12588864 Safety Management System in Hydrocarbon Industry Copy

-

Upload

jkhgvdj-mnhsnjkhg -

Category

Documents

-

view

226 -

download

1

description

Transcript of 12588864 Safety Management System in Hydrocarbon Industry Copy

SAFETY MANAGEMENT SYSTEM IN

HYDROCARBON INDUSRTY

Why Safety

• To protect human life

• To protect company property

• To protect surrounding environment /

community

• To enhance corporate image

• To efficiently run the business

• To enhance productivity

• To build up morale & team spirit

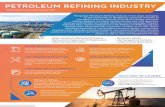

Special Risks Associated withPetroleum Refining

• Highly flammable material

• High Temperature/Pressure

• Modern Technologies use Hydrogen

extensively

• Corrosive / Reactive

• Self Ignition on Leakage from System

• Uncontrolled Process Reactions

• Loss of Containment/Accidental Releases

Safety Management

• In the early stage of industrialization safety was managed through training and following safe procedures, compliance with rules and regulations, etc.

• Next stage witnessed enhanced safety feature through technological upgradation - safe processes, safety features in built in design and prescriptive statutory rules.

• Finally safety is managed through systems approach. The ‘Cullen Report’, 1990 on Piper Alpha Disaster stressed the need for formal safety management system.

Safety Management System

An integrated approach of Management,

Leadership Commitment and Coordinated

Technical Interventions from concept to

commissioning to commercial operations

Safety Management Systems

• EPA Risk Management Programme

• API RP 750 : Management of Process Hazards

• CMA (Chemical Manufactures Association) Systems

• CCPS Guidelines for Technical Management of

Chemical Process Safety

• OSHA - Process Safety Management

Safety Management Systems

• Exxon OIMP (Operations Integrity Management

Practices)

• Caltex PSM (Process Safety Management)

• Dupont PSM

• MOBIL SMS

• ICI Standards

Elements of S, H & E Management Systems ( Indian Oil)

1. S, H & E Leadership and Commitment

2. Employee Participation

3. Process safety Information

4. Risk Analysis and Management

5. Reliability of Critical System and Devices

6. Facilities Design and Construction

7. Operation and Maintenance Procedure

8. Occupational Health and Hygiene

Elements of S, H & E Management Systems (Indian Oil) - Contd.

9. Environment Management

10. Personal safety

11. Training

12. Contractors and Business Associates

13. Work Permit System

14. Management of Change

15. Emergency Planning and Response

16. Incident Investigation and Analysis

17. Safety Audits

1. S, H & E Leadership and Commitment

• Corporate safety policy→ Approved by Board of Directors→ Periodical updation→ Made available to all the employees, contractors,

business associates

• Establishment of S, H & E Management Systems at all locations

• Monitoring of S, H&E Performance

• Formation of Safety Committees→ Management Safety Committee - headed by Unit

Head. Meeting once in a quarter→ Shop-floor Committee - 50% workmen. Meeting once

in a month

1. S, H & E Leadership and Commitment - Contd.

• Promotion of S, H & E Culture→ Safety Award Scheme→ Allocation of resources to improve safety, health and

environment performance→ Personal Protective Equipment - Punishment for non-

compliance→ Surprise checks→ Safety Promotional activities - display of poster, quiz,

safety talk to contractor workmen etc→ Assessment of Safety Awareness Level - once in a

year

• S, H & E Manual→ Safety → Fire → Occupational Health→ Environment Management

2. Employee Participation

Employees shall be involved in all the

elements of S, H & E Management System

• Plant Manager - Overall responsibility

• Training Co-ordinator - assess training need,

ensure skill and refresher training

• Supervisor - encourage for reporting of

potential hazards

2. Employee Participation - Contd.

• Scope of Employee Participation→ Compliance of S, H&E rules and regulations→ Follow safe operating practice→ Involvement in development and updation of

operation/maintenance procedure → Inclusion in pre-startup safety review team→ Involvement in development of training material→ Imparting training to fellow workers→ Use of PPE→ Updation of emergency planning and response

procedures→ Involvement in incident investigation→ Involvement in safety audit→ Help in controlling safety and environmental

incidences

3. Process Safety Information

• Complete and accurate information about

• Process Chemicals

• Process Technology

• Process Equipment

3. Process Safety Information - Contd.

• Process ChemicalsProcess Chemicals

• Physical Properties like vapour pressure, boiling

point etc

• Fire & Explosion Hazards like flash point, auto-

ignition temperature, explosive limits etc.

