2011 GMC Sierra & 2011 GMC Yukon Upfitting Wisconsin - Electrical

-

Upload

zimbrick-buickgmc-west -

Category

Automotive

-

view

2.522 -

download

33

description

Transcript of 2011 GMC Sierra & 2011 GMC Yukon Upfitting Wisconsin - Electrical

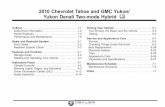

- 1. ElEctrical Manual 2011 light Duty Full SizE C/K truckSiPAGE IndexOVERVIEW Body Control System Description and Operation.............................................................................................................................. A-1 Power Mode Description and Operation............................................................................................................................................ A-1 Retained Accessory Power Description and Operation .................................................................................................................... A-3BACKUP ALARM/CAMERA Backup Alarm Relay Schematic ......................................................................................................................................................... A-5 Backup Lamp Schematic ................................................................................................................................................................... A-6 Chassis Harness Routing Diagram .................................................................................................................................................... A-7 Junction Block - Rear Lamps ............................................................................................................................................................. A-8 Junction Block - Rear Lamps X1 ....................................................................................................................................................... A-9 Junction Block - Rear Lamps X2 ..................................................................................................................................................... A-10BATTERY ISOLATORMedium Duty Battery Isolator Schematic ........................................................................................................................................ A-11Auxiliary Battery Schematic.............................................................................................................................................................. A-12BATTERY/IGNITION GROUND FEEDSInstallation of Electrical Aftermarket Accessories-Battery, Ignition and Ground Feeds.................................................................. A-13ELECTRICAL CHARGING SYSTEM DESCRIPTION AND OPERATION ............................................................................................. A-18ENGINE IDLE UP Elevated Idle / PTO / High Idle Are All Different Options ................................................................................................................. A-23 Adding PTO Option To A Vehicle Without (PTO).............................................................................................................................. A-24IMMOBILIZER ....................................................................................................................................................................................... A-25LIGHTINGForwardComponents .............................................................................................................................................................................A-27Harness Routing .......................................................................................................................................................................A-30Electrical Manual 2011 Light Duty Full Size C/K Trucks