1250_004-BE001-ESE-TU-GL-00-1003_0 - PIPING CLASS

-

Upload

gustavo-alexis-duarte -

Category

Documents

-

view

64 -

download

6

description

Transcript of 1250_004-BE001-ESE-TU-GL-00-1003_0 - PIPING CLASS

-

4 4/10/2013 PARA CONSTRUCCION - MODIF. INDICADAS AML/JAV AML/SNG JAV

2 12/13/2012 PARA CONSTRUCCION - MODIF. INDICADAS AML AML/SNG JAV

B 12/23/2011 REV. GRAL. S/ INGENIERIA DE DETALLE JCM

0 1/24/2012 PARA CONSTRUCCION JCM

SNG JAVA 9/13/2011 PARA INFORMACIN AML

REV APROBOREVISOEJECUTOFECHA DESCRIPCION

AML/SNG JAV

PIPING AND VALVES CLASSES

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

FECHA

REV

12/13/2012

4

DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

HOJA 1

DE 56

AML/SNG JAV

1 8/24/2012 PARA CONSTRUCCION - MODIF. INDICADAS JCM AML/SNG JAV

3 3/5/2013 PARA CONSTRUCCION - MODIF. INDICADAS JAV AML/SNG JAV

ISOLUX WATISOLUX CORSN

DEPARTAMENTO

PLANO EMITIDO PARA:

DE PROYECTOS

CALIFICACIN DE LA DOCUMENTACINISOLUX WATISOLUX CORSN

10/04/13

edcruzText BoxNOTA 1:El aval / liberacin de las Piping Classes:1- Se realiz de acuerdo con los documentos de entrada de Proceso disponibles, y est sujeto a la revisin y liberacin de los mismos:BE001-LDM-PR-LL-00-7135 Rev. 2LISTADO DE LNEAS DE PROCESO (REA DE GENERACIN)BE001-LDO-PR-GL-00-1104 Rev. 2LISTADO DE LNEAS DE PROCESO (REA DE PROCESO)BE001-LDO-PR-GL-00-1106 Rev. 0LISTADO DE FLUIDOS2. Queda sujeto igualmente a las revisiones o actualizaciones de los dems documentos que se generen en el desarrollo de la Ingeniera.3. Se encuentra sujeto, pero no limitado, a los comentarios incluidos en color rojo, aplicables a casos especficos con calificaciones no satisfactorias (ej. clculo de espesores, materiales, pruebas, etc..) dentro de algunas clases de tubera.4. No incluye las Clases PX1 y PZ1 (de material base GFRP), cuyo alcance fue objeto de estudio, anlisis y seleccin del proveedor Protesa.

edcruzStamp

ssuescaStamp

-

Specification Designation

ASME B31.1 Power PipingASME B31.3 Process Piping

Bolting

ASME B18.2.1 Square and Hex Bolts and Screws (Inch Series)ASME B18.2.2 Square and Hex Nuts (Inch Series)

Metallic Fittings, Valves, and Flanges

ASME B16.5 Pipe Flanges and Flanged FittingsASME B16.9 Factory-Made Wrought Steel Buttwelding FittingsASME B16.10 Face-to-Face and End-To-End Dimensions of ValvesASME B16.11 Forged Fittings, Socket-Welding and ThreadedASME B16.34 Valves-Flanged, Threaded, and Welding EndASME B16.36 Orifice Flanges, Class 300, 600, 900, 1500, and 2500ASME B16.47 Large Diameter Steel FlangesASME B16.48 Steel Line Blanks

API 5L Specification for Line PipeAPI 6D Specification for Pipeline ValvesAPI 6FA Specification for Fire Test for ValvesAPI 594 Check Valves: Flanged, Lug, Wafer and Butt-weldingAPI 598 Valve Inspection and TestingAPI 600 Bolted Bonnet Steel Gate Valves for Petroleum and Natural Gas IndustriesAPI 609 Lug- and Wafer-Type Butterfly ValvesBS 5351 Steel ball valves for the petroleum, petrochemicals and allied industriesMSS SP-6 Standard Finishes for contact Faces of Connecting-End Flanges of Valves and FittingsMSS SP-72 Ball valves with flanged or butt - welding ends for general serviceMSS SP-95 Swage (d) Nipples and Bull PlugsMSS SP-97 Integrally Reinf. Forged Branch Outlet Fittings, Socket Welding, Threaded, and Buttwelding EndsMSS SP-99 Instrument valves

Metallic Pipe and Tubes

ASME B36.10M Welded and Seamless Wrought Steel PipeASME B36.19M Stainless Steel Pipe

Miscellaneous

ASME B1.1 Unified Inch Screw Threads (UN and UNR Thread Form)ASME B1.20.1 Pipe Threads, General Purpose (Inch)ASME B16.20 Metallic Gaskets for Pipe Flanges Ring: Joint, Spiral Wound, and JacketedASME B16.21 Nonmetallic Flat Gaskets for Pipe FlangesAWWA C950/M45 Fiberglass Pressure Pipe/Pipe Design

The reference documents listed below form an integral part of this General Specification. Unless otherwise stipulated, the applicable version of

these documents, including relevant appendices and supplements, is the latest revision published at the effective date of the Contract

STANDARDS

DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

FECHA

REV

12/13/2012

4

HOJA 2

DE 56ISOLUX WATISOLUX CORSN

-

Scope

This specification covers the technical requirements of materials for pipes, fittings, flanges, valves and other piping

components covered by the B 31.1/ B 31.3 Codes.

The pipe design should be according to the document BE001-ESE-TU-GL-1001.

Pipe wall thickness

The calculation of pipe wall thickness values shall be in accordance with the ASME B 31.3 / B 31.1 design codes,

and shall include a corrosion allowance as well as mill tolerances as applicable.

The weld efficiency coefficient of welded pipes shall be in accordance Table 302.3.4 in ASME B 31.3 design code.

Pipe diameters

Pipe diameter smaller than " shall not be used. Pipe diameters of 1", 3", 5", 7", 9" and 22" shall not be used.

Equipment supplied with connections of these sizes shall be adjusted to a standard size immediately adjacent

to the equipment by means of a suitable reducing fitting. Bushings shall not be used.

Threaded joints

All threaded connections shall have taper threads in accordance with ASME B 1.20.1 (NPT).

Threaded joints are only authorized on utility lines if and where listed on the relevant piping material class.

High temperature

All class in this specification for temperature above 200C will be class 300# or higher in accordance with the

paragraph 2.5.2 in ASME B 16.5.

Valves

For large diameters or high pressures valves, it should be considered the use of operators gear and zipper,

provided with opening indicators, according to Piping Class specification.

For other conditions, and diameter valves 8", the use of gear operators, shall be considered,

except other indication. In those cases, the "G" code letter shall be added to TAG NUMBER

Grooved jointsAll grooved joint couplings, fittings, valves and specialities shall be the product of a single manufacturer.This manufacturer shall provide on site training for the contractor's field personnel in the instalation ofgrooved joint components and the use of grooving tools. The representative shall periodically visit the siteto ensure best practices are being followed.

4

HOJA 3

DE 56

GENERAL REQUIREMENTS

DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

FECHA

REV

12/13/2012ISOLUX WATISOLUX CORSN

edcruzText BoxVlvulas con condiciones P/T inconsistentes:- Para los tags de vlvulas con calificacin de material con condiciones P/T NO SATISFACTORIAS, se realiz una bsqueda dentro de los MTOs de vlvulas disponibles (Generacin e Interconexin); dentro del MTO del rea de Interconexin (BE001-LDM-PR-GL-00-1600 Rev. Rev. 5) se encontr que para los tags NFWLEP1 y NPWLEP1 (P/T conditions de clases BR3, BR3 VL-Vendor y KR1 VL-Vendor), y BLPPS41 (P/T cond. de clase KR2 VL-Vendor) queda PENDIENTE la validacin, dado que no se encontraron condiciones P/T particulares para estos tags dentro del MTO (se aclara que previamente no fueron encontradas en la MLL). - Igualmente, dentro del MTO del rea de Generacin (BE001-LDM-IA-LV-00-7136 Rev. 2) se encontr que los tags de vlvulas NFWLEP1 y BFWTCIA cumplen bajo condiciones P/T particulares incluidas dentro del MTO, encontrandose SATISFACTORIAS.- Para los tags de vlvulas con calificacin no satisfactoria y no incluidos dentro los MTOs vigentes, el impacto se considera bajo. De requerirse durante el desarrollo de la ingeniera, el impacto cambiar a alto y su uso se deber verificar/validar de manera puntual con el Dpto. de Proceso antes de proceder con su compra.

edcruzText BoxVer comentarios a pie de pgina

-

Piping specification numbering

The Piping specification number shall be 3 digit number.

Digit : 1 Digit : 2 FLANGE: ANSI B 16.5

UNION TYPE

B: CS/MS [NB based/ANSI B36.10] R= Class 150#

K: SS 304/ ALLOY STEEL [NB based/ANSI B36.19] S= Class 300#

M: SS 316L [NB based/ANSI B36.19] T= Class 600#

D: CS/MS [NB based/ANSI B36.10 Galvanized] U= Class 900#

H: 2 1/4 Cr. 1Mo / LOW ALLOY C.STEEL [NB based/ANSI B36.10] Y= Class 1500#

P: GFRP Glass Fiber Reinforced Plastic [AWWA C950/M-45] X= PN 16

L: SS 304 [OD based] A: SMS UNION

E: HDPE (High density polyethylene) Z: PN10

V: PVC (Polivinilo de Cloruro)

N: Polypropylene

Digit : 3

Valves specification numbering (C-Code)

Valves code number shall be 8 digit number.

Digit 1 and 2 Indicates type of valve

Valve Type Code

1. Butterfly Valve Digit 4 Indicates pressure rating

2 Ball Valve

3 Globe Valve

4 Flapped Check Valve 1 5 bar J

5 Dual Plate Wafer Check Valve 2 125 # K

6 Swing Check Valve 3. 150 # L

7 Gate valve 4. 300 # M

8 Lift Check Valve 5. 600 # N

9 Diaphragm Valve 6. 800 # P

Foot Valve 7. 900 # Q

Float Valve 8 1500 # R

12 Knife Valve KF 9 2500 # PN 6.5 S

13 Lubricated Plug Valve LP 10 - PN 10 T

Pinch Valve 11 - PN 16 X

12 - PN 25 Y

Digit 3 Indicates type of end connection

Code

1 Flanged (ANSI) A

2 Socket Welded S

3 Screwed / Threaded (NPT) P

4 Wafer W

Lugged L

Butt welded B

7 Complete SMS/IDF Union Y

8 Grooved G

2 31

6

NP

NS

GT

4 65

DIN Code

BF

5

10

11

DP

FT

Sr.No.

14 PN

FL

Type of End Connection

Shall be used to take care of piping specifications having same Material Of Constructionand flange rating but different pipe wall thickness or different valve specification etc.

7

4

DE 56

NUMBERING PROCEDURE

81 2 3

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

FECHA

REV

12/13/2012

4

TECHNICAL SPECIFICATION

HOJA

BE001-ESE-TU-GL-00-1003

DOCUMENTO No:

Sr.No. ANSI

NL

NF

Sr.No.

BL

GL

ISOLUX WATISOLUX CORSN

-

Digit 5,6,7 Indicates material of construction

Digit 8 Indicates optional requirements if any. This digit may or may not be used depending on requirements.