• Reactive hazards (tendency to react violently)

• Health hazard (toxicity)

• Corrosive properties

3. Process Safety Information - Contd.

• Process TechnologyProcess Technology

• Written down process description

• Process chemistry

• Safe Operating limits

• P&ID

3. Process Safety Information - Contd.

• Process EquipmentProcess Equipment

• Materials of construction

• Design Specifications

• Electrical classification

4. Risk Analysis and Management

Risk Analysis - Major components

• Hazard Identification

• Cause-consequence Analysis

• Hazard & Operability Studies (HAZOP)

• Quantitative Risk Analysis

• Safety Audit Studies

• Individual and Societal Risk Assessment

• Risk Contour Mapping

4. Risk Analysis and Management - Contd.

• Appropriate review of risk once in three years for existing plants based on

→ Internal/external safety audits → HAZOP Study→ Previous risk assessment→ Regulatory compliance→ Accident Investigation Reports

• Risk Analysis and assessment of new projects

• Utilisation of risk analysis study→ Compare the estimate against acceptance criteria

(Govt. of India is yet to stipulate. The Netherlands or UK criteria is used)

→ Implement risk reduction measures based on recommendations

→ Development of Emergency Management Plans

5. Reliability of Critical System and Devices

• Safety critical systems and devices to be identified and approved by management to:

→ Prevent serious process accident→ Mitigate the results of loss of containment

• Identification shall be based on:→ The identified system/device is the final element→ Consequence of failure is large

• Environmental critical systems and devices→ Prevent release of material that would cause serious

environmental impact→ Mitigate the environmental impact

5. Reliability of Critical System and Devices - Contd.

• Requirements

→ Identified systems/devices are periodically tested and

undergo maintenance

→ Procedure for testing and maintenance exists

→ Testing/maintenance is properly documented and analysed

→ Temporary deactivation/bypassing facility exists

→ Approval procedure for bypass/deactivation exists

→ System exists to communicate operation personnel/others

likely to be affected.

6. Facilities Design and Construction

• Initial hazard review for the new projects→ Plant layout→ Operating and design condition→ Basic specifications→ Operating philosophy→ control philosophy and redundancy→ Toxicity and hazard potential of the material involved→ Quantity of the material in process and storage

requirement

• Safety review by a specialised group during detailed design stage

• HAZOP Study on the final P&I drawings

6. Facilities Design and Construction - Contd.

• Some of the important items for consideration:→ Automatic valves at key locations in the plant and utility

system→ Automatic deluge sprinkler system in LPG storage/bottling/

pumping facilities→ Water spray on hot pumps→ Arrangement of fire fighting for tall structures→ Fire protection system and arrangement for draining water

used in fire fighting→ Water draining facility from LPG storage and location of

ROV (shall be first from the vessel)→ Access and exit from plant/equipment→ Earthquake resistant construction→ Electrical installations based on area classification→ Gas detection system→ Compliance of OISD-GDN-192 (Safety Practices during

Construction)

7. Operation and Maintenance Procedure

Comprehensive operating, inspection and maintenance Manuals should be prepared and made available to the concerned personnel. Shall be updated once in a year.

• Operating manual shall contain→ Equipment operation, normal start up and shut downs,

emergency handling procedures

→ Limits of operating parameters and consequence of

crossing the limit

→ Interlocks and safe shut-down instrument functions &

its special features

→ Contains work permit system, equipment hand-over, fire

protection/fighting facilities etc.

