1998 - Best Practice in Re Engineering - A Successful Example of the Porsche Research and...

Transcript of 1998 - Best Practice in Re Engineering - A Successful Example of the Porsche Research and...

BPMJ4,2

154

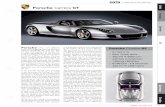

Best practice in reengineering:a successful example of the

Porsche research anddevelopment center

Stephan ZinserFraunhofer-Institute for Industrial Engineering, Stuttgart, Germany

Armin Baumgärtner and Frank-Steffen WalliserPorsche AG, Weissach, Germany

IntroductionStructural change necessitates a fundamental overall renewal of classicmanagement principles and organisational structures in many enterprises. Theincrease in pressure from the market has led to shifting the management focusfrom the realisation of tasks towards the shaping of business processes on theone hand and from rationalising towards market and customer orientation onthe other hand.

In the mid-1970s companies reacted to changes in the markets byconventional productivity management in order to accomplish an efficientexecution of tasks. The increasing individualisation of customer demandsentailed an increase in flexibility and swiftness of the companies concerned. Itwas necessary to improve the integration of companies: management ofintegration was given priority. At the beginning of the 1990s leanmanagement strove for flat hierarchies and short decision-makingprocedures. Continuous improvement processes, supported by all staffmembers, should result in improved efficiency, i.e. wasteful use of resources inall processes is avoided and thereby potentials for cost-saving aredemonstrated. Total quality management (TQM) has been regarded as acomprehensive company-wide approach, focusing on quality. Each and everysingle staff member regards himself as supplier for external and internalcustomers, who have to be supplied with goods of a previously determinedquality. This leads to a high level of customer orientation (Bullinger andZinser, 1996a).

Nowadays increasing international competition creates a steadily growingpressure for improvement. One thing is for sure: if you are working ininternational competition, you are forced to develop new methods, intellectualapproaches and structures in order to ensure and consolidate competitiveness.There is a need for organisational structures that bring together market andtechnology with the aim to assure a long-range survival and competitiveness ofthe company. Particularly in the field of organisation design there is a high

Business Process ManagementJournal, Vol. 4 No. 2, 1998, pp. 154-167. © MCB UniversityPress, 1355-2503

Best practice inreengineering

155

demand for a learning organisation with decentralised responsibility.Successful organisations are, on the one hand, in a position to create new andunfamiliar relationship patterns and to act accordingly, and, on the other hand,they find implementations for new ideas and concepts. (Bullinger and Zinser,1996b)

Those who want to be competitive, have to think about new methods ofimproving efficiency. It is not functions or hierarchies which are crucial, but theprocesses within an enterprise. This results in aligning enterprises with basicprocesses and in renouncing the old thinking in functions and hierarchies.Consequently iterations are avoided, stocks can be cut down, the processingtime is shortened, complexities are reduced and the redundant generation andinput of data can be avoided. Business reengineering stands as a model for this:by concentrating on newly rethought business processes, at the end of whichthe customer stands, further value is being created for the customer. It is themain focus of business reengineering to reshape a company fundamentally andto stress key business processes.

According to a study of the Fraunhofer Institute for Industrial EngineeringGerman firms have realised the necessity of business process management.Large and medium-sized companies of public and private sectors werequestioned in the study. Approximately 84 per cent of the people questionedwere from the top or middle management. 72 per cent of all companiesquestioned considered the reorganisation of processes as “important” or “veryimportant”. Many companies at least try to reorganise “around” the core tasks.48 per cent of the analysed companies have already finished this concept to alarge extent. Current models are clear processes, responsible self-organisationand profit-orientated action (Bullinger et al., 1995).

The modelling of innovative processes aims therefore at the processstructures along the chain of appreciation of the firm. Business reengineeringfits organisational structures to the processes, of which they are a part(Martinsons, 1995).