Sr.No. Optional Requirements Code Sr.No. Optional Requirements Code

3

NUMBERING PROCEDURE

CI22 EPDMASTM A126 CLASS B DI / SGI

1

Sr.No. Code

11

12

13

4

5

6

10

7

8

9

21

14

15

16

17

18

19

20

FECHA 12/13/2012

4

DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

39

43

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

41

42

HOJA 5

DE 56

35

27

26

30

40

REV

ASTM A126 Class B44

36

37

38

34

33

25

24

23

22

32

31

29

28

Body Material Trim Seat Material

CI1

CI3

CI4

DI / SGI

AISI 304

AISI 304

PTFE + EPDM BACK-UP

CI5

CI6

CI9

CS1

CS2

CS3

CS4

CIA

CIB

CIC

CID

CIE

CIF

CIG

CIH

CIJ

EP1

EP2

EP3

FC1

FC2

S41

S42

S43

S44

S45

S46

S47

S48

S49

S51

S52

S53

S54

S55

S56

AL1

AL2

CG1

CG2

ASTM A536 Gr.65-45-12

ASTM A126 CLASS B

ASTM A126 CLASS B

ASTM A126 CLASS B

ASTM A126 CLASS B

ASTM A126 CLASS B

ASTM A216 GR.WCB

ASTM A216 GR.WCB

ASTM A216 GR.WCB

ASTM A216 GR.WCB

ASTM A536 Gr.65-45-12

ASTM A536 Gr.65-45-12

ASTM A536 Gr.65-45-12

ASTM A536 Gr.65-45-12

ASTM A536 Gr.65-45-12

ASTM A536 Gr.65-45-12

ASTM A126 CLASS B

ASTM A126 CLASS B

ASTM A126 CLASS B

ASTM A216/MS+Epoxy

ASTM A216/MS+Epoxy

ASTM A216/MS+Epoxy

A105

A105

AISI 304 / CF8

AISI 304 / CF8

AISI 304 / CF8

ASTMA 351 Gr CF8M

ASTMA 351 Gr CF8M

ASTMA 351 Gr CF8

ASTMA 351 Gr CF8M

ASTMA 351 Gr CF8

ASTMA 351 Gr CF8

ASTMA 351 Gr CF8M

ASTM A351 GR CF8

ASTM A351 GR CF8M

ASTM A 351-Gr CF8M

ASTM A351 GR CF8M

ASTM A536 Gr.3

ASTM A536 Gr.3

A182 F22 CL.3

A217 WC9ASTM A216 WCB+Caucho Blando

PLTD o SS

A182 F6a

A182 F6a

45 CI7 ASTM A126 Class B

46 CI8 ASTM A 216 Gr WCB

AISI 304

GUN METAL

AISI 316

ASTM A216

AISI 304

AISI 304 / CF8

AISI 304

AISI 410

AISI 316 / CF8M

AISI 304 / CF8

DI / SGI

AISI 316 / CF8M

DI / SGI

AISI 304 / CF8

AISI316 / CF8M

DI/SGI

ASTM A216/MS+Epoxy

AISI 316

AISI 304

ASTM A216/MS+Epoxy

ASTM A216/MS+Epoxy

AISI 410

AISI 304

AISI 304

AISI 304

CAUCHO BLANDO

CAUCHO NATURAL

17-4PH/SS316

AISI 304

AISI 316

AISI 304

AISI 316

AISI 316

DI/SGI

AISI 304

AISI 316

AISI 316

AISI 304

PTFE O'RING

EPDM

AISI 304

NITRILE

EPDM

AISI 410

PTFE

AISI 410

AISI 410

PTFE + EPDM BACK-UP

PTFE + EPDM BACK-UP

PTFE + VITON BACK-UP

PTFE + VITON BACK-UP

PTFE + VITON BACK-UP

PTFE + EPDM BACK-UP

VITON

VITON

VITON

VITON

EPDM

PTFE

AISI 410

PTFE

PTFE

EPDM

AISI 304

EPDM

SILICONE

SILICONE

VITON

VITON

AISI 410

PTFE

EPDM

AISI 316

EPDM

EPDM/NITRILE

PTFE

Stellite

Stellite

CAUCHO BLANDO

--

PTFE + EPDM BACK-UP

PTFE + SILICONE BACK-UP

RTFE + SILICONE BACK-UP

48 S57 ASTM A 351 Gr CF8M ASTM A 351-Gr CF8M RTFE + SILICONE BACK-UP

Ductile Iron + EDGE SSCIK ASTM A 536 Gr 6047

1

2

3

4

G

S

M

L

5

Gear Operated

Spring Loaded

Sanitary Type (SMS)

Valve Lock Arrangement

High Performance H

6

7

8

9

10

Limit Switches Box

I

J

Gear Op+Lock Arrangmnt

ISOLUX WATISOLUX CORSN

edcruzText BoxTags de vlvulas inconsistentes:- Se identificaron diez (10) inconsistencias en la asignacin del cdigo o tag de vlvulas, teniendo en cuenta el sistema de codificacin para materiales de BODY, TRIM y SEAT MATERIAL/"O" RING (dgitos 5, 6 y 7) y la informacin de materiales contenida en cada Piping Class, las cuales se resumen a continuacin:

CLASSTAG BU1GTSRCIK, GTBRCIK, GLSRCIK, GLBRCIK, NSBRCIKMR1BFWTCIE, BFWTCIEGBR4S/726, VIC-MASTERSEAL, AGS-VIC300 - En todo caso, se consideraron materiales mandatorios los establecidos en la Piping Class.

edcruzText BoxVer comentarios a pie de pgina

-

AA1 Dehydrated Ethanol (200 proof) HCA Hydrated Lime

AA2 Dehydrated Ethanol (200 proof) HFO Heavy Fusel Oil

AAV Dehydrated Ethanol Vapor HPS High Pressure Steam

ACM Activated Cell Mass IAR Instrument Air

ADD Additive Solution IMW Imbibition Water

AFS Antifoam Solution JAL Alkanized Juice

AIR Air (Atmospheric) JCL Clarified Juice

AL1 Alcohol Water Liquid JFM Quarter Mill Juice

AL2 Alcohol Water Liquid JFT Filtered Juice

ARF Atmospheric relief JMX Mixed Juice

AV1 Alcohol Water Vapors JMZ Mixed Juice

AV2 Alcohol Water Vapors JTM Third Mill Juice

BFW Boiler Feed Water JUC Juice

BGL Bagasse JUV Juice Vapors

BGZ Bagasse JVM Five Mill Juice

BTC Bactericide LCA Lime Grouting

CAS Concentrated Sulphuric Acid LFO Light Fusel Oil

CAV Caustic Lye LPS Low Pressure Steam

CCW Cane Cleaning Water MPS Medium Pressure Steam

CDO Carbon Di-Oxide NCV non Condensate Vapors

CGL Coagulant NTG Nitrogen

CHZ Mud NUT Nutrient Solution

CIP CIP Solution (Caustic) OIL Oil

CIR CIP Solution (Phosphoric Acid) PAR Process Air

CIS CIP Solution (Nitric Acid) PC1 Juice Vapor Condensate

CLM Cell Mass PC2 Process Condensate (Vinasse Condensate)

CNS Conc. Nitric Acid PRW Process Water

CNZ Ashes RLV Relief to vent

COH Steam Condensate (High Pressure Steam) SAL Technical Alcohol

COL Steam Condensate (Low Pressure Steam) SAR Service Air

COM Steam Condensate (Medium Pressure Steam) SCW Scrubbing Water

CPS Concentrated phosphoric acid SEW Sealing Water

CWR Cooling Water Return SLG Sludge

CWS Cooling Water Supply SPL Spent Lees

DMW Demi Water SRW Service Water

DOL Diesel Oil SWC Soft Water

DOW Domestic Sewage Water TRW Treated Water

DRA Drain VIL Vinasse Mud

DRW Drinking Water VIN Vinasse

EFF Effluent VIV Vinasse Vapor

FFM Fire Foam VNT Vent Gases

FFW Fire Water WRW Raw Water

FIW Filtered Water WTW Waste Water

FLO Polymer YCM Yeast Cream

FMC Fermented Mash Cold (Beer)

FMH Fermented Mash Hot (Beer)

FOH Fusel Oil Draw (Liquid)

FOL Fusel Oil Product (Liquid)

FOW Fusel Oil Washing

GSL Gasoline

HAL Hydrous Alcohol (95% v/v)

FLUID LIST

FECHA

REV

12/13/2012

4

DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

HOJA 6

DE 56ISOLUX WATISOLUX CORSN

edcruzText BoxFLUID LIST:- La presente revisin no incluye ninguna verificacin de las metalurgias ya definidas en el Listado de Fluidos, Listado Mecnico de Lneas y el documento de Clases de Tubera vigentes. La verificacin entre estos documentos debe hacer parte del alcance del Grupo de Proceso. - Veintin (21) combinaciones de fluido - clase utilizadas en el Mechanical Line List no corresponden a lo indicado en el Servicio de la Piping Class. Por lo anterior, su asignacin en el MLL deber ser verificado por el Dpto. de Proceso:

P.CLASS FLUIDOen MLLen MLLBR1conDMW, DRABR3conCWR, CWS, DMW, EFF, SWC, VNTDR1conDMW, DRAHY1conCOL, LPSHY2conHPSKR1conDOW, DRW, FTJ, IARPX2conCWR, CWSVR1conSHC, VNT

- Se encontr que el material base definido en el documento Listado de Fluidos (BE001-LDO-PR-GL-00-1106_0), no coincide con el dado en el documento Piping Class (BE001-ESE-TU-GL-00-1003_4), para las clases HY1, KR3, BR3, BU1, ER1 y VR1; ver combinaciones de materiales/fluidos INCONSISTENTES al interno de cada p.class. El Dpto. de Proceso deber verificar/validar.

edcruzText BoxVer comentarios a pie de pgina

-

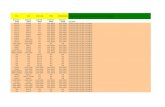

ASME

B31.1

Carbon

SteelA106 Gr.B

100 42

M.S. PVC - 40

18 BU1 BFW 900# - RTJ120 kg/cm2(g)

-29 @ 120 C1,5 mm

DIN

8074/75HDPE - 38

17 VR1 EFF 150 # - RF - -

ASME

B31.3

Carbon

SteelAPI 5L Gr.B

100 36

16 ER1 DRW 150 # - RF - -

AWWA

C950GFRP 0 34

15 BT1 COL 600 # - RF35,6 kg/cm2(g)

-29 @ 475 C1,5 mm

14 PZ1 CWR, CWS PN 1010 kg/cm2 (g)

-29 @ 120 C0 mm

1,5 mm

9

13

N/ASts.Steel

3040 150 mm

24

Carbon

Steel Galv.

