100287767-turbine-sop

Click here to load reader

-

Upload

mkhalil410 -

Category

Documents

-

view

212 -

download

0

Transcript of 100287767-turbine-sop

7/30/2019 100287767-turbine-sop

http://slidepdf.com/reader/full/100287767-turbine-sop 1/8

STANDARD OPERATING AND MAINTENANCE PROCEDURE – TURBINE

Specifications:

Make : Hang Zhou Steam Turbine Co., Ltd., China.

Model No. : EHNK 50/71/32

Rating : 17.0 MW (Season): 22.0 MW (Off S

eason)

Speed : 5743 rpm.

First Critical Speed : 2361 rpm.

Second Critical Speed : 4850 rpm.

Inlet Steam Pressure : 84 Kg/Cm2

Inlet Steam Temperature : 5100 C

Max. inlet steam pressure permitted : 87 Kg/Cm2

Max. inlet steam temp. permitted : 5200 C

No. of Stages : 19

Governor Type & Model : Woodward 505E Electrical& Hydraulic.

Gearbox make : Flender.

Type & Ratio : Double Helical & 3.83: 1

Lube oil & Manufacturer : Turbinol 46 & BP

Pre start Check:

Ensure the availability of water in cooling tower sump & condition of its Fans and pumps.

Ensure the condition of CEP & water level in hot well.

Ensure the quantity of lube oil in main oil tank & the condition of AOP, MOP andEOP.

Check the availability of instruments & ensure all instruments are in good condi

tion.

Ensure turbine inlet steam valve in closed position.

Ensure the running condition of Barring gear.

Ensure the running condition of Vapour exhaust fan, oil Centrifuge machine.

Ensure all valves are in good condition.

7/30/2019 100287767-turbine-sop

http://slidepdf.com/reader/full/100287767-turbine-sop 2/8

QC NRV & 2.5 ATA isolation valve should be closed & its drain valve should be inopen position.

Open all drain valves from turbine, inlet steam line, HP & LP extractions.

Ensure all drain valves in 2.5 ATA steam line in open position.

Procedure -Cold start:

If Turbine has been shut down for more than 24 hrs is consideredas cold Start up.

Start cooling water pumps (ACW).

Start AOP and check lube oil & control oil pressure. Also check their differential pressures across filters.

Open the overhead oil tank initial filling valve for filling the oil in over head tank..

Check for any leakage from lube oil pipelines.

Start the heater & centrifuge machine and increase the temperature to 450 C.

Start Jacking oil pump and check oil pressure.

Run the barring gear continuously.

Run CEP & maintain hot well 50%.

Start MCW pump & Tower fan and check their running condition

Warm up the turbine inlet steam lines, casing @ 50 C per minute and continuethis process to 3800 C.

Line up Starting ejector and pull vacuum (-0.9 Kg/Cm2)

Ensure the overhead oil tank is overflowing and closed the initial filling valve.

Give start command for turbine rolling after raise the steam pressure and temperature(75 kg/cm2,,400oC)& wait for 30 minutes at 1000 rpm. At this juncture checkvibration level, Temperature of the bearings, Lube oil & Control oil pressure.

Again give command to increase the speed thereafter turbine will run in its rated speed and throttle all drain valves.

Synchronize TG set with grid and close all drain valves completely.

Line up main ejector and then stop starting ejector.

Procedure -Hot start:

If Turbine has been shut down for less than 24 hours is considered as hot start up.

Ensure MCW pump, AOP & Barring gear is in running condition.

7/30/2019 100287767-turbine-sop

http://slidepdf.com/reader/full/100287767-turbine-sop 3/8

Ensure turbine inlet steam valve in closed position.

Ensure the running condition of Vapour exhaust fan, oil Centrifuge machine.

QC NRV & 2.5 ATA isolation valve should be closed & its drain valve should be inopen position.

Open all drain valves from turbine, inlet steam line, HP & LP extractions.

Ensure all drain valves in 2.5 ATA steam line in open position.

Run CEP & maintain hot well 50%.

Warm up the turbine inlet steam lines, casing @ 50 C per minute and continuethis process to 3800 C.

Line up Starting ejector and pull vacuum (-0.9 Kg/Cm2).

