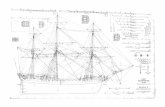

10. HMS Kingfisher B Hunt Construction

Transcript of 10. HMS Kingfisher B Hunt Construction

HMS Kingfisher POF Kit Development Hi Group, The latest kit that I am developing to be produced in limited quantities is the Swan class Sloop, HMS Kingfisher using David Antscherl's plans with his permission. I thought the group might be interested in seeing how this kit evolves. Development began several months ago with the drawing of the keel and all of the frames using AutoCAD. Once I completed these drawings, I created parts drawings laying all the parts out on 3" x 24" drawings because the wood I use to cut the parts out is in this dimension. ArtCAM was then used to create cutting files for my two CNC router mills. My wood supplier, HobbyMill Corp supplied me with boxwood billets of the proper thicknesses for all of the parts and the parts were cut out on the mills. Here are the first pictures of the prototype construction. For those of you who have David's book, you can follow along in the book starting with section 1.13. The first parts to be assembled are three keel parts. I made these parts so that the scarf joints were formed and so that the hole that will be used to mount the keel to the building jig base could be cut out. The first photo shows the first two keel parts with the hole at the stern of the ship.

These parts are glued together and then the third keel part is glued to the forward end of the keel part shown above resulting in the assembled keel.

Next, the forward keel part (section 1.15) is assembled from two layers. I designed this part in two layers so that the complex joint where the lower stem connects would be automatically created for you.

And that assembly gets attached to the keel assembly.

Next, the lower stem is added. This is also in two layers so that the jointed end is formed and matched to the forward keel.

The lower apron comes next (section 1.19). It's actually made from three layers; a thick inner layer and two thinner outer layers that form the steps. As per David's text, the width is 18". The inner layer is 12" and each outer layer is 3". This would be a complex part to make from scratch but the kit makes it easy. First you mark the location of the step parts using a template.

Then you glue the step parts to each side.

Before the lower apron can be added, the upper stem is added (section 1.1 and it is 14" wide compared to the lower stem which is 12" wide. Then, because of the orientation of the scarf joints, the upper apron is added and then the lower apron.

The lower apron can be added now but first it must be beveled (section 1.19).

Now we add the lower apron.

And we have the first part of our keel assembly completed.

After the upper and lower stem and upper and lower apron are attached to the keel, a template is used to taper the stem from top to bottom. The upper stem is 14" wide but tapers to 10" at the keel (section 1.22 in David's book).

A bevel edged chisel is used to carve away the excess wood. Once shaped the stem/aprons are sanded smooth.

We put the keel aside for a while and move to the stern. The stern deadwood is built up in its individual parts.

Here's where construction gets a little difficult and complicated. The stern deadwood has steps for the cant frames as the lower apron does. But the stern deadwood is tapered top to bottom. At the top where the steps are formed, the deadwood is 15" scale in width from side to side. But at the bottom where the deadwood meets the keel, the width or thickness is only 5" scale. The deadwood assembly is marked with several templates and then beveled at the point where the taper begins down to the keel. The bottom of this assembly is only .042" thick.

To form the steps, a second layer of parts is added. These parts match the lines of the first layer parts and are a scale 1-1/5" thick as stated in David's practicum, section 1.23.

The layering makes it easy to form the steps and by tapering the inner thicker layer of deadwood parts, the entire assembly becomes properly shaped with steps along the bearding line. The result is a simplified method of carving these steps. The inner sternpost is added and it too is tapered with a bevel edge chisel to match the profile.

Next, the sternpost is tapered using templates and a bevel edge chisel.

The sternpost is also layered to help in forming the complex rabbet where the inner sternpost meets the sternpost. On Kingfisher, the rabbet is "L" shaped at the bottom but as it rises it becomes more "U" shaped above the bearding line. I designed the kit to use a second piece of stock to make up the sternpost so that it can be shaped with a chisel more easily. See section 1.25 in David's book.

The upper area of the sternpost and inner sternpost was completed with strips that separate the transoms.

