10 - NRG - Protection Against Liquefaction

14

NRG ENGINEERING [email protected] The Power to Deliver™ Pipeline Design Training Pipeline protection design against soil liquefaction 14 August 2006

description

NRG - Protection Against Liquefaction

Transcript of 10 - NRG - Protection Against Liquefaction

Wall Thickness Design14 August 2006

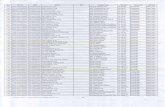

August 2 – August 28, by Mr. Eng Bin NG

Applicable Codes

Pipe Expansion Calculations

Flexibility Analysis Methodology

5

Pipeline Construction - Conventional & Unconventional

Weekending

Pipe Expansion Calculations, Flexibility Analysis Methodology

Allowable Free Span Calculations, On-bottom Roughness Analysis

Pipeline Protection against Anchors, Wave Liquefaction & Earthquake

Cathodic Protection Design

Pipeline Construction - Conventional & Unconventional

Installation Engineering

1 2 3 4 7 8 9 10 11 14 15 16 17 18 21 22 23 24 25 28

Workshop, revision, exercise

General

Wave-induced liquefaction is likely to affect the integrity of the pipeline. Examples include:

Pipeline may float out of the liquefied soil if the SG of the pipe is lower than the SG of the liquefied soil. Once exposed, the pipe may deflect laterally till failure occurs.

If SG of pipeline is much greater than SG of liquefied soil, then the pipe will sink further.

NRG ENGINEERING

General (cont’d)

Protection against soil liquefaction may be carried out by one of the following manners:

Burying the pipeline below the influence depth of liquefaction.

Backfilling the pipeline with suitable materials that will not liquefy

Designing the pipeline such that the SG of pipeline is almost equal to the SG of liquefied soil

NRG ENGINEERING

Backfill Design

“Manual on the Use of Rock in Coastal and Shoreline Engineering” (Ref. [1]). This manual provides theoretical basis for designing rock berm layers in offshore areas.

The backfill design in the offshore areas is based on the “Critical Shear Stress Method” as described further below:

NRG ENGINEERING

The Power to Deliver™ #*

Backfill Design (cont’d)

The critical shear stress to initiate movement for a given material is calculated using Shields’ criterion (Ref. [1]), where:

NRG ENGINEERING

ρr = Berm material oven-dried density (kg/m3)

ρw = Seawater density (kg/m3)

ψCR = Critical shields’ number

=

j = Angle of repose of the backfill layer (degree)

NRG ENGINEERING

The Power to Deliver™ #*

Backfill Design (cont’d)

The critical shear stress is equated to the actual applied shear stress due to wave and current action in order to find the backfill size.

The actual applied shear stress is calculated using the following equation (Ref. [1]):

NRG ENGINEERING

C = Chezy coefficient (m1/2/s)

≈ (1-3)D90

U = Wave-induced velocity (m/s)

fw = Wave-associated friction factor

NRG ENGINEERING

The Power to Deliver™ #*

Backfill Design (cont’d)

The nominal backfill layer diameter (Dn50) is related to the median sieve diameter (D50) by the following relation:

NRG ENGINEERING

The Power to Deliver™ #*

Backfill Design (cont’d)

The grading distribution curve for the backfill layer shall satisfy the requirement from Shore Protection Manual (Ref. [2]) as given below:

where: D50max = Maximum diameter exceeded by

50% of the rock berm material (mm)

D50min = Minimum diameter exceeded by

50% of the rock berm material (mm)

NRG ENGINEERING

Reference

[1] “Manual on the Use of Rock on Coastal and Shoreline Engineering”, CIRIA Special Publication 83, 1991.

[2] Shore Protection Manual, US Army Coastal Engineering Research Centre.

NRG ENGINEERING

August 2 – August 28, by Mr. Eng Bin NG

Applicable Codes

Pipe Expansion Calculations

Flexibility Analysis Methodology

5

Pipeline Construction - Conventional & Unconventional

Weekending

Pipe Expansion Calculations, Flexibility Analysis Methodology

Allowable Free Span Calculations, On-bottom Roughness Analysis

Pipeline Protection against Anchors, Wave Liquefaction & Earthquake

Cathodic Protection Design

Pipeline Construction - Conventional & Unconventional

Installation Engineering

1 2 3 4 7 8 9 10 11 14 15 16 17 18 21 22 23 24 25 28

Workshop, revision, exercise

General

Wave-induced liquefaction is likely to affect the integrity of the pipeline. Examples include:

Pipeline may float out of the liquefied soil if the SG of the pipe is lower than the SG of the liquefied soil. Once exposed, the pipe may deflect laterally till failure occurs.

If SG of pipeline is much greater than SG of liquefied soil, then the pipe will sink further.

NRG ENGINEERING

General (cont’d)

Protection against soil liquefaction may be carried out by one of the following manners:

Burying the pipeline below the influence depth of liquefaction.

Backfilling the pipeline with suitable materials that will not liquefy

Designing the pipeline such that the SG of pipeline is almost equal to the SG of liquefied soil

NRG ENGINEERING

Backfill Design

“Manual on the Use of Rock in Coastal and Shoreline Engineering” (Ref. [1]). This manual provides theoretical basis for designing rock berm layers in offshore areas.

The backfill design in the offshore areas is based on the “Critical Shear Stress Method” as described further below:

NRG ENGINEERING

The Power to Deliver™ #*

Backfill Design (cont’d)

The critical shear stress to initiate movement for a given material is calculated using Shields’ criterion (Ref. [1]), where:

NRG ENGINEERING

ρr = Berm material oven-dried density (kg/m3)

ρw = Seawater density (kg/m3)

ψCR = Critical shields’ number

=

j = Angle of repose of the backfill layer (degree)

NRG ENGINEERING

The Power to Deliver™ #*

Backfill Design (cont’d)

The critical shear stress is equated to the actual applied shear stress due to wave and current action in order to find the backfill size.

The actual applied shear stress is calculated using the following equation (Ref. [1]):

NRG ENGINEERING

C = Chezy coefficient (m1/2/s)

≈ (1-3)D90

U = Wave-induced velocity (m/s)

fw = Wave-associated friction factor

NRG ENGINEERING

The Power to Deliver™ #*

Backfill Design (cont’d)

The nominal backfill layer diameter (Dn50) is related to the median sieve diameter (D50) by the following relation:

NRG ENGINEERING

The Power to Deliver™ #*

Backfill Design (cont’d)

The grading distribution curve for the backfill layer shall satisfy the requirement from Shore Protection Manual (Ref. [2]) as given below:

where: D50max = Maximum diameter exceeded by

50% of the rock berm material (mm)

D50min = Minimum diameter exceeded by

50% of the rock berm material (mm)

NRG ENGINEERING

Reference

[1] “Manual on the Use of Rock on Coastal and Shoreline Engineering”, CIRIA Special Publication 83, 1991.

[2] Shore Protection Manual, US Army Coastal Engineering Research Centre.

NRG ENGINEERING