient cleaning is obtained if you adjust the distance to the surface which is to be cleaned.Thus you will also avoid damaging the surface.

6

3.0 Operating instructions GB

3.1 Connections

1. High pressure hose

Max. length of extension hose: 10 m.Only use ALTO high pressure hose.

The high pressure hose with imprinted max. working pressure and temperature should be attached to theoutlet socket (1) by the quick coupling (2).

2. Water connection

Important! Only use water withoutimpurities. The warranty does not coverdamages caused by impurities in theinlet water.

Min. length of hose: 6 m. ½".Clean water filter at monthly intervals.Max. water pressure: 10 bar.

Let water run through the inlet hose to remove any impurities. Clean all coupling parts of impurities.Attach the inlet hose to the quick coupling of the water inlet (1).The water supply system must supply min. 720 l/h (12 l/min.).If there is a risk of impurities (i.e. running sand) in the inlet water, an external sand filter should be mountedbeyond the internal filter of the cleaner. Please contact your ALTO distributor for further information.

NOTE: Connection to the public mains according to regulations.Pre-priming; see section 5.0.

3. Mains power connection

Only connect to an approved socket withearth connection.

Only connect to an approved socket with earth connection.Check voltage, fuse, cables and extension cables according to section 2.1.

Note for GB: Connection to the outside water tap must comply with Water Bye law 18, requiring the use ofa double check valve to prevent contaminated water being siphoned back into the mains.For mounting instructions, please refer to the enclosed manual. Non compliance can result in heavy fines.

7

Operating instructions GB

4. Spray handle - accessories

Clean nipple of any impurities each timethe spray lance has been dismounted.

Max. thrust of spray handle and lance -see section “1.2. Technical data”.

Pull forward the grey quick coupling trigger of the spray handle (1).Insert the nipple of the spray lance (2) in the quick coupling and release the trigger.Pul forward the spray lance or any other accessory to ensure correct mounting before starting the cleaner.

5. Detergents - dosing unit

Only use ALTO detergents.Use of aggressive detergents maydamage equipment and affect theenvironment.Flush with water after use.IMPORTANT: Always turn to step 0when not using detergents.

Detergents are added under low pressure through the built-in dosing system (1). Place the container eitheron the support for container (2) or on the floor. The suction hose with filter (3) of the dosing unit is placedon the right side of the machine seen from behind. Insert the suction hose with filter (3) into the container.The dosage is infinitely variable (0-5%), and the required dosage is reached by turning the knob (1) anti-clockwise, until the required step is against the arrow. Upon application of the detergent, the system shouldbe flushed through with pure water at step 5 for approximately 1 min., and the knob should be turned clock-wise to step 0.

3.2 Starting-up

Turn on the water.

Vent the machine.

Turn the start/stop button (1) to positionI.

Turn on the water. Activate the spray handle with the spray lance set at low pressure (or without spraylance) and let the water run until all air has escaped from the inlet hose and the pump.When starting-up the pressure may be irregular because of air in the pump system. After a short time inoperation the air will escape from the system, and the pressure will stabilize.Turn the start/stop button (1) to position I.NOTE: Machines with automatic start/stop (30CA). When the spray handle is released, the machine willautomatically stop. The machine can be restarted just by activating the spray handle.

1

2

8

Operating instructions GB

3.3 Operation

Always hold the spray lance with bothhands!Always lock the spray handle when thecleaner is not in operation.

Activate the high pressure washer by releasing the trigger of the spray handle (1). When the cleaner is notin use, secure the spray handle by turning the safety knob (2) into pos. 0.NOTE: Machines without automatic start/stop (30C). Never allow the machine to run for more than 5min. upon release of the trigger (only 3 min. if the temperature of the inlet water exceeds 50°C).

