17

-

Upload

shridhar-mathad -

Category

Documents

-

view

212 -

download

0

description

Transcript of 17

Cation Ordering and Dielectric Characteristics in Barium Zinc Niobate

Chun-Te Lee,w Yi-Chang Lin, and Chi-Yuen Huang*

Department of Resources Engineering, National Cheng Kung University, Tainan 701, Taiwan

Che-Yi Su and Ching-Li Hu

R&D Technology Center, Yageo Corporation, Kaohsiung 811, Taiwan

Barium zinc niobate (Ba(Zn1/3Nb2/3)O3) (BZN) complex pero-vskite has been reported to have special microwave dielectricproperties with close relation of its ordered structure. This studyinvestigated the effect of calcination on the evolution of orderedstructure and on quality factor with Raman spectroscopy, X-raydiffractometry, and transmission electron microscopy. The re-sults revealed that single calcination at a lower temperature in-hibited the growth of the ordered domain during sintering. Incontrast, the 1:2-ordered domain in double-calcined BZN pow-der grew significantly with a higher sintering temperature and alonger soaking time. It is attributed that double calcinationcaused a higher degree of 1:2 ordering and better homogeneity.At the same time, the quality factor of the sintered ceramic bodywas highly promoted when using double-calcined powder. Aclose relation of the quality factor with the size of ordered do-main, the degree of 1:2 ordering, and the relative density of BZNceramics was presented.

I. Introduction

THE complex perovskite compounds of Ba(B01/3B002/3)O3

(B05Mg21, Zn21; B005Nb51, Ta51), which exhibit ahigh relative permittivity, good quality factor (Q), and a near-zero temperature coefficient of resonant frequency (tf), havebeen used in manufacturing dielectric resonators in the wirelesscommunication system. Previous researches have confirmed thatthe barium zinc niobate (Ba(Zn1/3Nb2/3)O3) (BZN) ceramic hadexcellent microwave dielectric properties, and the ordering of B-site cations had a great effect on Q. Nevertheless, the extendedannealing time required for achieving a high-Q state sloweddown the commercialization of these ceramics, a shortcomingthat has drawn considerable attention since the 1980s.

Several researchers have discerned that the high-Q value re-sults from cation ordering and can be achieved with annealing.Firstly, Kawashima et al.1 reported that the Q value improvedwith increasing degree of ordering, but with at least 120 h ofannealing to achieve a perfect hexagonal ordered structure.Then, Endo et al.2 observed that the Q value increases withthe annealing temperature to reach a saturation value above14001C.

By contrast, Desu and O’Bryan3 reported that improved Q ofBa(Zn1/3Ta2/3)O3 (BZT) is observed even after the completion ofsuch an ordering. Thus, they implied that the improved Q valuewas derived from the loss of ZnO at high temperatures or fora long soaking time. Tamura et al.,4 who reported that minoraddition of BaZrO3 dramatically reduced the annealing time

required to reach a high-Q state, obtained a high Q value with-out observing a hexagonally ordered structure in a BZT–BaZrO3 system. Then, Davies and colleagues5,6 attributed theimprovement of theQ value to the segregation of Zr41 ion to theboundary region to stabilize the grain boundaries. Likewise,Chen et al.7 regarded the Q increase as a result of the decrease inthe lattice defects of grain boundary by examining the graingrowth at high sintering temperatures.

More recently, Reaney and colleagues8,9 observed that a pro-longed soaking time below the temperature of order–disordertransition could enhance 1:2 ordering and lead to an increase ofthe Q value. Janaswamy et al.10 showed that Ba(Mg1/3Ta2/3)O3

(BMT) could form an ordered trigonal phase or a disorderedcubic phase according to different preparation temperatures.They reported that the ordering of Mg, Ta, and Nb cations isclearly related to the ionic size, charge differences, and calcina-tion temperature. As viewed from the literature, no informationexists regarding the effects of calcination condition on the degreeof 1:2 ordering andQ. Thus, this study aimed to investigate howcalcination and sintering conditions can affect the ordered struc-ture and Q of a Ba(Zn1/3Nb2/3)O3 compound with Raman spec-troscopy, X-ray diffractometry (XRD), and transmissionelectron microscopy (TEM).

