3. MACHINES - Schurch Asco · 84 Machines February 2018 Av. du 1er Mars 33, CP 3052 CH-2001 ......

Transcript of 3. MACHINES - Schurch Asco · 84 Machines February 2018 Av. du 1er Mars 33, CP 3052 CH-2001 ......

84 Machines February 2018

Av. du 1er Mars 33, CP 3052CH-2001 Neuchâtel

Switzerland

Phone : +41 32 724 3434Fax : +41 32 724 3436

Email : [email protected] : www.schurch-asco.com

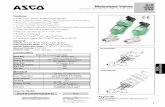

Workbench electronic Tapping-MachineALMAC TE 92

This bench tapping machine – from ALMAC’s standard line – is adaptable, rational and intelligent, just like the heavyweights! This new version is controller-based, and combines programming flexibility with user-friendliness. The basic model of the TE 92 is designed to perform tapping operations from 0.6 to 3 mm dia.

Quality control functionIf a tapping operation cannot be performed to programmed specifications (three unsuccessful attempts), despite the machine being properly adjusted, a warning signal is emitted. Specifications must then be checked before resetting the operation.The halogen Lamp WALDMANN Model HI 20 ref 16439, page 167, with jointed head is preferably designed for this application.

Characteristics:Automatic uncloggingNumber of turns: 0,1 to 99,99Tap turning speed: 50 to 1000 tr/minRegulation of the cutting couple: 7 to 100%Electric supply: 220 V 50/60 HzPlier type: ER 8Weight: 6 kg + 5,8 kg

Technical specifications subject to change.

Plier ER 8 mm for Tapping-Machine

Arbor diameter is 8 mm and the chucks for the following tools are available: 1, 1.5, 2, 2.5, 3, 3.5, 4, 4.5, 5.The model must be precised in the order.

3. MACHINES

Conditions of sale: Net prices

Ref. Designation Tapping range Price

16236Almac TE 92

S 0.60 → M 3.00 11’211.0016237 S 0.30 → M 1.80 12’034.00

Ref. Designation Price

16239 Plier ER 8 mm DIA. 1 mm 40,0016240 Plier ER 8 mm DIA. 1.5 mm 40,0016241 Plier ER 8 mm DIA. 2 mm 40,0016242 Plier ER 8 mm DIA. 2.5 mm 40,0016243 Plier ER 8 mm DIA. 3 mm 33,7516244 Plier ER 8 mm DIA. 3.5 mm 33,7516245 Plier ER 8 mm DIA. 4 mm 33,7516246 Plier ER 8 mm DIA. 4.5 mm 33,7516247 Plier ER 8 mm DIA. 5 mm 33,75

Machines 85February 2018

Av. du 1er Mars 33, CP 3052CH-2001 Neuchâtel

Switzerland

Phone : +41 32 724 3434Fax : +41 32 724 3436

Email : [email protected] : www.schurch-asco.com

Conditions of sale: Net price.

Circular-graining Digital controled MachineDigital control:

A digital control I.C.N. Pico STX 2 type with interpolated axes in control +/-10V and an analogic outlet for the runner, including the ISO programmation (linear and circular interpolations), parameterized, and a RS 232 port for computer, RAM 320 kb, various programmable automaton tasks, processor 486, 1 Mb flash memory, etc.Module with 32 entrances and 16 exits 24 VDC for the automaton tasks.

Motorization:A brushless OMRON motorization for the 2 linear axes including 2 digital servo-amplifiers, two 100 W servomotors with connection and power cables.A runner driving including a 180 W monophased SCHNEIDER Electric frequency dimmer switch and a 90 W asynchronous triphased motor.

Electric cupboard:A collection of electric material including a metallic cupboard behind the machine, the magnetothermic cut-outs, the fuse holders, the contactors, the push buttons, the transformers, a 24 VDC blanking alimentation, the interface relays, an emergency stop management module, a runner’s zero speed detection module, a bi-manual command management module, the proximity detectors for the origins, the connection terminals, the cooling fans with filter, the general sectioner, etc.Voltage 380 V.

Pneumatic collection:A pressure regulator with manometer, a general inlet air sectioner, a filter, a lubrication system, a 24 VDC lockgate with pedal for the bellows’ directing.A vacuum available for the setting of pieces.

2 digital axes of the cross-slideApproximative average circular-graining speed: more than 120 circles per minute.Rapid speed on the two GO axes : 5 meters per minute.Max. work gains on the two G 1 axes: 2 meters per minute.Travels : 130 mm max on X and 70 mm on Y.Desk surface: 320 x 120 mm.X and Y axes made up with NSK rails in purified casting with balls screw 16 mm diameter with 2 mm pitch.

