17-1cs-Normal Tightening and Loosening of Flange Bolts

-

Upload

yulianussr -

Category

Documents

-

view

33 -

download

0

description

Transcript of 17-1cs-Normal Tightening and Loosening of Flange Bolts

CONSTRUCTION STANDARD

NORMAL TIGHTENING AND LOOSENING

OF FLANGE BOLTS 17-1CS

DATE: 01 APR 2003 ENGINEERING SERVICES BY KBR TECHNICAL SERVICES, INC. PAGE 1 OF 3

CONFIDENTIALITY NOTICE: This document contains information that is proprietary to Kellogg Brown & Root, LLC. (KBR) and is to be held in confidence. This document and the information contained herein shall not be copied or used for other than the purposes for which it is or has

been provided or disclosed in any form or medium to third parties, except as expressly permitted by KBR.

1. GENERAL 1.1 Scope 1.1.1 This standard covers the general procedures for placing gaskets and for the normal tightening and

loosening of carbon, ferritic alloy, and strain hardened austenitic alloy steel flange bolts for all pressure services and of non-strain hardened austenitic alloy steel flange bolts for pressure services with ratings under ASME Class 300.

1.1.2 Unless otherwise specified, this standard does not cover: a. The tightening of non-strain hardened austenitic alloy steel flange bolts with a rating of ASME Class 300

and over. b. Controlled tightening of flange bolts to specific torque or strain measurements. c. Bolting of manufacturer's proprietary closures and connections, which shall be performed in accordance

with the manufacturer's standards. 2. PROCEDURE 2.1 Preparation 2.1.1 Assembly drawings will list the service bolt type and size, gasket type and size, and any other

requirements or precautions which shall be followed. 2.1.2 Flange faces shall be thoroughly cleaned and the gasket surface inspected for any defects. All rust and

burrs shall be completely removed. Particular attention shall be paid to the seating surfaces for metal gaskets such as the grooves in ring joint flanges.

2.1.3 Bolts shall be checked for proper size, length, conformance to specifications, cleanliness, and absence of

burrs. 2.1.4 Bolt threads and each bearing surface of bolts and nuts shall be coated with one of the following

lubricants, or an equal. The lubricant chosen shall be suitable for the bolt and flange material and the service. a. Graphite and oil: 650°F maximum - Key Graphite Past manufactured by W.K.M. Div. Joy MFG. Co., P.O.

Box 4334, Houston, TX 77210-4334. b. Molybdenum disulfide: 750°F maximum - FEL PRO C-100 manufactured by Fel-Pro Inc., 7450 North

McCormick Boulevard, P.O. Box C1103, Skokie, IL 60076; or Molylube Anti-Seeze manufactured by Bel-Ray Co., Inc., Box 526 Farmingdale, NJ 07727.

c. Colloidal copper: 1000°F maximum Fel-Pro C5-A (not suitable for use on austenitic stainless steel

materials) manufactured by Fel-Pro Inc., 7450 North McCormick Boulevard, P.O. Box C1103, Skokie, IL 60076 and Jet-Lube SS-30 (suitable for use on austenitic stainless steel materials) manufactured by Jet-Lube, P.O. Box 21258, 4849 Homestead Road, Houston TX 77028.

d. Colloidal nickel or silver for austenitic stainless steel material): all temperatures - Never-Seez Nickel

Special (Colloidal nickel) manufactured by Emhart Corp., Bostik Div., Never-Seez Products, Boston St., Middleton, MA 01949 and Silver Goop (colloidal silver) manufactured by Crawford Fitting Company, 29500 Solon Road, Solon, OH 44139.

CONSTRUCTION STANDARD

NORMAL TIGHTENING AND LOOSENING

OF FLANGE BOLTS 17-1CS

DATE: 01 APR 2003 ENGINEERING SERVICES BY KBR TECHNICAL SERVICES, INC. PAGE 2 OF 3

CONFIDENTIALITY NOTICE: This document contains information that is proprietary to Kellogg Brown & Root, LLC. (KBR) and is to be held in confidence. This document and the information contained herein shall not be copied or used for other than the purposes for which it is or has

been provided or disclosed in any form or medium to third parties, except as expressly permitted by KBR.

