12154E64AP – Unconventional Machining Processes

-

Upload

george-oliver -

Category

Documents

-

view

215 -

download

1

description

Transcript of 12154E64AP – Unconventional Machining Processes

PRIST UNIVERSITY(Estd. u/s 3 of UGC Act, 1956)Vallam, Thanjavur -613403

________________________________________________________________________

B.Tech. Mechanical Engineering (Part Time)

QUESTION BANK

Course Details

Course Code & Title: 12154E64AP Unconventional Machining ProcessesRegulations : 2012 Regulations(For Students admitted from June 2012 onwards)

Nature of the Course:Elective

Semester: VI

HOD Staff-In-Charge

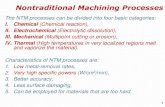

UNIT-1PART-A1. How non-traditional machining processes are classified?2. Why unconventional mechanical machining process is not so effective on soft metals like aluminum?3. What is meant by unconventional machining process4. Define SOD.5. Define MRR.6. What is necessity for unconventional machining processes?7. What are electro chemical energy methods of unconventional machining?8. How nontraditional machining process are classified9. What are the properties required for die electrical fluids for EDM10. How will you compare various nontraditional processes?

PART-B

1. Compare the mechanical and electrical energy processes in terms of physical parameters, shape capabilities, process capability, and process economy.2. Explain the factors that should be considered during the selection of an appropriate unconventional machining process for a given job3. With help of neat sketch, describe the EDM process4. Explain the reasons for the development of unconventional machining process. Discuss about the criteria recommended in selection of these processes.5. State the needs for unconventional machining process6. What are the classifications for unconventional machining process and explain

UNIT-2PART-A1. Define AJM?2. What is the transfer medium in AJM3. What are the applications of AJM?4. What are the desirable properties of carrier gas in AJM5. What are the different types abrasives used in AJM? 6. What are the advantages of WJC over conventional cutting methods?7. What are the types of work materials for USM8. What are the commonly used additives in WJM?9. What are the applications of USM? 10. What is ultrasonic transducer?PART B1. Explain the principles of working of the AJM process with its advantages and its disadvantages2. Discuss in detail about the AJM process variables that influence the rate of material removal and accuracy in the machining3. Explain the USM machine setup an discuss various feed mechanisms4. Explain the process parameters in WJM processs. 5. With a neat sketch explain the process of WJM? Briefly discuss the application and limitation of WJM 6. Explain the following detailsa. Types for transducers for USMb. Feed mechanism for USMc. USM typical applications d. Abrasives for USM UNIT-3PART-A1. What are the working principles for EDM process?2. What is the purpose of die electric in EDM? 3. Name the common tool materials4. What are the basic requirements of tool material for EDM?5. List the applications of EDM6. What are the voltages, amperes and temperatures involved in EDM process7. Name the most common used spark generating circuits 8. Indicate the range of pulse durations and current in EDM9. What are the draw backs of using relaxations circuits?10. Give the wear ratio for non metallic electrodePART B1. Explain the principles of working of wire cut EDM process with sketch.2. Describe the wire cut EDM equipment, its working, applications and advantages3. Explain the process of electrical discharge machining, its process parameters and applications. 4. Explain how the stratified wire works. Also discuss about the recent developments in wire EDM. 5. Explain the principles of working of EDM process with sketch6. Explain about metal removal rate and surface finished in EDM process.UNIT-4PART-A1. What are the process parameter s of electro chemical machining?2. Name any two electrolyte used in ECM.3. What are the materials used for tools in electro chemical machining.4. Write the principle of ECM process.5. State the principle of chemical machining process.6. Name the etchants used in chemical machining process.7. List the advantages of electro chemical grinding process.8. List the application of ECG process.9. What are the essential characteristics of an electrolyte used in ECM process.10. State the function of electrolyte used in ECM process.

PART-B1. Explain the working principle of electrochemical discharge grinding and discuss the process capabilities.2. List the requirements of tool materials for ECM. Write the commonly used tool materials.3. List the advantage, disadvantages and application of ECG process.4. Explain the principle of ECG and ECH .(8)5. List the advantage and disadvantages of ECH process. (8)6. Explain the process of electrochemical machining with neat sketch.7. Explain the process of electrochemical machining, its process parameter and application.8. Describe the ECH and ECG equipments with neat sketch its application and advantages

UNIT-5PART-A.1. State the working principles of EBM.2. Define plasma3. List the applications of EBM.4. What are the main elements of the EBM equipment?5. Why the deflection coil is is provided for EBM?6. State the principles of LBM.7. What are the gases used in PAM?8. What is transferred the type plasma?9. Write any two application of PAM.10. Stat the working principles of PAM.

PART-B1. Explain the process of LBM and PAM with a neat sketchs2. With neat sketch process of LBM. List its application and limitation?3. With neat sketch process of EBM. List its application and limitation?4. Explain the principles and elements of EBM, also how the work table is protected from getting damaged by electron beam. With neat sketch process of PAM. List its application and limitation?5. Explain plasma arc machining process?6. Describe Electron beam machine? And list the advantageous and disadvantageous