30772672 Steel Trusses

Transcript of 30772672 Steel Trusses

-

8/9/2019 30772672 Steel Trusses

1/21

Table of content

Introduction..3 Historical development..4

Truss Definition5

Characteristics of trusses..5

Modeling of trusses6

Behavior of truss..7 FULL-SCALETESTING..7

General design principles .8 Optimum depth of truss girder ..8 Design of compression chord members ..8 Design of tension chord members..8 Design of vertical and diagonal members.9

Lateral bracing for truss bridges..9

Trusses classifications11According the row materials ..11

y Timber truss11y Steel trusses.11

-

8/9/2019 30772672 Steel Trusses

2/21

According to plane .11y Plane truss..11y Space Truss12

Space grids..12 Double layer grids12

According Functions.13y Bridges truss..13y Roof truss system.14y Girder and valley truss system14

According s

hape .15

Advantage of trussesAdvantages of space truss.18Advantages of steel pipes.18Advantage of bridge truss..18

Components of the truss .....19

Connecting systems (joints ).....19 Nodular systems19Mero connector19

y Tuball..19y Octatube.19y Plate connector..20

References.....21

-

8/9/2019 30772672 Steel Trusses

3/21

Introduction:

Trusses are a structural frame usually fabricated from pieces of metal or timber

to form a series of triangles lying in a single plane. The linear members are subject

only to compression or tension. The horizontal pieces forming the top and bottom

of the truss are called the chords, and the sloping and vertical pieces connecting the

chords are collectively called the web.

The truss exerts no thrust but only downward pressure; supporting walls

require no buttressing or extra thickening. Trusses have been used extensively in

roofing and bridges. Wood trusses were probably first used in primitive dwellings

c. 2500 BC. Wood was replaced by iron, which in turn was succeeded by steel.

Trusses usually contain straight members that connected to form collection of

triangles to achieve required stability to the constructions; loads in truss applied at

the joints where the members connected and that are joints behave as a pin

connection. These characteristics mean that trusses are only axial member forces

and so all the members parts used in resisting loads and this cause efficiency in

using row material; and so the trusses are light structures.

Best sections for the trusses are the circular or rectangular sections since there

is no week axis like W shapes or other shapes

-

8/9/2019 30772672 Steel Trusses

4/21

Historical development:

The early trusses was simple and small , its function was to help people to

cross the rivers and valleys, trusses principle which the bridges was its first

application caused a commercial revolution in Europe and was the beginning of thenew life style.

Andrea Palladio, a Venetian architect (1518-1580), is usually credited as the

first to describe the form of structure we recognize as a truss, as presented in his

Four Books of Architecture, he was the first to publish information known to many

at that time, including examples constructed (and possibly still extant). In either

event, little attention was paid to his writings until the middle of the 18th

century.

Most trusses was not covered timber bridges, although the oft-cited Schaffhausen

Bridge over the Rhine River, constructed by the Grubenmann brothers in 1758,

which included an awkward and inefficient timber roof, was an impressive two-span (171-ft) and (193-ft) bridge. These early timber bridges consisted of piles

driven into the riverbed, with timber beams spanning longitudinally between pile

caps.

In the first half of the 19th Century, there were many designs and patents,

notably by Town (1820, Canfield (1833, iron truss bridge), Howe (1840), Whipple

(1841. Trusses allowed using relatively short elements, first timber and later iron

and steel, in order to construct much bigger overall span length. These trusses used

simple, axial tension and compression members, and the corresponding tension andcompression material properties rather than bending.