II. Experimental Procedure

Sample powders of BZN were prepared using a conventionalsolid-state reaction method starting with BaCO3, ZnO, andNb2O5 (all of 99.9% purity), which were ball mill mixed in eth-anol and with yttrium-stabilized zirconia media for 6 h. Thestarting mix was heat treated with single and double calcination.For single calcination, the dried mix was calcined at 10001C orat 12501C, for 6 and 12 h in air, respectively. For double cal-cination, the starting mix was first calcined at a low temperatureof 10001C for 6 h to remove CO2 and to avoid initial ZnO loss,followed by a second calcination at 12501C for 12 h. After eachcalcination, the calcined powders were all re-homogenized withball milling for 6 h. The green compacts were then sintered at12501–15501C for 4–48 h with both heating and cooling rates setat 51C/min for sintering. The green compacts were sintered in acrucible by muffling the BZN powder in order to reduce theZnO loss during sintering.

The phase composition was characterized using XRD (Sie-mens D5000, Bruker-AXS, Karlsruhe, Germany) with graphite-monochromated CuK1 radiation (l5 1.5406 A) from 101 to1201 2y, with a step size of 0.021 2y and a sampling time of 8 s/step. The electron diffraction patterns of the polished sampleswere obtained and analyzed using TEM (FEI Tecnai G2 F20,FEI Philips, Eindhoven, the Netherlands;). Raman’s spectrawere measured with a Dilor XY Raman spectrometer (J.Y.Ramonor u1000 double monochromator, Horiba, Jobin YvonSAS, Longjumeau, France, 1 cm�1 resolution) with a detectiontime of 10 s. Samples were excited by an Ar ion laser beam witha wavelength of 515 nm and a power output of 100 mW.

P. Davies—contributing editor

Supported by the National Science Council of Taiwan under contract No.NSC 94-2216-E-006-045.

*Member, American Ceramic Society.wAuthor to whom correspondence should be addressed. e-mail: [email protected]

Manuscript No. 21675. Received April 7, 2006; approved August 21, 2006.

Journal

J. Am. Ceram. Soc., 90 [2] 483–489 (2007)

DOI: 10.1111/j.1551-2916.2006.01432.x

r 2006 The American Ceramic Society

483

The relative permittivity (er) and quality factor (Q) at micro-wave frequency (B6 GHz) were measured with the Hakki–Coleman dielectric resonator method using an HP 8757D net-work analyzer (Agilent Technologies, Palo Alto, CA) and anHP8350B sweep oscillator (Agilent Technologies). The Q valueswere determined using a TE011 resonant peak, and the tempera-ture coefficient of resonant frequency (tf) was calculated aftermeasuring resonant frequency in the temperature range of 1251to 1851C with

tf ¼ðf2 � f1Þ

f1ðT2 � T1Þ;

where f1 and f2 represent the resonant frequency at tempera-tures T1 and T2, respectively. To compare the dielectric charac-teristics at microwave frequencies, the product of quality factorand resonant frequency (Q� f ) was used.

III. Results

(1) Phase Stability and Ordering: XRD Study

Figure 1 shows the XRD patterns of the powders calcined undervarious conditions. All XRD patterns are indexed with the sim-ple cubic perovskite structure. The pure BZN phase was formedafter 10001C/6 h of calcination. However, the single-calcinedpowder of 12501C/12 h showed peaks of the second phase: bar-ium niobate. Desu and O’Bryan3 proposed a mechanism to ex-plain the formation of a ZnO-deficient phase Ba3Ta2O8 in BZTceramic. In the current investigation, the second phaseBa5Nb4O15 was confirmed from the data of energy-dispersivespectroscopy (EDS) and the XRD pattern. It indicated that thelow synthesis temperature at 10001C effectively avoided initialZnO loss and removed CO2 to form the pure BZN phase.