The next series of photos show the construction of the last full frame, 14A(ft.

And 14 F(ore completed:

The frames reduce in size. The floors and cross chocks are 10" scale (1/4" scale). The second futtocks are 9-1/2" scale, the first futtocks are 10" and the toptimbers to the aft frames such as 14 aft are 9" scale. The toptimbers of the fore frames such as 14 fore are 9-1/2" scale. The next photo shows the completed keel. The false keel has been added, the rabbet joint has been cut from the stern deadwood to the stem and although they're not visible, copper pins have been installed in the keel at the scarf joints of the individual keel pieces.

The next photo shows the building jig base. The keel is clamped at each end and hidden screws hold it tightly to the base and on the centerline.

And in the next photo, you can see the removable jig parts that hold the frames in alignment. These parts fit into slots along the edges of the jig. The notches in the jig hold the frames in proper alignment.

In this photo, frame 14A has been seated and temporarily installed. It has not been glued. The actual framing will begin at the wing transom. After it has been installed, the other transoms will be installed and then aft cant frame 1 and the fashion piece will be installed. You will continue to add cant frames working your way forward. The frames and cant frames are not glued to the jig. After being glued to the keel or deadwood, chocks will be added at the top of the frames tying each frame to the previous. When an entire jig section is completed, the jig will be removed and you will use chisels to fair out the interior. Then the next jig section will be installed and the frames for that section will be added. You'll also work from the bow aft in the same fashion For the remainder of this week I'll be assembling whole frames. Next week I will cut out the cant frames and begin assembling them so that I can start framing the hull out. I'll post more photos as I get further along.

Take care, Bob Hunt the Kingfisher is a different story. Because it is historically correct, it will be much more difficult to build. But my jig design will help immensely in keeping the frames in proper alignment and spacing and that's 90%of the difficulty in building such a model. The jig will be included in the kit and will come on 6 sheets of particle board 1' x 2' in size. As my development progresses, I will post updates and photos showing the evolution of the kit and model. Here is a photo of Greg Herbert's framed Pegasus model and my Kingfisher kit will look exactly the same in framing.

Things are moving along well. Today I completed the fairing of all of the stern cant frames and the first full frame, frame 14 A(ft. Now I can move forward with full frames until I reach the center of the hull. Then I reverse directions and start with the bow cant frames and bow timbers and work my way aft. The first 3 photos show the CNC milled transoms and wing transom. Bevel patterns are rubber cemented to the top and bottom and the transoms are beveled before they are glued to the sternpost.

Next, the wing transom is chiseled on the top and bottom to give it the arch effect which matches the arch in the deck beams.

In the next photo, the first aft cant frame is assembled. It has two layers. The first layer contains the scarf joint joining the two timbers that create the frame. Then a thin layer is applied in pieces to form rabbet joints. When it is installed in the jig, it will sit on the

stern deadwood and the transoms will fit into the rabbet joints as outlined in David's book.

The transoms are glued first in the notches in the stenrpost. I used epoxy to glue them in place. Then the first cant frame is glued to the stern deadwood and to the transoms.

With the transoms and first cant frame in place, the remaining cant frames can be added one by one. Each cant frame is attached to the previous frame with a small chock at the top of the frame.

At cant frame 10, the frame has a bend in it to form the aft side of a gunport as shown in the next photo.

And finally, the first full frame is added and it too is tied to the last cant frame with a chock at the top.

The model is removed from the jig at this stage so that it can be faired inside and out. I used the Dremel tool with the drum sander to do most of the fairing and finished the fairing with 80 grit and 150 grit sandpaper and a sanding block. The remaining timbers beneath the 4th transom were added and the fashion piece was added. The remaining photos show the faired hull after sanding and a light coat of Wipe on Poly.