3.4 Spray lance, pressure regulation

Turn pressure reducing valve:

Clockwise (B): high pressure

Counter clockwise (A): low pressure /addition of detergents

The spray lance features 2 nozzles, a high pressure nozzle and a low pressure nozzle.When the pressure reducing valve (1) is completely closed (turned clockwise - B), only the high pressurenozzle is used - high pressure mode.When the pressure reducing valve is quite open (turned counter clockwise - A) both spray lances are used- low pressure mode / addition of detergents. The pressure is infinitely variable between these positions.

3.5 End of operation

Turn start/stop button (1) to position O.

Stop the machine by turning the start/stop button (1) to position O. Unplug. Turn off the water supply andactivate the spray handle to relieve the high pressure hose of pressure. Dismount the high pressure hoseand the water inlet hose.

NOTE: Machines with automatic start/stop (30CA). When the spray handle is released, the machine willautomatically stop. The machine can be restarted just by activating the spray handle.If the motor protection system engages, the machine should be restarted by turning the start/stop button toposition O. (See section “7.0 Trouble shooting and correction”)

1

2

1

9

Operating instructions GB

3.6 Placement of accessories, hose and cable

Spray lance in support for spray lance (1)

Electric cable and high pressure hose onthe handle (2)

Container in support for container (3).

Place the spray lance in the support for spray lance (1), nozzle facing upwards. Wind up the electric cableand place it on the transport handle (2). Then wind up the high pressure hose and place it on the electriccable.

3.7 Transport directions - transport handle

Lifting points: handle (3) and under thefront edge of the bottom (4).

The machine has a transport handle (1) and wheels so that it is easy to transport.The transport handle can be pushed up and down according to requirements. Press the release (2) andpull up the handle until you hear a click when the handle is in top position. By pressing the release (2) thehandle can be pushed down again.When lifting the machine manually lift it by the handle (3) when folded up and, if necessary, under the frontedge of the bottom (4). When lifting by crane lift it by the lifting handle (3) - use a lifting strap.

3.8 Storage

Frost-free room!

Empty pump, hose and accessories ofwater prior to storing.

Prior to storing, the pump, hose and accessories should be completely emptied of water as follows:

1. Stop the machine and detach the water inlet hose and any accessory.2. Restart the machine and activate the spray handle.

Let the machine run until all water has run out of the spray handle.3. Stop the machine and detach the high pressure hose.

FROST PROTECTION: If the store room is not frost-free the machine should be protected with an anti-freeze solution, and hoses and accessories should be emptied of water.

10

4.0 Fields of application and working methods GB

4.1 Fields of applicationThe most important fields of application for this product are:

Agriculture Cleaning of machinery, agricultural implements, stalls, equipment, andbuildings.

Transport Cleaning of trucks, buses, cars etc.

Light industries Degreasing and cleaning of machines, workpieces, and vehicles.

Service Cleaning of vehicles, cleaning of public paths, institutions etc.

Domestic use Car, motor cycle, boat, caravan, trailer, tiles, wood works, roofs, outhouses,

greenhouses, barbecue, garden furniture etc.

4.2 Working pressureThe high pressure washer may be used with high or low pressure at your own option.

Low pressure Is first and foremost used for application of detergents and for washing off.

High pressure Is used for cleaning.

4.3 DetergentsThe most efficient cleaning is reached with detergents in conjunction with the high pressure cleaning. Forthat purpose ALTO can offer you a series of products specially developed for high pressure cleaning,among other fields within:

Cleaning of cars, caravans, boats etc. DescalingCleaning of tiles, roofs, wood works etc. Degreasing of workpiecesCleaning of buildings, machinery, stalls etc. Disinfection

The products are water-based, without phosphates, and the applied tensides (surface active substances)comply with the present requirements for easy biodegradability.Contact your ALTO distributor for directions as to which product will fulfill your requirements.The method of application and the dosage of the individual products appear on the product labels or thedata sheet. The dosage is adjusted on the high pressure washer.

4.4 Dosing of detergentThe high pressure washer features a built-in injector enabling dosing of detergent to the water when thecleaner is in low pressure mode. With this dosing unit it is possible to vary the dosing of detergent infinitelybetween 0-5%, and thus most cleaning jobs will be covered (also see section 3.1.5).

