047-ITP FOR OXYGEN LINES FABRICATION AND INSTALLATION.pdf

-

Upload

koeksal-patan -

Category

Documents

-

view

105 -

download

22

Transcript of 047-ITP FOR OXYGEN LINES FABRICATION AND INSTALLATION.pdf

-

Pearl GTL Project

LINDE ENGINEERING

Shell Project No: HP-3000-QAT Contractor Project No: 5887

Project Document Number: T- 4.318.609 Project Rev.: O Page 2 of 27

Purchase Order Number:

2MH127

Tag/Item Number(s): N/A

Unit(s): ASU

PCWBS: Z

-

QATAR SHELL GTL PROJECT (PEARL) C2 AIR SEPARATION UNITS CONSTRUCTION

F O 21.02.09 Company Comments Incorporated AB EO AG CCI

E O 18.02.09 Company Comments Incorporated AB EO AG CCI

D O 14.02.09 Company Comments Incorporated AB EO AG CCI

C O 10.02.09 Issued for Company Comments AB EO AG ICC

B 03.02.09 Issued for Review AB EO AG IFR

A 03.02.09 Issued for Internal Review AB EO AG IIR

GAMA Rev.

Project Rev

Date Description Prepared

By Checked

By

Approved By

Status

No. No. ORIGINATOR

LINDEGINEERING AG

Document Title:

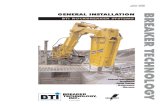

INSPECTION TEST PLAN FOR OXYGEN LINES FABRICATION AND INSTALLATION

Contractor

Gama Qatar Co. W. L. L.

Document No. LOC470

GAM ITP QAC GTL 047 F

Org.

Code

Doc.

Type

Disc. Code

Geogr. Area

Seq.

No

Rev. No

Vendor Code

Project Document Number: T-4.318.609

Rev No: O

-

QSGTL PEARL PROJECT Document No.: GAM-ITP-QAC-GTL-047

C2 ASU Construction Works

ITP FOR OXYGEN LINES FABRICATION & INSTALLATION DATE: 21.02.2009 REV. F

S. GAMA QATAR X. CONTRACTOR QC C. COMPANY A. THIRD PARTY (TPI)

I: INSPECTION / TEST R: DOCUMENT ISSUED/REPORT REVIEW S: SURVEILANCE H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item Activity Test

Frequency Reference Document Acceptance Criteria

Responsible Party

Verifying Documents S X C A

T-4.318.609 Rev. O Page 4

1.0

DOCUMENTATION (FABRICATION AND INSTALLATION)

1.1 Contractor isometric drawings / Spool drawings

100% T.4.234.542;T.4.250.935;

T.4.250.936 RFC QCI RFC I R R

1.2 Approved W.P.S.

100%

T.4.251.025; T.4.250.938 DEP 30.10.60.18;ASME SEC

IX;ASME B31.3;

T.13.377.441;T.13.377.433E;

WI GAM-QCR-QAC-GTL-106 H H R

1.3 Approved PQRs 100% T.4.251.025; T.4.250.938 WI GAM-QCR-QAC-GTL-105 H H R H

1.4

Welder Performance Qualifications

100%

T.4.250.939 WI GAM-QCR-QAC-GTL-100

WSD-QC 2, WSD-QC 3 H H W

1.5 Verify calibration of inspection, measuring and test equipment

100%

T.4.250.915 DEP 30.10.60.18; T.13.377.433E;

T.13.377.441; T.13.377.437E QCI Calibration certificate H R R

2.0 MATERIALS (FABRICATION AND INSTALLATION)

2.1 Receiving inspection / Verification of Material

100%

T.4.250.927;T.4.250.928; T.13.376.797E; T.13.377.438E

T.4.096.688 QCI LINDE MRCR SYSTEM H R S

2.2

Storage & Segregation of Material

100%

T.4.250.927;T.4.250.928; T.4.250.932

T.13.377.454E; T.13.377.438E QCI H S S

2.3 Welding consumable control, verifying the tools & storage procedure

100%

WPSs / PQRs; T.4.250.931

ASME SEC II PART C

DEP 30.10.60.18; T.13.377.433E; T.13.377.437E

T.13.377.441;T.4.096.687

WI Test certificate 3.1 H S S

2.4 Pipe length internal cleanliness 100% T.4.250.930 T.4.096.688;DEP 61.10.08.11 QCI GAM-QCR-QAC-GTL-177 H W W/R

-

QSGTL PEARL PROJECT Document No.: GAM-ITP-QAC-GTL-047

C2 ASU Construction Works

ITP FOR OXYGEN LINES FABRICATION & INSTALLATION DATE: 21.02.2009 REV. F

S. GAMA QATAR X. CONTRACTOR QC C. COMPANY A. THIRD PARTY (TPI)

I: INSPECTION / TEST R: DOCUMENT ISSUED/REPORT REVIEW S: SURVEILANCE H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item Activity Test