Special runner:A runner 32 mm diameter, rotation speed 6 000 tr/min max.Special lenghtened nose for plyers type B8.Round belt 4 mm diameter transmission.

Portable cutting machine:Disk 80 mm diameter. Rotation speed: ca. 200 tr/min.Voltage 230 V, power circa 2 W.

•

•

•

•

•

•

•

•

••••••

•••

••

Ref. Designation Price

16250 Circular-graining machine CNC 66’000.00

86 Machines February 2018

Av. du 1er Mars 33, CP 3052CH-2001 Neuchâtel

Switzerland

Phone : +41 32 724 3434Fax : +41 32 724 3436

Email : [email protected] : www.schurch-asco.com

Conditions of sale: Net price

Microdrill Tapping-Machine

Mechanical description:Runner driving engine’s power: 180 W.Runner speed from O to 5 000 tr/min, commanded by a frequency dimmer switch.Runner rotation sense: clockwise and anticlockwise.Smooth bearing runner, pressurized and lubricated by vapourized oil.Runner controlled by a highly sensible levers system.Belt runner drive.Runner travel : ca. 24 mm.Plier type: SCHAÜBLIN P4.5,1 to 4.5 mm diameter.Drilling banking vernier graduated in 1/100~ mm.Desk height adjustable with a micrometrical ring.Mini-bellows electrically directed by a pedal.A pressure regulator with manometer, a general inlet air sectioner, a filter, a lubrication system.Machine weight: 56 kg.Compressed air alimentation pression: 4 bars.Lighting by lamp WALDMANN 20 W.

Tapping:Speed variation identical to the drill.Manual regulation of the reversion.Return voltage manually adjustable.Tapping : maxi. M2.5, mini. S0.5 depending on cases.Reversion command incorporated in the levers system of the runner’s descending.

Electric cupboard:A collection of electric material including a metallic cupboard behind the machine, a speed dimmer for asynchronic engine 180 W, protection cut-outs, a power contactor, push buttons, a 24 VDC blanking alimentation, an emergency stop management module, an analogical temporizer, connection terminals, the principal switch sectioner, etc.Voltage 230 V L + N + PE.

•••••••••••••••

•••••

•

•

Ref. Designation Price

16252 Microdrill tapping-machine 18’500.00

Machines 87February 2018

Av. du 1er Mars 33, CP 3052CH-2001 Neuchâtel

Switzerland

Phone : +41 32 724 3434Fax : +41 32 724 3436

Email : [email protected] : www.schurch-asco.com

Conditions of sale: Net price

Chamfering Lathe W20

Speed variation

Mechanical description:

Steel base plate, dimensions 500 x 500 x 12 mm.Bottom sheet for the frequency dimmer switch.Asynchronous triphased flange, type 63, power 180 W 2’760 tr/min.A square runner engine support, adjustable in height and in depth.Belt transmission.A frequency dimmer switch with switches, potentiometer and emergency stop switch.A WALDMANN articulated lamp STE 111 type.An adjustable vacuuming system with recuperation system for parts.An adjustable reverberation plate. RAL 7035 painting.

Runner58 mm diameter, length 109 mm.W20 nose for Plier and stakes.Rotation speed: 1 500 to 7 000 tr/min.W20 nose concentricity: 4 Pm.

••••••••••

••••

Ref. Designation Price

16251 Chamfering piercer W20 5’950.00

Recommended accessories:Wood and leather grinding-wheels for W20 piercer on page 114.Buffing paste on page 131

•

•

88 Machines February 2018

Av. du 1er Mars 33, CP 3052CH-2001 Neuchâtel

Switzerland

Phone : +41 32 724 3434Fax : +41 32 724 3436

Email : [email protected] : www.schurch-asco.com

Conditions of sale: Net price

Ref. Designation Price

16253 Vertical lathe 90’300.00

Vertical LatheDigital control:

An I.C.N. digital control type EXA SX with 2 * 2 interpolated axes on +/-10V control An analogical exit for the runner, including the ISO programmation (linear and circular interpolations), parameterized, an RS 232 exit for computer, RAM 416 K max, different programmable automaton tasks, processor 486, 1 Mb flash memory, graphic screen, etc.Module with 32 entrances and 16 exits 24 VDC for the automaton tasks.

Motorization:A brushless OMRON motorization for the 4 linear axes including 4 digital servo-amplifiers, four 100 W servomotors with connection and power cables.A runner driving including a 750 W monophased SCHNEIDER Electric frequency dimmer switch with external braking resistance and a 750 W asynchronous triphased motor on special carrying out with Fein 24 VDC blocking when put under voltage.