ITEM

7

1810

22

4 KR4 DRA

MR1

0 mm

26

BR4

100 mm

FFW, FFM

150 # - RF

Carbon

SteelAPI 5L Gr.B

10

30

AWWA

C9500

21/4 Cr.1 Mo

A335 P.22100

32

ASME

B31.1

GFRP

ANSI

B16.5

Sts.Steel

304

ASME

B31.3

BR1AA2, AFS, AL1, CWR, CWS, FOL, PAR, PRW, SEW, SRW,

SWC150 # - RF

9.9 kg/cm2 (g)

-29 @ 52 C

150 # - RFASME

B31.3

BR3

150 # - RF14 kg/cm2 (g)

-29 @ 60 C

PX1 CWR, CWS PN 1614 kg/cm2 (g)

-29 @ 120 C

HPS, BFW 1500# - RTJ85 kg/cm2 (g)

-29 @ 542 C

LA1 CLM5.5 kg/cm2 (g)

-29 @ 48 C

1,5 mm

BR2 CAS, DRA

CPS, DRA

14 kg/cm2 (g)

-29 @ 120 C1,5 mm

150 # - RF5.5 kg/cm2 (g)

-29 @ 48 C

10

10

10

CIS, CNS, CIR, DMW, DRASts.Steel

304

150 # - RF

0 mm150 # - RF

N/A ATM >70C

KR2AAV, AL2, AV1, AV2, BTC, FOH, HFO, LFO, NCV, PC2,

SCW, SPL, VIL, VIN, VIV, VNT150 # - RF

MATERIAL

12.5 kg/cm2 (g)

-29 @ 140 C0 mm

Sts.Steel

304

8.8 kg/cm2 (g)

-29 @ 160 C

ASME

B31.3

AA1, ACM, AIR, AL1, ADD, CAV, CDO, CIP, DRA, EFF,

FMC, FMH, FOW, HAL, JUC, NUT, JAL, JCL, JFM, JFT,

JMX, JMZ, JTM, JVM, SAL, YCM

Sts.Steel

316L

SERVICIO RATING TEMP. DIS. CORROSIN

150 # - RF

7.7 kg/cm2 (g)

-29 @ 75 C

ASME

B31.3

1,5 mmHY1

KR37.2 kg/cm2 (g)

-29 @ 110 C

ARF, BFW, BGL, BGZ, CCW, CHZ, COL, COM, DOL, DRA,

FIW, FLO, GSL, HCA, IMW, JUV, LCA, LPS, MPS, NTG,

OIL, PC1, RLV, SAL, TRW, WRW, WTW150 # - RF

6.6 kg/cm2 (g)

-29 @ 170 C1,5 mm

DR1 DMW, DRW, IAR, SAR

2

CD.

3

6

11

12

9

5

8

10

13

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

FECHA

REV

12/13/2012

4

HOJA

0 mmASME

B31.3

DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

1ASME

B31.3

Sts.Steel

304KR1 10

CLASE

SUMMARY

Carbon

SteelA106 Gr.B

20

Carbon

SteelAPI 5L Gr.B

10

7

DE 56

PG.

11

Rx

%

0

28

Carbon

SteelAPI 5L Gr.B

10ASME

B31.3

0 mmASME

B31.316

1,5 mmASME

B31.3

ISOLUX WATISOLUX CORSN

edcruzText Box** Clculo de espesores:- De manera general se concluye que el chequeo de espesores de acuerdo a la Piping Class, es satisfactorio, sin embargo se recomienda realizar una validacin por parte de Proceso de las condiciones de diseo reportadas en la Piping Class y el Listado de Mecnico de Lneas (MLL).- Se recomienda no llevar a condiciones de techo de rating a las clases BR1, BR3, BR4 y HY1, dado que el espesor especificado sera insuficiente para soportar la p. interna de diseo de la tubera. - En el caso eventual de incluir lneas con condiciones superiores a las indicadas en el Listado Mecnico de Lneas (MLL) o la Piping Class, se deber hacer la verificacin correspondiente. - Todas las lneas que se encuentran dentro de las clases con condiciones de presin de vaco (KR1, BR3 y HY1), cumplen con lo indicado por el ASME seccin VIII Divisin I para. UG-28 Ed.2010. ** Pruebas de Impacto:- La nica clase de tubera que requiere prueba de impacto es la BT1, para el rango de dimetros de 8 a 24. Se recomienda incluir estos requerimientos de Pruebas de Impacto para esta clase dentro del documento de Clases de Tubera. De acuerdo al MLL slo se va a emplear tubera con dimetro de 1, pero si eventualmente aparecen lneas en el rango de 8 a 24, se debern evaluar las temperaturas mnimas de operacin, diseo y prueba de cada lnea especfica para revaluar la inclusin del ensayo.** Alivio trmico (PWHT):- Se detectaron slo 3 clases (HY1, BT1, y BU1), que requieren tratamiento trmico despus de aplicar procesos de soldadura sobre la tubera (ver detalles al interno de cada P.Class).** Ensayos no destructivos (NDEs):- Se recomienda extender el criterio de aplicacin de % de RX segn rating, para complementarlo con otros NDE, como: Partculas magnticas, Tintas Penetrantes y Ultrasonido.** Vlvulas, Bridas y Accesorios:Ver comentarios en color rojo al interno de cada Piping Class.

edcruzRectangle

edcruzText BoxDe acuerdo con el ASME B31.3 (Nota 57, Tabla A-1), NO se recomienda el uso de este material por encima de los (427C) 800 F.

edcruzLine

edcruzRectangle

edcruzText BoxVer comentarios a pie de pgina

-

1 BEVELED ENDS ACCORDING TO ASME B 16.25

2 UNDERGROUND PIPES SHALL HAVE A THREE LAYER POLYETHYLENE EXTERNAL COATING AS PER CAN CSA Z245.21-02

3 ERW : ELECTRICAL RESISTANCE WELDED

4 SAW : SUBMERGED ARC WELD (100 % RADIOG.)

5 IF THREADED CONNECTIONS ARE REQUIRED ,THEN NIPPLE WITH SPECIFIED THCK. SHALL BE USED.

6 NPT END ACCORDING TO ASME B 1.20.1

7 BETWEEN 1/2" to 1 1/2" MAY BE REPLACED BY FORGED FITTING, SW ENDS, FOR ELBOWS, TEE, COUPLING, RED. COUPLING

8 NPT ENDS SHALL BE USED FOR COUPLING, LARGE COUPLING (LENGTH WILL BE 1" OVER INSULATION), HEX.HEAD PLUG, HEXAGONAL NIPPLE

9 BW SHALL BE USED FOR 90 L.R. ELBOW, 45 L.R. ELBOW, EQUAL TEE, REDUCING TEE, CONCENTRIC RED.,EXCENTRIC RED., CAPS

10 SCHEDULE/THICKNESS ACCORDING TO PIPE SCHEDULE

11 RAISED FACE (RF): SPIRAL OR CONCENTRIC SERRATED FACING FINISH SHALL BE 125-250 RA, AS PER STANDARD MSS SP-6

12 RING JOINT (RJ): FACING FINISH SHALL BE 63 RA AS PER STANDARD MSS SP-6

13 WN RF FLANGE SHALL BE USED FOR OPERATING TEMP. > 130C OR FOR RECIPROCATING COMPRESSORS PIPING

14 FLANGES LARGER THAN 24", SHALL BE IN ACCORDANCE WITH ANSI B16,47 TYPE "A"

15 FLANGES LARGER THAN 24", SHALL BE IN ACCORDANCE WITH ANSI B16,47 TYPE "B"

16 NOT APPLICABLE

17 FOR ORIFICE FLANGE, GASKETS SHALL BE SPIRAL WOUND TYPE ACC./TO 300# CLASS

18 LENGTH ACCORDING TO ASME B 16.5 (EXCEPT FOR PSV, ORIFFICE PLATE, DRIP RING, WAFER TYPE VALVES)

19 DRAIN HOLE, SHALL BE " DIAM. THREADED NPT TYPE UP TO 2" PIPE DIAM. AND 3/4" UPPER TO 2" PIPE DIAM.

20 THCK. NPT END SHALL BE EQUAL TO THCK. NIPPLE.

21 STRESS RELIEF

22 DO NOT USE FOR PIPING OPERATING TEMPERATURE ABOVE 130 C.

23 UNLESS FULL BORE IS STATED IN P&Id.

24 IN SPECIAL CASES, FLANGED 150# RF ENDS SHALL BE USED.

25 IN SPECIAL CASES, FLANGED 300# RF ENDS SHALL BE USED.

26 IN SPECIAL CASES, FLANGED 600# RF ENDS SHALL BE USED.

27 IN SPECIAL CASES, FLANGED 900# RF ENDS SHALL BE USED.

28 IN SPECIAL CASES, FLANGED 900# RTJ ENDS SHALL BE USED.

29 IN SPECIAL CASES, FLANGED 1500# RTJ ENDS SHALL BE USED.

30 IN SPECIAL CASES, 2000 WOG or CLASS 800# NPT ENDS SHALL BE USED

31 IN SPECIAL CASES, 5000 WOG or CLASS 1500# NPT/SW ENDS SHALL BE USED.

32 OUTSIDE SCREW AND YOKE.

33 SUITABLE FOR REPACKING UNDER PRESSURE IN OPEN POSITION.

34 TO BE MOUNTED BETWEEN RF FLANGES ACCORDING TO ASME B16.5.

35 TO BE MOUNTED BETWEEN RTJ FLANGES ACCORDING TO ASME B16.5.

36 TO BE MOUNTED BETWEEN FF FLANGES ACCORDING TO ASME B16.5.

37 REDUCED BORE VALVES: FOR EXAMPLE 16"x12" or 18"x14" MAY BE ACCEPTED

38 THREADED CONNECTIONS SHALL BE AVOIDED.

39 PIPE MATERIAL "ASTM A53 Gr.B" MAY BE REPLACED BY "ASTM A106 Gr.B" or "API 5L Gr.B"

40 IMPACT TESTING REQUIRED

41 EXTENDED ENDS, L=100mm. EACH SIDE, PLAIN ENDS

42 FOR SIZE RANGE, SEE BRANCH CONNECTION TABLE

43 OLET FITTING RATING OR SCHEDULE SHALL BE ACCORDING TO STANDARD MSS SP-97, TABLE 1

44 AS PER MANUFACTURER STANDARD FOR GIVEN PRESSURE

45 MATERIAL GRADE FOR OLET FITTING SHALL BE SIMILAR TO MAIN PIPE MATERIAL GRADE

46 DO NOT USE FOR PIPING OPERATING TEMPERATURE ABOVE 140 C.

47 DRAIN HOLE, SHALL BE " DIAM. SOCKET WELD TYPE UP TO 2" PIPE DIAM. AND 3/4" UPPER TO 2" PIPE DIAM.

48 CS LJ FLANGES MAY ALSO BE USED INSTEAD OF THE SPECIFIED STAINLESS STEEL

49 BOLTS AND NUT TREATMENT SHALL BE GREEN PASSIVED

50 ACCEPTABLE USE SEAMLESS PIPE NIPPLES

51 FLANGES WILL BE MADE BY DESIGN

52 CALCULATE LENGTH ACCORDING TO FLANGE THICKNESS

53 USE PLANE WASHERS AS BACK SEAT

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

FECHA

REV

12/13/2012

4

HOJA 8

DE 56

GENERAL NOTES

DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 0 mm

MATERIAL: Sts.Steel 304

CODE: B 31.3

SERVICE:

REFER BRANCH TABLE I

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

WELDED PIPING 10S ASME B 36.19 PE " - 1 " (5)

WELDED PIPING 10S ASME B 36.19 BE 2" - 4" (1)

WELDED PIPING 5S ASME B 36.19 BE (1)

WELDED (EFW) PIPING 10S ASME B 36.19 BE (1)

WLD PIPING (NIPPLE) 40S ASME B 36.19 NPT " - 3/4" (6) (50)

FORGED HALF COUPLING ASTM A182 Gr. F304 3000# ASME B 16.11 SW

FORGED HALF COUPLING ASTM A182 Gr. F304 3000# ASME B 16.11 NPT " - 1" (6) (8)

WROUGHT PIPE FITTINGS ASTM A403 WP. F304 ASME B 16.9 BW " - 24" (7) (9) (10)

FLANGE ASTM A182 Gr. F304 150# ASME B 16.5 SO / RF " - 3/4" (11) (13)

FLANGE ASTM A-105 150# ASME B 16.5 LJ / FF 1" - 24" (13)

STUB END ASTM A403 WP. F304 SHORT PATTERN

BLIND FLANGE ASTM A182 Gr. F304 150# ASME B 16.5 BLIND RF " - 3/4" (11)

BLIND FLANGE A-105 + AISI 304 Liner 150# ASME B 16.5 BLIND RF 1" - 24" (11)

GASKETS FLAT RING LAP e=1,6mm 150# ASME B 16.21 " - 8" (17)