Change from application of detergent under low pressure to cleaning under high pressure is simply effectedby switching from »low pressure mode« to »high pressure mode« on the spray lance. You will not have tomount or dismount any parts by normal use of detergent.

For foam cleaning you will have to mount the special foam injector between the high pressure washer andthe high pressure hose. Insert the suction hose of the injector into the foam detergent. Mount foam lanceon spray handle and you are now ready for foam application. Upon the application dismount the foaminjector and replace the foam lance by a spray lance and you are ready for cleaning.

11

Fields of application and working methods GB

4.5 Working methodsYour high pressure washer has been developed for cleaning according to the so-called »2-step method«.

STEP 1 Application of detergentSTEP 2 High pressure cleaning

In practice the working process is laid down in accordance with the actual job, but as a starting point thefollowing working method can be described for a job:

1. Apply detergent under low pressure. The dosage is chosen according to the job which is to be carried outand the adjustment is made on the dosing unit.

2. Await acting time. Let the detergent act on the dirt/surface for a short time prior to pressure cleaning -usually a few minutes.

3. High pressure cleaning. Clean all surfaces under high pressure.4. Rinse afterwards, if necessary, to make sure that residual impurities are removed from the surface.

In connection with the working process, the optimum cleaning will be reached by following these 3 piecesof advice:

Advice no. 1When using a detergent, always apply it on a dry surface. If the surface is rinsed with water at first, it maybe difficult for it to absorb the detergent, and the result is a reduced effect of the detergent.

Advice no. 2When applying a detergent on large vertical surfaces (i.e. the sides of a truck) work from below and moveupwards. Thus you will avoid the detergent running off the surface through grooves and dark streaks ap-pearing on the surface whilst cleaning.

Advice no. 3During the high pressure cleaning you should work so that the high pressure water does not run over thesurface which has not been cleaned yet. This is to ensure that there is sufficient detergent on the surfacewhen the high pressure water is applied.

5.0 Pre-priming

The cleaner is pre-priming and can take water from a tank, a stream or the like. In suction mode the waterinlet hose and the pump should be filled with water prior to starting. The suction height depends on thewater temperature. Max. suction height of 1 m is reached with cold water up to 10°C.

If there is a risk of impurities (i.e. running sands) in the inlet water, an external suction filter should bemounted beyond the internal filter of the cleaner. Contact your ALTO distributor for further information.

12

6.1 Cleaning of high pressure nozzleClogging up in the nozzle causes a pump pressure which is too high, and cleaning is immediately required.

1. Stop the cleaner and detach the spray lance.2. Carefully clean the nozzle. You may use ALTO nozzle cleaning tool no 6401654.

IMPORTANT: ONLY use the cleaning tool when the spray lance is detached!3. Flush the spray lance backwards with water.4. If the pressure is still too high, repeat items 1-3.

6.0 Maintenance GB

Your ALTO high pressure washer is maintenance-free and therefore no special qualifications are requiredfor the daily use.

However, it applies to the most exposed components that a minimum of maintenance ensures a prolongedand problem-free operation. Therefore it will be a good idea to make a habit of the following:

Before mounting the water inlet hose and the high pressure hose, the couplings should becleaned free of dust and sand.

Before mounting spray lance or any other accessory on the spray handle, the machine shouldbe started and the coupling cleaned of dust and sand.

In periods where detergents are not used, the injector system should be flushed through withpure water to avoid drying up/clogging up of soap in the system.

The water filter should be cleaned once a month or more frequently if required.

The machine should be stored in a frost-free room. If by mistake the machine freezes up, itmust not be started. Let machine, hoses and accessories thaw out before starting up.NEVER START A FROZEN MACHINE.

6.2 Cleaning of water inlet filterThe water filter (1) should be cleaned once a monthor more frequently if required. Remove the springring (2) by means of a screw driver and take out thewater filter. Loosen large persistant particles andcarefully clean the filter. Remount the water filterbefore using the machine again.