The XRD patterns at a low angle were also investigated(upper left inset of Fig. 1), and the weak superlattice reflectionwas found at 2y5B17.71. It is the formation of 1:2 ordered thatcause the trigonal symmetry ðP�3m1Þin unit cell. Moreover, theweak superlattice reflection of 1:1 ordering could be observed at2y5B19.51 for the single-calcined powder at 10001C/6 h. Itshows that the 1:1 ordered Ba(Zn1/2Nb1/2)O3 phase was presentin this BZN powder. The intensity of the superlattice reflectionsis proportional to K S fB0 � fB00ð Þf g2, where K represents a con-stant consisting of a polarization factor, a Lorentz factor, andmultiplicity factor; S is a long-range order parameter; and fB0and fB00 are atomic scattering factors of B0 and B00 cations, re-spectively. The difference in scattering factor between Zn andNb ions is quite small, which leads to a much weaker intensity ofthe superlattice reflections than that of the fundamental reflec-tions.

On the other hand, the splitting of XRD peaks will occurwhen ordering results in a lower symmetry. The (420) reflectionat B114.61 2y will split into (422) and (226) reflections in thepresence of 1:2 ordering. Profiles of the (422) and (226) reflec-tions were examined at a high angle of XRD patterns underdifferent calcination conditions (upper right inset of Fig. 1).However, no splitting of the (420) peak was observed, whichshowed little lattice distortion in the BZN powders after anycalcination.

Noh et al.11 reported that the second phase, barium niobate,was found when the BZN specimens were sintered at a tem-perature higher than 13501C. Figure 2 shows the XRD patternsof sintered specimens with the double-calcined BZN powder (at10001C/6 h and 12501C/12 h). No second phase was observedwhen the sintering temperature was increased up to 14001C. Itappears that the second calcination at 12501C stabilized Zn inthe structure and reduced its vapor pressure during the finalfiring to prevent the formation of the second phase. However,a prolonged soaking time at 13501C/48 h still caused the

Fig. 1. X-ray diffractometry (XRD) patterns of specimen calcined under various conditions. (a) Calcined at 10001C/6 h, (b) calcined at 12501C/12 h,and (c) double-calcined at 10001C/6 h and 12501C/12 h.

484 Journal of the American Ceramic Society—Lee et al. Vol. 90, No. 2

second-phase barium niobate to form on the specimen surfacedue to ZnO loss, although specimens were muffled in the powderof the same composition during sintering.

The trigonal distortion caused by the cation ordering can berevealed by the departure of the lattice parameter, c/a ratio,from the ideal value of

ffiffiffiffiffiffiffiffi3=2

p¼ 1:224745 in cubic symmetry.

Desu and O’Bryan3 reported that an improvement of the Qvalue in BZT was accompanied by an increase in the c/a ratioand the splitting of (420) into (422) and (226) reflections with thesoaking time. In this study, the c/a ratio was held with littlechange around 1.2247–1.2253 under 13001–14001C sinteringconditions. Nevertheless, Fig. 2 revealed that a long soakingtime did cause the splitting of (420) into (422) and (226) reflec-tions at B114.61 2y (upper right inset of Fig. 2). This indicatedthat 1:2 ordering was enhanced with longer soaking time from 4to 48 h at 13501C. In contrast, the superlattice reflection atB17.71 2y disappeared, and the splitting of (420) reflection wasnot observed at 14001C, showing that the 1:2 ordering decreasedat 14001C. From the above XRD analysis, the order–disorderphase transition occurred at 14001C in these BZN specimens.

(2) Ordering-Induced Microstructures: TEM Study

Figure 3 shows the TEM analysis of the BZN specimen, doublecalcined and sintered at 13501C/4 h. Figure 3(a) showed that onegrain consisted of several domains, which were separated byanti-phase boundaries (APBs). The APBs were observed be-cause of the influence of chemical ordering regions, which had

