14 Ti H.T

description

Transcript of 14 Ti H.T

Heat Treatment of Titanium and Titanium Alloys

Titanium is a relatively light metal (density = 4.54 g/cm3) but has highstrength (96 ksi f r 99.!" Ti)# and s titanium and its all ys can c m$ete fav rably %ith aluminum all ys f r s me aer s$ace a$$licati ns even th ugh titanium c sts much m re (&3.'5/lb f r Ti versus &!.6 /lb f r l in *!!+. Titanium is als used f r a$$licati ns %here it has su$eri r c rr si n resistance t many chemical envir nments such as s luti ns f chl rine and in rganic chl ride s luti ns.

Titanium metal is e,$ensive because it is difficult t e,tract in the $urestate fr m its c m$ unds. t high tem$eratures titanium c mbines %ith ,ygen# nitr gen# hydr gen# carb n# and ir n# and s s$ecial techni-ues must be used t cast and % rk the metal.

Titanium has the 0 crystal structure (al$ha) at r m tem$erature# %hich transf rms t the 1 (beta) structure at ''32 . lements such as aluminum and ,ygen stabili e the a $hase and increase the tem$eratureat %hich thea $hase transf rms t the β $hase. ther elements such asvanadium and m lybdenum stabili e the beta $hase and l %er thetem$erature at %hich the β $hase is stable.

till ther elements such as chr mium and ir n reduce the transf rmati n tem$erature at %hich the β $hase is stable by causing a eutect id reacti n that $r duces a t% 7$hase structure at r m tem$erature.

Why Use Titanium?

Titanium alloys have excellent corrosion and erosionresistance as well as very high tensile strength andtoughness, even at extreme temperatures. Titanium’sbenefts can be summarized as

• !xcellent strength"to"weight ratio

• #ompatibility with carbon$epoxy materials

• !levated temperature %&'()"*'''() servicecapability

• +uperior oxidation and corrosion resistance

• !xcellent atigue and racture resistance

%-

• iocompatibility

Applications for titanium alloys include:

• /anned and unmanned aircra t 0commercial andmilitary aircra t, rotorcra t1

• 2rtillery 0howitzers1• /ilitary vehicles 0tan3s, hovercra t1• 4aval and marine applications 0sur ace vessels, subs1• Turbines 0power generation1• /edical devices 0implants, instruments1• #hemical processing plants 0petrochemical, oil

plat orms1• 2rchitecture 0sculptures1• 2utomotive 0motorcycles, per ormance automobiles1• 5ulp and paper industry 0washing and bleaching

systems1• #onsumer electronics 0batteries, watches1• +ports e6uipment 0bicycle rames, gol clubs1

Types of Alloys

Titanium alloys are classifed in our main groups based onthe types and amounts o alloying elements they contain

• 2lpha 0a1 7 cannot be strengthened by heattreatment8 low to medium strength, good notchtoughness, ormable, weldable, good creepresistance 0superior to beta alloys1 at somewhatelevated temperatures.

• 4ear alpha 7 medium strength and good creepresistance.

• 2lpha"beta 0a"b1 7 strengthened by heat treatment8medium to high strength, high ormability, good

%%

creep resistance 0but less than most alpha alloys1,alloys with beta content less than -'9 are weldable.

The most amiliar alloy in this category is Ti":2l";<.

• eta 0b1 7 strengthened by heat treatment8 highstrength, air creep resistance, prone to a ductile"to"brittle transition temperature.

+ome alloying elements 02l, =a, =e, #, >, 41 raise thealpha"to"beta transition temperature 0alpha stabilizers1while others 0/o, <, Ta, 4b, /n, )e, #r, #o, 4i, #u, +i1 lowerthe beta transition temperature 0beta stabilizers1.

