2014 Dr Ghazy SPRUING for 2nd Year

-

Upload

mohamed-hamed-ghazy -

Category

Documents

-

view

237 -

download

0

Transcript of 2014 Dr Ghazy SPRUING for 2nd Year

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

1/20

24/03/201

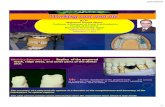

SPRUING

For the 2ndyear

Academic year 2013/2014

March 9&13, 2014

Presented by

Dr. Mohamed H. GhazyProfessor of fixed prosthodontics

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

2/20

24/03/201

Sprueing the wax pattern

Investing the wax pattern

Burning out the wax

pattern

Casting the dental alloy

Devesting the cast

Sandblasting the

framework

Finishing the framework

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

3/20

24/03/201

The process of casting consists

of surrounding the wax pattern

with a mold made of heatresistant investmentmaterial.

Eliminating the wax by heating.

Introducing molten metal into themold through a channel called the

sprue.

The sprue

Definition:

It is a channel

through which

molten alloy canreach the mold in

an invested ring

after the wax has

been eliminated.

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

4/20

24/03/201

Sprue former provides a channel in theinvestment material. Through this sprue channel

molten wax can escape during the burnout process,and molten metal can reach the mold cavity.

Basic requirements of the sprue former:

1. Allow the molten wax to escape from the mold.

2. Enable the molten metal to flow into the mold.

3. The metal within it must remain molten slightly

longer than the alloy that has filled the mold.

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

5/20

24/03/201

Spruing methods:

Direct sprue directed towards the pattern

without any deviations

Reservoir

Spruing methods:

Indirect sprue goes through different angles

along its path towards the pattern (using a

runner bar)

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

6/20

24/03/201

Factors affecting selection of sprue former:

1.Materials of sprue former

2.Diameter

3.Length

4-Location

5-Attachment

6-Angulation

7-Shape and number

1. Types of sprue formers

according to its material

Wax sprue former (preferred).

Plastic sprue former:

1. Solid

2. Hollow

Metallic sprue former:

1. Solid

2. Hollow

Factors affecting selection of

sprue former:

1.Materials of sprue former

2.Diameter

3.Length

4-Location

5-Attachment

6-Angulation

7-Shape and number

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

7/20

24/03/201

Wax sprue former:

Available in different

shapes and diameters.Wax sprues are preferred

for most castings because

they melt at the same rate

as the pattern and thus

allow easy escape of the

molten wax.

Plastic sprue former

When?Plastic sprues can be useful when

casting fixed partial denturesin one piece

Why?Because their added rigidity minimizes

distortion.

Which type?Solidplastic sprues soften at a higher

temperature than the wax pattern and mayblockthe escape of wax, resulting inincreased casting roughness.

Hollowplastic sprues are available thatpermit the escape of the wax.

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

8/20

24/03/201

It should be made of non-rusting metaltoavoid possible contamination of the wax.

Metal sprues are often hollowto increasecontact surface area and strengthen theattachment between the sprue and the pattern.

They are usually removedeasily after coatingtheir external surface with wax, from theinvestment at the same time as the crucibleformer .

Metallic sprue former:

2. Sprue former diameter

Factors affecting selection of

sprue former:

1.Materials of sprue former

2.Diameter

3.Length

4-Location

5-Attachment

6-Angulation

7-Shape and number

Sprue former diameter depends on:

A)Size of wax pattern

i)A 2.5-mm (10-gauge) sprue is recommended for molar and metal-

ceramic patterns.

ii)A smaller 2-mm (12-gauge) is adequate for premolars and partialcoverage restorations.

B)Casting technique

With air-pressure machines the melt is made directly in the

depression created by the crucible former and then forced into the

mold by the sudden change in air pressure. With this technique a

narrow sprue prevents the molten metal from flowing into the mold

prematurely.

A sprue former should be thickerthan the thickest

portion of the wax pattern to permit solidification

of the metal in the casting prior to the sprue and

button.

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

9/20

24/03/201

3. Sprue former length

Average 6 mm

Distance between pattern and ring topGypsum-bonded investment -------- 6-8 mm

Phosphate-bonded investment ------ 3-4 mm

Factors affecting selection of

sprue former:

1.Materials of sprue former

2.Diameter

3.Length

4-location

5-Attachment6-Angulation

7-Shape and number

Thermal zone

The length of the sprue

should be adjusted in such

a way so as to place the

wax pattern away from the

center of the ring (the

hottest zone).

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

10/20

24/03/201

1

4. Sprue former location

-The sprue should be attached to

the bulkiest part of the pattern

( nonfunctional cusp).