At the stage of the last photo, the model is put back into the jig. The outer jig frame holding parts will be put back in place and additional full frames will be added until frame 9. Then the model will be removed from the jig and that new section will be faired out. And after that, the next removable section of the jig will be added, more full frames will be added and the process will be repeated. Hope you're enjoying the construction of the prototype. Bob Hunt

Hi Group, I've been adding more frames and by the time I got to the third gunport, I realized I had a problem. Gunports are extremely difficult to frame up in the historically correct manner. I exchanged some emails with Greg Herbert and he too had a very difficult time with them. My original plan was to provide stripwood of the correct thickness and width to make the gunport sills. But after doing this on two ports, I was convinced that if I was having so much trouble, kit owners with lesser experience than I have would have a terrible time. You only get one chance. If you don't get the notches cut correctly as outlined in David's book, you ruin the frame and that's a major problem. So I came up with a better solution. The sills are milled in the correct dimension with the correct tenons in them. They appear as a complete gunport with top sill, bottom sill and what appears to be side parts. These side parts are only temporary and hold the upper and lower sills at the correct angle and spacing. Then, in conjunction with a template for marking their location, the mortises are cut shallow with a #11 Xacto and the gunport frame part is installed. Once the glue has dried, the excess sides of the frame are removed with an Xacto and what is left is the upper and lower sills, correctly positioned and angled correct as well as spaced correctly and the historical mortise and tennons. Sounds complicated but I'll here are some photos to help explain it all. First a template is used to mark the angle of the port and its upper and lower sill locations.

The next photo shows what the CNC milled gunport looks like.

It actually takes 3 of these glued together in a stacked fashion because the frames curve inwards as they rise.

This frame blank has scale tenons on it. As you can see, the upper sill is a beveled tenon while the lower sill is called a birds beak tenon. These tenons are only .020" deep or 1" scale. You use the blank to mark the location of the mortises you have to cut with your Xacto. These mortises are very shallow and the trick is to not cut them too deep. Once you've cut them and test fitted the gunport blank, you glue it in place.

The blank will protrude on the outside and inside of the hull and when the glue is dry, you sand it down with the Dremel tool and the drum sander attachment.

After sanding, you use your #11 Xacto to trim the center height bar and two side bars away leaving the sills in place, properly aligned and at the precise height needed.

Hi Group, It's been a while since I posted an update because I've been hard at work on the model. Here's where I am as of today. The forward cant frames and hawse pieces have been installed now and shaped. The first two full frames aft of the forward cant frames have also been installed and faired with the cant frames leaving only full frames left to install. The model is 2/3rd's framed now and the building jig continues to do its job in ensuring that the framework comes out correctly. It's all downhill from here. Here is a photo of the overall model with the forward cant frames installed and all of the aft frames installed from the center of the ship aft.

Here's a forward shot showing the faired out forward cant frames with hawse pieces.

There is one additional gunport near the front that has not been installed. Those cant frames will be cut later and sills will be installed. I still have a little more sanding to do inside and out on the forward cant frames to remove some roughness from the Exacto knife used to rough fair the hawse pieces. Next week I'll start installing the remaining full frames and within 2 weeks, the model will be fully framed. Meanwhile, I've begun work on the upper deck drawings and hope to have all of the drawings finished sometime in September. Once I've completed the remaining drawings, I'll order wood and begin the final phase of construction, the decks and deck furniture.

Well, here it is, the fully framed model. I still have to frame the oar sweep ports and there is one additional gunport near the bow that has to be opened and framed but I'm holding off on that until I get ribands on the port side and some planking on the starboard side because the framework is very fragile right now with the reduced chocks at the top.

After the model was full framed and faired out, templates were used to mark the top of the frame work and it was trimmed down with the Dremel drum sanding attachment and a #11 Xacto. The timberheads were marked for height and trimmed down also. The trimming reduced the height of the chocks between the frames but their bottom edges were not uniform and still too large. A #11 Xacto was used to trim them down also so that they were smaller and uniform in size across the entire ship. There are still a number of chocks to be installed between certain frames called frame bends which are shown in David's book and on the original admiralty drawings. These chocks will greatly strengthen the ship once I've installed them. One additional comment - At the bow there are raised areas in the hawse pieces. The wales go below the raised area. This area was raised or thicker and planking did not cover it so that water would drain better from the hawse ports which will be located within the raised area. My raised area is curving upward and I will have to correct that. This is the kit prototype and that's why we build a prototype, to flush out any problems in the kit. I had milled this raised area into the hawse pieces but in the production model, they will probably be added separately after the model is framed. That way they can be properly aligned with the flow of the wales.