7. Operation and Maintenance Procedure - Contd.

• Maintenance manual shall contain→ Procedure for carrying out preventive maintenance

→ Procedure for carrying out predictive maintenance

→ Shut-down/emergency maintenance

→ Job description

→ Interface with other functions

→ Details of major and critical equipment

→ Details of special maintenance procedures

→ Testing procedures

→ Materials specifications

→ Methods of documentation

8. Occupational health and Hygiene

• Objective→ Promote health care of the man behind the machine

→ Early detection of occupational disease

→ Identify, evaluate and control of hazard at work

environment

• Occupational health monitoring shall be in line

with OISD-GDN-166

• Hazardous substances/operations classified

under Schedule-I of The Factories Act, 1948

shall be identified. Employees working in

these areas forms the target group.

8. Occupational health and Hygiene - Contd.

• Major requirements→ Pre-employment medical examination

→ Periodical medical examination - target organs

→ Biological monitoring

→ Well person screening of employees above 40 years

→ Thorough examination of food handlers - skin infection,

chest infestation, worm infestations

→ Sound level monitoring in high noise areas - once in 6

months

→ Checking and surveillance of First Aid boxes

→ Provision of safe drinking water

→ Proper disposal of Bio-medical waste

→ Auditing - once in 2 years

9. Environment Management

• Compliance of statutory requirements

• Identify sources of water pollution. Reduce

generation of waste water and recycle

• Identify sources of atmospheric pollution.

Reduce generation

• Adopt cleaner technology

• Safe disposal of hazardous wastes

• Waste water treatment - compliance with

MINAS

• Ambient air quality monitoring

9. Environment Management - Contd.

• Compliance of NOC/EC conditions

• Documented oil spill response

• Development of green belts/tree plantation

• Training and awareness to all employees,

family members and local community

• Establishment of Quality Management System

- continual improvement

10. Personal Safety• Provide appropriate type of Personal Protective

Equipment (PPE) for protection of → Head

→ Eye

→ Face

→ Respiratory system

→ Hearing

→ Hand

→ Foot

• Enforce and ensure correct use

• Provide fall protection while working at height

• Communicate exceptions/limitations of PPE

11. Training

• Training of new entrants

• Training on operating instructions

• Emergency response training

• Skill of trainers

• Training effectiveness

• Change of assignment/retraining

• Certification

12. Contractors and Business Associates

• Constitute large proportion of work-force• Engaged in construction, repair and

maintenance jobs in hazardous areas• Evaluation of S, H&E Performance of

Contractors• Trained for safe operation• Personal Protective Equipment (PPE) • Information about potential fire, explosion and

toxic release hazards• Contractors are responsible for organising their

work and maintain tools/tackles in such a manner that risk of accident is minimised.

12. Contractors and Business Associates - Contd.

• For project construction jobs, contractors to

deploy full time safety officer

• Frequent safety talk to contractor labours to

raise their safety awareness

• Contractors to ensure that their employees

follow safety rules of the corporation

• Regular safety meeting with the contractors

• Ensure that the contractors comply OISD-GDN-

192 (Safety Practices during Construction)

• Carry out construction safety audit

13. Work Permit System

• Duly authorised written permit is a pre-requisite for carrying out any job in hazardous premises other than by the operating personnel

• Formal work permits system as per OISD-STD-105

• The system operates on ‘Owner-Incharge’ concept. Management issue appropriate authority limits - Gas Safety Inspector & Fire Permit Signatory

• Permits are printed, serially numbered and colour coded

• Before issuing permit, proper isolation of

equipment, gas test, oxygen deficiency tests to

be ensured.

• For the jobs to be carried out by the contractors,

permits are issue to the company supervisors.

• For critical jobs like dyke cutting approval from

higher level officers are required.

• Ensure that after completion of the job, area is

cleaned and the permit is returned to the issuer

who also signs and keeps record for one month.