6.3 Cleaning of ventsThe machine should be kept clean so as to letcooling air pass freely to the machine vents, sidesand bottom (3). Prevent water from penetrating thecleaner through these vents.

13

7.0 Troubleshooting and correction GB

You have chosen the best quality and therefore deserve the best service. To avoid unnecessary disap-pointments, you should check the following before contacting the nearest ALTO service organisation.

Fault Cause CorrectionMotor refuses to start Plug not connected Connect plug.

Defective socket Try another socket.Fuse blown Change the fuse.Extension cable defective Try without extension cable.Overcurrent release activated Push the start button twice. *)

Motor stops Fuse blown Change the fuseWrong mains voltage Check that the mains voltage corresponds to

the specifications on the model tag.Overcurrent release activated Restart, turning the start button to position O. *)

Fuse blows Change to an installation higher than the ampere consumption of the machine.

Pump pressure too high Nozzle partly clogged up Clean the nozzle (see section 6.1)(Check whether the water filter is missing).

High pressure hoses too long Detach high pressure extension hoses and retry(extension hoses max. 10 m).

Pump pressure fluctuating Air in the water hose/pump Allow the cleaner to run with open spray handleand the spray lance adjusted to low pressureuntil the pressure is regular.

Inadequate water supply Check that the water supply corresponds tospecifications.NB: Avoid long thin hoses (min. ½")

Water filter clogged up Clean the filter (see section 6.2).Hoses squeezed Straighten out the hoses.High pressure hoses too long Detach high pressure extension hoses and retry

(extension hoses max. 10 m).Pressure too low but steady Nozzle worn Change the nozzle

Dirt in by-pass valve Activate and release the spray handle 5 timesin quick succession.

Motor starts but Pump/hoses or accessories Let pump/hoses or accessories thaw out.no working pressure frozen up

No water supply Connect the water supply.Water fitler clogged up Clean the filter (see section 6.2).Nozzle clogged up Clean the nozzle (see section 6.1).

*) Overcurrent release Wrong mains voltage See section 2.1.activated Extension cable too long See diagra, section 2.1.

Mains voltage fluctuating Restart the machine.Nozzle partly clogged up Clean the nozzle (see section 6.1).

The machine can be restarted by turning the start button to position O. Wait until the motor has cooled.

Machines with automaticstart/stop:The machine starts Pump, high pressure hose, or Contact your local ALTO service department.irregularly by itself spray handle leaky

Should other malfunctions occur than those mentioned above, please contact the nearest ALTO serviceorganisation.

Customer Services (only UK): WAP/ALTO Cleaning Systems Ltd. Phone: 01 768 86 89 95Gilwilly Industrial EstatePenrith, Cumbria CA11 9BN

98

8.0 Functional description GBHigh pressure pump, water systemThe water passes from the inlet nipple (a) through a water filter (b) and into the high pressure pump (c). The high pressure pump is a pistonpump with internal valve systems ensuring that the pump will supply an exactly measured out water volume per unit of time.The water circulates from the pump (c) to the automatic start/stop valve system (g).When the spray handle is closed or the nozzle (o) is blocked, the water will automatically be recirculated to the suction side of the pump.The circulation valve is adjusted (constructed) to open at approximately 20 bar above the working pressure. When stopped the cleaner willautomatically be devoid of pressure. The water proceeds through the detergent injector (h) which is controlled by the dosing unit (j) with filter(i) and then it passes through the outlet socket of the machine (k).It then proceeds through the hose (l) and the valve of the spray handle (m) and the valve of the spray lance (n) and finally through the nozzle(o) where the water has reached a very high speed. The pump pressure is shown on the pressure gauge (p).Electric motorThe air-cooled motor is protected against overloading, as the starter switch features an overcurrent release. This cuts out the current in theevent of a continuously high power consumption or a blocked fan.If the power for the motor is cut off because of overloading, the motor can only be restarted by activating the start button (see section 3.5).In case the motor stops because of interrupted power supply the motor can be restarted by connecting the power supply.NB: it is not permissible to change the electric system of the machine.