NON-ASBESTOS e=3,2mm (17)

STUD BOLTS

NUTS

SPECTACLE 150# ASME B 16.48 RF " - 12" (11)

PADDLE 150# ASME B 16.48 RF 14" - 24" (11)

DRIP RING 150# ASME B 16.5 RF 1" - 12" (11) (19)

DIELECTRIC JOINT ARAMIDA/NBR FIBER 150# ASME B 16.21 RF " - 24"

SWAGE NIPPLE ASTM A312 TP.304 MSS SP-95 BW-PE-NPT " - 2" (6) (10) (20)

BRANCH REINFORCEMENT ASTM A312 TP.304

13.5

-29a38 100 130 150

20 16 15 14.5

(18) (49)ASTM A-193 Gr. B7

ASTM A-194 Gr. 2H

ASME B 18.2.1

ASME B 18.2.2

ASTM A-240 Gr.304

ASTM A-240 Gr.304

ASTM A-240 Gr.304

ASME B 31.3

COMP. FIBER

ASTM A312 TP.304

ASTM A312 TP.304

ASTM A312 TP.304

KR1PIPING CLASS COMPONENTS

REV

12/13/2012 HOJA

AA1, ACM, AIR, AL1, ADD, CDO, CAV, CIP, DRA, EFF, FMC, FMH, FOW, HAL,

JUC, NUT, JAL, JCL, JFM, JFT, JMX, JMZ, JTM, JVM, SAL, YCM

4BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

200

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

DOCUMENTO No: FECHA 9

DE 56

10" - 24"

ASTM A312 TP.304

6" - 8"

ASTM A358 TP.304

" - 1"

1" - 24"

10" -24"

ASME B 16.9

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 0 mm

MATERIAL: Sts.Steel 304

CODE: B 31.3

SERVICE:

A351 Gr.CF8

A351 Gr.CF8

-

-

A351 Gr.CF8

A351 Gr.CF8

A351 Gr.CF8

A351 Gr.CF8

Butterfly BFWLCI7 CAV, CIP, DRA, JAL, JCL, JFT, JMX, JUC - Temperature up to 90C

Butterfly BFWLCI7G CAV, CIP, DRA, JAL, JCL, JFT, JMX, JUC - Temperature up to 90C

CAV, CIP, DRA, JAL, JCL, JFT, JMX, JUC - Temperature above 90C

CAV, CIP, DRA, JAL, JCL, JFT, JMX, JUC, JMZ - Temperature above 90C

Fl.Check NFWLS42 1 8 AIR

Dual Pl. Check NPWLS42 10 AIR

AA1,ACM,ADD,AL1,CAV,CDO,CIP,CLM,COL,DRA,EFF,FIW,FMC,FMH,FOW,

HAL,JAL,JCL,JFM,JFT,JMX,JMZ,JTM,JUC,JUV,JVM,NUT,SAL,SWC,YCM

AA1,ACM,ADD,AL1,CAV,CDO,CIP,CLM,COL,DRA,EFF,FIW,FMC,FMH,FOW,

HAL,JAL,JCL,JFM,JFT,JMX,JMZ,JTM,JUC,JUV,JVM,NUT,SAL,SWC,YCM

NOTE

1 - Refer Valve Numbering procedure sheet 4 and 5 for description of valves Code

2 - Valves supplied by vendors shall have a commodity code according to rev 2 of this piping class - See Annex I

8

A351 Gr.CF8 AISI 304 AISI 304 #150

#150AISI 304

#150

FLANGED[RF] KFALS43

Dual Pl. Check

NFWLS48

NPWLS48

1 8

10

2" - 12"

BFWLS57G 8

Butterfly

-29a38 100 130 150

Dual Plate

check 10"

Globe"

2 6

Fl.Check

Ball

Butterfly

BFWLS57 2 6

15 14.5 13.5

Flapped check

Knife

PN 10

Butterfly

TABLE-A

VALVE CODES VALVE SIZE (NPS) FLUIDS

FLANGED[RF]AISI 304

AISI 304

AISI 304 FLANGED[RF]

SCRD - NPT[F]

Foot Valve 1" A351 Gr.CF8 AISI 304 FTALS43

1" 8" A351 Gr.CF8 AISI 304 #150 WAFER

GTALS43

GLALS43

#800 SCRD - NPT[F] GTPPS43Gate

" AISI 304 AISI 304

"

See Table "A" for Valve

Code

#150 FLANGED[RF]

See Table "A" for Valve

Code-

AISI 304 AISI 304

" AISI 304

-

AISI 304 -

8" AISI 304

WAFER

GLPPS43

- PN 10 WAFER

#800 SCRD - NPT[F]

#150 WAFER

See Table "A" & Note 2 for

Valve Code

BLALS41

BLPPS41"

" 8"

2" 6" AISI 304

AISI 304

PTFE

PTFE

#800 SCD-NPT[FM]

FLANGED[RF]#150

Seat / "O" Ring ClassDescription Size (NPS) Body Trim End Tag. No.

AISI 304

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

HOJAFECHA

REV

12/13/2012

4

AA1, ACM, AIR, AL1, ADD, CDO, CAV, CIP, DRA, EFF, FMC, FMH, FOW, HAL,

JUC, NUT, JAL, JCL, JFM, JFT, JMX, JMZ, JTM, JVM, SAL, YCM

PIPING CLASS - VALVES

10DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

20 16

200

DE 56

NLPPS43Lift Check

Valve =" " A351 Gr.CF8 AISI 304 AISI 304 #800

KR1

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 0 mm

MATERIAL: Sts.Steel 304

CODE: B 31.3

SERVICE:

REFER BRANCH TABLE I

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

WELDED PIPING 10S ASME B 36.19 PE " - 1 " (5)

WELDED PIPING 10S ASME B 36.19 BE 2" - 4" (1)

WELDED PIPING 5S ASME B 36.19 BE (1)

WELDED (EFW) PIPING 10S ASME B 36.19 BE (1)

WLD PIPING (NIPPLE) 40S ASME B 36.19 NPT " - 1" (6) (50)

FORGED HALF COUPLING ASTM A182 Gr. F304 3000# ASME B 16.11 SW

FORGED HALF COUPLING ASTM A182 Gr. F304 3000# ASME B 16.11 NPT " - 1" (6) (8)

WROUGHT PIPE FITTINGS ASTM A403 WP. F304 ASME B 16.9 BW " - 24" (7) (9) (10)

FLANGE ASTM A182 Gr. F304 150# ASME B 16.5 SO / RF " - 3/4" (11) (13)

FLANGE ASTM A-105 150# ASME B 16.5 LJ / FF 1" - 24" (13)

STUB END ASTM A403 WP. F304 SHORT PATTERN

BLIND FLANGE ASTM A182 Gr. F304 150# ASME B 16.5 BLIND RF " - 3/4" (11)

BLIND FLANGE A-105 + AISI 304 Liner 150# ASME B 16.5 BLIND RF 1" - 24" (11)

GASKETS FLAT RING LAP e=1,6mm 150# ASME B 16.21 " - 8" (17)

NON-ASBESTOS e=3,2mm (17)

STUD BOLTS

NUTS

SPECTACLE 150# ASME B 16.48 RF " - 12" (11)

PADDLE 150# ASME B 16.48 RF 14" - 24" (11)

DRIP RING 150# ASME B 16.5 RF 1" - 12" (11) (19)

DIELECTRIC JOINT ARAMIDA/NBR FIBER 150# ASME B 16.21 RF " - 24"

SWAGE NIPPLE ASTM A312 TP.304 MSS SP-95 BW-PE-NPT " - 4" (6) (10) (20)

BRANCH REINFORCEMENT ASTM A312 TP.304

NOTE

Requirement of stiffening rings for straight run of pipe for lines under Full Vacuum depend on the routing of pipe & the same will be

confirmed after detailing. Stiffening Ring MOC is same as Piping MOC.

6" - 8"

ASME B 16.9

ASTM A312 TP.304

12.3

ASTM A312 TP.304

ASTM A-193 Gr. B7

COMP. FIBER

(18) (49)

ASTM A358 TP.304 10" -24"

KR2PIPING CLASS COMPONENTS

ASTM A312 TP.304

ASTM A-240 Gr.304

ASTM A-240 Gr.304

" - 1"

10" - 24"

ASME B 18.2.1

ASTM A-240 Gr.304

ASTM A-194 Gr. 2H

1" - 24"

16

150

13.514.5

-29a38 100 160 200 250

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

14

HOJA 11FECHA

TECHNICAL SPECIFICATION

BE001-ESE-TU-GL-00-1003

20

DE 56

AAV, AL2, AV1, AV2, BTC, FOH, HFO, LFO, NCV, PC2, SCW, SPL, VIL, VIN, VIV, VNT

ASME B 31.3

REV

12/13/2012DOCUMENTO No:

ASTM A312 TP.304

4

ASME B 18.2.2

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 0 mm

MATERIAL: Sts.Steel 304

CODE: B 31.3

SERVICE:

A351 Gr.CF8

A351 Gr.CF8

A351 Gr.CF8

A351 Gr.CF8

A351 Gr.CF8

A351 Gr.CF8

Fl.Check NFWLS42 PC2, VNT, VIL, BTC

Dual Pl. Check NPWLS42 PC2, VNT, VIL, BTC

AL2, AV1, AV2, FOH, HFO, LFO, NCV, SPL, SCW, VIN, VIV

AL2, AV1, AV2, FOH, HFO, LFO, NCV, SPL, SCW, VIN, VIV

Notes: 1 - Refer Valve Numbering procedure sheet 4 and 5 for description of valves Code2 - Valves supplied by vendors shall have a commodity code according to rev 2 of this piping class - See Annex I

1 8

10

1 8Fl.Check NFWLS48

Dual Pl. Check NPWLS48 10

TABLE-B

VALVE CODES VALVE SIZE (NPS) FLUIDS

A351 Gr.CF8M

A351 Gr.CF8M

SCRD - NPT[F] GTPPS43

" AISI 304 AISI 304 #150 FLANGED[RF] GTALS43

AISI 304 AISI 304 #150 FLANGED[RF] GLALS43

Gate" AISI 304 AISI 304 #800

WAFERRefer Table "B" for

Valve Code

Globe" AISI 304 AISI 304 #800 SCRD - NPT[F] GLPPS43

"

#150 WAFER

Butterfly

Refer Table "B" for

Valve Code

Dual Plate

check 10" AISI 304 - #150

8" CF8M RTFE+Sil. Backup PN 10 WAFER

Flapped check 1" 8" A351 Gr.CF8 AISI 304 -

PTFE #150 FLANGED[RF] BLALS41

2" 6" CF8M RTFE+Sil. Backup PN 10 WAFER BFWLS57

BFWLS57G

(See Note 2)

End Tag. No.