The iron material allowed to achieve much increased span lengths compared to

timber; for example Linville build a 320 ft. span over the Ohio River in 1864, and

a 519 ft. truss of the Cincinnati Southern bridge in 1876. However, the real

progress in building big and reliable truss bridges took place at the end of the 19th

Century and continued through the beginning of the 20th Century. It was related to

the developments in manufacturing of steel, and specifically the mass production

using the Bessemer process. The new material was approximately one quarter

stronger than iron and of better quality and homogeneity. At the same time, therewas rapid industrial development requiring increased transportation of materials,

goods, and people. Bigger, faster, and frequent trains with heavier and stronger

locomotives and numerous cars had appeared. Truss bridges were very well suited

to serve such traffic and to cross even the biggest rivers (including the Mississippi,

Missouri, Ohio, etc.) and other terrain and man-made obstacles. Especially the

simple and logically constructed truss followed the natural flow of internal forces

-

8/9/2019 30772672 Steel Trusses

5/21

such as the Pratt truss, initially pin-connected and later riveted, became the

preferred form and most common design between 1885 and 1920.

Truss Definition:

Truss, in architecture and engineering, a supporting structure or framework

composed of beams, girders, or rods commonly of steel or wood lying in a single

plane. A truss usually takes the form of a triangle or combination of triangles, since

this design ensures the greatest rigidity. Trusses are used for large spans and heavy

loads, especially in bridges and roofs. Their open construction is lighter than, yet

just as strong as, a beam with a solid web between upper and lower lines. The

members are known as tie-beams, posts, rafters, and struts; the distance over whichthe truss extends is called the span. The upper and lower lines or beams are

connected by web members.

External forces and reactions to those forces are considered to act only at the

nodes and result in forces in the members which are either tensile or compressive

forces. Moments (torsional forces) are explicitly excluded because, and only

because, all the joints in a truss are treated as revolutes.

Characteristics of trusses

A truss is composed of triangles because of the structural stability of that

shape and design. A triangle is the simplest geometric figure that will not change

shape when the lengths of the sides are fixed. In comparison, both the angles and

the lengths of a four-sided figure must be fixed for it to retain its shape.

The simplest form of a truss is one single triangle. This type of truss is seen in

a framed roof consisting of rafters and a ceiling joist. Because of the stability of

this shape and the methods of analysis used to calculate the forces within it, a truss

composed entirely of triangles is known as a simple truss.

A space frame truss is a three-dimensional framework of members pinned at their

ends. A tetrahedron shape is the simplest space truss, consisting of six members

which meet at four joints.

-

8/9/2019 30772672 Steel Trusses

6/21

Modeling of trusses:

Varoglu & Barrett made one of the first attempts to model roof truss systems

by developing a structural analysis program for roof systems (SAR) at Forintek

Canada Corp. Varoglu later used the results of the tests conducted by Wolfe &

McCarthy and Wolfe & LaBissoniere to verify the program. He found good

agreement (within 56%) between the vertical deflection predicted by SAR and

experimental results. Larger errors were observed in some trusses due to the

interaction between the supporting walls and the side trusses. He finally concluded

that system response is significantly better than individual truss performance.

Lam used SAR to assess load-sharing behavior of trusses in roof systems. He used

parallel chord trusses with one configuration and evaluated the performance of a

single truss inside and outside the roof assembly. He found an average system

factor of 1.111.31 for tension members and 1.131.27 for compression members,

using combined dead and snow.

Cramer & Wolfe developed a roof-truss system model using the program,

ROOFSYS, to study loadsharing effects in light frame wood roof assemblies. In

the model, simple hinged connections were used. Additionally, composite action

(T-beam action) and two-way action of the sheathing were also included.

To represent roof sheathing in the direction perpendicular to the truss span,

sheathing was modeled as a single continuous beam on each side of the ridge. The

sheathing beam was rigidly connected to each truss. The strong and weak axes of

bending of the sheathing beam were perpendicular and parallel to the truss slope,

respectively.

Cramer and Mtenga. developed the NARSYS program (Nonlinear Analysis of

Roof System) for determining the strength of roof assemblies. The program

included linear elastic three dimensional frame elements to represent the wood

truss members, nonlinear springs and rigid links to represent the joint connections,

and deep beams to represent the roof sheathing.