8.0 Funktionsbeschreibung DHochdruckpumpe, WassersystemDas Wasser wird über die Einlaß-Schnellkupplung (a) durch das Wassereinlaßfilter (b) in die Hochdruckpumpe (c) geleitet. Die Hochdruck-pumpe ist eine Stempelpumpe mit internen Ventilsystemen, die sicherstellen, daß die Pumpe eine genau abgemessene Wassermenge jeZeiteinheit liefern kann. Das Wasser wird von der Pumpe (c) in das automatische Start/Stop-Ventilsystem (g) geleitet.Wenn die Spritzpistole geschlossen oder eine Düse verstopft ist, wird das Wasser automatisch zur Ansaugseite der Pumpe zurückgeleitet.Das Umlaufventil ist konstruktiv so eingestellt, daß es sich bei 25 bar Überdruck öffnet. Bei Betriebsstop wird das Gerät automatisch entlastet.Das Sicherheitsventil ist werksseitig justiert und verplombt. Seine Einstellung darf nicht geändert werden.Das Wasser läuft an dem Reinigungsmittelinjektor (h) vorbei, der von der Dosierungseinheit (j) mit Filter (i) gesteuert wird, und läuft danachaus dem Auslaßstutzen (k) des Gerätes. Danach durch den Schlauch (l) und das Ventil (m) der Spritzpistole und schließlich durch die Düse(o), wo das Wasser eine sehr hohe Geschwindigkeit erreicht.Der ElektromotorDer luftgekühlte Motor ist gegen Überlastung geschützt, indem der Ein-Ausschaltknopf mit einem Motor-schutzschalter versehen ist. Beiandauernd hohem Stromverbrauch sowie bei blockiertem Rotor und Phasenausfall wird die Stromzufuhr unterbrochen.Wird der Motor wegen Überlastung unterbrochen, ist der Motor durch Betätigen des Ein-Ausschaltknopfes neu anzulassen.Bei Stromausfall startet der Motor, wenn die Stromversorgung wieder hergestellt worden ist.NB! Eine Änderung der elektrischen Kupplung des Gerätes ist nicht gestattet.

8.0 Description de fonctionnement FLa pompe haute pression - le système hydrauliquePar la tubulure d’entrée (a), l’eau est conduite à travers le filtre hydraulique (b) dans le nettoyeur haute pression (c). La pompe haute pressionest une pompe à pistons avec des systèmes internes de vannes assurant que la pompe livre un débit d’eau constant.De la pompe (c), l’eau est conduite à la soupape Marche/Arrêt Automatique (g) avec la valve de sécurité (f).Lorsque l’on ferme la poignée-gâchette ou si une buse (o) est obstruée, l’eau est automatiquement reconduite du côté aspiration de la pompe.La vanne de dérivation est réglée (construite) pour ouverture àenviron 20 bars au-dessus de la pression de service. Lors d’un arrêt, lapression descend automatiquement. L’eau passe par l’injecteur de détergent (h), dirigé par l’injecteur/doseur (j) avec filtre (i) et elle sortensuite du nettoyeur par la tubulure d’évacuation (k).Ensuite, elle passe à travers le flexible (l) et la vanne de la poignée-gâchette (m), la vanne de la lance (n) et finalement par la buse (o) oùl’eau circule à très grande vitesse. Relever la pression à la pompe sur le manomètre (p).Le moteur électriqueLe moteur à refroidissement par air est protégé contre toute surcharge, le bouton de mise en marche étant muni d’une protection moteur.Celle-ci coupe le courant en cas d’une consommation continue à surtension ainsi que dans le cas où un rotor serait bloqué.Si le moteur est coupé à cause d’une surcharge, il doit être redémarré par le bouton de mise en marche - voir point 3.5. En cas de coupure àcause d’une coupure de courant, le moteur redémarre lors du rétablissement de l’alimentation en courant.NB : Les modifications des couplages électriques du moteur sont interdites.