Ball" AISI 304 PTFE #800 SCD-NPT[FM] BLPPS41

" 8"

Description Size (NPS) Body Trim Seat / "O" Ring Class

AISI 304

PIPING CLASS - VALVES

12DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

KR2

AAV, AL2, AV1, AV2, BTC, FOH, HFO, LFO, NCV, PC2, SCW, SPL, VIL, VIN, VIV, VNT

250

12.3

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

HOJAFECHA

REV

12/13/2012

4 DE 56

-29a38 100 150 160 200

20 16 14.5 14 13.5

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 0 mm

MATERIAL: Sts.Steel 304

CODE: B 31.3

SERVICE:

REFER BRANCH TABLE I

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

WELDED PIPING 10S ASME B 36.19 PE " - 1 " (5)

WELDED PIPING 10S ASME B 36.19 BE 2" - 4" (1)

WELDED PIPING 5S ASME B 36.19 BE (1)

WLD PIPING (NIPPLE) 40S ASME B 36.19 NPT " - 1" (6) (50)

FORGED HALF COUPLING ASTM A182 Gr. F304 3000# ASME B 16.11 SW

FORGED HALF COUPLING ASTM A182 Gr. F304 3000# ASME B 16.11 NPT " - 1" (6) (8)

WROUGHT PIPE FITTINGS ASTM A403 WP. F304 ASME B 16.9 BW " - 8" (7) (9) (10)

FLANGE ASTM A182 Gr. F304 150# ASME B 16.5 SO / RF " - 3/4" (11) (13)

FLANGE ASTM A-105 150# ASME B 16.5 LJ / FF 1" - 8" (13)

STUB END ASTM A403 WP. F304 SHORT PATTERN

BLIND FLANGE ASTM A182 Gr. F304 150# ASME B 16.5 BLIND RF " - 3/4" (11)

BLIND FLANGE A-105 + AISI 304 Liner 150# ASME B 16.5 BLIND RF 1" - 8" (11)

GASKETS e=3mm 150# ASME B 16.21 " - 8" (17)

STUD BOLTS

NUTS

SPECTACLE 150# ASME B 16.48 RF " - 8" (11)

DRIP RING 150# ASME B 16.5 RF 1" - 8" (11) (19)

DIELECTRIC JOINT ARAMIDA/NBR FIBER 150# ASME B 16.21 RF " - 8"

SWAGE NIPPLE ASTM A312 TP.304 MSS SP-95 BW-PE-NPT " - 4" (6) (10) (20)

BRANCH REINFORCEMENT ASTM A312 TP.304

PTFE: Poly-TetraFluro-Ethylene

(18) (49)ASTM A-193 Gr. B7

ASTM A-194 Gr. 2H

ASME B 18.2.1

ASME B 18.2.2

ASTM A312 TP.304

ASTM A312 TP.304

" - 1"

6" - 8"

4

CIR, CIS, CNS, DMW, DRA

BE001-ESE-TU-GL-00-1003

HOJA

TECHNICAL SPECIFICATION

-29a38 75

FLAT RING LAP

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

13FECHA

REV

12/13/2012DOCUMENTO No:

ASTM A312 TP.304

ASTM A312 TP.304

1" - 8"ASME B 16.9

ASME B 31.3

KR3PIPING CLASS COMPONENTS

ASTM A-240 Gr.304

ASTM A-240 Gr.304

PTFE

DE 56

100 150 200

20 17 16 14.5 13.5

ISOLUX WATISOLUX CORSN

edcruzText BoxEn el FLUID LIST se encontr un MATERIALE BASE distinto para el fluido DMW: Carbon Steel Galv.

edcruzRectangle

edcruzLine

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 0 mm

MATERIAL: Sts.Steel 304

CODE: B 31.3

SERVICE:

A351 Gr.CF8

A351 Gr.CF8

A351 Gr.CF8

A351 Gr.CF8

A351 Gr.CF8

A351 Gr.CF8

NOTE

1 - Refer Valve Numbering procedure sheet 4 and 5 for description of valves Code

2 - Valves supplied by vendors shall have a commodity code according to rev 2 of this piping class - See Annex I

EPDM

#150

FLANGED[RF]

SCRD - NPT[F]

GTALS43

BFWLCI9

(See Note 2)

SCRD - NPT[F] GTPPS43

WAFER

A126 Class B

FLANGED[RF] GLALS43

#150

#800

GLPPS43#800

NFWLS48

Gate" AISI 304 AISI 304

" AISI 304 AISI 304

Globe" AISI 304 AISI 304

" AISI 304 AISI 304

Flapped check 1" 8" A351 Gr.CF8 AISI 304 VITON #150

#800 SCD-NPT[FM]

Butterfly 2" 6" CF8M PN 10

#150 FLANGED[RF]Ball

BLALS41

WAFER

End Tag. No.

" AISI 304 PTFE BLPPS41

AISI 304 PTFE

Description Size (NPS) Body Trim Seat / "O" Ring Class

" 8"

FECHA

REV

12/13/2012

4 DE 56

PIPING CLASS - VALVES

14DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

KR3

CIR, CIS, CNS, DMW, DRA

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

HOJA

-29a38 75 100 150 200

20 17 16 14.5 13.5

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: N/A

DESIGN PRESSURE kg/cm (g) CORROSION: 0 mm

MATERIAL: Sts.Steel 304

CODE: N/A

SERVICE:

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

WELDED PIPING 5S ASME B 36.19 BE

WROUGHT PIPE FITTINGS ASME B 16.9 BW 2" - 12" (9) (10)

FIELD TEST: TIGHTNESS

PRUEBA DE CAMPO: ESTANQUEIDAD

Note: Joints between pipe and fittings shall be full penetration but welds

DRA

AISI 304 5S

AISI 304 2" - 12"

PIPING CLASS COMPONENTS KR4

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

ATM

TECHNICAL SPECIFICATION

>70

DOCUMENTO No: FECHA 12/13/2012 HOJA 15

BE001-ESE-TU-GL-00-1003 REV 4 DE 56ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 0 mm

MATERIAL: Sts.Steel 316L

CODE: B 31.3

SERVICE:

REFER BRANCH TABLE I

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

WELDED PIPING 10S ASME B 36.19 PE " - 1 " (5)

WELDED PIPING 10S ASME B 36.19 BE 2" - 4" (1)

WELDED PIPING 5S ASME B 36.19 BE (1)

WELDED (EFW) PIPING 10S ASME B 36.19 BE (1)

WLD PIPING (NIPPLE) 40S ASME B 36.19 NPT " - 1" (6) (50)

FORGED HALF COUPLING ASTM A182 Gr. F316L 3000# ASME B 16.11 SW

FORGED HALF COUPLING ASTM A182 Gr. F316L 3000# ASME B 16.11 NPT " - 1" (6) (8)

WROUGHT PIPE FITTINGS ASTM A403 WP. F316L ASME B 16.9 BW " - 24" (7) (9) (10)

FLANGE ASTM A182 Gr. F316L 150# ASME B 16.5 SO / RF " - 3/4" (11) (13)

FLANGE ASTM A-105 150# ASME B 16.5 LJ / FF 1" - 24" (13)

STUB END ASTM A403 WP. F316L SHORT PATTERN

BLIND FLANGE ASTM A182 Gr. F316L 150# ASME B 16.5 BLIND RF " - 3/4" (11)

BLIND FLANGE A-105 + AISI 316L Liner 150# ASME B 16.5 BLIND RF 1" - 24" (11)

GASKETS FLAT RING LAP e=1,6mm 150# ASME B 16.21 " - 8" (17)

NON-ASBESTOS e=3,2mm (17)

STUD BOLTS

NUTS

SPECTACLE 150# ASME B 16.48 RF " - 12" (11)

PADDLE 150# ASME B 16.48 RF 14" - 24" (11)

DRIP RING 150# ASME B 16.5 RF 1" - 12" (11) (19)

DIELECTRIC JOINT ARAMIDA/NBR FIBER 150# ASME B 16.21 RF " - 24"

SWAGE NIPPLE ASTM A312 TP.316L MSS SP-95 BW-PE-NPT " - 4" (6) (10) (20)

BRANCH REINFORCEMENT ASTM A312 TP.316L

ASTM A-240 Gr.316L

ASME B 18.2.2

COMP. FIBER

4

CPS, DRA

14.3

ASME B 16.9

11.4

ASME B 31.3

MR1PIPING CLASS COMPONENTS

ASTM A-240 Gr.316L

ASTM A-240 Gr.316L

(18) (49)ASTM A-193 Gr. B7

ASTM A-194 Gr. 2H

" - 1"

ASME B 18.2.1

10" -24"

10" - 24"

ASTM A312 TP.316L

TECHNICAL SPECIFICATION

12.2

100 150

16.2

1" - 24"

-29a38 75

16DOCUMENTO No:

ASTM A312 TP.316L

6" - 8"

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

FECHA 12/13/2012 HOJA

BE001-ESE-TU-GL-00-1003

ASTM A358 TP.316L

ASTM A312 TP.316L

200

13.6

ASTM A312 TP.316L

DE 56REVISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 0 mm

MATERIAL: Sts.Steel 316L

CODE: B 31.3

SERVICE:

A351 Gr.CF8M

A351 Gr.CF8M

A351 Gr.CF8M

A351 Gr.CF8M

A351 Gr.CF8M

A351 Gr.CF8M

A126 CLASS B

A126 CLASS B

NOTE

1 - Refer Valve Numbering procedure sheet 4 and 5 for description of valves Code

2 - Valves supplied by vendors shall have a commodity code according to rev 2 of this piping class - See Annex I

GTPPS53

" AISI 316 AISI 316 #150 FLANGED[RF] GTALS53Gate

" AISI 316 AISI 316 #800 SCRD - NPT[F]

Globe" AISI 316 AISI 316 #800 SCRD - NPT[F]

" AISI 316 AISI 316 #150

WAFER NPWLS47

8" CF8M PN 10 WAFER

WAFER

(See Note 2)

Dual Plate

check 10" A351 Gr.CF8M AISI 316 VITON #150

Flapped check 1" 8" A351 Gr.CF8M AISI 316

BFWLCI7

BFWLCI7G

NFWLS47VITON #150

ButterflyEPDM + PTFE

liner

2" 6" CF8M PN 10 WAFER

#150 FLANGED[RF] BLALS51

#800 SCD-NPT[F]

GLPPS53

FLANGED[RF] GLALS53

End Tag. No.

Ball" AISI 316 PTFE BLPPS51

" 8" AISI 316 PTFE

Description Size (NPS) Body Trim Seat / "O" Ring Class

FECHA

REV

12/13/2012

4 DE 56

PIPING CLASS - VALVES

17

TECHNICAL SPECIFICATION

MR1

DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

CPS, DRA

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

HOJA

-29a38 75 100 150 200

16.2 14.3 13.6 12.2 11.4

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1,5 mm

MATERIAL: Carbon Steel

API 5L Gr.B

CODE: B 31.3

SERVICE:

REFER BRANCH TABLE II

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

WELDED (ERW) PIPING 40 ASME B 36.10 BE " - 6" (1) (2) (39)

WELDED PIPING 20 API 5L BE 8" - 12" (1) (2)

WELDED PIPING 10 API 5L BE (1) (2)

WELDED PIPING 7.9mm API 5L BE (1) (2)

WELDED PIPING 8.7mm. API 5L BE (1) (2)

ERW PIPING (NIPPLE) 80 ASME B 36.10 NPT " - 1" (6) (50)

FORGED HALF COUPLING ASTM A-105 3000# ASME B 16.11 SW

FORGED HALF COUPLING ASTM A-105 3000# ASME B 16.11 NPT " - 1" (6) (8)

WROUGHT PIPE FITTINGS ASTM A-234 Gr. WPB ASME B 16.9 BW " - 48" (7) (9) (10)

FLANGE ASTM A-105 150# ASME B 16.5 SO / RF " - 24" (11) (13)

FLANGE ASTM A-105 150# ASME B 16.47 (A) WN / RF 26" - 48" (11)(13) (14)

BLIND FLANGE ASTM A-105 150# ASME B 16.5 BLIND RF " - 24" (11)

BLIND FLANGE ASTM A-105 150# ASME B 16.47 (A) BLIND RF 26" - 48" (11) (14)

GASKETS FLAT RING LAP e=1,6mm 150# ASME B 16.21 " - 8" (17)

NON-ASBESTOS e=3,2mm (17)

STUD BOLTS

NUTS

SPECTACLE 150# ASME B 16.48 RF " - 12" (11)

PADDLE 150# ASME B 16.48 RF 14" - 24" (11)

DRIP RING 150# ASME B 16.5 RF 1" - 12" (11) (19)