Types of Heat Treatments

While pure titanium is so t and relatively wea3, heattreating can signifcantly enhance its properties. Titaniumand titanium alloys are heat treated in order to

• educe residual stresses rom abrication 0stressrelieving1

• 5roduce an optimum combination o ductility,machinability, and dimensional and structuralstability 0annealing1

• @ncrease strength 0solution treating and aging1

• >ptimize specifc properties such as racturetoughness, atigue strength, and high"temperaturecreep strength

• #reate specifc material conditions

Standard heat treatments include:

• 2nnealing 7 increases racture toughness andductility 0at room temperature1 and improvesdimensional stability and creep resistance. 2nnealing

%;

may be necessary ollowing severe cold wor3 and toenhance abrication and machining.

• Aomogenizing 7 improves chemical homogeneity incastings.

• +olution treating and age hardening 0aging1 7 aprocess o heating into the beta or high in the alpha"beta phase region, 6uenching and then reheatingagain to the alpha"beta region. 2 wide range o strength levels is possible. )atigue strength increaseswhile ductility, racture toughness and creepresistance are enhanced.

• +tress relie 7 used to reduce residual stresses duringabrication or ollowing severe orming or welding to avoid crac3ing or distortion and to improve atigueresistance. +trength and ductility will not beadversely aBected and cooling rate is not critical.

• Tempering 7 When titanium is 6uenched rom anelevated temperature, reheated to a temperaturebelow the beta"transus, held or a length o time and again 6uenched, it is said to have been tempered.

Three variables exist in tempering the phasespresent, the time held and the temperingtemperature.

Custom heat treatments include:

• eta vacuum annealing and vacuum aging 7improves atigue and yield strength as well aselongation in alloys such as Ti"&&&% 0Ti"&2l"&<"&/o"%#r1.

%&

• razing 7 induction, resistance and urnace brazing inan argon atmosphere or in vacuum. #leanliness isimportant to avoid contamination.

• #reep orming 7 ta3es advantage o the act that titanium moves and ta3es a set well at temperature.

• Cegassing 7 involves removing o entrapped gasessuch as hydrogen 0to under &' ppm1 to avoidembrittlement.

• CiBusion bonding 7 powder metallurgy whereindividual particles use rom intimate sur acecontact.

• Aydriding 7 the deliberate addition o hydrogen toembrittle the material.

• @sothermal trans ormation 7 involves 6uenching analloy rom the all"beta region into the alpha"betafeld, holding and then continuing to 6uench to roomtemperature. This causes precipitation o the alphaphase rom the beta.

• +intering 7 typically involving hot isostatic pressingand laser sintering o powder particles to orm near" net"shape components.

Practical Considerations – What’s Important?

Aeat"treat" urnace capacity is an important considerationsince many titanium parts are volume"limited rather thanweight"limited. Doad support is a critical issue in manyapplications to prevent creep or other dimensionalchanges, especially or intricate or complex part geometry.

Temperature measurement and control must be exact 7usually E*' () 0&.&(#1 or better throughout the entirewor3ing zone o the urnace. Wor3 thermocouples are re6uired because part temperature must be 3nown.Caution: when heating parts over *F%'() 0G;%(#1,

%:

titanium cannot be in contact with a nic3el alloy orstainless steels since eutectic melting will occur.

<acuum pumping systems must be capable o reachinghigh vacuum levels " * x *' "& torr or lower be ore startingto heat. This vacuum level must be maintained whileheating 0re6uiring very slow ramp rates1 and attemperature. CiBusion pumping systems must be properlymaintained or maximum eHciency and to avoid bac3streaming.

+ince titanium is a strong IgetterJ material, vacuum"urnace interiors must be pristine. @deally, all"metal hotzones and dedicated urnaces are desired, but graphite"lined urnaces, also used or other processes, are typical throughout the industry as a practical necessity. Thusfxtures and urnaces must be Iba3ed outJ 0cleaned1be ore use typically at -;''() 0*%*&(#1.

)inally, the reason why vacuum is used to processtitanium is

• +uperior buy"to"Ky ratio 0no wasted material1

• /inimization o alpha case 7 avoidance o an oxygen contamination layer that is very brittle and must beremoved by mechanical or chemical means 0allowscloser near"net"shape parts1.

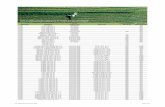

Conversions

°F to °C Ceduct %-, then multiply by &, then divide by G

°C to °F /ultiply by G, then divide by &, then add %-

%F