Frequency Reference Document Acceptance Criteria

Responsible Party

Verifying Documents S X C A

T-4.318.609 Rev. O Page 5

2.5 Cutting /Transfer of ID and heat No.s

100% Drawings;T.4.250.928

DEP 30.10.60.18; ASME B 31.3 T.13.377.433E; T.13.376.815E

DEP 31.38.01.11; DEP 31.38.01.31; T.13.376.796E;

QCI WSD Isometric Supplement

Sheet H S S

2.6 PMI (If applicable) 100% T.4.250.934;T.4.250.938 WI WSD-QC 4 H W W/R

3.0 WELDING (FABRICATION)

3.1

Welder identification and

performance verification

100% T.4.250.938;T.4.250.939 DEP 30.10.60.18; T.13.377.433E

; T.13.377.441 ASME B 31.3

WI WSD-QC 2 H R R

3.2 Issue of welding consumable to welder

100%

T.4.250.931: T.4.250.938 WI GAM-QCR-QAC-GTL-060 R S S

3.3 Fit-up and tack welding 100% T.4.250.938;T.4.250.936

WPSs / PQRs

DEP 30.10.60.18;ASME B 31.3 T.13.377.433E; DEP

31.38.01.31; T.13.376.796E; T.13.377.441

WI GAM-QCR-QAC-GTL-098

T-13.377.441

H H(*) S

3.4 Root pass visual inspection

100% T.4.250.938;T.4.250.935;

T.4.250.937 DEP 30.10.60.18; ASME B31.3 T.13.377.433E; T.13.377.441

WI H H I

3.5 Root pass magnetic check

100%

T.4.250.938

DEP 30.10.60.18 T.13.377.433E WI GAM-QCR-QAC-GTL-098 H I I

3.6 Inter pass temp controlling /

cleaning

100%

T.4.250.938 DEP 31.38.01.31;ASME B31.3

T.13.376.796E; WI S S S

3.7 Arc strike control and repair 100% T.4.250.938 DEP 30.10.60.18;ASME B 31.3 T.13.377.433E; T.13.377.441

WI GAM-QCR-QAC-GTL-043 H S S

(*) :Linde shall inspect 100%of fit-up until a confidence maintained and COMPANY approval

-

QSGTL PEARL PROJECT Document No.: GAM-ITP-QAC-GTL-047

C2 ASU Construction Works

ITP FOR OXYGEN LINES FABRICATION & INSTALLATION DATE: 21.02.2009 REV. F

S. GAMA QATAR X. CONTRACTOR QC C. COMPANY A. THIRD PARTY (TPI)

I: INSPECTION / TEST R: DOCUMENT ISSUED/REPORT REVIEW S: SURVEILANCE H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item Activity Test

Frequency Reference Document Acceptance Criteria

Responsible Party

Verifying Documents S X C A

T-4.318.609 Rev. O Page 6

3.8 Weld identification and marking

100% T.4.250.938;T.4.250.935 WI GAM-QCR-QAC-GTL-098 I I S

3.9

Welding, purge log , process parameter monitoring

100%

T.4.250.938; T.4.250.901 WPSs / PQRs

DEP 30.10.60.18;ASME B31.3 T.13.377.433E; T.13.377.441

DEP 31.38.01.31; T.13.376.796E; WI GAM-QCR-QAC-GTL-090 I I S

3.10 Visual Inspection of Welds

100% T.4.250.931

DEP 30.10.60.18; ASME B31.3 T.13.377.433E; T.13.377.441

WI GAM-QCR-QAC-GTL-098 H W W

4.0 NON DESTRUCTIVE EXAMINATION ( FABRICATION AND INSTALLATION)

4.1 Radiographic Film Interpretation/

ultrasonic examination

100%

T.4.250.914;T.4.250.938

DEP 31.38.01.31; ASME B31.3 T.13.376.796E;

WI WSD-QC 6 WSD-QC 7

H W/R W/R

4.2

Liquid Penetrant

100%

T.4.250.909;T.4.250.938

WI WSD-QC 9 H W/ R W/R

4.3 1.1 FERRITE CHECK

100%

T.4.250.933; DEP

30.10.60.18; T.13.377.433E ;T.13.377.441

3-8 FN WI WSD-QC 10 H W/R W/R

5.0 REPAIR CONTROL (FABRICATION AND INSTALLATION)

5.1 Repair welding 100% T.4.250.940; T.4.250.901 DEP 30.10.60.18;ASME B31.3 T.13.377.433E;T.13.377.441

WI GAM-QCR-QAC-GTL-097 H W S

-

QSGTL PEARL PROJECT Document No.: GAM-ITP-QAC-GTL-047

C2 ASU Construction Works

ITP FOR OXYGEN LINES FABRICATION & INSTALLATION DATE: 21.02.2009 REV. F

S. GAMA QATAR X. CONTRACTOR QC C. COMPANY A. THIRD PARTY (TPI)

I: INSPECTION / TEST R: DOCUMENT ISSUED/REPORT REVIEW S: SURVEILANCE H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item Activity Test