The key questions are: which function-transcending tasks and measuresare crucial to the success of the company, and how are they achieved? Takingaccount of strategic relevance there will develop a hierarchy of processes:business processes, main processes and subprocesses. Each interfaceprovokes a frictional loss, which becomes apparent in changes of processingtime, loss of information and double work. Further symptoms of a lack ofthinking in processes or of uncontrolled processes are (Bullinger and Zinser,1997):

• excessive exchange of information, redundant data, multiple entries;• long delivery times, huge stocks, buffer and other reserves;• a great deal of control in comparison with appreciation;• much extra work to make up/iterations and• a high complexity, i.e. a great amount of exception rules/special cases.

BPMJ4,2

156

The radical new shaping of existing processes does not, however, warrantworking business processes. In the end there will be not integrated processeswithout the support of so-called “enablers”. Innovative information andcommunication technology are for instance key enablers within reengineeringconcepts (Kaplan and Murdock, 1991). They are the key to, but not the objectiveof, changes in organisation and processes.

The creative use of modern information technology is therefore of crucialimportance in the reshaping and reorientation of the enterprise with regard toan increase in innovation energy. Innovative I&C technology is, according to theaforementioned IAO survey (see Figure 1), crucial to realising customer andinnovation orientation. Successful use of I&C technologies within a businessreengineering project requires that all essentially new possibilities, whichtoday’s information technology has created, are taken into account (Teng et al.,1995).

3 × 3-method for process reengineeringInnovations are being regarded as strategic competition factors within the evershortening market cycles. The development process is therefore of crucialimportance to the competitiveness of companies. Entrepreneurial objectiveshave to concentrate on a faster time-to-market, i.e. on the acceleration ofinnovation processes, the reduction of error rates in product development and adecrease in introduction costs (Bullinger and Zinser, 1997). With theseobjectives in mind, a new process for obtaining parts of prototypes has beendeveloped and implemented in the Porsche research and development center inWeissach. The main goal of reengineering was to lower the processing timefrom the average eight days to only one day. A specially devised 3 × 3-methodwas used for the process reengineering. Some components had been taken fromthe business reengineering pioneers, Hammer and Champy (Hammer and

Figure 1.I&C technologies atreengineering projects

Customer Focus

Innovation Focus

Quality Leadership

Cost Leadership

Differentiation of Services

0 10 20 30 40 50

KeyI&C-technologiesare a crucial factorI&C-technologieshave no influence

%

Best practice inreengineering

157

Champy, 1993), some had been taken from the previous experiences of thereengineering team.

The 3 × 3 principle, shown in Figure 2, takes into account a phase of stabilitywithin the implementation of new processes as an essential extension oftraditional methods in reengineering. Only after reaching this phase of stabilityis it possible to finish the reengineering project and to dissolve thereengineering base team.

The 3 × 3 principle encompasses three main phases, they themselves havethree different subphases each. In the first phase – the initiation of a project – therecognised problems are described within a team. A careful selection andanalysis of data relating to the problems ensures their objectivity at theirpresentation. To obtain an objective view on the process, a team was established.

In the definition phase causes are analysed and appropriate countermeasuresdefined. Wherever possible, temporary measures should be applied in order totest their outcome.

The implementation of the defined measures is pursued in the control phase.On the basis of appropriate reference data and review methods the processefficiency is tracked up to the phase of stability and finally the team receives thegrateful recognition for its engagement.

A practical example: new acquisition of prototype parts indevelopmentSuccessful reengineering requires systematic action, the sensible use ofmethods and tools and the consideration of critical factors of success. The

Figure 2.3 × 3 principle of

process reengineering

Controllingsuccess

Recognisingthe problem

1

Recognisingthe problem

1

Forming ateam

2

Describingthe problem

3

Initiation

Analysingthe cause

Definingmeasures

RealisingtemporarymeasuresDefinition

Stabilisingsuccess

Congratulatingthe

teamControl

BPMJ4,2

158

example of a reengineering project for the acquisition of prototype parts inthe development center of the Porsche AG will demonstrate the 3 × 3reengineering approach, the methods and tools used and the structure of thereengineering project. Besides the presentation of this method in practicaluse, we will give much attention to the experiences of this reengineeringproject.