Give start command for turbine rolling & wait for 20 minutes at 1000 rpm. At this juncture check vibration level, Temperature of the bearings, Lube oil & Control oil pressure.

Again give command to increase the speed thereafter turbine will run in its rate

d speed and throttle all drain valves.

Synchronize TG set with grid and close all drain valves completely.

Line up main ejector and then stop starting ejector.

Enable of HP & LP extractions:

Turbine load should be maintained above 12 MW

Open drain valves in 8 ATA & 2.5 ATA steam line.

Open 6” drain valve ( 4 thread of spindle opening)

Ensure PRDS isolation & control valve of 2.5 ATA in closed position.

Slowly open QC NRV.

Press ACTR in Governor panelDisplay : @ HP Valve Dmd 40 %

LP Valve Dmd 100 %Ensure the LP Valve Dmd in display is 100 % & Cross check wi

th Actuator

Press EXT/ADM in Governor panel

Display : @ Ext Input 0.234 Kg/cm2 (approx.)Set Pt 1.000 Kg/cm2

Ensure the set point in display is 1.000 Kg/cm2

Press SCROLL DOWN ArrowDisplay : @ Ext Input 0.234 Kg/cm2

Extr Active / Not in CtrlPress YES

Display : @ Ext Input 0.234 Kg/cm2Extr Active / Enabled

7/30/2019 100287767-turbine-sop

http://slidepdf.com/reader/full/100287767-turbine-sop 4/8

Press ACTRDisplay : @ HP Valve Dmd 40 %

LP Valve Dmd (Vary from 100 – 0%)

Ensure the LP Valve Dmd in display is reducing from 100 to 0% & Cross check with Actuator also.

Ensure complete removal of condensate & steam flow through 6” drain valve.

Open isolation valve slowly.

Ensure the extraction steam pressure & flow then slowly close 6” drain valve completely.

Close all drain valves in extraction steam lines after complete removal of condensate.

Disable of HP & LP extractions:

HP Extraction Control Valve will automatically disable if load reduced less than10.5MW.

For Disabling the LP extraction following procedures has to be followed.

Press EXT/ADM in Governor panelDisplay : @ Ext Input 1.328 Kg/cm2 (approx.)

Set Pt 1.540 Kg/cm2

Reduce the Set Pt. to 1.000 Kg/cm2 by pressing ADJ Down Arrow

Press SCROLL DOWN ArrowDisplay : @ Ext Input 0.824 Kg/cm2 (approx.)

Extr Active / Not in CtrlPress NO

Display : @ Ext Input 0.824 Kg/cm2 (approx)Extr Active / Disabled

Press ACTRDisplay : @ HP Valve Dmd 40 %

LP Valve Dmd (Vary from 2 – 100%)

Ensure the LP Valve Dmd in display is increasing from 0 to 100% & Cross check with Actuator also.

Close QC NRV manually

Close LP isolation valve.

Shut down to cold:

Reduce power generation

Disable HP & LP extractions and close QC NRV. Bring down to minimum load and trip the turbine manually. This will close ESV.

Open all drain valves.

7/30/2019 100287767-turbine-sop

http://slidepdf.com/reader/full/100287767-turbine-sop 5/8

Start barring gear when turbine speed came to zero.(Check JOP is running)

Kill the vacuum and stop CEP.

MOP / AOP must run continuously till steam temperature at turbine inlet fall down to 500 C.

Stop MCW pump & Cooling tower fan and run ACW pump till lube oil temperature come to 350 C.

Stop GVC air blower.

Stop MOP / AOP when steam temperature at turbine inlet fall down to 500 C and stop vapour exhaust fan..

Shut down to Hot:

Reduce power generation

Disable HP & LP extractions and close QC NRV. Bring down to minimum load and trip the turbine manually. This will close ESV.

Open all drain valves.

Start barring gear when turbine speed came to zero.(Check JOP is running).

Kill the vacuum and stop CEP. (If boiler is not running.)

MOP / AOP must run continuously.

Stop MCW pump & Cooling tower fan and run ACW pump.

Maintenance Schedule - Daily:

Shaft position indicator – Compare actual value with reference value given in test

report.