8.0 Werkingsprincipe NLHogedrukpomp, watersysteemHet water stroomt via de inlaatnippel (a) door het waterfilter (b) naar de hogedrukpomp (c). De hogedrukpomp is uitgevoerd met zuigers, dieervoor zorgen dat via een intern kleppensysteem per tijdseenheid telkens een exact afgemeten hoeveelheid water wordt geleverd.Het water circuleert van de pomp (c) naar het omloopventiel met automatische start/stop functie (g).Als het spuitpistool (m) gesloten is of de nozzle (o) verstopt is, zal het water automatisch terugstromen naar de zuigzijde van de pomp.Het omloopventiel is (van fabriekswege) afgesteld op opening bij ca. 20 bar boven de werkdruk. Bij uitschakeling is de reiniger automatischdrukloos.Het water loopt vervolgens door de reinigingsmiddelen-injecteur (h) die wordt ingeregeld door de doseerknop (j) met filter (i) en verlaat daarnade machine via de hogedrukkoppeling (k). Dan door de slang (l), het pistool (m) en de lans (n) en tenslotte door de nozzle (o), waar het watereen zeer hoge snelheid bereikt. De pompdruk kan afgelezen worden op de manometer (p).ElektromotorDe luchtgekoelde motor is beveiligd tegen overbelasting, daar de schakelaar is uitgevoerd met een overbelastingsbeveiliging.Deze schakelt de stroom uit ingeval van een continu hoog stroomverbruik of een geblokkeerde rotor.Indien de elektromotor door overbelasting geen stroom meer krijgt, kan de motor alleen opnieuw worden gestart door middel van de AAN/UIT-knop (zie paragraaf 3.5). Als de motor stopt door stroomuitval kan de motor opnieuw gestart worden door de stroom weer aan te sluiten.N.B.: het is niet toegestaan het elektrisch systeem van de machine te wijzigen.

99

M

a b

dc

f

g h ji

k l nm o)

(

) (

)(

p

100

8.0 Descripción de funcionamiento EBomba de alta presión, sistema de circulación del aguaEl agua pasa desde la boquilla de entrada (a) a través de un filtro de agua (b) hasta la bomba de alta presión (c). La bomba de alta presiónes una bomba de pistón con sistemas de válvulas internos que aseguran que la bomba suministre un volumen de agua exacto por unidad detiempo.El agua circula desde la bomba (c) hasta el sistema de válvulas de arranque/paro automático (g).Cuando se cierra la pistola o se bloquea la boquilla (o), el agua recircula automáticamente al lado de aspiración de la bomba.La válvula de circulación ha sido ajustada (construida) para abrirse aprox. a 20 barias por encima de la presión de trabajo. Al pararse lalimpiadora estará automáticamente libre de presión. El agua sigue adelante a través del inyector de detergente (h) controlado por el dosifica-dor (j) con el filtro (i) y luego pasa a través de la boca de salida de la máquina (k). A continuación, sigue su paso a través de la manguera (l),la válvula de la pistola (m) y la válvula de la lanza (n) y finalmente a través de la boquilla (o), donde el agua ha alcanzado una velocidad muyalta. La presión de la bomba está indicada en el manómetro.Motor eléctricoEl motor refrigerado por aire está protegido contra sobrecarga, puesto que el interruptor de arranque tiene un dispositivo de protección. Estecorta la corriente en caso de un elevado consumo de corriente continuado o de un rotor bloqueado.Si se corta la alimentación al motor como consecuencia de una sobrecarga, sólo puede volverse a arrancar activando el interruptor dearranque (véase la sección 3.5). En el caso de que el motor se pare por interrupción en la alimentación, puede volverse a arrancar conectan-do de nuevo la alimentación de corriente. NOTA: No está permitido modificar el sistema eléctrico de la máquina.