DIELECTRIC JOINT ARAMIDA/NBR FIBER 150# ASME B 16.21 RF " - 24"

SWAGE NIPPLE A 53 Gr. B MSS SP-95 BW-PE-NPT " - 4" (6) (10) (20)

A 53 Gr. B

BR1

COMP. FIBER

A 53 Gr. B

14" - 18"

PIPING CLASS COMPONENTS

42" - 48"

ASTM A-516 Gr. 70 ZINC

ASTM A-516 Gr. 70 ZINC

ASTM A-516 Gr. 70 ZINC

DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

API 5L Gr. B (PSL1)

API 5L Gr. B (PSL1)

API 5L Gr. B (PSL1)

API 5L Gr. B (PSL1)

AA2, AFS, AL1, CWS, CWR, FOL, PAR, PRW, SEW, SRW, SWC

HOJA

TECHNICAL SPECIFICATION

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

1812/13/2012FECHA

REV 4

18 16

20"-40"

" - 1"

(18) (49)ASTM A-193 Gr. B7

ASTM A-194 Gr. 2H

ASME B 18.2.1

ASME B 18.2.2

10" - 48"

DE 56

200

14

-29a38 52 100 150

20 19.4

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1,5 mm

MATERIAL: Carbon Steel

API 5L Gr.B

CODE: B 31.3

SERVICE:

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

-

-

NOTES:

1 - Refer Valve Numbering procedure sheet 4 and 5 for description of valves Code

2 - For butterfly valve of size above 24", having seat of PTFE with EPDM, the HIGH PERFOMANCE BUTTERFLY VALVE with valve

code BFWTCI3H shall be used

3 - Valves supplied by vendors shall have a commodity code according to rev 2 of this piping class - See Annex I

Check

Butterfly

Butterfly

Butterfly

Check

Check

Check

1 8

AA2, AL1, CCW, CWR, CWS, FOL, SWC - Temperature up to 90C

AA2, AL1, CCW, CWR, CWS, FOL, SWC - Temperature up to 90C

AA2 - Temperature above 90C

AA2 - Temperature above 90C

SEW

AA2,AL1,AFS,FOL,PAR

AA2,AL1,AFS,FOL,PAR

CWS,CWR,PRW,SEW,SRW,SWC

NFPLEP2

NFWLEP1

NPWLEP1

NFWLEP2

2 8

10

10

1/2"

1 8

10

BFWLCI8G

TABLE-A

VALVE CODES VALVE SIZE (NPS) FLUIDS

Butterfly BFWLCI8 2 8

BFWLCI9

BFWLCI9G

GLPPCS2

" AISI 410 AISI 410 #150 FLANGED[RF] GLALCS2

AISI 410 #150 FLANGED[RF] GTALCS2

Globe" AISI 410 AISI 410 #800 SCRD - NPT[F]

Refer Table "A" for

Valve Code

Gate" AISI 410 AISI 410 #800 SCRD - NPT[F] GTPPCS2

" AISI 410

WAFER

Butterfly

Refer Table "A" for

Valve Code

Dual Plate

check 10"

A216 Gr.WCB / M.S.+

EPOXY

A216/MS+E

POXYVITON #150 WAFER

-

Flapped check 1/2" 8"A216 Gr.WCB / M.S.+

EPOXY

A216/MS+E

POXY- #150

PN10 WAFER

PN10 WAFER-

2" 6" -

8"

BLPPCS1

" AISI 304 PTFE #150 FLANGED[RF] BLALCS1Ball

" AISI 304 PTFE #800 SCD-NPT[F]

BR1

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

Description Size (NPS) Body Trim Seat / "O" Ring Class End Tag. No.

-29a38 52 100 150

PIPING CLASS - VALVES

19DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

19.4 18 16 14

AA2, AFS, AL1, CWS, CWR, FOL, PAR, PRW, SEW, SRW, SWC

HOJAFECHA

REV

12/13/2012

4 DE 56

(See Note 3)

Refer Table "A" for

Valve Code

Check NPWLEP2 10 CWS,CWR,PRW,SEW,SRW,SWC

200

20

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1.5 mm

MATERIAL: Carbon Steel

A106 Gr.B

CODE: B 31.3

SERVICE:

REFER BRANCH TABLE II

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

SEAMLESS PIPING 40 ASME B 36.10 BE " - 4" (1) (2)

SEAMLESS PIPING STD ASME B 36.10 BE 6" - 8" (1) (2)

SMLS PIPING (NIPPLE) 80 ASME B 36.10 NPT " - 1" (6)

FORGED HALF COUPLING ASTM A-105 3000# ASME B 16.11 SW

FORGED HALF COUPLING ASTM A-105 3000# ASME B 16.11 NPT " - 1" (6) (8)

WROUGHT PIPE FITTINGS ASTM A-234 Gr. WPB ASME B 16.9 BW " - 8" (7) (9) (10)

FLANGE ASTM A-105 150# ASME B 16.5 SO / RF " - 8" (11) (13)

BLIND FLANGE ASTM A-105 150# ASME B 16.5 BLIND RF " - 8" (11)

GASKETS FLAT RING LAP e=3mm 150# ASME B 16.21 " - 8" (17)

STUD BOLTS

NUTS

SPECTACLE 150# ASME B 16.48 RF " - 8" (11)

DRIP RING 150# ASME B 16.5 RF 1" - 8" (11) (19)

DIELECTRIC JOINT ARAMIDA/NBR FIBER 150# ASME B 16.21 RF " - 8"

SWAGE NIPPLE ASTM A106 Gr.B MSS SP-95 BW-PE-NPT " - 4" (6) (10) (20)

PTFE: Poly-TetraFluro-Ethylene

HOJA

TECHNICAL SPECIFICATION

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

2012/13/2012DOCUMENTO No:

BE001-ESE-TU-GL-00-1003 4

ASTM A-193 Gr. B7

ASTM A-194 Gr. 2H

ASME B 18.2.1

ASME B 18.2.2

100 150

ASTM A106 Gr.B

ASTM A106 Gr.B

FECHA

REV

CAS, DRA

200

20 19.4

ASTM A-516 Gr. 70 ZINC

ASTM A-516 Gr. 70 ZINC

(18) (49)

16 14

" - 1"

PTFE

ASTM A106 Gr.B

18

DE 56

BR2PIPING CLASS COMPONENTS

-29a38 52

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1.5 mm

MATERIAL: Carbon Steel

A106 Gr.B

CODE: B 31.3

SERVICE:

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

BFWLCI7

NOTES

1 - Refer Valve Numbering procedure sheet 4 and 5 for description of valves Code

2 - Valves supplied by vendors shall have a commodity code according to rev 2 of this piping class - See Annex I

Gate" AISI 410 AISI 410 #800

CF8M

SCRD - NPT[F]

" AISI 410

AISI 410 AISI 410 #150

#150 FLANGED[RF] GTALCS2

FLANGED[RF] GLALCS2

-29a38 52 100 150 200

AISI 410

20 19.4 18 16 14

WAFER

#800 SCD-NPT[F]

End

SCRD - NPT[F]

PTFE WITH

EPDM BACK-UP

"

NFWLEP1Flapped check 1" 8"A216 Gr.WCB / M.S.+

EPOXY

A216/MS+E

POXYVITON #150

A126 Class B /

A 395

AISI 410

GTPPCS2

PN10 WAFER

AISI 410 #800 GLPPCS2

" AISI 304 PTFE

2" - 6"

Description

Butterfly

Ball" AISI 304 BLPPCS1

FLANGED[RF] BLALCS1

Globe"

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

HOJAFECHA 12/13/2012

Tag. No.

TECHNICAL SPECIFICATION

BR2

CAS, DRA

PIPING CLASS - VALVES

PTFE

21DOCUMENTO No:

BE001-ESE-TU-GL-00-1003 REV 4

(See Note 2)

DE 56

Class

#150

Size (NPS) Body Trim Seat / "O" Ring

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1,5 mm

MATERIAL: Carbon Steel

API 5L Gr.B

CODE: B 31.3

SERVICE:

REFER BRANCH TABLE II

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

WELDED (ERW) PIPING 40 ASME B 36.10 BE " - 6" (1) (2) (39)

WELDED PIPING 20 API 5L BE 8" - 12" (1) (2)

WELDED PIPING 10 API 5L BE (1) (2)

WELDED PIPING 7.9mm API 5L BE (1) (2)

WELDED PIPING 8.7mm API 5L BE (1) (2)

SMLS PIPING (NIPPLE) 80 ASME B 36.10 NPT " - 1" (6)

FORGED HALF COUPLING ASTM A-105 3000# ASME B 16.11 SW

FORGED HALF COUPLING ASTM A-105 3000# ASME B 16.11 NPT " - 1" (6) (8)

WROUGHT PIPE FITTINGS ASTM A-234 Gr. WPB ASME B 16.9 BW " - 48" (7) (9) (10)

FLANGE ASTM A-105 150# ASME B 16.5 SO / RF " - 24" (11) (13)

FLANGE ASTM A-105 150# ASME B 16.47 (A) WN / RF 26" - 48" (11)(13)(14)

BLIND FLANGE ASTM A-105 150# ASME B 16.5 BLIND RF " - 24" (11)

BLIND FLANGE ASTM A-105 150# ASME B 16.47 (A) BLIND RF 26" - 48" (11) (14)

GASKETS FLAT RING LAP e=1,6mm 150# ASME B 16.21 " - 8" (17)

NON-ASBESTOS e=3,2mm (17)

STUD BOLTS

NUTS

SPECTACLE 150# ASME B 16.48 RF " - 12" (11)

PADDLE 150# ASME B 16.48 RF 14" - 24" (11)

DRIP RING 150# ASME B 16.5 RF 1" - 12" (11) (19)

DIELECTRIC JOINT ARAMIDA/NBR FIBER 150# ASME B 16.21 RF " - 48"

SWAGE NIPPLE A 53 Gr. B MSS SP-95 BW-PE-NPT " - 4" (6) (10) (20)

450

4.7

170 400

20 18 15 6.6

API 5L Gr. B (PSL1)

API 5L Gr. B (PSL1)

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

ARF, BFW, BGL, BGZ, CCW, CHZ, COL, COM, DOL, DRA, FIW, FLO, GSL, HCA,

IMW, JUV, LCA, LPS, MPS, NTG, OIL, PC1, RLV, SAL, TRW, WRW, WTW

22DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

-29a38 100

HOJA

TECHNICAL SPECIFICATION

ASTM A-516 Gr. 70 ZINC

ASTM A-516 Gr. 70 ZINC

ASTM A-516 Gr. 70 ZINC

API 5L Gr. B (PSL1)

API 5L Gr. B (PSL1)

A 53 Gr. B

A 53 Gr. B

14" - 18"

PIPING CLASS COMPONENTS

42" - 48"

" - 1"

FECHA

REV

12/13/2012

4

20" - 40"

DE 56

(18) (49)ASTM A-193 Gr. B7

ASTM A-194 Gr. 2H

ASME B 18.2.1

ASME B 18.2.2

BR3

COMP. FIBER

10" - 48"

ISOLUX WATISOLUX CORSN

edcruzText BoxEn el FLUID LIST se encontr un MATERIALE BASE distinto para el fluido BFW: 2 1/4 Cr 1 Mo

edcruzLine

edcruzRectangle

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1,5 mm

MATERIAL: Carbon Steel

API 5L Gr.B

CODE: B 31.3

SERVICE:

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

NOTE

1.- Refer Valve Numbering procedure sheet 4 and 5 for description of valves Code

2.- Do not use for piping operating temperature above 130 C.

3.- Do not use for piping operating temperature above 200 C.

4.- Do not use for piping operating temperature above 60 C.