-

8/9/2019 30772672 Steel Trusses

7/21

Behavior of truss

A vast amount of literature has been accumulated on single trusses and metal-

plate-connected (MPC) joints, but the system behavior of truss assemblies has been

studied by only a few researchers. In the past few decades, a number of

investigators have studied the structural behavior of wood truss assemblies, using

both experimental testing and computer modeling. Experimental testing of truss

assemblies is expensive and therefore only simple truss assemblies have been

tested.

FULL-SCALETESTING

Research on full-scale testing of truss assemblies has been sporadic over the

last several decades. A few studies have been conducted on different types of

assemblies, mainly highlighting load sharing among various components of an

assembly. Wolfe & McCarthy provided an excellent review of the literature onfull-scale testing of roof assemblies conducted until the early 1980s. Their

conclusion was that most of the studies suggested load sharing and assembly

interaction, but failed to quantify it.

In two major studies, Wolfe & McCarthy and Wolfe & LaBissoniere tested

four full-scale roof systems to improve design methods for light frame roof

systems. Their goal was to use the results of the tests in the development and

evaluation of analytical models capable of predicting roof system stiffness and load

capacity.

In the first study, Wolfe & McCarthy investigated the structural performance of

light frame roof assemblies with high truss stiffness variability by testing full-

scale, nine-truss assemblies.

Two-dimensional analysis can be attributed to the three-dimensional behavior

of the roof that is not considered in the simplifying assumptions. If the SDP is

used for analyzing and designing assemblies, both of the findings (concerns) of

Waltz may not be an issue.

-

8/9/2019 30772672 Steel Trusses

8/21

General design principles

Optimum depth of truss girder

The optimum value for span to depth ratio depends on the magnitude of the live

load that has to be carried. The span to depth ratio of a truss girder bridge

producing the greatest economy of material is that which makes the weight of

chord members nearly equal to the weight of web members of truss. As per bridge

rules published by Railway board, the depth should not be greater than three times

width between centers of main girders. The spacing between main Trusses depends

upon the railway or road way clearances required.

Design of compression chord members

Generally, the effective length for the buckling of compression chord memberin the plane of truss is not same as that for buckling out-of-plane of the truss i.e.

the member is weak in one plane compared to the other. The ideal compression

chord will be one that has a section with radii of gyration such that the slenderness

value is same in both planes. In other words, the member is just likely to buckle in

plane or out of plane. These members should be kept as short as possible and

consideration is given to additional bracing, if economical.

The effective length factors for truss members in compression may be

determined by stability analysis. In the absence of detailed analysis one can follow

the recommendations given in respective codes. The depth of the member needs to

be chosen so that the plate dimensions are reasonable. If they are too thick, the

radius of gyration will be smaller than it would be if the same area of steel is used

to form a larger member using thinner plates.

Design of tension chord members

Tension members should be as compact as possible, but depths have to be large

enough to provide adequate space for bolts at the gusset positions and easily attach

cross beam. The width out-of-plane of the truss should be the same as that of the

verticals and diagonals so that simple lapping gussets can be provided without theneed for packing. It should be possible to achieve a net section about 85% of the

gross section by careful arrangement of the bolts in the splices. This means that

fracture at the net section will not govern for common steel grades.

In this case also, box sections are preferable for ease of maintenance but open

sections may well prove cheaper. For detailed design reader is referred to the

chapter on Design of Tension members.

-

8/9/2019 30772672 Steel Trusses

9/21

Design of vertical and diagonal members

Diagonal and vertical members are often rolled sections, particularly for the

lightly loaded members, but packing may be required for making up the rolling

margins. This fact can make welded members more economical, particularly on the

longer trusses where the packing operation might add significantly to the erection

cost.

Aesthetically, it is desirable to keep all diagonals at the same angle, even if the

chords are not parallel. This arrangement prevents the truss looking over complex

when viewed from an angle. In practice, however, this is usually overruled by the

economies of the deck structure where a constant panel length is to be preferred.