Frequency Reference Document Acceptance Criteria

Responsible Party

Verifying Documents S X C A

T-4.318.609 Rev. O Page 7

5.2 NDE of repaired weld 100% T.4.250.940;T.4.250.938 DEP 31.38.01.31;ASME B 31.3

T.13.376.796E;

WI SAME AS ACTIVITY 5.0 H

W/R

W/R

5.3 NDE (TRACERS) 100% T.4.250.940;T.4.250.938 ASME B 31.3 WI WSD-QC 11 H R R

6.0 FINAL INSPECTION(FABRICATION)

6.1 Marking of spool, identification and Material traceability

100%

T.4.250.928;T.4.250.935 T.13.377.437E;T.13.376.797E QCI WSD-QC 12 H H S

6.2 Reinforcement pad leak test 100% T.4.250.908 DEP 31.38.01.11;ASME B 31.3

T.13.376.815E; QCI GAM-QCR-QAC-GTL-109 H H W/R

6.3 Orifice flange internal verification 100% T.4.250.935 DEP 31.38.01.11; T.13.376.815E; T.13.375.791E;DEP 61.38.10.10

QCI GAM-QCR-QAC-GTL-095 H H W/R

6.4 Closure of all openings and protection of flanges in each spool

100%

T.4.250.935 DEP 31.38.01.11; T.13.376.815E;ASME B 31.3

QCI GAM-QCR-QAC-GTL-086 H H S

6.5 Piping spools release for painting and updating spool tracking system

100% T.4.250.938; T.4.250.935;

WSD; SPOOL DRAWINGS DEP 31.38.01.11; T.13.376.815E; DEP 31.38.01.31; T.13.376.796E

QCI/WI GAM-QCR-QAC-GTL-086 H H S

6.6 Flawless Start-up Initiative (FSI) - Cleanliness

Internal Cleaning

T.13.377.360 Rev E & T.4.096.688

No external materials inside the pipe & Internal Cleaning shall be done

Site Eng Visual H I I

7.0 WELDING (INSTALLATION)

7.1 Pipe internal cleanliness 100% T.4.250.930 T.4.096.688;DEP 61.10.08.11 QCI GAM-QCR-QAC-GTL-070 H H H

7.2 Welder identification and

performance verification 100% T.4.250.938;T.4.250.939

DEP 30.10.60.18; T.13.377.433E ; T.13.377.441 ASME B 31.3

WI WSD-QC 2 H R R

-

QSGTL PEARL PROJECT Document No.: GAM-ITP-QAC-GTL-047

C2 ASU Construction Works

ITP FOR OXYGEN LINES FABRICATION & INSTALLATION DATE: 21.02.2009 REV. F

S. GAMA QATAR X. CONTRACTOR QC C. COMPANY A. THIRD PARTY (TPI)

I: INSPECTION / TEST R: DOCUMENT ISSUED/REPORT REVIEW S: SURVEILANCE H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item Activity Test

Frequency Reference Document Acceptance Criteria

Responsible Party

Verifying Documents S X C A

T-4.318.609 Rev. O Page 8

7.3 Issue of welding consumable to welder

100%

T.4.250.931: T.4.250.938 WI GAM-QCR-QAC-GTL-060 S S S

7.4 Fit-up and tack welding 100% T.4.250.938;T.4.250.936

WPSs / PQRs

DEP 30.10.60.18;ASME B 31.3 T.13.377.433E; DEP

31.38.01.31; T.13.376.796E; WI

GAM-QCR-QAC-GTL-098

H H S

7.5 Root pass visual inspection

100% T.4.250.938;T.4.250.935;