I will have to chisel and sand these off on my prototype model and then add them back as separate pieces of wood. I'm not sure what caused the misalignment but if it can happen to me, it can surely happen to the modeler building the kit so I need to fix it so that it comes out correct without trouble or concern. Although adding the pieces afterwards is not historically correct construction, it will still look historically correct on the model. This completes the first stage of construction and the kits development. In the next stage, I will be developing the drawings for the upper deck and its details, quarterdeck and forecastle deck and their details to determine wood requirements so that I can order the wood and begin cutting those parts. For the 32 lucky modelers who have purchased this kit, I will be contacting you in a few weeks once I have determined the next stage of wood and I'll need another installment to cover the purchase of that wood (please don't send any money just yet, I'll let you know). I've also completed writing chapter 2 of the kits practicum which covers the construction of the keel assembly. Chapter 3 will cover making frames and chapter 4 will cover the building jig. Chapter 5 will cover actual framing. I'm very pleased with the way the model came out. The photo doesn't do it justice. It's a big model and difficult to fit the entire model in the frame of the camera all at once! I hope you like the look of it and are enjoying the development. Thanks, Bob Hi Group, I've completed construction of the ships stove and here are the photos. The stove is made entirely of styrene plastic in various sizes and shapes. All of the needed strips and pieces will be included in your kit to build the stove exactly as I have. This first photo shows the stove as seen in David's book on page 82, Volume 2. The only thing missing is the chain on the spit which you'll see in a later photo.

The next photo is a similar shot from the front, a little out of focus and again, the chain has not yet been attached.

The next photo shows the other side and other end of the stove where the spigots are.

Here's another shot of the other side.

And this last shot is again like the one in David's book but it shows the chain which is actually a piece of black rope.

This was not easy to build because of it's small size. The stove is missing two copper lids that go on top of the pan with the small pipe sticking out of it. Those lids will be made of real copper, CNC milled but right now I haven't gotten my miniature Sherline mill up and running yet. I'll post a new photo once I cut those two parts out. I'm cutting out parts for phase 2 of the prototype today and probably tomorrow and then I'll get back to work on the model itself. Hope you like the photos, Finally, I've completed the upper planking on the starboard side and have also completed the treenailing of those planks. The kit will contain instructions on how to treenail but actual treenails will not be included. I used a treenail cutter that fits into the dremel tool to make the treenails which you can buy from Vandalay (see my links page). The enhanced kit will have ebony veneer wales. The under layer is basswood and the ebony layer is about 1/32" thick overlaid on the basswood layer.

The next step will be to install the chocks on the port side and then build the stern area before adding the ribbands which will leave the framework open and completely visible. Then I'll begin work on the interior with the hundreds of parts I've already cut out.

This picture shows the port side of the model with ribbands allowing the full framework to be shown. I took this photo right after the ribbands were installed. Later, I framed in all of the oar sweep ports which don't show in this photo. This picture shows the keelson, mast steps and breasthooks installed.

The enhanced kit will include wood to make the well and shot locker. Later the chain pumps also included in the enhanced kit will be added with full chain details.

The shot locker contains cannon balls or shot, part of the enhanced kit.

The well/shot locker installed in the hold. Additional details on the lower deck for the well will be included in the enhanced kit.

The wing transom knees installed. These are built from two layers of wood. The upper layer has notches in it for the beams and ledges while the bottom layer does not.

Two beams have been added. The beams are also built up in layers so that the notches for the carlings are automatically formed making deck construction much easier.