5 - Valves supplied by vendors shall have a commodity code according to rev 2 of this piping class - See Annex I

DRA - Temp 90C

CCW, CWR, CWS, DOL, FIW, GSL, IMW, PC1, TRW, RWR - Temp 90C

CCW, CWR, CWS, DOL, FIW, GSL, IMW, PC1, TRW, RWR - Temp 90C

CHZ, COL, JUV, LPS, PC1, VNT - Temp > 90C

CHZ, COL, JUV, LPS, PC1, VNT - Temp > 90C

JUV - Temp > 90C

8"

24

Butterfly

Butterfly

BFWLCI7

BFWLCI9

BFWLCI8G

BFLLCIKG

Butterfly BFWLCI9G 8"

Butterfly BFWLCI8 2" 6"

TABLE-A

VALVE CODES VALVE SIZE (NPS) FLUIDS

2" 6"

2" 6"Butterfly

DPALCG1

Caucho

Natural

1"-1 1/2" SCRD - NPT[F]PN 16Diaphragm

NOTE 4#150

Butterfly

AISI 304

Pinch

NOTE 42"-4"

2"-10" AISI 304

PNALCG2A126 CLASS B

FLANGED[FF] FTAKCI5

DPPXCG1

NPWLEP1

FLANGED[RF]

Caucho

Natural

#150 FLANGED[RF]

Foot A126 CLASS B

Globe " AISI 410

A216M +

Epoxy

AISI 410

Flapped check

NOTE 3

A216 Gr.WCB +

Caucho Blando

GTSPCS2

FLANGED[RF] GTALCS2

#800 SW

WAFER

KFALCS2

FLANGED[RF] LPALCS1

SW

GLSPCS2

FLANGED[RF] GLALCS2

NFWLEP1#150

Gate " AISI 410 AISI 410

" AISI 410 AISI 410

" AISI 410 AISI 410

VITON 1" 8"A216 Gr.WCB / M.S.

+ Epoxy

BLALCS1

AISI 304 PTFE

Dual Plate check

NOTE 3 10"

A216 Gr.WCB / M.S.

+ EpoxyWAFER#150

A216M +

EpoxyVITON

SCRD-NPT[F]#800

#150

#800

#150

FLANGED[RF]

#150 FLANGED[RF]

End Tag. No.

Ball NOTE

2" AISI 304 PTFE BLPPCS1

" AISI 304 PTFE

Description Size (NPS) Body Trim Seat / "O" Ring Class

REV

12/13/2012

4

-29a150 170 200 400 450

BR3

23DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

HOJA

ARF, BFW, BGL, BGZ, CCW, CHZ, COL, COM, DOL, DRA, FIW, FLO, GSL, HCA,

IMW, JUV, LCA, LPS, MPS, NTG, OIL, PC1, RLV, SAL, TRW, WRW, WTW

FECHA

20 15 14 6.6 4.7

PIPING CLASS - VALVES

Knife 2" - 10" AISI 410 AISI 410 #150

1" - 4" #150

Refer Table "A" for

Valve Code 8" PN 10 WAFER

#125

Plug NOTE

2

2" 6"

2"-4"

DE 56

Butterfly(See Note 5)

PN 10 WAFER

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1,5 mm

MATERIAL: Carbon Steel

API 5L Gr.B

CODE: B 31.3

SERVICE:

REFER BRANCH TABLE II

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

WELDED (ERW) PIPING 40 ASME B 36.10 BE / GE " - 6" (1) (2) (39)

WELDED PIPING 20 API 5L BE / GE 8" - 12" (1) (2)

WELDED PIPING 10 API 5L BE / GE (1) (2)

ERW PIPING (NIPPLE) 80 ASME B 36.10 NPT " - 2" (6) (50)

ERW PIPING (NIPPLE) 40 ASME B 36.10 NPT 3" - 4" (6) (50)

FORGED HALF COUPLING ASTM A-105 3000# ASME B 16.11 SW

FORGED HALF COUPLING ASTM A-105 3000# ASME B 16.11 NPT " - 1" (6) (8)

DUCTILE IRON FITTINGS ASTM A-536 CAST VICTAULIC GE

FAB'D STEEL FITTINGS A-53 Gr. B STD VICTAULIC GE

WROUGHT PIPE FITTINGS ASTM A-234 Gr. WPB ASME B 16.9 BW / GE " - 24" (7) (9) (10)

FLANGE ASTM A-105 150# ASME B 16.5 SO / RF " - 24" (11) (13)

FLANGE ADAPTER ASTM A-536 150# VIC-STYLE 741 /W741 FF 2" - 16" (11) (13)

BLIND FLANGE ASTM A-105 150# ASME B 16.5 BLIND RF " - 24" (11)

GASKETS FLAT RING LAP e=1,6mm 150# ASME B 16.21 " - 8" (17)

NON-ASBESTOS e=3,2mm (17)

STUD BOLTS

NUTS

SPECTACLE 150# ASME B 16.5 RF " - 12" (11)

DRIP RING 150# ASME B 16.5 RF 1" - 12" (11) (19)

PADDLE 150# ASME B 16.5 RF 14" - 24" (11)

DIELECTRIC JOINT ARAMIDA/NBR FIBER 150# ASME B 16.21 RF " - 24"

SWAGE NIPPLE A 106 Gr. B ASME B 36.10 BW-PE-NPT " - 4" (6) (10) (20)

ASME B 18.2.1

HOJA

TECHNICAL SPECIFICATION

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

2412/13/2012FECHA

REV

16.9

ASTM A-516 Gr. 70 ZINC

ASTM A-516 Gr. 70 ZINC

DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

API 5L Gr. B (PSL1)

API 5L Gr. B (PSL1)

ASTM A-193 Gr. B7

ASTM A-194 Gr. 2H ASME B 18.2.2

16.9

4

" - 1"

10" - 24"

A 53 Gr. B

BR4

COMP. FIBER

A 53 Gr. B

14" - 24"

16.9 16.9

1" - 16"

ASTM A-516 Gr. 70 ZINC

PIPING CLASS COMPONENTS

A 53 Gr. B

1" - 16"

DE 56

FFW, FFM

16.1

(18) (49)

-29a38 50 100 120 150

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1,5 mm

MATERIAL: Carbon Steel

API 5L Gr.B

CODE: B 31.3

SERVICE:

A216 Gr.WCB

A216 Gr.WCB

A536 2-PC

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

ASTM A536 Gr.65-45-12 BFWTCID

ASTM A536 Gr.65-45-12 BFWTCIDG

ASTM A536 Gr.65-45-12

ASTM A536 Gr.65-45-12

NOTE

Refer Valve Numbering procedure sheet 4 and 5 for description of valves Code

GTPPCS2

" AISI 410 AISI 410 #150 FLANGED[RF] GTALCS2

AISI 410 #150 FLANGED[RF] GLALCS2

Gate" AISI 410 AISI 410 #800 SCRD - NPT[F]

SCRD - NPT[F] NLPPFC1

Globe" AISI 410 AISI 410 #800 SCRD - NPT[F] GLPPCS2

"

Lift Check

Valve =" " A105 AISI 410 AISI 410 #800

FECHA

REV

12/13/2012

4

-29a38 50 100 120

PIPING CLASS - VALVES

25DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

BR4

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

FFW, FFM

HOJA

Seat / "O" Ring Class End Tag. No.Description Size (NPS) Body Trim

Ball

" AISI 304 PTFE

1" PLTD or SS PTFE

#800 SCD-NPT[F] BLPPCS1

" AISI 304 PTFE #150 FLANGED[RF] BLALCS1

NFWLEP1

VIC-MASTERSEAL

Butterfly

2" 6" DI / SGI PN 10

8" DI / SGI

WAFER

#150 WAFER

PN 10

Flapped check 1" 8"A216 Gr.WCB / M.S.+

EPOXYA216/M.S.+

EPOXY

EPDM / NITRILE

VITON

VITON

#150 WAFER NPWLEP1Dual Plate

check 10"

A216 Gr.WCB / M.S.+

EPOXYA216/M.S.+

EPOXY

GROOVED S/726

8" DI / SGI #300 GROOVED AGS-VIC300

WAFER

PTFE w/VITON

BACKUP

AISI 410

2" 6" DI / SGI EPDM / NITRILE #300 GROOVED

PTFE w/VITON

BACKUP

DE 56

150

20 19.6 18 16.9 16.1

#800

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 900 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1,5 mm

MATERIAL: Carbon Steel

A106 Gr B

CODE: B 31.1

SERVICE:

REFER BRANCH TABLE II

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

SEAMLESS PIPING 80 ASME B 36.10 PE " - 1" (5)

SEAMLESS PIPING 160 ASME B 36.10 PE 1" - 2" (5)

SEAMLESS PIPING 160 ASME B 36.10 BE (1)

SEAMLESS PIPING 120 ASME B 36.10 BE 4" - 8" (1)

SEAMLESS PIPING 140 ASME B 36.10 BE 10" (1)

FORGED HALF COUPLING ASTM A-105 3000# ASME B 16.11 SW

WROUGHT PIPE FITTINGS ASTM A-234 Gr. WPB ASME B 16.9 BW 2" - 10" (10)

FLANGE ASTM A-105 900# ASME B 16.5 SW / RTJ " - 1" (10) (12)

FLANGE ASTM A-105 900# ASME B 16.5 WN / RTJ 2" - 10" (10) (12)

BLIND FLANGE ASTM A-105 900# ASME B 16.5 RTJ 2" - 10" (12)

SPECTACLE BLIND FLANGE A516 Gr 70 Zinc 900# ASME B 16.5 RTJ " - 10" (10)

GASKETS

STUD BOLTS

NUTS(18) (49)

ASTM A-194 Gr. 2H

BICHROMATEDASME B 18.2.2

OVAL RING JOINT SOFT

IRON

-

TEMPERATURE C FLANGE CLASS: 900 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1,5 mm

MATERIAL: Carbon Steel

A106 Gr B

CODE: B 31.1

SERVICE:

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

NOTE

Refer Valve Numbering procedure sheet 4 and 5 for description of valves Code

Check Swing

Valve2" - 10" A216 Gr.WCB AISI 316 STELLITE-6 #900 BW / FL NSBRCIK

GLSRCIK

2" - 10" AISI 316 STELLITE-6 #900 BW / FL GLBRCIK

STELLITE-6 #900 BW / FL GTBRCIK

Globe" - 1" AISI 316 STELLITE-6 #900 SW

Tag. No.

Gate" - 1" AISI 316 STELLITE-6 #900 SW GTSRCIK

2" - 10" AISI 316

BFW

PIPING CLASS - VALVES BU1

Description Size (NPS) Body Trim Seat / "O" Ring Class End

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

132

TECHNICAL SPECIFICATION

120

DOCUMENTO No: FECHA 12/21/2012 HOJA 27

BE001-ESE-TU-GL-00-1003 REV 3 DE 56

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1.5 mm

MATERIAL: Carbon Steel GALV.