Phase 1: InitiationIn the initiation phase important business processes are identified andscrutinised for their potential for improvement. Within this analysis theacquisition process of prototype parts was identified as a crucial process withinthe development.

Phase 1.1: recognising the problem – new demands on the acquisitionprocesses of prototype parts. The increasing demands on the reduction indevelopment time within the automobile industry can only be realised by theefficient use of the most up-to-date development methods (for example,simultaneous engineering) and technologies. New technologies prove effectiveby their consideration of integrated processes. Rapid prototyping (RP)technology permits for instance a very fast production of complex parts andthereby allows the optimisation of the product at much earlier stages in itsdevelopment. This potential for the RP technology can only be completelyexploited, if the sectors preceding and succeeding it are likewise optimised. Theacquisition process is within the front sector of the entire rapid prototypingprocess. The study in the Porsche development center showed that theprocessing time for the acquisition of prototype parts no longer meet today’srequirements.

Phase 1.2: forming a team – reengineering structure and forming a team.The reengineering team structure, as shown in Figure 3, links the necessaryprocess knowledge for the analysis and the devising of measures directly to theenterprise-wide co-ordination of all activities in process improvement. Thesolutions are not merely academic, but they reflect a sound knowledge ofprocesses, which in turn is used in all improvement measures.

The selection of the team manager takes place primarily with regard to thelater implementation. Team managers directly affected by changes, show amuch keener interest in a practicable and implemented solution, than those forwhom the improvement project is but one of many. This is also a reason, why noexternal consultants have been called in to this method of process improvement.

The reengineering team consists of members of all departments concerned.A rough process mapping is done beforehand to identify the involved sectors.Each reengineering team has its own team mission, wherein objectives, costsand deadlines as well as the process phase to be examined are laid down in full.The team of this reengineering project got an office on their own. This measureproved extremely sensible for efficient teamwork. Other sources often confirmthis experience (Kennedy, 1994).

Best practice inreengineering

159

Phase 1.3: describing the problem – the old process of the acquisition ofprototype parts. After forming the reengineering team with members frompurchasing, equipment, construction, research, data processing departmentsand the workshop, a detailed description of the potential for improvement wasprepared on the basis of the rough process mapping. An internal customer-supplier-relation was chosen as the foundation; development engineers fromconstruction and research (exhibitors) with an own need of parts were regardedas internal customers. The purchasing department functioned as the supplier inthis case, as they were responsible for the acquisition of the parts.

The discussions with all sectors concerned provided the following potentialfor improvement:

• shorter processing times,

• improvement of information quality,

• better co-ordination of the interfaces between different departments.

Phase 2: definitionPhase 2.1: analysing the causes – process mapping to examine the potential forimprovement. After process mapping the deficiencies of the process capable ofimprovement became obvious.

• waiting time until a requirement report is approved;

• differences in media between report form, EDP-system and order form;

Figure 3.Structure of

reengineering team

Reengineering-steering committee

A

Reengineering-steering committee

B

direct reporting

Reengineeringteam-leader 1

Reengineeringteam-leader 2

Reengineeringteam-leader 3

Department 1Department 1

Department 2

Department 3

Department 4

Department 1

Department 2

Department 3

Department 4

Department 1

Department 2

Department 3

Department 4

CEO

Prio

risat

ion

and

co-o

rdin

atio

nP

roce

ss k

now

ledg

e

BPMJ4,2

160

• waiting time until order is approved;• transport to supplier by mail;• organisational separation of all involved units.

The traditional process (Figure 4) required a conventional form to be filled in,which in turn had to be approved by the project manager. There was noobligation to check the available funds of the budget section used nor to checkthe prices given.

After approval the form was sent by in-house mail to the purchase department.There the request form was entered into a central EDP-system. The purchasedepartment chose or confirmed the suppliers and the prices. After printing theorder form it was duly signed by the person responsible for purchase and thensent to the supplier by mail. This process normally took about eight days, up to30 days were, however, no exception.