nucleated out of phase. The APBs are easily distinguished be-cause that they do not lie on a specific set of crystallographicplanes, whereas the ferroelastic domains have domain walls par-allel to certain crystallographic planes.12 The presence of super-lattice reflections by chemical ordering could be verified fromselected-area electron diffraction (SAED) patterns. Figure 3(b)shows the typical SAED pattern of the chemical ordering do-mains besides APBs, and it was indexed on the basis of a simplecubic perovskite structure. The occurrence of 71/3{111}-typesuperlattice reflections clearly showed the presence of a 1:2 cat-ion-ordered structure with a trigonal ðP�3m1 ) symmetry. Figure3(c) shows the high-resolution TEM (HR-TEM) image of a 1:2ordered domain in the BZN compound. The wavelength of thesuperlattice modulation was 0.71 nm, which corresponded to thetriple of the {111}-planer spacing of simple cubic unit cell(d1115 2.363 A). It appeared that the B-site cations were ar-ranged along the /111S direction as Zn–Nb–Nb–Zn–Nb–Nby in the BZN compound. It was difficult to distinguish the de-gree variation of 1:2 ordering by the SAED patterns. However,the 71/3 {111} type of superlattice reflections weakened anddiffused for the specimen sintered at 14001C, which indicatesthat the degree of 1:2 ordering decreased because of the presenceof diffused superlattice reflections in the SAED pattern. Thisresult was consistent with the observation of XRD patterns inFig. 2, in which superlattice reflection at 2y5 17.71 disappearedto indicate an order–disorder phase transition at 14001C.

Figure 4 shows the dark-field image and the SAED patternsusing one set of 71/3 {111} reflections to investigate the

Fig. 2. X-ray diffractometry (XRD) patterns of barium zinc niobate (Ba(Zn1/3Nb2/3)O3) (BZN) ceramics from powders double calcined at 10001C/6 hand 12501C/12 h, and sintered at (a) 13001C/4 h, (b) 13501C/4 h, (c) 14001C/4 h, and (d) 13501C/48 h.

February 2007 Dielectric Characteristics in Barium Zinc Niobate 485

sintered BZN specimen after being single calcined at 10001C/6 h.The TEM dark-field image (Fig. 4(a)) of the 13501C/4 h sinteredsample showed many small-ordered domains (regions of lightcontrast), typically 20–50 nm in size. Figure 4(b) shows that nosuperlattice reflections were observed in some dark regions ofFig. 4(a). It appeared that the disordered structure existed inthese dark regions. Furthermore, Fig. 4(c) shows the existence of1:1 ordered phase Ba(Zn1/2Nb1/2)O3 in the microstructure. Itappeared that the 1:2 ordered, the 1:1 ordered, and the disor-dered phase coexisted in the specimen. Figure 4(d) shows thatthe ordered domain size did not grow significantly on prolong-ing the soaking time from 4 to 48 h. It appeared that the growthof ordered domains was restrained when the BZN powder wassingle calcined at a low temperature (10001C/6 h).

Figure 5 shows a dark-field TEM micrograph for the sinteredspecimen of double-calcined BZN powder (at 10001C/6 h and12501C/12 h). The dark regions did not correspond to the dis-ordered regions but rather to the ordered domains whose superlattice reflections were not enclosed by the objective aperture ofTEM. Figure 5(a) shows that ordered domains, typically 50–100

nm in size, were present in the specimen of a shorter soakingtime (4 h). The ordered domains grew by an order of magnitudewhen the soaking time was increased from 4 to 48 h at 13501C,as shown in Fig. 5(b) of lower magnification. Apparently, thesynthesis condition had a pronounced effect on the growth ofordered domain in the sintered BZN specimen after comparingFigs. (4) and (5).

(3) Analysis of Raman Spectrum

Kim et al.13 demonstrated that Raman spectroscopy is a usefultool for probing the 1:2 ordering in Ba(Ni1/3Nb2/3)O3 andBa(Zn1/3Nb2/3)O3 compounds. If the B0 and B00 ions are ran-domly distributed, the structure is a disordered cubic perovskitewith Pm3m symmetry and there is no Raman-active mode pres-ent. For the 1:1 ordered structure of Fm3m symmetry, the Ra-man spectra will show four strong active modes at 105 cm�1 ofF2g(Ba), 378 cm�1 of F2g(O), 429 cm�1 of Eg(O), and 783 cm�1

of A1g(O). In addition to these four active modes, the Ramanspectra of the 1:2 ordered structure of trigonal P�3m1 symmetrywill show three extra active modes, 175 cm�1 of Eg(O), 269 cm