13. Work Permit System - Contd.

14. Management of Change

• Encure evaluation of potential impact, authorising and control for changes in process technology, equipment, instrumentation and procedures

• Proposed changes to be reviewed by related functions/departments

• Operating/maintenance personnel are to be trained on changes

• Same control to be exercised for temporary as well as permanent changes. Temporary changes should not be permanent by default

• Documentation and communication to all concerned

15. Emergency Planning and Response

• Dedicated Fire fighting facilities

• Fire tenders/Nursers/Hydrant system/Fire

Water Storage/Pumps/Alarms etc.

• Detectors for Early Warning

• Well trained fire crew round the clock

• Mock drill every month

15. Emergency Planning and Response - Contd.

• Regular running of equipment & tests on facilities

• Emergency Management Plans

- on site

- off site

• On site drills once in 6 months

• Off site drill with Dist. Administration once in a year

• Mutual aid Agreements with Neighbouring industries/District Fire Services.

• Updation of plans - once in 3 years

16. Incident Investigation and Analysis

• Incident reporting

• To ascertain cause, recommend remedial

measures to prevent recurrence and document

lessons learnt

• Investigation by multi disciplinary team

• Implementation of recommendations

• Near-miss situations

• Case studies for in-house training programmes

17. Safety Audit

• To check and affirm System Effectiveness

• To be carried out on structured check list by

Multi Disciplinary Teams

• Internal Audit - Every Year

• External Audit (once in 2/3 years) & Surprise

Audit (once in a year) by OISD

• Pre-commissioning safety audit - internal and

OISD

• Implementation of recommendations

• Review - Unit Head/Divisional Director/Board of

Directors

Statutory Compliance

Though not an element of IOC S, H & E Management

System, compliance of following rules are mandatory:• The Factories Act, 1987• The Petroleum Rules, 1976• The Gas Cylinder Rules, 1981• The SMPV (U) Amendment Rules, 1999• The Manufacture, Storage & Import of

Hazardous Chemicals (MSIHC) Rules, 2000• The EP Act, 1986

and other relevant rules like Indian Electricity Act, Boiler Regulations, Central Motor Vehicle Rules etc. to be followed.

Safety

Management

Rating Systems

• International Safety Rating Systems (ISRS)

• 5 Star Audit - British Safety Council, UK

ISRS

• Developed by DNV in 1978

• 20 elements

• 126 sub elements

• 650 requirements

• 10 levels

ISRS Elements• Leadership and administration

• Leadership training

• Planned inspections and maintenance

• Critical task analysis and procedures

• Accident/incident investigation

• Task Observation

• Emergency preparedness

• Rules and work permits

• Accident/incident analysis

• Knowledge and skill training

ISRS Elements• Personal Protective Equipment

• Health & Hygiene control

• System evaluation

• Engineering and change management

• Personal communications

• Group communications

• General promotion

• Hiring and placement

• Materials and services management

• Off-the-job safety

5 - Star Audit

• Assesses management and staff practices

• Measures safety performance

• Recommends courses of action

• Encourages continuous improvement

Objectives

• Detailed examination of the premises

• Identifying all areas of potential risk and loss

• Courses of action suggested to prevent accidents and injuries

FIVE STAR AUDIT

KEY ELEMENTS (5) SUB ELEMENTS (82)

SAFETY ORGANISATION - 26

MANAGEMENT CONTROL SYSTEMS - 26

FIRE CONTROL SYSTEMS - 12

MEASUREMENT & CONTROL SYSTEMS - 6

WORK PLACE IMPLEMENTATION - 12

82 key elements are examined in 5 major areas

MAX. MARKS

• Safety Organisation 1510• Management Control Systems 1315• Fire Control Systems 830• Measurement & Control Systems 475• Work Place Implementation 470

TOTAL 4600

Five Star Grading System

92% - 100% Excellent

85% - 91.9% Very Good

75% - 84.9% Good

60% - 74.9% Average

50% - 59.9% Below Average

Very Low Risk

Low Risk

Acceptable Risk

Unacceptable Risk

Remedial Action Required

The Sword of Honour

Organisations who achieve a five star grading from their Five Star Audit are invited to apply for the Sword of Honour. Approximately 200 organisations apply for the award and the best 40 are given ‘Sword of Honour’.

Thank You