8.0 ÐÅÑÉÃÑÁÖÇ ËÅÉÔÏÕÑÃÉÁÓ GR

ÁÍÔËÉÁ ÕØÇËÇÓ ÐÉÅÓÇÓ, ÓÕÓÔÇÌÁ ÍÅÑÏÕ

Ôï íåñü ðåñíÜ áðü ôç èçëÞ åéóüäïõ (á) ìÝóù ôïõ ößëôñïõ íåñïý (â) êáé êáôáëÞãåé óôçí áíôëßá õøçëÞò ðßåóçò (c). Ç áíôëßá õøçëÞò ðßåóçòåßíáé ôýðïõ åìâüëïõ ìå åóùôåñéêÜ óõóôÞìáôá âáëâßäùí ðïõ åîáóöáëßæïõí üôé ç áíôëßá èá ðáñÝ÷åé Ýíá õðïëïãéóìÝíï üãêï íåñïý óôç ìïíÜäá

÷ñüíïõ. Ôï íåñü êõêëïöïñåß áðü ôçí áíôëßá (c) óôï óýóôçìá êõêëïöïñßáò (g) ìÝóù ôçò âáëâßäáò áóöÜëåéáò (f).Ïôáí ç ëáâÞ ôïõ åêôïîåõôÞñá åßíáé êëåéóôÞ Þ ôï óôüìéï (ï) öñáãìÝíï, ôï íåñü èá äéåõèõíèåß áõôüìáôá óôç ìåñéÜ ôçò áíáññüöçóçò ôçò áíôëßáò.

Ç âáëâßäá êõêëïöïñßáò åßíáé ñõèìéóìÝíç í� áíïßãåé üôáí ç ðßåóç õðåñâåß ôç êáíïíéêÞ ðßåóç ëåéôïõñãßáò êáôÜ ðåñßðïõ 20 bar.Ïôáí ôï ìç÷Üíçìá óôáìáôÞóåé, áõôüìáôá èá áöáéñåèåß üëç ç ðßåóç. Ôï íåñü ðñï÷ùñåß ìÝóù ôïõ åã÷õôÞ (h) ðïõ åëÝã÷åôáé áðü ôç äïóïëïãéêÞìïíÜäá (j) ìå ôï ößëôñï (i), êáé ðåñíÜ ìÝóù ôïõ óõíäÝóìïõ åîüäïõ (k). Åðåéôá ìÝóù ôïõ óùëÞíá (l) êáé ôçò âáëâßäáò ôçò ëáâÞò øåêáóìïý (n)

öèÜíåé óôï óôüìéï (ï) ìå ìåãÜëç ôá÷ýôçôá. Ç ðßåóç ôçò áíôëßáò åìöáíßæåôáé óôïí åíäåßêôç ðßåóçò (p).

ÇËÅÊÔÑÉÊÏÊÉÍÇÔÇÑÁÓ

Ï áåñüøõêôïò çëåêôñïêéíçôÞñáò ðñïóôáôåýåôáé êáôÜ ôçò õðåñöüñôùóçò ìå ìéá áóöÜëåéá óôï äéáêüðôç åêêßíçóçò. ÁõôÞ óôáìáôÜ ôï ñåýìá óå

ðåñßðôùóç óõíå÷ïýò õøçëÞò êáôáíÜëùóçò ñåýìáôïò Þ ìðëïêáñéóìÝíïõ ñÜïõëïõ.ÅÜí ôï ñåýìá ðñïò ôï êéíçôÞñá äéáêïðåß ëüãù õðåñöüñôùóçò, ï ìüíïò ôñüðïò åêêßíçóçò ôïõ ìç÷áíÞìáôïò åßíáé ìÝóù ôïõ äéáêüðôç

åêêßíçóçò (âëÝðå ðáñÜãñáöï 3.5). ÅÜí ç ëåéôïõñãßá ôïõ êéíçôÞñá äéáêïðåß ëüãù äéáêïðÞò ôñïöïäïóßáò ñåýìáôïò, ï êéíçôÞñáò ìðïñåßíá åðáíá-ëåéôïõñãÞóåé óõíäÝïíôÜò ôïí ìå ôç ðáñï÷Þ ñåýìáôïò. ÐÑÏÓÏ×Ç: Äåí åðéôñÝðåôáé ç áëëáãÞ ôïõ çëåêôñéêïý óõóôÞìáôïò ôïõ

ìç÷áíÞìáôïò.