This picture shows some of the upper deck framing. The beams are built up from 3 layers of CNC cut parts. The outer 2 layers have notches in them for the carlings. The lodging knees are also made this way as are the carlings. The carlings and ledges will be added later. Because each modeler's hull might be slightly different due to sanding of the interior, hanging knees are not complete. The lower portion of those knees has been omitted for simplicity because if they were CNC cut out, it is likely that they would not fit some models and would therefore have to be remade from scratch. So only the visible portion of the hanging knee is shown on the upper deck. You can also see simulated bolts in the lodging knees. These are not provided in the kit and are ebony treenails that the modeler can make himself if he wishes to add this detail.

This picture shows half of the upper deck framing in place. The center beam has beam arms on each side and the upper well is shown below. The well details are only provided in the enhanced kit.

This is the upper well provided only in the enhanced kit. The five posts are built in layers. A thin layer has grooves milled into for the louvers. The louvers are made from stripwood. This is a difficult structure to build and will tax your patience!

Another photo of the upper well structure after photo etched hinges have been attached. A black nail head was used to simulate the door knob. These will be provided in the enhanced kit.

The upper well added to the two lower deck beams installed above the lower well.

Upper well with upper deck beams installed.

Head shot showing the aft half of the upper deck beams now in place with the upper and lower well installed also.

This picture shows the upper deck with all of the beams, hanging knees and lodging knees in place. The next step will be to add the carlings and ledges.

This picture shows the unusual curved lodging knee at the waist of the upper deck.

The picture shows the first set of carlings added at the bow.

This picture shows the next set of carlings added at the bow.

This picture shows the upper deck after carlings and ledges have been added between beams 1 through 7. Like the beams, the carlings are built from 3 layers, 2 of which are CNC milled parts which form the notches for the ledges. The ledges are made from stripwood provided in the kit.

Here you see the fully framed upper deck. The next step will be to add the deck details.

Chain pumps, enhanced kit only (and all kits purchased after 10/1/07) with photo etched parts. Pumps are octagonal in cross section and made from stripwood leaving the inside hollow.

Chainpumps installed.

Waterway plank installed, spirketting (black) installed, upper deck quickwork and quarterdeck/forecastle deck clamps (red) installed.

Gunports and oar sweep ports painted red, port steps have been added per David's book

Cistern with chainpump mechanism which consists of photoetched parts and other miniature hardware included in enhanced kits and all kits purchased after 10/1/07.

This picture shows the 8 CNC milled pieces used to make a typical hatch. This is the fore hatch on the upper deck.

Here is the hatch after the pieces have been glued together. The layering effect automatically creates the joinery for the hatch and makes it easy to round the portion that is above the planking level.

Another picture of the hatch. The sides have been sanded to create the slight bevel of the hatch at the joint line of the layered pieces. This joint line won't show because the planking around the hatch meets the joint line.

Here the grating has been added. The grating is made from 10 CNC milled pieces that have the notches in them. Stripwood measuring .015" x .056" is then added for the battens.

And here's a picture of the hatch after it's been added to the upper deck.

This photo shows the jeer bitts and hatch.

This photo shows the other cistern pump. I chose not to model the chain mechanism on this one so that it could be shown with the hood.

This photo shows the double capstan. The capstan rod is CNC milled on a 4 axis mill. The lower portion is 10 sided while the upper portion is 12 sided.

This photo shows the riding bitts.

This photo shows the main topsail sheet bitts and jeer bitts with main hatch.

This photo shows the starboard side deck planking. Only enough planking was added to hold the cannons (enhanced kit only) so that much of the deck detail could still be seen.

This photo shows the forward bulkhead fitted to the bulwarks and forecastle beam. The bulkhead would have extended from one side to the other but I chose to model only one half of the bulkhead because I'm trying to leave the port side in plain frame with

The forward bulkhead after trim work has been added. I still have the windows to add to the open area. They will have panes to them.

Cannon carriage before the trucks have been added (front and back).

This photo shows the lower and upper counter planking. I only planked one side as I want to show the transom frames without details on the port side of the model.