Electric cupboard:A collection of electric material including a metallic cupboard behind the machine, the magnetothermic cut-outs, the fuse holders, the contactors, the push buttons, the transformers, a 24 VDC blanking alimentation, the interface relays, an emergency stop management module, a runner’s zero speed detection module, a bi-manual command management module, the proximity detectors for the origins, the connection terminals, the cooling fans with filter, the general sectioner, an electrical centralized greasing pump, etc.Voltage 380 V.

Pneumatic collection:Two pressure regulators with manometer, a general inlet air sectioner, a filter, a lubrication system, a pressostat with pressure control, a 24 VDC bistable lockgate for the ejection, the pulverization and the vacuuming.

4 digital axes of the cross-slide:Travels: 45 mm max on X and A, 16 mm max on Y and B.X and A axes made up with rails in purified casting with 12 mm x 2 mm ball screws.Y and B axes made up with rails in purified casting with 10 mm x 2 mm ball screws.2 adjustable MULTIFIX tool ports for central cuttingCentralized lubricating with measures and an automatic BIJUR pump.

Counter-point:Pneumatic counter-point, 30 mm diameter, jack ISO 25 with pressure regulation from 50 N to 300 N and a support shock absorber on the bottom plate, including a GEPY rotating point.

Base:5 mm welded mechanic sheeting with a purified casting base for the implantation of the carriages and the runner, including a wooden plate, a container for the oil recuperation and a digital control console.

The special runner:50 mm diameter runner, rotation speed of max 5 500 tr/min, including a compact jack piece ejection with adjustable pressure and an indexation system by inductive detector.

••

•

•

•

•

•

•

•••••

•

•

•

Machines 89February 2018

Av. du 1er Mars 33, CP 3052CH-2001 Neuchâtel

Switzerland

Phone : +41 32 724 3434Fax : +41 32 724 3436

Email : [email protected] : www.schurch-asco.com

Ref. Acceptable shaft diameter Price

16195 1 91,0516196 1.50 72,0516197 2.00 72,0516198 2.50 72,0516199 3.00 59,4516200 4.00 59.00

Plier ESX-9Plier SCHAUBLIN for floating chuck PHA-E9

Conditions of sale: Net prices.

Floating chuckPHA-E9

Parallel to the axe, for high performance reaming Acceptable Plier diameter: 1 to 5 mm.Precise positioning parallel to the axe.Reamer-independent centering.Superior drilling and finishing precision.Better tolerance and increased reamer longevity.Time sparing for a better performance. Ideal with the ESX Plier above

••••••••

Ref. Length Price

16191 10 995.00

Conditions of sale: Net price

Ref. Acceptable Shaft Dia. ext. Dia. Number Price

16204 2.00 ISO 12 12200 100,9516205 3.00 JAP 12 12300 100,9516231 4.00 DIN+ISO+JAP 16 16400 62.0016206 1.00 12 12100 AL 150,4016207 1.50 12 12150 AL 150,4016208 2.00 12 12200 AL 150,4016227 1.00 16 16100 AL 150,4016228 1.50 16 16150 AL 150,4016229 2.00 16 16200 AL 150,4016209 screw for tapping-machine Plier M 2.5 x 2.30 1,50

Compensation Plier ET1Standard and elongated Plier (AL) with 12 and 16 ext. diameter, DIN 6499, ER/ESX, 8° for small dimension tapping.

Conditions of sale: Discount of 10 % for 10 identical pieces.

90 Machines February 2018

Av. du 1er Mars 33, CP 3052CH-2001 Neuchâtel

Switzerland

Phone : +41 32 724 3434Fax : +41 32 724 3436

Email : [email protected] : www.schurch-asco.com

Conditions of sale: Discount: 10 % per assortment of 10 pieces. 15 % per assortment of 100 pieces.

For the assembly of constituents like disc, pulley without hub or brake disk on exit arbor, engeneers use the traditional system of keyway assembly. However, this assembly system often implies an imprecise axial and radial components positioning and the resulting operational costs, like the switching off of the machines and the productivity losses, are high. The gripping hub Trantorque is easily assembled and eliminates the opertional problems associated with keyway assembly. It can avoid the corrosion fretting, the torsion play and the matting of the key associated with a keyway assembly. It can be put on a grooved arbor to replace a used or damaged key and it needs only one gripping nut.