T.4.250.937 DEP 30.10.60.18; ASME B31.3 T.13.377.433E; T.13.377.441

WI H H I

7.6 Root pass magnetic check

100% T.4.250.938 DEP 30.10.60.18 T.13.377.433E WI GAM-QCR-QAC-GTL-098 H I I

7.7 Inter pass temp controlling /

cleaning

100%

T.4.250.938 DEP 31.38.01.31;ASME B31.3

T.13.376.796E; WI S S S

7.8 Arc strike control and repair 100% T.4.250.938 DEP 30.10.60.18;ASME B 31.3 T.13.377.433E; T.13.377.441

WI GAM-QCR-QAC-GTL-043 H S S

7.9 Weld identification and marking

100% T.4.250.938;T.4.250.935 WI GAM-QCR-QAC-GTL-098 I I S

7.10 Welding, purge log , process parameter monitoring

100%

T.4.250.938; T.4.250.901 WPSs / PQRs

DEP 30.10.60.18;ASME B31.3 T.13.377.433E; T.13.377.441

DEP 31.38.01.31; T.13.376.796E; WI GAM-QCR-QAC-GTL-090 I I S

7.11 Visual Inspection of Welds 100% T.4.250.931 DEP 30.10.60.18; ASME B31.3 T.13.377.433E; T.13.377.441

WI GAM-QCR-QAC-GTL-098 H W W

8.0 MECHANICAL ERECTION INSPECTION (INSTALLATION)

8.1 Flanges Alignment 100% T.4.250.936

T.13.376.815E; ASME B 31.3;DEP 31.38.01.31;

T.13.376.796E;DEP 61.10.08.11

QCI GAM-QCR-QAC-GTL-142 H W I

8.2 Torquing of bolts 100% T.4.250.936 DEP 31.38.01.11;

T.13.376.815E QCI GAM-QCR-QAC-GTL-041 H W W

-

QSGTL PEARL PROJECT Document No.: GAM-ITP-QAC-GTL-047

C2 ASU Construction Works

ITP FOR OXYGEN LINES FABRICATION & INSTALLATION DATE: 21.02.2009 REV. F

S. GAMA QATAR X. CONTRACTOR QC C. COMPANY A. THIRD PARTY (TPI)

I: INSPECTION / TEST R: DOCUMENT ISSUED/REPORT REVIEW S: SURVEILANCE H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item Activity Test

Frequency Reference Document Acceptance Criteria

Responsible Party

Verifying Documents S X C A

T-4.318.609 Rev. O Page 9

8.3 Hydraulic Tensioning of bolting in special flanges/components

100% T.4.250.936 DEP 31.38.01.11;

T.13.376.815E QCI GAM-QCR-QAC-GTL-041 H W W

8.4 As-built Check per Isometric

100% T.4.250.936

DEP 31.38.01.11;ASME B 31.3 T.13.376.815E;DEP

31.38.01.29:T.13.376.807E QCI

0100-W-DW-1102 As-Built Isometric

As-Built BOM WSD ISO Supplement

Sheet

H H S

8.5 Test pack preparation and

submission 100%

T.4.250.908;Test Pack

DEP 31.40.40.38;DEP 61.10.08.11

QCI Test Package H H H

8.6 Mechanical Check of Test System

100% T.4.250.908;Test Pack DEP 31.40.40.38;DEP

61.10.08.11 QCI

MC Inspection And Test Record

R1: Mechanical Check Of Test System

H H H

8.7 Pressure test 100%

T.4.250.908

DEP 31.38.01.11; T.13.376.815E; ASME B 31.3;DEP 31.38.01.31;

T.13.376.796E

QCI

MC Inspection And Test Record

R2: Piping: Testing/ Flashing/Drying

H H H

8.8 Reinstatement Punch out

100%

T.4.250.908

DEP 61.10.08.11 QCI

MC Inspection And Test Record

R3: Reinstatement Punch List

H H W

8.9 Flawless Start-up Initiative (FSI) - Tightness

T.13.377.360 Rev E,

DEP 31.38.01.11- Gen Full Tight without leak Site Eng

Joint Integrity Control Procedure T.13.377.453 ,

T.13.376.815 H H W

8.10 Handover of Documentation Per Test System

100%

T.4.250.908: T.4.251.035 QCI QC DOSSIER H I/R I / R

-

GAM-QCR-QAC-GTL-041 Rev. O

C2 ASU PEARL GTL PROJECT

RASLAFFAN INDUSTRIAL CITY

BOLT TIGHTENING INSPECTION REPORT

Subcontract Ref.: Report No.:

Item Description: Inspection Date:

Item Location / Area:

Test Code No.:

Subsystem: ITP No.:

Ref. DWG / Docs:

Used Measuring and test equipment ref. (if applicable):

INSPECTIONS

Item No/Spool No

Mark No./Joint No Bolting Bolt Tightening (Torque Value)

Inspectors Signature Grade Size

ORGANIZATIONS DATE NAME SIGNATURE

Accepte

d B

y THIRD PARTY REP.

GAMA REP.

LINDE REP.

QSGTL OR its PMC REP.