8.0 Descrizione funzionale IPompa ad alta pressione, circuito idraulicoL’acqua entra nel nipplo (a) ed attraversa il filtro (b),quindi entra in pompa (c). La pompa genera pressione tramite pistoni e valvole idonee garan-tiscono una portata costante e definita. L’acqua viene fatta circolare dalla pompa (c) al sistema di valvole con avvio/arresto automatico (g).Quando la pistola è chiusa, oppure c’è l’ugello ostruito,l’acqua viene fatta rifluire verso la zona di aspirazione della pompa stessa.La valvola diricircolo è tarata a 20 atm. aldisopra della pressione di lavoro.Una volta spenta si ha la certezza di assenza di pressione nella idropulitrice(resta soltanto quella di rete).L’acqua attraversa l’iniettore del detergente (h) che a sua volta è munito di regolatore (j) con filtro (i), ed esce sul raccordo di uscita (k).L’acqua entra nel tubo alta pressione (l), va sulla pistola (m), sulla lancia (n) per fuoruscire dall’ugello (o), punto in cui l’acqua assume lamassima velocità. La pressione della pompa può essere rilevata sul manometro (p).Motore elettricoIl motore elettrico è comandato da un interruttore munito di relèe di sovraccarico. Questo toglie corrente nel momento in cui si verifica unassorbimento superiore a quello di normale funzionzmento.Il motore può essere riavviato azionando l’interruttore di avvio (cfr. sez. 3.5). Anche nel caso di arresto per mancanza di tensione, occoreripremere l’interruttore di avvio. N.B E’ VIETATO MODIFICARE I COLLEGAMENTI ELETTRICI.

8.0 Descrição do funcionamento PA bomba de alta pressão sistema hidraulicoA água admitida através de uma união rápida (a), passa por um filtro (b) e é conduzida até à bomba de alta pressão (c). Esta é uma bombade pistões com umsistema interno de válvulas que asseguram um fluxo de água , regular por unidade de tempo. A partir da bomba (c), aágua é conduzida ao sistema da valvula de paragem automática (g) equipado com válvula de by-pass (f).Sempre que o punho seja desactivado ou ocorra o bloqueio do bico (o), a água entrará automáticamente em recirculação do lado desucção da bomba.A válvula de by-pass está ajustada (de fábrica) para abrir aproximadamente 20 bar acima da pressão de trabalho. Sempre que parada amáquina ficará automáticamente sem pressão. A água passa pelo injector de detergentes (h) controlado pela unidade doseadora (j) comfiltro (I) e daí caminha para o bico de saída da máquina (k).De seguida passa através do tubo de alta pressão (l) para a válvula do punho (m) e pela válvula reguladora da lança (n) e finalmente pelobico (o) onde então a água atinge uma grande velocidade. A pressão de trabalho é lida no manómetro de pressão (p).Motor electricoO motor electrico é arrefecido a ar e está protegido contra sobrecargas de corrente estando o interruptor equipado com um dispositivo deproteção do motor. Este corta a corrente sempre que ocorra um consumo contínuo e elevado de corrente ou o bloqueio do rotor. Casoocorra uma paragem de motor devido a uma sobrecarga, o seu funcionamento será retomado pelo accionamento do interruptor (versecção 3.5). Se a paragem fôr causada pela interrupção no fornecimento será retomado após o seu restabelecimento. N.B. Estão interditasquaisquer alterações nas ligações eléctricas do motor.

101

M

a b

dc

f

g h ji

k l nm o)

(

) (

)(

p

![FXV^NdebS 9bN^R 8bXRNi h @NbQW h 6NfXS y 8? Î Î Cb VbN] x N]](https://static.fdocuments.us/doc/165x107/62560cd74f70602f12607748/fxvndebs-9bnr-8bxrni-h-nbqw-h-6nfxs-y-8-cb-vbn-x-n.jpg)