�1

of Eg(Nb), and 294 cm�1 of A1g(Nb).Figure 6(a) shows the Raman spectra of BZN powders cal-

cined under different conditions. The spectra in this researchconcurred with those in previous BZN studies,13,14 and the spec-tra of the 1:2 ordered trigonal ðP�3m1Þ structure are similar tothose of other complex perovskite compounds, such as

APB

200 nm

(c)

(b)

(a)

00.71nm

110 111

000 001

200 nm

Fig. 3. Transmission electron microscopy (TEM) analysis of 1:2 order-ing structure in barium zinc niobate (Ba(Zn1/3Nb2/3)O3) (BZN) sinteredat 13501C/4 h from double calcined powders. (a) Anti-phase boundaries(APBs), (b) selected-area electron diffraction (SAED) pattern of �110

� �

zone axis, and (c) high resolution (HR-TEM) image.

(a)

(c)

(d)

(b)

100000

011 111

½½½

Fig. 4. Transmission electron microscopy (TEM) analysis of sinteredspecimens after single calcination at 10001C/6 h. (a) Dark-field image ofa specimen sintered at 13501C/4 h, (b) selected-area electron diffraction(SAED) pattern of the disordered phase, (c) SAED pattern of the 1:1ordered phase, and (d) dark-field image of a specimen sintered at13501C/48 h.

486 Journal of the American Ceramic Society—Lee et al. Vol. 90, No. 2

BMT,15,16 BZT,17 and Ba(Mg1/3Nb2/3)O3.16,18,19 The 1:2 order-

ing showed up in BZN powders after different calcination con-ditions, which was evidenced from the ‘‘extra’’ weaker modes inthe close-up region in Fig. 6(a). It is also observed in Fig. 6(a)that the stretch mode of the oxygen octahedra A1g(O) at 782cm�1 shifted toward a higher wave number (786 cm�1) withhigher calcination temperature or double calcination, which im-plied a stronger bonding in the structure, and consequently amore stable-ordered phase. Furthermore, the intensity of double

calcination became clearly higher, indicating that the degree ofordering was enhanced.

Figure 6(b) shows the variation of the full-width at half-max-imum (FWHM) of four active modes in the Raman spectra(Fig. 6(a)) under different calcination conditions. All FWHMsof these active modes decreased with higher calcination tem-perature or double calcination, which suggested less variation inthe Nb–O bond length, and a higher degree of ordering.

Figure 7 shows the Raman spectra of the BZN specimens,which were double calcined and sintered at different tempera-tures. The intensity of Raman-active modes increased with high-er sintering temperature (from 13001 to 13501C), and with alonger soaking time (from 4 to 48 h at 13501C), which suggestedthat the 1:2 ordered nano-regions grew with sintering tempera-ture and soaking time. Some weak peaks between 312 and 336cm�1 were observed for the 13501C/48 h spectrum (Fig. 7(c)),probably due to the formation of the second phase, barium ni-obate, from ZnO loss during sintering. For the 14001C/4 h spec-trum (Fig. 7(d)), the intensity of all active modes decreased andthe width broadened, accompanied by the disappearance of theactive modes of the 1:2 ordering at 270 cm�1 of Eg(Nb) and 297cm�1 of A1g(Nb). Apparently, the degree of ordering decreased

Fig. 5. Dark-field transmission electron microscopy (TEM) images of the barium zinc niobate (Ba(Zn1/3Nb2/3)O3) (BZN) specimen after doublecalcination and sintering at (a) 13501C/4 h and (b) 13501C/48 h.

Fig. 6. (a) Raman spectra of barium zinc niobate (Ba(Zn1/3Nb2/3)O3)(BZN) compounds calcined under different conditions. (b) Variation offull width at half-maximum (FWHM) of four active modes under dif-ferent calcination conditions.

Fig. 7. Raman spectra of barium zinc niobate (Ba(Zn1/3Nb2/3)O3)(BZN) ceramics that were double calcined and sintered at (a) 13001C/4 h, (b) 13501C/4 h, (c) 13501C/48 h, and (d) 14001C/4 h.