-

GAM-QCR-QAC-GTL-043 Rev. O

Test Report Liquid Penetrant Examination (PT)

C2 ASU Pearl GTL PROJECT -Qatar Date :

Report No :

Testing Contractor Testing Consumables Doc No:

Testing Code, Standard Ilumination [lx] System Trade Name Batch

Data Penetrant

General Evaluation Standard Surface Temperature [C] Cleaner

Developer

Object Data Testing Data Testing Results (a = accepted / na = not accepted)

Test Defect

No. Line No. Area NPS Welder 1 Piping Testing Penetr. Develop. Test no no Type. Length Location Pos. Comments a/na

1) Sheet No. Weld No.

Thick-ness

Welder 2 Contractor before/

after PWHT Time [min]

Time [min]

Date Defects Defects after

grinding 2) [mm] 3) 4)

Abbreviations GAMA REP Third Party

1)

R1 Repair N new after Rep. G non pressure tested weld

2) Type. Of Defect G = globular L = in Line

3)

Location of Defect B = Base Material T = Transition Area W = Weld Metal

4) Position of Defect Distance to Reference Point in [mm]

Date Name Signature

Date Name Signature

LINDE REP _______________________________________ Date Name Signature

QSGTL OR its PMC REP _______________________________________ Date Name Signature

-

C2 ASU PEARL GTL PROJECT RAS LAFFAN INDUSTRIAL CITY

WELDING ELECTRODE ISSUE REGISTER

Subcontract Ref.: Report No.

Item Description: Inspection Date:

Item Location / Area: Test Code No.:

Subsystem: ITP No.:

Ref. DWG / Documents:

Used Measuring and test equipment ref. (if applicable):

DATE WELDING

ELECTRODES AWS CLASS

SIZE IN MM

ISSUE QUANTITY

WELDER NO WELDER NAME BATCH NO AREA

RETURN ELECTRODE

(WHITE PAINT)

SIGNATURE OF WELDER

SIGNATURE OF CONSUMABLE STORE MAN

ORGANIZATIONS DATE NAME SIGNATURE

Accepte

d B

y THIRD PARTY REP.

GAMA REP.

LINDE REP.

QSGTL REP.

GAM-QCR-QAC-GTL-060 Rev. O

QQQ AAA TTT AAA RRR

-

Project No: REPORT NO: DATE:

Piping

Contractor: Page 1 of 1

Date Signature GAMA Signature Linde Signature PMC Date Signature GAMA Signature Linde Signature PMC

Cle

an

line

ss C

lass

Erection

System CleanlinessAcceptance Report

Sh

ee

t

Prefabrication

Isometric No:

(Line No)

1110 A05M

GAMA

Insp

ectio

n

resu

lt

Insp

ectio

n

me

tho

d

Sp

oo

l

Cle

an

ing

Me

tho

d

QQQ AAA TTT AAA RRR

GAM-QCR-QAC-GTL-070

Rev. 01

Status: 30.11.2006

-

REPORT NO :

DATE :PROJECT: C2 ASU PEARL GTL PROJECT-RAS LAFFAN INDUSTRIAL CITY

SL SHEET DWG SPOOL DIMENSION TRACEABILITY WELD RF PAD FLANGE PIPE ENDS

NO NO NO NO CHECK CHECK SUMMARY TESTING PROTECTED CLOSED

Name Name Name

Sign Sign Sign

Date Date Date

GAM-QCR-QAC-GTL-086 Rev. O

GAMA REP LINDE REP QSGTL or its PMC

REMARKSMARKING

NOTE: VERIFY SPOOL INTERNAL CLEANLINESS AND ALL OPEN PIPE END & FLANGE SHALL BE COVERED. INSPECTIONS OF ABOVE MENTIONED

SPOOLS ARE FOUND SATISFACTORY AND ITEMS ARE RELEASED FOR PAINTING.

PIPING SPOOL INSPECTION REPORT

AREA ISO. NO MATRLREV

QQQ AAA TTT AAA RRR

-

C2 ASU PEARL GTL PROJECT RAS LAFFAN INDUSTRIAL CITY

PURGE DAM TRACKING RECORD

ITP NO: REPORT NO:

TEST CODE: DATE:

ISO NO WELD

NO

GAS FLOW RATE

OXYGEN LEVEL

PURGE DAM INSTALLATION PURGE DAM REMOVAL

DATE GAMA LINDE DATE GAMA LINDE

NOTES:

GAM-QCR-QAC-GTL-090 Rev. O

ORGANIZATIONS DATE NAME SIGNATURE

GAMA QATAR REP

LINDE REP

QSGTL REP

-

___________________________________________________________________________________________GAM-QCR-QAC-GTL-095 Rev. A

C2 ASU PEARL GTL PROJECT

RAS LAFFAN INDUSTRIAL CITY

ORIFICE METER RUN INSTALLATION PROCESS

SHEET

Report no:

Date:

Sheet:

ORIFICE TAG NUMBER: ___________________ AREA : ________________________

ISO. NO/SHEET.: __________________ ____ SPOOL NO. .________________________

DESCRIPTION VALUE

ACCEPTED

NOT

ACCEPTED

REMARKS

1. UPSTREAM PIPE INSIDE DIAMETER MEASURED &

ACCEPTABLE

i) Horizontal Reading

ii) Vertical Reading

iii) Mean Upstream Diameter

iv) Specified Upstream Diameter

vi) Actual Variation

vii) Specified Maximum Variation

DOWNSTREAM PIPE INSIDE DIAMETER

MEASURED & ACCEPTABLE

i) Horizontal Reading

ii) Vertical Reading

iii) Mean Upstream Diameter

iv) Specified Upstream Diameter

vi) Actual Variation

vii) Specified Maximum Variation

4. Orifice flange Inspections

i.) Cleanliness of inner surface(free of rust, weld spatter, burr, debris) in the area of the inlet and outlet section.

N/A

ii) Grinding of flange weld root, flush to the base material and free of undercuts

N/A

*The installation of the above orifice meter run has been satisfactorily completed in accordance with the

drawings & specifications.

ORGANIZATIONS DATE NAME SIGNATURE

Gama Qatar Rep

Linde Rep

QSGTL or its REP

QQQ AAA TTT AAA RRR

-

C2 ASU PEARL GTL PROJECT RAS LAFFAN INDUSTRIAL CITY

WELD REPAIR AUTHORIZATION

REPORT NO: DATE:

GAM-QCR-QAC-GTL-097 Rev. O

AREA LINE NO DRG NO SHEET NO REV

TYPE AND AREA OF REPAIR (SIZE, DEPTH, ROOT, FILL)

NDE REPORT NO.

Inspection Class: Material: Weld No. SIZE: THK. WPS used WELDED BY:

PROPOSED

DEFECT REMOVAL METHOD: REPAIR METHOD:

WPS: WELDER: BACKING GAS:

CONSUMABLES ISSUED FOR REPAIR:

NDE REQUIRED: TYPE OF NDE:

PREPARED BY _______________ ______________ __________ Name Signature Date APPROVED BY ______________ _____________ __________

Name Signature Date

INSPECTION OF REPAIR PREPARATION

SIGNATURE

WELD IDENTIFIED AND DEFECTS REMOVED

CONFINED SPACE ENTRY PERMIT

INTERNAL CLEANING SATISFACTORY

FIT UP RELEASED FOR WELDING

NDE COMPLETED

VT PT MT RT UT PAMI

GAMA LINDE SHELL

THE ABOVE MENTIONED WELD HAS BEEN SATISFACTORILY REPAIRED AND ACCEPTED

ORGANIZATIONS NAME DATE SIGNATURE

GAMA QATAR REP

LINDE REP

QSGTL REP

-

PROJECT : C2 ASU PEARL GTL PROJECT-- RAS LAFFAN INDUSTRIAL CITY

Date : Page :

SHOP FIELDWeld Piping Welder Welder PWHT

Area Iso No. Sheet Rev. Sp'l No. Class 1 2 Req'd Req'd % Fit-up/Root Final

DAILY WELDING REPORT

Report No. :

ISOMETRIC NUMBERMat'l Item No. Heat No. Dia Sch WPS No.

NDE Inspection ResultRemarks

ORGANIZATIONS DATE NAME SIGNATURE

QSGTL or its PMC

Gama Qatar Rep

Linde Rep

QQQ AAA TTT AAA RRR

GAM-QCR-QAC-GTL-098 Rev. O

-

QUALIFIED WELDER LIST

PROJECT : C2 ASU PEARL GTL PROJECT-RAS LAFFAN INDUSTRIAL CITY

No. WQT No.

Name WPS No.

Welding Process

Position Material Size Dia. Test Date

Result

VT RT Bend

Prepared by QA/QC : Reviewed by QA/QC Manager

Distribute to LINDE :

GAM-QCR-QAC-GTL-100 Rev. O

-

Page 1 of 3

Gas(es) % Comp.