The equipment department, responsible for the provision of the parts for theprototype body, was not fully informed of the latest time plan. This used to beso critical, because the production processes of prototype parts do not allowsuch precise time forecasts as possible with series production processes.Therefore dates could change quite quickly, which required reaction andcountermeasures at the prototype body. Only like this could production datesfor the complete prototype be kept.

Phase 2.2: defining measures – two-day-workshop to find new ideas and todefine measures. The reengineering team held a two-day-workshop to generatenew measures. The preliminary examination and the analysis of weaknesseshelped in formulating very ambitious but nevertheless realisable goals. Theprocessing time should be shortened to one day, and information flow on thecurrent state should be improved.

During the two-day-workshop the team clung to the goal, although it seemedtotally out of reach at first. The interdepartmental composition of the team,

Figure 4.Process of theacquisition of prototypeparts before thereengineering

Issuer

8-30 days

Prototypepart

Projectmanager

Purchasedepartment

Head ofdepartment supplier Equipment

department

Orderform

signature 2signature 1

Orderform

Requestform

Requestform

signature 1

Best practice inreengineering

161

however, provided new ideas, which complemented each other, and finally asolution was found; a solution so simple and radical, that it left all peopleinvolved deeply impressed (see Figure 5).

The ideas of the new process were built into concrete, individually realisablemodules (see Figure 6). This provided for an organisation-specific adaptation ofthe solution at the later implementation.

Module 1: component teamAt the focus of the new process was the formation of a so-called componentteam (BTT, prototype parts team PPT). This permanent interdepartmentalteam should be composed by staff from purchase, equipment and of researchdepartments. This team should be entrusted with the complete co-ordinationand ordering of prototype parts and be situated in proximity to the exhibitor.

Figure 5.The process of

prototype partsacquisition after the

reengineering

Database-prices

Database-parts

Issuer BTT Supplier Equipmentdepartment

1-3 days

online Fax

Prototypepart

Prototype-planning

SAP-budget-checker

Purchase Head

Order

Figure 6.The six solution

modules within the newprocess

ComponentTeam

ComponentTeam

Data bankof prices

Budget-checker

Workflowsystem for

requirementforms

Budgetguidelines

Abolished:signature

One dayprocessing

time

BPMJ4,2

162

The main advantage of the team was its intrinsic concentration of know-howfrom the formerly separated departments.

Module 2: workflow system for requirement formsTo shorten idling time and to eliminate transport time an on-line requirementform was realised on the existing EDP-system. This on-line system accesses theexisting data base and checks the validity of the item numbers ordered.

Module 3: databank of pricesThe databank of prices allows parallel entering. The purchase departmententers supplier, price and validity of price; the on-line requirement formaccesses the prices from this special databank.

Module 4: budget guidelinesTo improve information flow on the material budget the envisioned quantitiesare shown on each requirement form. This allows constant comparison with theguidelines and hence entails an improved budget control.

Module 5: budget checkerAs the remaining budget funds are shown by the budget checker, everyone whoorders material will see immediately the effects of his doing so on the materialbudget.

Module 6: signature procedures abolishedOne problem in realising such workflow systems is the approval or theillustration of a signature on an electronic document. The solution wasamazingly simple: the signatures were replaced with the budget checker. Theresponsibility for the material budget was assigned to the issuer; the control ofwhich could be abolished. The signature of the person responsible forpurchase was henceforth only necessary for the entries in the databank ofprices.

Phase 2.3: realising temporary measures – faster realisation of the firstmodules. The modules needed to be implemented as soon as possible. Theplanned software would require about six months of programming. Themodular approach, however, allowed the immediate use of some modules. Onlytwo months later, after refining the necessary details, the first component teamfor a project could be assembled. The experiences of this project could be usedat later implementations in other departments.

Phase 3: controlPhase 3.1: controlling success: realisation in the pilot project and observation ofthe efficiency of the process. After the workshop the real work began. After theapproval of the ideas for reengineering of the acquisition of prototype parts bythe board of directors and the CEO, the ideas were divided into smaller tasks,which were then tackled by a core team of three. The biggest part of it was of

Best practice inreengineering

163

course the software development, which was done using existing systems inorder to enable its testing at a much earlier stage.