-The point of attachment should

permit a stream of metal to be

directed to all parts of the Mold.

Factors affecting selection of

sprue former:

1.Materials of sprue former

2.Diameter

3.Length

4-Location

5-Attachment6-Angulation

7-Shape and number

Sprue former location

Incorrect sprue placement in

the central fossa obliterates

occlusal anatomy and may

result in poor mold filling.

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

11/20

24/03/201

5.Sprue former Attachment

The sprue's point of attachment to thepattern should be carefully smoothed to

minimize turbulence.The attachment area should not be restricted

because necking increases casting porosityand reduces mold filling.

The joint is a drop of waxsmoothed notrestricted to minimize turbulence andcasting porosity

Factors affecting selection of

sprue former:

1.Materials of sprue former

2.Diameter

3.Length

4-Location

5-Attachment6-Angulation

7-Shape and number

6. Sprue former Angulations

The sprue former should not

be placedperpendicular to a

flat portionof the pattern

to lessen the chance of

excessive turbulence duringcasting and the subsequent

formation of porosity.

Factors affecting selection of

sprue former:

1.Materials of sprue former

2.Diameter

3.Length

4-location

5-Attachment

6-Angulation

7-Shape and number

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

12/20

24/03/201

1

7. Shape and number

a) shape Direct sprue directed

towards the pattern without

any deviations for casting

gold alloy.

Indirect sprue goes through

different angles along its

path towards the pattern

(using a runner bar) forcasting base metal alloys.

Factors affecting selection of

sprue former:

1.Materials of sprue former

2.Diameter

3.Length

4-location

5-Attachment6-Angulation

7-Shape and number

b)Number Single spruing

Double spruing

Multiple spruing

i)Single spruingmay be :

Straightin case of casting

with direct technique forgold alloys.

Zigzagin case of indirect

casting technique of base

metal alloys

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

13/20

24/03/201

1

b)Double spruing

Direct spruing (V & Y

shaped)is also used in

casting gold alloy

While the indirectspruingstaple shapedsprue is used forcasting base metal

alloys

c)Multiple sprues

Direct Indirect

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

14/20

24/03/201

1

d) Accessory sprue The thin auxiliary sprue may help gases escape and ensure

the casting solidifies in a criticalarea.

Used for casting thin wall restoration e.g buccal surface of

veneered restoration to prevent perforation of the surface

due to incomplete shrinkage compensation of the thin wall

Venting

The thin auxiliary sprue may help gases escape and

ensure the casting solidifies in a criticalarea.

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

15/20

24/03/201

1

Crucible Former

The sprue is attached to a crucible former,usually made of rubber, which constitutes the baseof the casting ring during investing.

It provides a funnel to facilitate entrance ofmolten alloy

Casting ring holds investment in place and restricts expansion

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

16/20

24/03/201

1

Ring liner allows for hygroscopic expansion,

venting, facilitates removal of investment, and

directs expansion outwards

RINGLESS INVESTMENT TECHNIQUE

- Use higher-strength, phosphate-bonded investments.

- It is designed to allow unrestricted expansion of the

alloys of higher melting temperature to compensate for

high shrinkage.Plastic ring

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

17/20

24/03/201

1

SPRUING TECHNIQUE

for a single casting

1.Attach a wax sprue to the bulkiest

nonfunctional cusp of the wax pattern, and

angle it to facilitates filling of the mold.

SPRUING TECHNIQUE

for a single casting

2. Add wax to the point of attachment and

smooth

it to prevent turbulence during casting.

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

18/20

24/03/201

1

SPRUING TECHNIQUE

for a single casting

3. Remove the

pattern from the die,

using extreme

caution not to distort

it by bending the

fingers of the left

hand.

SPRUING TECHNIQUE

for a single casting

4 - Insert the sprue into the

hole in the crucible former

with forceps and lute with

wax which should be

smoothed.

- Use of a surfactant greatly

enhances wetting of the

pattern during investing

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

19/20

24/03/201

1

SPRUING TECHNIQUE

for a single casting

5. Line the casting ring,

keeping it flush with the

open end, and moisten

the liner.

6. Place the ring over

the pattern to ensure it

is sufficiently long tocover the pattern with

about 6 mm of

investment.

SPRUING TECHNIQUE

for multiple castings

- When more than two

units are being cast

together, each is joined to

a runner bar.A single sprue is used

to feed the runner bar.

-

8/12/2019 2014 Dr Ghazy SPRUING for 2nd Year

20/20

24/03/201

Thats All,

Any Questions ?