Lateral bracing for truss bridges

Lateral bracing in truss bridges is provided for transmitting the longitudinal

live loads and lateral loads to the bearings and also to prevent the compression

chords from buckling. This is done by providing stringer bracing, braking girders

and chord lateral bracing. In case of highway truss bridges, concrete deck, if

provided, also acts as lateral bracing support system.

The nodes of the lateral system coincide with the nodes of the main trusses.

Due to interaction between them the lateral system may cause as much as 6% of

the total axial load in the chords. This should be taken into account. Fig. 1 shows

the two lateral systems in its original form and its distorted form after axial

compressive loads are applied in the chords due to gravity loads.

The rectangular panels deform as indicated by the dotted lines, causing

compressive stresses in the diagonals and tensile stresses in the transverse

members. The transverse bracing members are indispensable for the good

performance of St. Andrews cross bracing system. In diamond type of lateralbracing system the nodes of the lateral system occur midway between the nodes of

the main trusses [Fig.1(c)]. They also significantly reduce the interaction with main

trusses. With this arrangement, scissors-action occurs when the chords are

stressed, and the chords deflect slightly laterally at the nodes of the lateral system.

Hence, diamond system is more efficient than the St. Andrews cross bracing

system.

-

8/9/2019 30772672 Steel Trusses

10/21

It is assumed that wind loading on diagonals and verticals of the trusses is

equally shared between top and bottom lateral bracing systems. The end portals

(either diagonals or verticals) will carry the load applied to the top chord down to

the bottom chord. In cases, where only one lateral system exists (as in Semithrough

trusses), then the single bracing system must carry the entire wind load.

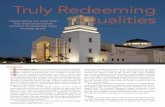

Figure 1: Lateral bracing

-

8/9/2019 30772672 Steel Trusses

11/21

Trusses classifications

According the row materials:

- Timber truss:Wood trusses are the first trusses used by the human they are widely used in

single and multifamily residential, institutional, agricultural and commercial

construction. A truss is a structural frame relying on a triangular arrangement of

webs and chords to transfer loads to reaction points. This arrangement gives them

high strength- to-weight ratios, which permit longer spans than conventional

framing, and offers greater flexibility in floor plan layouts. They can be designed

in almost any shape or size, restricted only by manufacturing capabilities, shipping

limitations and handling considerations. Light frame wood trusses are

prefabricated by pressing galvanized steel truss plates into wood members that are

pre cut and assembled in a jig.

- Steel trusses:Steel trusses are frequently used in industrial and residential buildings, mainly

as roof structures. The truss members are joined with bolts and screws, or using

multiple presses joined or Rosette type connections. For medium and large span

trusses, bolted connections are usually recommended. There are examples of cold-

formed steel trusses with built up back toback lipped channel sections in chords

and single lipped channels for diagonals, joined by bolts, able to cover spans until

60 meters. Concerning the joints behavior of this type of trusses, usually they are

with eccentrically connections, and this feature must be taken into account in the

global analysis.

According to plane:

Planar truss

A planar truss lies in a single plane. They are typically used in parallel to form

roofs and bridges.

The depth of a truss, or the height between the upper and lower chords, is what

makes it an efficient structural form. A solid girder or beam of equal strengthwould have substantial weight and material cost as compared to a truss. For a given

span length, a deeper truss will require less material in the chords and greater

material in the verticals and diagonals. An optimum depth of the truss will

maximize the efficiency.

-

8/9/2019 30772672 Steel Trusses

12/21

Space Truss

Skeleton, three dimensional frame works consisting of pin connected bars are

called space trusses. They are characterized by hinged joints with no moments

or tensional resistance. All members carry only axial compression or tension.

- Space gridsA grid may be defined as two or more sets of parallel beams intersecting each

other at any angle and loaded by an external loading normal to the plane.

They are characterized as two ways or three ways depending upon whether the

members intersecting at a node run in two or three directions.