Shielding

Trailing

Backing

Client :

Project Name: Subcontract No:

Oscillation: Temp. Monitoring Method:

POSITION (QW -405)

TECHNIQUE (QW-410)

PROCEDURE QUALIFICATION RECORDReference: ASME B31.3, ASME Sec IX,

Contractor: Sub Contractor:

Multipass or Single Pass (Per Side):Interpass Temp.(In Degree Centigrade):

Travel Speed: See Page 2 of 3

String or Weave Bead:

ELECTRICAL CHARACTERISTICS (QW-409)

Current & Polarity:

Amps / Volts: See Page 2 of 3

Heating Rate:

Welding Process:

Types (Manual, Automatic, Semi-Auto):

Rev: Date:

WPS No.: Rev: Date:

PQR No:

JOINTS DESIGN:(QW-402)

Heating Method:

BASE METAL(QW-403) POSTWELD HEAT TREATMENT(QW-407)

Material Spec.:

PQR Test Coupon:

Position of Groove:

Position of Fillet:

Weld Progression (Uphill, Downhill): Tungsten Electrode Class & Size:

PREHEAT (QW - 406)

Minimum Recorded:

GAS: PERCENTAGE COMPOSITION (QW-408)

Method of Heating:

Material Certificate No: Pipe -

Soaking Temp:

Soaking Time:

Cooling Rate:

Thickness of Test Coupon:

Preheat Temp. (Min):

Dia of Test Coupon:

Heat No: Pipe -

Maximum Recorded :

Single or Multiple Electrodes:

FILLER METALS (QW-404)- See Table - Page 2 of 3

Flow Rate

Type or Grade:

P.No. / Group No.:

4

5

1

354

2

3 1mm

37.5 2.5

1.6 0.8 mm

6 87

GAM-QCR-QAC-GTL-105 Rev. O

-

Page 2 of 3

Client :

Project Name: Subcontract No:

PROCEDURE QUALIFICATION RECORDReference: ASME B31.3, ASME Sec IX,

Contractor: Sub Contractor:

Rev: Date: PQR No:

F.No.

A.No.

AWS

CLASS DIA

TYPE AND

POLARITY Amps VOLTS

S.No.

1

2

3

4

Specimen

No.

Tensile

Strength

(N/mm2)

Heat Input

KJ / mm

TRAVEL

SPEED

mm / min

5. TENSILE TEST -(QW-150) Report No.:

Size, (mm)

Report No. Date

CURRENT

Tensile Load (N)

SUMMARY OF WELDING PARAMETERS RECORDED

Visual Inspection

Magnetic Particle Inspection

Result

Area, (mm2)

Radiographic Inspection

Ultrasonic Inspection

WELD

PASS NO.

Type of Inspection

Fracture Location

FILLER METALS

Dia (mm) ManufactureTrade

Name Lot No.

Weld

Pass No.AWS Class Certificate No.

FILLER METAL

SFA

PROCESS

GAM-QCR-QAC-GTL-105 Rev. O

-

Page 3 of 3

Client :

Project Name: Subcontract No:

PROCEDURE QUALIFICATION RECORDReference: ASME B31.3, ASME Sec IX,

Contractor: Sub Contractor:

Rev: Date: PQR No:

Specimen

No.

Test

Temp.OC

A B C

S.No. Date

1

2

3

Laboratory ResultReport No.Type of Inspection

Hardness Test

Average

(Joules)

8. OTHER TESTS:

Specimen

No.

Notch

Location

Result

Impact Values (Joules)

QSGTL or its PMC GAMA

Name, Signature & Date

LINDE

Name, Signature & Date

Specimen

Size,(mm)

OTHER DETAILS:

Remarks

Micro Examination

Number of Welders:

Angel of Bend

(Degrees)Mandrel Diameter

6. GUIDED - BEND TESTS (QW-160) - Report No.:

TYPE

7. TOUGHNESS TESTS (QW-170) - REPORT No.:

Weld Finishing:

Welder's Name(s):

Tack Welding Method:

Tack Welding Parameters:

Test Witnessed By:

Name, Signature & Date

Welder ID:

Test Coupon Welded on:

Test Conducted By:

We certify that the Statements in this record are correct and that test welds were prepared, welded and tested in

accordance with the requirments of ASME Section IX

Macro Examination

GAM-QCR-QAC-GTL-105 Rev. O

-

Client : Contractor :

WPS No: Rev: Date:

PQR No: Rev: Date:

Type(s):

P -No. To P-No

To

To

Fillet:

Fillet:

Others:

F No:

A- No

Groove:

Fillet:

Prepared By

Group No.

OR

Group No.

Chem.Analysis and Mech. Prop:

Specification Type and Grade:

PAGE 1 of 2

OR

Deposited weld metal Thk.