2.1.5 Gaskets shall be checked for size, conformance to specifications, and cleanliness. Metal gaskets shall have grease, rust, and burrs completely removed. All gaskets shall be fitted against each flange gasket seating surface to check alignment with the surface.

2.2 Flange Preassembly 2.2.1 Flanges shall be preassembled as follows: a. Bolt holes of mating flanges shall be aligned using a spud wrench or other tool. b. Two bolts shall be installed diametrically opposite each other, and one bolt half way between the previously

installed bolts (for flanged joints in horizontal lines, on the underside) for retaining the gasket (e.g. bolts 2, 3 and 4 in Figure 1). The nuts shall then be engaged.

c. The gasket shall be inserted, and centered between the flanges. Nuts shall be hand tightened to hold the

gasket in place. When flanged joints are in horizontal lines, gaskets without centering devices such as ring joint gaskets shall be lowered to the bolts for retention and then raised into position.

d. The remaining bolts and nuts shall be installed and hand tightened with the flange faces parallel. Care shall

be taken to assure proper seating and centering of the gasket within the allowable tolerances. e. Bolts shall be wrench tightened and inspected for tightness in accordance with Article 2.3. 2.2.2 Flanged joints of studded construction shall have studs in place before assembling flanges. 2.2.3 Heavy covers of horizontal equipment shall be provided with external supports and suitable guidance

which shall be maintained until the joint is tightened. 2.3 Tightening of Bolts 2.3.1 The following procedure shall be used for each successive step when wrench tightening bolts. a. Two diametrically opposite bolts shall be tightened either simultaneously or in direct sequence. Care shall

be taken to prevent over-tightening one side of the flange which may result in gasket crushing or flange distortion. Suitable feeler gages may be used for this purpose. Such precaution is particularly desirable when tightening flanges containing ring joint, spiral wound and similar type gaskets. Use of feeler gages is mandatory for the first tightening sequence on lens ring gaskets.

b. Thereafter, two diametrically opposite bolts located half-way between the two bolts previously tightened

shall be tightened, again being careful not to distort the flanges. This procedure shall be repeated until all bolts have been tightened once. The sequence of tightening pairs of bolts shall then be repeated at least six more times until the bolts are uniformly tight and the gasket evenly compressed with the flange faces parallel. If bolts must be tightened more than the six additional times, the same sequence shall be followed.

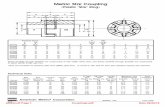

c. As an example, the tightening sequence is shown in Figure I for an eight bolt and sixteen bolt flange.

Similar sequence shall be used for flanges having different numbers of bolts.

CONSTRUCTION STANDARD

NORMAL TIGHTENING AND LOOSENING

OF FLANGE BOLTS 17-1CS

DATE: 01 APR 2003 ENGINEERING SERVICES BY KBR TECHNICAL SERVICES, INC. PAGE 3 OF 3

CONFIDENTIALITY NOTICE: This document contains information that is proprietary to Kellogg Brown & Root, LLC. (KBR) and is to be held in confidence. This document and the information contained herein shall not be copied or used for other than the purposes for which it is or has

been provided or disclosed in any form or medium to third parties, except as expressly permitted by KBR.

FIGURE 1 - TYPICAL BOLT TIGHTENING SEQUENCE

2.3.2 After the flanged connection has been tightened, the joint shall be inspected for uniform bolt loading by

wrench testing each bolt in the same sequence listed in Paragraph 2.3.1 until all bolts are judged to have the same level of tightness.

2.4 Disassembly and Reassembly 2.4.1 When disassembly of a joint is required, the bolts shall be loosened in the same sequence specified in

Article 2.3 for tightening. 2.4.2 Each nut shall be loosened one-twelfth turn in the proper sequence, and the loosening sequence

repeated at least once before any bolt is completely loosened. 2.4.3 The retightening of bolts on reassembly shall follow the original procedure for tightening and inspection.

In addition the bolts, nuts, and bolt and nut bearing surfaces shall be relubricated as specified in Paragraph 2.1.4.