In parallel with that was the co-ordination and information of all relevantdepartments and the departments which did not participate in the workshoprespectively. This entailed about 80 individual talks and meetings, whichclarified the necessary need of information and communication ofreengineering projects further. This high level of communication expenditurewas accepted deliberately to ensure the smooth start of this pilot project and toovercome the expected resistance. To support the introductory phase evenmore, process manuals were designed for all staff members, which explained indetail the use of the new software and the processes.

Figure 7 shows the intensity of communication with the development ofinformation points. Points were awarded per information and member of staff.The more intense the information became, the more points could be awarded: awritten information scored one point for instance, a workshop two points.Three points were the maximum. This maximum score was only awarded forthe transfer of given information into own individual action.

The continuous measurement of information allowed a co-ordinated use ofinformation events. The pilot project began in the engine development unit afterthe software had been accomplished. In order to obtain statistical predictions onthe improvement in process efficiency, the average processing times wererecorded each week. The pilot project began with one staff member each fromequipment and research. A purchase department member could be integratedinto the team about three months later.

The graphical representation of the processing time statistics in Figure 8clearly shows three phases during the implementation process:

Phase 1: euphoria. The first four weeks displayed a visible increase in effort,as the staff were in the focus of the new project. The latest processing times

Figure 7.Intensity of

communication inreengineering projects

600

500

400

300

200

100

0

Preparation and Co-ordination

Start of Implementation

Information points

weeks

BPMJ4,2

164

were continuously communicated and the process was supported by thereengineering core team by intervening in conflicts of co-ordination, which areinevitable in such times of change. During these four weeks the processing timewas well within the envisioned objective.

Phase 2: learning. The next weeks saw the normalisation of the efforts of thestaff involved. As only now all exceptional and special cases occurred, theprocessing time deteriorated increasingly or was subject to great fluctuations.The main reason for this situation was the incomplete filling of the databank ofprices, without which there could be no further processing. The reengineeringcore team did not intervene deliberately at this time to give the component teamthe opportunity of tackling the tasks on their own with the relevant units. Someerrors in the software and the tight capacity of personnel (only two staffmembers) depressed motivation even further.

Phase 3: stability. By complementing the team with the purchase departmentmember and by fixing the software errors, the process stabilised and theenvisioned objectives were within reach. Figure 9 shows the allocation ofprocessing time (the time used for the entry of data into the databank wasignored in this figure). At this point, the reengineering core team withdrew fromdirect involvement in the process and restricted themselves to simpleobservation of the process.

Phase 3.2: stabilising success – caring for the new process and improving oninitial difficulties quickly. The phases depicted in Figure 8 show clearly that it isparamount to actively monitor the process right up to the phase of stability.This can only be achieved successfully by internal implementation teams. Inparticular, fixing some minor errors in the software and the conciliating, neutral

Figure 8.Average processingtime per week andquantity of orderedparts

60

40

20

0

processing time in days

5 10 25 30 35 40

250

200

150

100

50

0

number of requests

stabilityeuphoria

weeks in 1997

Keyrequestaveragegoal

learning

Integration of purchasedepartment member

Best practice inreengineering

165

role of the reengineering core team helped the process to achieve growingacceptance and hence stability in process efficiency.

Phase 3.3: congratulating the team – final workshop with participation ofmanagement. To end the reengineering project a workshop with participationof management was held. This gave the opportunity to gather and adapt allexperiences, which are necessary for the introduction of the new process inother departments. From this time on any further optimisation takes placewithin the component team.

SummarySuccessful reengineering requires a systematic approach, the sensible use ofmethods and tools and the consideration of critical factors for success. The casestudy explained the 3 × 3-method of process reengineering at Porsche AG andshowed their experiences in implementing a new process in the acquisition ofprototype parts. The main factors for success in reaching a state of stabilitywere:

• The support of top management. Although top management is onlyactively involved in the initiation of the project, many top managers cedethe actual reengineering work too early and too fast to their staff alone.There is a causality between the engagement of management and theachievement of the project. The top management should devote at least20 to 50 percent of their time to the reengineering project, especially inthe initiation phase.