Temperature measuring Devices – Note down the temperature readings for every hourin a log book till the turbine come to cold state.

Pressure measuring Devices - Note down the pressure readings for every hour in alog book till the turbine come to cold state.

Centrifuge – Run centrifuge machine once in a day for 4 hours.

Oil filter – Check for its differential pressure across the filter. If differential pressure exceeds 0.8 Kg/Cm2, change over the valve and clean the filter.

Oil Cooler – Check inlet & outlet temperature of oil and never exceed oil outlet temperature to 450 C.

MOP/AOP – Check the running performance of pump.

Oil level – Check oil level in main oil tank as well as in over head oil tank.Cooling Water – Check cooling water pressure at condenser inlet & outlet and oil cooler inlet & outlet. Ensure all the parameters are within the limit.

Vibration – Check vibration values for turbine front & rear, gearbox and generator

7/30/2019 100287767-turbine-sop

http://slidepdf.com/reader/full/100287767-turbine-sop 6/8

. Also note it down in a log book.

Axial Displacement – Check axial displacement of the turbine & note it down in a log book.

Condenser – Check condenser vacuum, temperature of the steam inlet and outlet.

Check for any steam, water & oil leakages if any and note it down. Rectify the problem if possible.

Check for any gland leakages from CEP and attend immediately if it occurs.

Maintenance Schedule - Weekly:

Change CEP once in a week.

Check spring supports of steam lines.

Check the availability of EOP.

Maintenance Schedule - Monthly:

Change oil cooler & clean the stand by.

Check & clean the dust in centrifuge machine.

Clean lube oil filter & control oil filter.

Change main ejector & put running ejector to standby.

Clean suction strainers of CEP.

Check the quality of turbine lube oil.

Check the quantity of lube oil & top up details to be recorded separately.

Maintenance Schedule – at shut down:

Test emergency trip gear for proper functioning.

Open or close ESV by means of starting device.

Check control valve spindles for smooth operation.

Valve actuator to be checked for proper functioning.

MOP, AOP & EOP to be overhauled.

Oil tank and its pipelines to be cleaned & fixed.

Turbine lube oil quality to be checked & maintain a separate record.

Both CEP to be overhauled.

Oil centrifuge machine to be overhauled.

Lube oil cooler tubes to be cleaned & hydro test to be completed.

Condenser tubes to be cleaned.

7/30/2019 100287767-turbine-sop

http://slidepdf.com/reader/full/100287767-turbine-sop 7/8

Turbine rotor to be rotated for 1800 once in every day during idle condition.

HP and LP Valve calibration.Gear box pinion and gear inspection and Checking the backlash

ESV steam strainer Checking

Lube oil tank inlet filter to be cleaned.

TURBINE TRIP SETTINGS

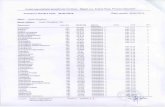

S.NoDescriptionValues1Turbine Front Bearing Temperature HH1200 C2Turbine Rear Bearing Temperature HH1200 C3

Pinion Front Bearing Temperature HH1100 C4Pinion Rear Bearing Temperature HH1100 C5Gear Front Bearing Temperature HH1100 C6Gear Rear Bearing Temperature HH1100 C7Axial Displacement HH

+/- 0.6 mm8Turbine Vibration HH83.0microns9Gearbox Vibration HH83.0microns10Generator Vibration HH305.0microns11Lube oil pressure LL1.0 Kg/Cm2

12Control oil pressure4.0 Kg/Cm213Turbine inlet steam pressure HH91.0Kg/Cm214Turbine inlet steam pressure LL60.0Kg/Cm215

7/30/2019 100287767-turbine-sop

http://slidepdf.com/reader/full/100287767-turbine-sop 8/8

Turbine inlet steam temperature HH5500 C16Turbine inlet steam temperature LL3800 C17Condenser Vacuum LL-0.35Kg/Cm218Turbine exhaust steam(to condenser) temperature HH1300 C19Hot well level HH90.0 %20Turbine mechanical lever Trip2 nos.21Turbine Emergency stop push button2 Nos.22Turbine Over speed6250 rpm23

Generator front bearing temperature HH900 C24Generator Rear bearing temperature HH900 C25Generator winding temperature HH1200 C