- Double layer gridA space truss can be formed by two or three layers of grids. A double

layer grid consist of two plane grids forming the top and bottom layers, parallel

to each other and interconnected by vertical and diagonal members. A spacetruss is a combination of prefabricated tetrahedral, octahedral or skeleton

pyramids or inverted pyramids having triangular, square or hexagonal basis

with top and bottom members normally not lying in the same vertical plane.

Double layer flat grid truss, having greater rigidity allow greater flexibility in

layout and permit changes in the positioning of columns. Its high rigidity

ensures that the deflections of the structures are within limits. They are usually

built from simple prefabricated units of standard shape. Due to its high

indeterminacy, buckling of any member under any concentrated load may not

lead to the collapse of the entire structure.

Figure 2: Space truss

-

8/9/2019 30772672 Steel Trusses

13/21

According Functions:

- Bridges trussTruss Girders, lattice girders or open web girders are efficient and

economical structural systems, since the members experience essentially axial

forces and hence the material is fully utilized. Members of the truss girder

bridges can be classified as chord members and web members. Generally, the

chord members resist overall bending moment in the form of direct tension and

compression and web members carry the sheer force in the form of direct

tension or compression. Due to their efficiency, truss bridges are built over

wide range of spans. Truss bridges compete against plate girders for shorter

spans, against box girders for medium spans and cable-stayed bridges for long

spans. Some of the most commonly used trusses suitable for both road and rail

bridges are illustrated in next figure.

Figure 3: Bridges trusses

For short and medium spans it is economical to use parallel chord trusses such

as Warren truss, Pratt truss, Howe truss, etc. to minimize fabrication and

erection costs. Especially for shorter spans the warren truss is more economical

as it requires less material than either the Pratt or Howe trusses. However, for

longer spans, a greater depth is required at the centre and variable depth trusses

-

8/9/2019 30772672 Steel Trusses

14/21

are adopted for economy. In case of truss bridges that are continuous over many

supports, the depth of the truss is usually larger at the supports and smaller at

mid span.

- Roof truss systemA standard gable roof is the simplest arrangement, with gable end trusses at

both ends and common trusses spaced in between. Gable end trusses sit on the

end walls and carry roof loads directly into the wall below. Common trusses are

designed to act as bending members spanning between the exterior walls.

Figure 4: Roof truss

- Girder and valley truss systemBuildings with intersecting ridge lines can be framed as shown below.

Valley trusses are supported on top of the common trusses to form the

intersecting ridge. If a clear span opening is required where the roofsintersect, a girder truss can be used to support the valley trusses and

common trusses at the intersection. The girder trusses usually are specially

made with heavier chords and plates and can consist of a number of trusses

laminated with nails or bolts.

Figure 5: Girder and valley truss

-

8/9/2019 30772672 Steel Trusses

15/21

According shapes:

- Howe

Figure 6:Howe truss

- Fink

Figure 7:Fink truss

- Triangular (Kingpost)

Figure 8: Triangular truss

These three trusses may be simple span, multiple bearing, or cantilevered.

Where the truss height exceeds approximately 3m (Height - Width restrictions vary

by location for shipping. Also plants can be limited by equipment. Some jobs may

be built one piece & shipped with an escort.)

-

8/9/2019 30772672 Steel Trusses

16/21

- MonoThis shape may be simple span, multiple spans, or cantilevered. Top

chord bearing is possible.

Figure 9: Mono truss

- InvertedThe inverted truss is used to provide a vaulted ceiling along a portion of thespan.

Figure 10: Inverted truss

- Cut- offThis shape may be used where a triangular truss will not fit. Usually

stubbed at jogged exterior or at change to vaulted ceiling in opposite

direction.

Figure 11: Cut-off truss

-

8/9/2019 30772672 Steel Trusses

17/21

- Dual SlopeThis truss provides an asymmetric roof slope.