Size Of Filler Metals :

Spec No. (SFA):

Company Name :

Backing (Yes/ No):

Project Name:

Time Range:

FILLER METALS(QW - 404)

Specification Type and Grade:

Other:

Joint Design :

JOINTS ( QW - 402)

Welding Process :

Backing Material (Type ):

Rate of Cooling:

Consumables Insert:

POST WELD HEAT TREATMENT(QW - 407)POSITION(S)(QW - 405)

Rate of heating:Position(s) of fillet:

Welding Progression:

Positions Of Groove:

Other:

Trade Name:

Temperature Range :

Chem.Analysis and Mech. Prop:

Thickness Range : Groove :

Base Metals ( QW - 403) Also as per QW 420.2

Electrode-Flux (Type):

AWS No. (Class):

WELDING PROCEDURE SPECFICATIONS (WPS)

Diameter Range : Groove :

Reference : ASME B31.3 , ASME Sec IX, AWS D 1.1

LINDE REP QSGTL or its PMC

GAMA REP

Checked By

5

4

2

3 1mm

37.5 2.5

1.6 0.8mm

6

1

3

GAM-QCR-QAC-GTL-106 Rev. O

-

WPS No: Rev . No: Date:

Pre Heat Min:

Interpass temp :

Current AC or DC Polarity

Amps Range Voltage range

Initial and Interpass Cleaning :

Piping Class:

Service :

PQR Impact test temperature :

prepared By

PAGE 2 of 2

Mode of Metal Transfer GMAW

OTHERS:

Weld Pass

Electrode Wire Feed Speed Range

Method of Back gouging:

Contact Tube To Work Distance

TECHNIQUE(QW - 410)

String or Weave Bead :

Orifice or Gas Cup Size :

Travel Speed

mm/minVolts Range

Amps

RangeDia mm

CurrentFiller Metal

Class

ProcessHeat Input

KJ/mm (Max.)

Method of Heating:

ELECTRICALCHARACTERISTICS(QW - 409)

Backing Gas(es):

Temp Monitoring Method:

Polarity

Multiple Or Single Pass (per side)

Multiple or Single Electrodes

PRE- HEAT (QW - 406)

WELDING PROCEDURE SPECIFICATIONS (WPS) Reference : ASME B31.3 , ASME Sec IX, AWS D 1.1

GAS (QW - 408)

Trailing shielding gas

composition:

Percent Composition(Mixture):

Shielding Gas(es):

Shielding gas flow Rate:

Notes :-

Oscillation

Travel Speed(Range)

Tungsten Electrode Size and Type

LINDE REP QSGTL or its PMC

GAMA REP

Checked by

Weld SequenceTest coupon: 6" SCH XXS

GAM-QCR-QAC-GTL-106

-

REINFORCEMENT PAD TEST

REPORT

PROJECT : C2 ASU PEARL GTL PROJECT-RAS LAFFAN INDUSTRIAL CITY

Description Acceptance Signature

Test No ISO No Spool No

Pad Ref

Date of Test

Gama Linde QSGTL (OR) PMC

REMARKS

ORGANIZATIONS DATE NAME SIGNATURE

GAMA REP

LINDE REP

QSGTL or its PMC

GAM-QCR-QAC-GTL-109 Rev. O

-

Flange Alignment

Flanschausrichtung

Proj. Nr. / Proj No 1110 A05M Kommission / Code Pearl Qatar Acceptance Sheet / Abnahmeprotokoll

Dok-Nr. / Doc No:

0100-W-QA 1503

TEST PACKAGE NO 1-21P31-003A Seite / Page 1 von / of 1

For alignment check flanges shall be disconnected Ausrichtungs-Prfung bei gelsten Flanschen

I II III IV

I

Bolt hole Offset

II

Face Distance

III

Face Parallelism

IV

Centerline Offset

Requ. Dimensions with Tolerance

mm

mm

mm

n/a

mm

n/a

Actual Dimensions mm

mm

mm

* mm

*

Accepted yes

no

yes

no

yes

no

yes

no

(*) Max. deviation in 'oclock position' (1 12), from the view towards the equipment

Max. Abweichung in 'Uhrzeiger-Position' (1 12), Blickrichtung zum Equipment

Remarks: Bemerkungen

ORGANIZATIONS NAME SIGNATURE DATE

AC

CE

PT

ED

BY

GAMA.

LINDE.

QSGTL OR its PMC REP.

GAM-QCR-QAC-GTL-142 Rev. O

Report No Bericht Nr.

Area Baufeld

Equipment No Equipment Nr.

Line No Leitungs Nr.

Nozzle No Stutzen Nr.

-

Project No:REPORT

NO:DATE:

Piping

Contractor:

Date

Name

Sign

Spool

GAMA

Name

Sign

Date

LINDE QSGTL or its PMC

Name

Sign

Date

Isometric No

1110 A05M

GAMA

Inspection

result

Cleaning

Method

Page 1 of 1

Cleanliness ClassSheet

Pipe Length Internal Cleanliness Report

for Oxygen Lines

QQQ AAA TTT AAA RRR

GAM-QCR-QAC-GTL-177 Rev. O