Gripping hub TRANTORQUE

Ref. Type ØaxisConstituent

diameter

Maximum Pressureon axisN/mm2

L1 L2 A BWeight

g

Clamping Torque

NmPrice

Nm kN

16771

min

i

TTQM0516 5 16 9 3 84 19 10 13 3 18.8 10 35.0016772 TTQM0616 6 16 12 4 93 19 10 13 3 18.1 10 35.0016773 TTQM0720 7 20 22 6 103 22 11 16 3 33.9 28 38.0016774 TTQM0820 8 20 32 7 113 22 11 16 3 32.9 28 38.0016775 TTQM0920 9 20 42 9 123 22 11 16 3 31.8 28 38.0016776 TTQM1023 10 23 51 11 119 26 13 19 5 48.9 44 40.0016777 TTQM1123 11 23 60 12 115 26 13 19 5 47.2 44 40.0016778 TTQM1223 12 23 69 13 111 26 13 19 5 45.4 44 40.0016779 TTQM1426 14 26 96 14 110 29 16 22 5 64.9 66 46.0016780 TTQM1526 15 26 122 15 108 29 16 22 5 62 66 46.0016781 TTQM1626 16 26 149 16 107 29 16 22 5 59 66 46.0016782

stan

dard

TTQM1732 17 32 174 18 100 30 22 30 6 118.6 110 48.0016783 TTQM1832 18 32 198 21 92 30 22 30 6 113.9 110 48.0016784 TTQM1932 19 32 223 24 85 30 22 30 6 108.9 110 48.0016785 TTQM2035 20 35 258 26 82 33 24 32 7 144 150 50.0016786 TTQM2235 22 35 293 27 80 33 24 32 7 131.5 150 50.0016787 TTQM2438 24 38 330 29 87 35 25 36 8 166.3 185 52.0016788 TTQM2538 25 38 368 31 94 35 25 36 8 158.8 185 52.0016789 TTQM2845 28 45 459 38 101 41 29 46 11 292.9 300 60.0016790 TTQM3045 30 45 550 45 108 41 29 46 11 272.2 300 60.0016791 TTQM3250 32 50 616 44 100 44 30 50 12 377.4 265 73.0016792 TTQM3550 35 50 681 42 91 44 30 50 12 340.2 265 73.00

Mini Serie

A

L2

B

L1

d D

Machines 91February 2018

Av. du 1er Mars 33, CP 3052CH-2001 Neuchâtel

Switzerland

Phone : +41 32 724 3434Fax : +41 32 724 3436

Email : [email protected] : www.schurch-asco.com

The recommended minimal diameter of the exit arbor allowing the resistance to the exit torque of one unit of Trantorque M is indicated in the table below. These values are given for a constituent entirely covering the L2 dimension of the hub.

Gripping hub TRANTORQUE

Ø axeCalibre

componantPression on shaft N/mm2

Breackdown Torque N/mm2

125 150 175 200 225 250 275 300 325 350 375 400output shaft minimum Diamètre (security factor = 1)

min

i

5 16 84 32 28 26 25 23 22 22 21 21 20 20 206 16 93 35 30 28 26 24 23 23 22 21 21 21 207 20 103 48 41 37 34 32 30 29 28 28 27 26 268 20 113 53 44 39 36 33 32 30 29 28 28 27 279 20 123 58 48 42 38 35 33 31 30 29 28 28 27

10 23 119 65 53 47 42 39 37 36 34 33 32 32 3111 23 115 62 52 45 42 39 37 35 34 33 32 31 3112 23 111 60 50 44 41 38 36 35 33 32 32 31 3014 26 110 67 56 50 46 43 41 39 38 37 36 35 3415 26 108 66 55 49 45 42 40 39 37 36 36 35 3416 26 107 65 55 49 45 42 40 39 37 36 35 35 34

stan

dard

17 32 100 74 64 57 53 50 48 46 45 44 43 42 4118 32 92 69 60 55 51 49 46 45 44 43 42 41 4019 32 85 65 57 53 49 47 45 44 43 42 41 40 4020 35 82 69 62 57 53 51 49 47 46 45 44 44 4322 35 80 68 60 56 53 50 48 47 46 45 44 43 4324 38 87 79 69 63 59 56 54 52 51 50 49 48 4725 38 94 84 73 66 61 58 56 54 52 51 50 49 4828 45 101 106 91 82 75 71 68 65 63 62 60 59 5830 45 108 114 96 85 78 74 70 67 65 63 61 60 5932 50 100 116 100 90 83 78 75 72 70 68 67 65 6435 50 91 107 94 85 79 75 72 70 68 66 65 64 63

Standard Serie

A

L2

B

L1

d D