• Ambitious objectives. Reengineering is not worth the trouble if thecompany anticipates only small improvements. Reengineering efforts,

Figure 9.Allocation of processing

times BTT

100,0%

75,0%

50,0%

25,0%

0,0%>0-2 >2-4 >4-6 >6-8 >8-10 >10

68,6%

9,3% 9,3% 10,6%

1,0% 1,2%

Processing time in days

Allocation of processing time

BPMJ4,2

166

anticipating only 10 percent in cost reduction, 20 percent in processingtime reduction or an increase in turnover of 15 percent, have ratesfrequently of success well below average. Successful businessreengineering necessitates ambitious objectives, i.e. improvements in therange of at least 30 to 50 percent.

• The deployment of a creative team to problem solving. A team is formedout of the most competent staff members to plan and execute areengineering project. These should distinguish themselves by process-specific experiences, creativity and a strong ability for motivation. It isimportant that the project provides a real career opportunity for all staffmembers concerned. One tends to underestimate the longevity of theexisting company culture. It turned out that many reengineeringprojects fail because of the resistance of the staff.

• Process approach and integration of EDP. Most of the time onlyprocedures or partial processes are reshaped, but not the complete chainof appreciation. The effects on the success of reengineering can hardly befelt then, i.e. processes need to be right in the center of the organisationalshaping. Business processes are shaped consequently on customerdemands and therefore transcend company boundaries. Another dangerin department-isolated reengineering lies in the fact that only symptomsare tackled. Most of the time this happens at the end of the chain ofappreciation, the reasons for inefficiency and ineffectiveness can befound at one or many points within the process of appreciation.

Furthermore it evolved during the reengineering project, that the effort forappropriate information and communication is excessively high. The massiveuse of information and communication technology is of utmost importance tosuch aggressive objectives, as was the case with this project. In many cases thestructure of information technology within the firm has to be rethought in orderto improve existing structures on the one hand and to achieve completely newobjectives at the other hand, all with the help of state-of-the-art technology. Thepresent case confirmed in this respect that the use of information andcommunication technology is imperative to reaching the phase of stability in amodified process.

ReferencesBullinger, H.-J. and Zinser, S. (1996a), “Business reengineering”, in Knauth, P. and Wollert, A.

(Eds), Human Resource Management, ch. 5.2.3, pp. 1-33, Deutscher Wirtschaftsdienst,Cologne.

Bullinger, H.-J. and Zinser, S. (1996b), “The management of creative corporations: structures andprocesses in learning organizations”, in UNESCO Chair on Mechatronics Bogazici UniversityIstanbul (Ed.), Technology Management: University/Industry/Government Collaboration, pp. 598-602.

Bullinger, H.-J., Zinser, S. (1997), “Die Notwendigkeit von Innovationen” (“The necessity ofinnovations)”, in Grosskopf, W., Herdzina, K., Blessin, B. and Wuerthner, M. (Eds),Innovationen im Mittelstand (Innovations at Medium-sized Enterprises), pp. 13-25,Schlaumeier, Stuttgart.

Best practice inreengineering

167

Bullinger, H.-J., Wiedmann, G. and Niemeier, J. (1995), Business Reengineering: ManagementConcepts in German, IRB, Stuttgart.

Hammer, M. and Champy, M. (1993), Reengineering the Corporation, Harper Business, New York,NY.

Kaplan, R.B. and Murdock, L. (1991), “Core process redesign”, The McKinsey Quarterly, Summer,pp. 27-43.

Kennedy, C. (1994), “Re-engineering: the human costs and benefits”, Long Range Planning, No. 5,pp. 64-72.

Martinsons, M.G. (1995), “Radical process innovation using information technology: the theory,the practice and the future of reengineering”, International Journal of InformationManagement, No. 4, pp. 253-69.

Teng, J., Grover, V. and Fiedler, K. (1995), “Re-designing business process using informationtechnology”, Long Range Planning, No. 1, pp. 95-106.