CODE: B 31.3

SERVICE: DRW, IAR, SAR

REFER BRANCH TABLE III

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

SEAMLESS PIPING 80 ASME B 36.10 NPT " - 1" (6) (39)

SEAMLESS PIPING 80 ASME B 36.10 NPT 2" - 4" (6) (39)

SMLS PIPING (NIPPLE) 80 ASME B 36.10 NPT " - 1" (6)

FORGED FITTINGS ASTM A-105 Galvanized 3000# ASME B 16.11 NPT (6) (8)

FLANGE ASTM A-105 Galvanized 150# ASME B 16.5 THD / RF " - 4" (11) (13)

BLIND FLANGE ASTM A-105 Galvanized 150# ASME B 16.5 BLIND RF " - 4" (11)

GASKETS FLAT RING LAP e=1,6mm 150# ASME B 16.21

STUD BOLTS

NUTS

DRIP RING 150# ASME B 16.5 RF 1" - 4" (11) (19)

SWAGE NIPPLE A 53 Gr. B Galvanized MSS SP-95 NPT " - 4" (6) (20)

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

2812/13/2012

200120

DE 56

20 19.4 18 16.9 14

HOJA

DR1

4

100

A 53 Gr. B Galvanized

-29a38 52

ASTM A-516 Gr. 70 ZINC

DOCUMENTO No:

BE001-ESE-TU-GL-00-1003

NON-ASBESTOS

A 106 Gr. B Galvanized

REV

PIPING CLASS COMPONENTS

FECHA

TECHNICAL SPECIFICATION

(18) (49)ASTM A-193 Gr. B7

ASTM A-194 Gr. 2H

ASME B 18.2.1

ASME B 18.2.2

A 53 Gr. B Galvanized

" - 4"

COMP. FIBER

" - 4"

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1.5 mm

MATERIAL: Carbon Steel GALV.

CODE: B 31.3

SERVICE: DMW, DRW, IAR, SAR

A216 Gr.WCB

A216 Gr.WCB

A216 Gr.WCB

2" 4" A216 Gr.WCB AISI 410 AISI 410 PN 10 THREADED-NPT[F] NFPTCS2

A126 CLASS B

NOTE

Refer Valve Numbering procedure sheet 4 and 5 for description of valves Code

HOJA 29

BE001-ESE-TU-GL-00-1003 REV 4 DE 56

100 120 200

DOCUMENTO No: FECHA 12/13/2012

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

20 19.4 18 16.9 14

TECHNICAL SPECIFICATION

-29a38 52

PIPING CLASS - VALVES DR1

Description Size (NPS) Body Trim Seat / "O" Ring Class End Tag. No.

Ball =" 4" AISI 304 PTFE #800 THREADED-NPT[F] BLPPCS1

Gate =" 4" AISI 410 AISI 410 #800 THREADED-NPT[F] GTPPCS2

Globe =" 4" AISI 410 AISI 410 #800 THREADED-NPT[F] GLPPCS2

Lift Check =" 1" A216 Gr.WCB AISI 410 AISI 410 PN 10 THREADED-NPT[F] NLPTCS2

Flapped check

ButterflyPTFE WITH

EPDM BACK-UP =2" 4" CF8M PN 10 WAFER BFWLCI7

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 1500 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1,5 mm

Table 2-1.10 PressureTemperature Ratings for Group 1.10 Materials MATERIAL: 2 1/4 Cr.1Mo (A335 P.22)

Examination: Per ASME B31.1 CODE: B 31.1

Postweld Heat Traatment (Stress Relief: Per ASME B31.1)

Extension: 100% of all welds

SERVICE: HPS, DRA

REFER BRANCH TABLE IV

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

SEAMLESS PIPING 160 ASME B 36.10 PE " - 1 " (5)

SEAMLESS PIPING 160 ASME B 36.10 BE 2" - 24" (1)(2)

SEAMLESS (NIPPLE) XXS ASME B 36.10 NPT " - 2" (6)

FORGED FITTINGS ASTM A182 Gr.F22 CL3 6000# ASME B 16.11 SW " - 1" (7)

FORGED FITTINGS ASTM A182 Gr.F22 CL3 6000# ASME B 16.11 NPT " - 1" (6) (8)

WROUGHT PIPE FITTINGS ASME B 16.9 BW 2" - 24" (9) (10)

FLANGE 1500# ASME B 16.5 SW / RTJ " - 1" (10)(12)

FLANGE ASTM A182 Gr.F22 CL3 1500# ASME B 16.5 WN / RTJ 2" - 24" (10)(12)

BLIND FLANGE ASTM A182 Gr.F22 CL3 1500# ASME B 16.5 BLIND RTJ " - 24" (12)

ORIFICE FLANGE ASTM A182 Gr.F22 CL3 1500# ASME B 16.36 WN / RTJ 1" - 24" (10)(12)

GASKETS 1500# ASME B 16.20

STUD BOLTS ASTM A-193 Gr. B16 (18) (49)

NUTS ASTM A-194 Gr.4

SPECTACLE 1500# ASME B 16.48 RTJ " - 6" (12)

PADDLE 1500# ASME B 16.48 RTJ 8" - 24" (12)

DRIP RING 1500# ASME B 16.5 RTJ 1" - 12" (12)

DIELECTRIC JOINT MICARTA FENLICA/ALGODN 1500# ASME B 16.20 RTJ " - 24"

OLET FITTINGS ASTM A182 Gr.F22 CL3 MSS SP-97 BW-SW (6)(10)(42)(43)

SWAGE NIPPLE MSS SP-95 BW-PE " - 4" (6) (10) (20)

Note:

-29a38 100 200 400 542

263.7 262.7 248.2 186.7 87.5

ASTM A234 Gr.WP22 CL3

HOJA 30

ASTM A182 Gr.F22 CL3

DOCUMENTO No:

550

79.7

BE001-ESE-TU-GL-00-1003

TECHNICAL SPECIFICATION

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

FECHA

REV

1/24/2012

1 DE

A335 Gr.P22

A335 Gr.P22

JUNTA ANILLO

OCTOGONAL(Alloy Steel 5Cr. 1/2Mo)

56

For use at temperatures above 450C, the carbon content of the base material and, where applicable, weld filler metal shall be

0.05% or higher. See ASME B31.1 para. 124.2(D)

" - 24"

HY1

ASTM A387 Gr.22 CL2

ASTM A387 Gr.22 CL2

ASTM A234 Gr.WP22 CL3

ASTM A387 Gr.22 CL2

PIPING CLASS COMPONENTS

ISOLUX WATISOLUX CORSN

edcruzRectangle

edcruzLine

edcruzText BoxEn el FLUID LIST se encontraron MATERIALES BASE distintos para el fluido DRA: A106 Gr.B, API 5L Gr.B, Sts. Steel 304, Sts. Steel 316L

edcruzText BoxAccesorios:- Con respecto a los materiales de los accesorios de la clase HY1, se encontr que no poseen resistencia mecnica equivalente a la de la tubera (su resistencia es menor), cuando se encuentran a la temperatura de diseo de la Piping Class (542C / 1008F), obtenindose un resultado NO SATISFACTORIO. Sin embargo, al revisar los esfuerzos admisibles con respecto a las condiciones mximas de diseo del Listado Mecnico de Lneas - MLL (530C / 986F), su resistencia mecnica s es equivalente a la de la tubera, con lo cual el resultado cambi a SATISFACTORIO.

edcruzRectangle

edcruzRectangle

edcruzLine

edcruzLine

edcruzLine

edcruzLine

edcruzRectangle

edcruzLine

edcruzText BoxVer comentarios adicionales a pie de pgina

-

TEMPERATURE C FLANGE CLASS: 1500 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 1,5 mm

Table 2-1.10 PressureTemperature Ratings for Group 1.10 Materials MATERIAL: 2 1/4 Cr.1Mo (A335 P.22)

Examination: Per ASME B31.1 CODE: B 31.1

Postweld Heat Traatment (Stress Relief: Per ASME B31.1)

Extension: 100% of all welds

SERVICE: HPS, DRA

A182 F22 CL.3

A217 WC9

A217 WC9

A182 F22 CL.3

A217 WC9

A217 WC9

A182 F22 CL.3

A217 WC9

NOTE

Refer Valve Numbering procedure sheet 4 and 5 for description of valves Code

542 550

263.7 262.7 248.2 186.7 87.5 79.7

#1500

#1500

#1500

Stellite

Stellite

Stellite

SW

BW

4" 24"

= " 1"

2" 24"

A182 F6a

A182 F6a

A182 F6a BWSwing Check

Valve

BW

Globe

= " 1" A182 F6a #1500 SW

2" 3"

4" 24"

#1500A182 F6a

#1500 BW

#1500 BW

Stellite

Stellite

GTSRAL1#1500 SW

Gate

= " 1" A182 F6a Stellite

2" 3" A182 F6a Stellite

A182 F6a Stellite

HY1

Seat / "O" Ring Class End

PIPING CLASS - VALVES

GTBRAL2G

GTBRAL2

Description Size (NPS) Body Trim Tag. No.

TECHNICAL SPECIFICATION

-29a38 100 200 400

HOJA 31DOCUMENTO No:

BE001-ESE-TU-GL-00-1003 DE 56

NSBRAL2

NSSRAL2

GLSRAL1

GLBRAL2

GLBRAL2G

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

FECHA

REV

1/24/2012

1ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 0.0 mm

MATERIAL: Sts. Steel 304

CODE:

SERVICE:

REFER BRANCH TABLE I

DESCRIPTION MATERIAL SCH. RATING DIM. CODE ENDS SIZE NOTES

1" - 2"

WELDED PIPING LKM/Equivalent 2" - 3"

1" - 2"

ELBOW LKM/Equivalent 2" - 3"

1" - 2"

REDUCING TEE LKM/Equivalent 2" - 3"

1" - 2"

LKM/Equivalent 2" - 3"

UNION Sanitary Finish

Welding type

MALE PART

LINER

NUT

SEAL RING / GASKET

FLANGE (*)

NOTE:

* FLANGES, SHALL BE ACCORDING TO ASME B.16.5

be EPDM

AISI 304

Sanitary Finish

Sanitary Finish

Sanitary Finish

Sanitary Finish

Gasket shall

Welding type

SMSLKM/Equivalent

REDUCER

EQUAL TEE LKM/Equivalent

150# ASME B16.5

LKM/Equivalent

LKM/Equivalent

LKM/Equivalent

AISI 304

1.6mm PE Sanitary Finish

AISI 304

AISI 304

AISI 304

AISI 304

AISI 304

1.2 mm

1.6mm PE

1.2 mm

1.2 mm

PE1.6mm

2.0mm

2" - 3"

4"

Welding type

2.0mm

PE

PE

18.7

BE001-ESE-TU-GL-00-1003

140

14.8

REV

1.2 mm

2.0mm

1.6mm

TECHNICAL SPECIFICATION

CLM

PIPING CLASS COMPONENTS

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

HOJADOCUMENTO No: FECHA

50

4"

1.2 mm

SMS

2.0mm

1.6mm

AISI 304

4"

LA1

Sanitary Finish

1" - 2"

32

4

12/13/2012

PE Sanitary Finish

AISI 304

AISI 304

EPDM

SO-FF

LKM/Equivalent

SMS

SMS

SMS

DE 56

4"

1" - 4"

1" - 4"

1" - 4"

1" - 4"

1" - 4"

1" - 4"

90 LR

ISOLUX WATISOLUX CORSN

-

TEMPERATURE C FLANGE CLASS: 150 lbs

DESIGN PRESSURE kg/cm (g) CORROSION: 0.0 mm

MATERIAL: Sts. Steel 304

CODE:

SERVICE:

NOTE

Refer Valve Numbering procedure sheet 4 and 5 for description of valves Code

LA1

AISI 304

12/13/2012

TECHNICAL SPECIFICATION

Class

CLM

PIPING CLASS - VALVES

PN 10 SMS-SMS BLYTS42M

4

Ball A351 Gr.CF8 AISI 304 PTFE

140

14.8

> 1" 4"

PLANTA INTEGRADA DE PRODUCCION DE ETANOL CARBURANTE "EL ALCARAVAN"

DOCUMENTO No: FECHA

50

18.7

HOJA 33

BE001-ESE-TU-GL-00-1003 REV

Description Size (NPS) Body Trim Seat / "O" Ring

Butterfly EPDM

End Tag. No.

SMS-SMS

1" 4" AISI 304 PN 10 SMS-SMS