February 2007 Dielectric Characteristics in Barium Zinc Niobate 487

and the order–disorder transformation occurred after 14001C/4h sintering. The order–disorder transition temperature of BZNis clearly lower than that of the BZT compound, which wasreported to be 16001C.20,21

(4) Microwave Dielectric Properties

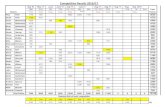

Table I summarizes the microwave dielectric properties of BZNceramics under various calcination and sintering conditions. Therelative permittivity varies little around 35–41, but the Q� fvalues were significantly affected by the calcination and sinteringcondition.

For BZN specimens single calcined at 10001C/6 h and sin-tered for 4 h, there was no second phase formation, and all had ahigh relative density (497%) but relatively low Q� f values. Ahigher sintering temperature (12501–13501C) did increase theQ� f value but not by much. Prolonged soaking time (13501C/48 h) also increased the Q� f value slightly. For sintered BZNspecimens after 12501C/12 h of single calcination, the relativedensity decreased due to second phase formation, but the Q� fvalue increased markedly.

For specimens double calcined at 10001C/6 h and 12501C/12h, the Q� f values became much higher than those with singlecalcination. The highest Q� f of 236,753 GHz was observed forthe specimen sintered at 13501C/48 h. Raising the sintering tem-perature (13001–13501C) or prolonging the soaking time can in-crease the Q� f value, but not when sintered at 14001C orwithout powder muffling during sintering to prevent ZnO loss.

IV. Discussion

This study shows that the calcination condition had a significantinfluence on the formation of 1:2 ordering and the growth ofordered domain, which is closely related to the quality factor(Q� f ). All BZN-sintered specimens from 10001C/6 h single-calcined powders showed much lower Q� f values (3720–11 560GHz) even when the sintering temperature or the soaking timewas increased. The low Q� f value was due to small ordereddomains (20–50 nm) and a high density of APBs in the structure,which was attributed to the poor homogeneity in the single-cal-cined powder. Furthermore, the low calcination temperature of10001C caused a low degree of 1:2 ordering, and the formationof the 1:1 ordered Ba(Zn1/2Nb1/2)O3 phase and a disorderedphase. The disordered phase is a Nb51-rich phase that wasformed in order to maintain the electroneutrality in the structureby compensating the charge imbalance in the unstable Ba(Zn1/2Nb1/2)O3 phase. The strong internal field brought by from thecombination of these two charge-imbalanced phases wouldinhibit the growth of ordered domains during sintering,14 andresulted in low Q� f values.

On the other hand, the sintered BZN ceramics from double-calcined powders showed much higher Q� f values. The homo-geneity in BZN powders brought about by double calcinationcaused a relatively high degree of 1:2 ordering in the structure asevidenced by the analysis of XRD patterns and Raman spectra.The ordered domains grew significantly in this homogeneousstructure during sintering and resulted in high Q� f values. Theordered domains in a 13501C sintered specimen grew by anorder of magnitude (from 100 nm to 1 mm) when the soakingtime was increased from 4 to 48 h, and this BZN ceramic showeda high Q� f value of 236753 GHz. However, prolonged sinter-ing caused ZnO loss when powder muffling was not applied,resulting in a lower density and a large reduction of the Q� fvalue (to 67 714 GHz). Also, the order–disorder phase transitionof BZN occurred at B14001C, and sintering at 14001C/4 hcaused a low degree of ordering and a decrease in the Q� fvalue from 112686 (13501C/4 h) to 69 975 GHz.

V. Conclusion

By examining the effects of calcination condition on the orderedstructure and the quality factor for BZN microwave dielectricceramics, this study has verified that the calcination conditionplays an important role in the formation of an ordered phaseand the growth of an ordered domain. The quality factor isclosely related to the size of ordered domain, the degree of 1:2ordering, and relative density. A BZN specimen sintered at13501C/48 h from the double-calcined powder possessed an erof 39.7, a tf of 15 ppm/1C, and a Q� f value of 236 753 GHz.