Figure 12: Dual slope

- Vierendeel truss

The Vierendeel truss is a truss where the members are not triangulated but form rectangular openings, and is a frame with fixed joints that are

capable of transferring and resisting bending moments. Regular trusses

comprise members that are commonly assumed to have pinned joints with

the implication that no moments exist at the jointed ends.

The utility of this type of truss in buildings is that a large amount of the

exterior envelope remains unobstructed and can be used for fenestration and

door openings. This is preferable to a braced frame system, which would

leave some areas obstructed by the diagonal braces.

Figure 13: Vierendeel truss

-

8/9/2019 30772672 Steel Trusses

18/21

Advantage of truss

Advantages of space truss

y They are light, structurally efficient and use materials optimally. It can bedesigned in such a way that the total weight comes between 15 to 20kg/m2sign

y It can be built up from simple, prefabricated units of standard size and shapey The small size components simplify the handling, transportation and

erection.

y They allow great flexibility in designing layout and positioning of endsupports.

y Services such as lighting, air conditioning etc., can be integrated with spacestructures.

y The use of complicated and expensive temporary supports during erection iseliminated.

Advantages of steel pipes

y The load carrying capacity increases because of increase in moment ofinertia.

y Circular section may have as much as 30 to 40% less surface area than thatof an equivalent rolled shape and thus reduces the cost of maintenance, cost

of painting.

y There is no better section than the tabular one for torsional resistance.y Tubes are of special interest to architect from an aesthetics viewpoint.y Under dynamic loading the tube has a higher frequency of vibration than any

other cross section including a solid round bar.

Advantage of bridge truss

y the truss bridge is fairly economical in the amount of material it usesy truss bridges are more rigid than most other bridge types (this is usually an

advantage as it can help avoid problems with oscillation

y truss bridges are made where the bridge deck is between the tops of thetrusses (the trusses are under the bridge). This solves the two issuesmentioned above, but is generally only used to cross gorges where there is

plenty of room to put the trusses under the bridge without having to raise the

bridge deck high in the air

y Truss bridges are usually built mostly on-site and cheaper and easier inwork.

-

8/9/2019 30772672 Steel Trusses

19/21

Components of the truss:

- Elements (members)Axial members which may be tubes or any other shapes. Connect

between the joints and resist tension or compression forces only.

- Connectors which join the members together- Bolts connecting members with nodes.

Figure 14: Components of truss

Connecting systems (joints)

- Nodular systemsThey consist of members and nodes.

- Mero connectorThe space frames successfully due to factory mass production of standard

components and easy field assembly. It can accept as many as 18 members

y TuballIt consists of 14 of hollow sphere as cap and 3/4 as cup. It is made of steroidal

graphite. The ends of members are fitted with treated solid props by welding. It is

lighter, less expensive. Each end of a member has a cast end piece with a threaded

boring to receive a bolt. There are also other type connectors such as triodetic,

nodus, schkul etc.

y OctatubeIt is a plate connector and developed in 1973. It can be fabricated at any well

equipped workshop. The joint consist of three plates an octogonal base plate and

two half octagonal plates. Each member end is pressed to form a flat shape. A

-

8/9/2019 30772672 Steel Trusses

20/21

-

8/9/2019 30772672 Steel Trusses

21/21

References:

- Design of steel structure, Prof. S.R.Satish Kumar and Prof. A.R.SanthaKumar.

- BEHAVIOUR OF COLD FORMED STEEL TRUSS BOLTED JOINTS,R. ZAHARIA and D. DUBINA, University of Timisoara.

- Deterioration of Pin-Connected Bridge Trusses, Jan Jarosz and DonSorgenfrei.

- System behaviour of truss assemblies, Rakesh Gupta, Oregon StateUniversity, USA.

- http://encyclopedia2.thefreedictionary.com/trusses.- http://en.wikipedia.org/wiki/Trusses.

- http://www.tfhrc.gov/structur/pubs/04098/03.htm