Rudder after assembly. The pintles on the rudder and gudgeons on the ship are done in styrene. You can see the styrene wedges fitted with a pin. Later, they will all be painted black and styrene strips will be added across the sides of the rudder to simulate the strapping of the pintles. They too will be painted black.

This photo shows the gudgeon wedges added to the slots in the sternpost. These have holes in them so that the pins of the pintles can slip into the holes. Straps will be added later across the hull and painted black.

This photo shows the rudder temporarily mounted. The rudder is lifted into position and then the pins are let down into the holes in the gudgeon wedges.

Here you can see the rudder mounted again and the straps on the pintles have been painted black. The rudder actually moves left and right as it should and it can be dismounted easily and stored so that it doesn't get damaged as construction of the model progresses .

This photo shows the interior planking across the counter. The small strip of deck planks is necessary because the locker sits on the deck.

This is a photo of the locker. Small brass hinges will be added later because the lid could be opened to store things inside.

This photo shows the interior planking across the counter. The small strip of deck planks is necessary because the locker sits on the deck.

This is a photo of the locker. Small brass hinges will be added later because the lid could be opened to store things inside.

This is a photo of the rudder head trunk. You can see drawings and more information in David's book, volume 2, page 118 and 119.

And this photo shows the trunk and locker installed. I'm only detailing the starboard side of the ship so I did not extend the locker all the way across the deck. Locker and trunk are in swiss pear and holly.

This photo shows the chain pumps installed with the forward cranks. Please note that there will be two elm tree pumps installed also, just forward of the chain pumps.

A closer view of the chain pumps and forward cranks.

Another view of the chain pumps with the pump dale added. A scupper was drilled through to the outside which can be seen in one of the previous photos.

A close up view of the chain pumps and forward cranking hardware. Note the rhoding that holds the crank to the main topsail bitts.

The focus on this photo is the rhoding that holds the crank hardware to the main topsail bitts.

This photo shows the aft crank and hardware to the chain pumps.

This photo shows the brake pump.

Another photo showing both brake pumps

This photo shows the first few forecastle deck beams installed. The bowsprit bitts have been installed and the manger has been started (there's one more plank to add

to the manger). Two hanging knees on the forecastle deck have also been shaped and installed.

This photo shows the forecastle breastworks. The stove has also been installed and stove pipe as well as the topsail sheet bitts and jeer bitts.

Another shot of the breastworks.

This photo shows the temp bowsprit installed. It has a tenon on the end that fits the mortise in the bowsprit bitts. The catheads have been installed as well as the topsail sheet bitts and one of the steam hatches.

The galley stove with copper lids which will be supplied in the kit.

The galley stove installed. Note the hanging knees and the one that is angled due to the gunport.

Another photo of the galley stove installed and the forecastle deck beams.

Expanded view of the model and decks.

Resin cast cannon set.

Another shot of the resin cast cannon set.

Overhead view of the forecastle deck with breastworks painted black. There's still one steam grating/hatch to install.

Better shot of the steam grating/hatch. The grating is in scale and extremely delicate and difficult to put together. I imagine many kit owners will have great difficulty with these parts and may not be able to install them at all.

The planksheer has been added and the timberheads shaped. I decided to paint this black although I'm not sure I like it now that it's painted. Personal choice of the modeler.

Another shot of the breastworks and planksheer with timberheads, painted black.

Overhead shot of the planksheer with timberheads, painted black.

This photo shows the fully framed quarterdeck. The next step is to build and add the deck furniture.

In this photo you can see the bulkheads on the upper deck beneath the quarterdeck.

Close up of the aft bulkhead on the upper deck.

This is the companionway which will be later installed on the quarterdeck.

Ships wheel, assembled from 24 individual CNC milled parts. To imagine its size, it is not much bigger than a quarter.

View of the quarterdeck with hatches, companionway and ship's wheel. The frieze is printed on a piece of paper. The paper is glued to the hull and then painted. This shows the frieze as it is being glued to the hull (it comes in several parts).

Now the frieze has been painted and the moldings beneath it have been added. The freize was given a coat of wipe on poly using a small brush.