References

1S. Kawashima, M. Nishida, I. Ueda, and H. Ouchi, ‘‘Ba(Zn1/3Ta2/3)O3 Cer-amics with Low Dielectric Loss at Microwave Frequencies,’’ J. Am. Ceram. Soc.,66 [6] 421–3 (1983).

2K. Endo, K. Fujimoto, and K. Murakawa, ‘‘Dielectric Properties of Ceramicsin Ba(Co1/3Nb2/3)O3–Ba(Zn1/3Nb2/3)O3 Solid Solution,’’ J. Am. Ceram. Soc., 70 [9]C-215–8 (1987).

3S. B. Desu and H. M. O’Bryan, ‘‘Microwave Loss Quality of BaZn1/3Ta2/3O3

Ceramics,’’ J. Am. Ceram. Soc., 68 [10] 546–51 (1985).4H. Tamura, T. Konoike, Y. Sakabe, and K. Wakino, ‘‘Improved High Q Di-

electric Resonator with Complex Perovskite Structure,’’ J. Am. Ceram. Soc., 67 [4]C59–61 (1984).

5P. K. Davies, J. Tong, and T. Negas, ‘‘Effect of Ordering-Induced DomainBoundaries on Low-Loss Ba(Zn1/3Ta2/3)O3–BaZrO3 Perovskite MicrowaveDielectrics,’’ J. Am. Ceram. Soc., 80 [7] 1727–40 (1997).

6M. A. Akbas and P. K. Davies, ‘‘Ordering- Induced Microstructures andMicrowave Dielectric Properties of the Ba(Zn1/3Ta2/3)O3–BaZrO3 System,’’ J. Am.Ceram. Soc., 81 [3] 670–6 (1998).

7X. M. Chen, D. Liu, R. Z. Hou, X. Hu, and X. Q. Liu, ‘‘Microstructures andMicrowave Dielectric Characteristics of Ca(Zn1/3Nb2/3)O3 Complex PerovskiteCeramics,’’ J. Am. Ceram. Soc., 87 [12] 2208–12 (2004).

8I. M. Reaney, P. L. Wise, I. Qazi, C. A. Miller, T. J. Price, D. S. Cannell,D. M. Iddles, M. J. Rosseinsky, S. M. Moussa, M. Bieringer, L. D. Noailles,

Table I. Microwave Dielectric Properties of BZN Ceramics Under Different Calcination and Sintering Conditions

Calcination condition Sintering condition Relative density (%) Second phase er Q� f (GHz)

10001C/6 h 12501C/4 h 97.2 None 39.4 574913001C/4 h 97.6 None 40.9 709413501C/4 h 97.8 None 40.2 891513501C/48 h 96.2 Ba5Nb4O15 39.2 1156013501C/4 hw 97.5 None 40.1 3720

12501C/12 h 13501C/4 h 85.5 Ba5Nb4O15 35.3 902714501C/4 h 96.5 Ba5Nb4O15 39.9 6627815501C/4 h 93.8 Ba5Nb4O15 38.2 41639

10001C/6 h and 12501C/12 h 13001C/4 h 96.7 None 40.6 4710113501C/4 h 96.4 None 39.4 112 286

Double calcination 14001C/4 h 95.4 None 41.1 6967513501C/48 h 95.0 Ba5Nb4O15 39.7 236 75313501C/48 hz 93.8 Ba5Nb4O15 37.7 67714

wAnnealing at 12501C/12 h after sintering of 13501C/4 h. zWithout muffling powder during sintering. BZN, barium zinc niobate (Ba(Zn1/3Nb2/3)O3).

488 Journal of the American Ceramic Society—Lee et al. Vol. 90, No. 2

and R. M. Ibberson, ‘‘Ordering and Quality Factor in 0.95BaZn1/3Ta2/3O3–0.05SrGa1/2Ta1/2O3 Production Resonators,’’ J. Euro. Ceram. Soc., 23, 3021–34(2003).

9I. M. Reaney, Y. Iqbal, H. Zheng, A. Feteira, H. Hughes, D. Iddles, D. Muir,and T. Price, ‘‘Order-Disorder Behaviour in 0.9Ba([Zn0.60Co0.40]1/3Nb2/3)O3–0.1Ba(Ga0.5Ta0.5)O3 Microwave Dielectric Resonator,’’ J. Euro. Ceram. Soc., 25,1183–9 (2005).

10S. Janaswamy, G. S. Murthy, E. D. Dias, and V. R. K. Murthy,‘‘Structural Analysis of BaMg1/3(Ta,Nb)2/3O3 Ceramics,’’ Mater. Lett., 55,414–9 (2002).

11S. Y. Noh, M. J. Yoo, S. Nahm, C. H. Choi, H. M. Park, and H. J. Lee,‘‘Effect of Structural Changes on the Microwave Dielectric Properties of Ba(Zn1/3Nb2/3)O3 Ceramics,’’ Jpn. J. Appl. Phys., 41, 2978–81 (2002).

12H. J. Lee, H. M. Park, Y. K. Cho, Y. W. Song, J. H. Paik, S. Nahm, and J. D.Byun, ‘‘Two Types of Domain Boundaries in Lanthanum Magnesium Niobate,’’J. Am. Ceram. Soc., 83 [11] 2875–7 (2000).

13B. K. Kim, H. Hamaguchi, I. T. Kim, and K. S. Hong, ‘‘Probing of 1:2Ordering in Ba(Ni1/3Nb2/3)O3 and Ba(Zn1/3Nb2/3)O3 Ceramics by XRD andRaman Spectroscopy,’’ J. Am. Ceram. Soc., 78 [11] 3117–20 (1995).

14S. Kamba, H. Hughes, D. Noujni, S. Surendran, R. C. Pullar, P. Samoukhina,J. Petzelt, R. Freer, N. M. Alford, and D. M. Iddles, ‘‘Relationship Between

Microwave and Lattice Vibration Properties in Ba(Zn1/3Nb2/3)O3-Based Micro-wave Dielectric Ceramics,’’ J. Phys. D.: Appl. Phys., 37, 1980–6 (2004).

15I. G. Siny, R. Tao, R. S. Katiyar, R. Guo, and A. S. Bhalla, ‘‘Raman Spec-troscopy of Mg-Ta Order-Disorder in Ba(Mg1/3Ta2/3)O3,’’ J. Phys. Chem. Solids,59 [2] 181–95 (1998).

16C. T. Chia, Y. C. Chen, H. F. Cheng, and I. N. Lin, ‘‘Correlation of MicrowaveDielectric Properties and Normal Vibration Modes of xBa(Mg1/3Ta2/3)O3–(1–x)Ba(Mg1/3Nb2/3)O3: I. Raman Spectroscopy,’’ J. Appl. Phys., 94 [5] 3360–4 (2003).

17S. J. Webb, J. Breeeze, R. I. Scott, D. S. Cannell, D. M. Iddles, and N. M.Alford, ‘‘Raman Spectroscopic Study of Gallium-Doped Ba(Zn1/3Ta2/3)O3,’’J. Am. Ceram. Soc., 85 [7] 1753–6 (2002).

18A. Dias, V. S. T. Ciminelli, F. M. Matinaga, and R. L. Moreira, ‘‘RamanScattering and X-ray Diffraction Investigations on Hydrothermal Barium Mag-nesium Niobate Ceramics,’’ J. Euro. Ceram. Soc., 21, 2739–44 (2001).

19R. L. Moreira, F. M. Matinaga, and A. Dias, ‘‘Raman-Spectroscopic Evalu-ation of the Long-Range Order in Ba(B01/3B

002/3) O3 Ceramics,’’ Appl. Phys. Lett.,

78 [4] 428–30 (2001).20I. M. Reaney, I. Qazi, and W. E. Lee, ‘‘Order-Disorder Behavior in

Ba(Zn1/3Ta2/3)O3,’’ J. Appl. Phys., 88 [11] 6708–14 (2000).21I. Qazi, I. M. Reaney, and W. E. Lee, ‘‘Order-Disorder Transition in

Ba(Zn1/3Ta2/3)O3,’’ J. Euro. Ceram. Soc., 21, 2613–6 (2001). &

February 2007 Dielectric Characteristics in Barium Zinc Niobate 489