00100_EA-10-01

-

Upload

jfisher2534 -

Category

Documents

-

view

222 -

download

0

Transcript of 00100_EA-10-01

-

8/2/2019 00100_EA-10-01

1/9

P AG E 1 O F 9E D I T I O N 1 ZZ A U G U S T 1 9 9 6

EAL-G20 Z C AL IB R A T IO N O F S T YL U S IN S T R U M E N T S F O R M E A S U R IN G R O U G H N E S SEALEuropean cooperation for

Accreditation of Laboratories

EAL-G20Publication Reference

P U R P O S E

Calibra t ion of Stylus

Inst ruments for Measur ingSurface Roughness

This document has been produced by EAL to improve the harmonisation in surface roughness

measurement. It provides guidance to national accreditation bodies to set up minimum requirements

for the calibration of stylus instruments and gives advice to calibration laboratories to establish practical

procedures.

-

8/2/2019 00100_EA-10-01

2/9

EAL-G20 Z C AL IB R A T IO N O F S T YL U S IN S T R U M E N T S F O R M E A S U R IN G R O U G H N E S S

E D I T I O N 1 ZZ A U G U S T 1 9 9 6P AG E 2 O F 9

Authorship

This publication has been written by EAL Committee 2 (Calibration and Testing activities).

Official language

The text may be translated into other languages as required. The English language version remainsthe definitive version.

Copyright

The copyright of this text is held by EAL. The text may not be copied for resale.

Guidance Publications

This document represents a consensus of EAL member opinion and preferred practice on how therelevant clauses of the accreditation standards might be applied in the context of the subject matterof this document. The approaches taken are not mandatory and are for the guidance of accreditationbodies and their client laboratories. Nevertheless, the document has been produced as a means of

promoting a consistent approach to laboratory accreditation amongst EAL member bodies,particularly those participating in the EAL Multilateral Agreement.

Further information

For further information about this publication, contact your National member of EAL:

Calib National member Testing National member

Austria BMwA BMwA

Belgium BKO/OBE BELTEST

Denmark DANAK DANAK

Finland FINAS FINAS

France COFRAC COFRAC

Germany DKD DAR

Greece Ministry of Commerce ELOT

Iceland ISAC ISAC

Ireland NAB NAB

Italy SIT SINAL

Netherlands RvA RvA

Norway NA NA

Portugal IPQ IPQ

Spain ENAC ENAC

Sweden SWEDAC SWEDAC

Switzerland SAS SAS

United Kingdom UKAS UKAS

-

8/2/2019 00100_EA-10-01

3/9

P AG E 3 O F 9E D I T I O N 1 ZZ A U G U S T 1 9 9 6

EAL-G20 Z C AL IB R A T IO N O F S T YL U S IN S T R U M E N T S F O R M E A S U R IN G R O U G H N E S S

1 Introduct ion 4

2 Scope and field of applica t ion 4

3 Terminology 4

4 Reference standards 5

5 Example of a ca libra t ion procedure 5

6 Uncer ta in ty of measurement 7

7 Calibra t ion cer t ifica te 8

8 References 9

Section Page

Contents

-

8/2/2019 00100_EA-10-01

4/9

EAL-G20 Z C AL IB R A T IO N O F S T YL U S IN S T R U M E N T S F O R M E A S U R IN G R O U G H N E S S

E D I T I O N 1 ZZ A U G U S T 1 9 9 6P AG E 4 O F 9

1 In t r od u c t ion

1.1 The purpose of this technical guideline is to improve the harm onisation within

EAL for surface roughness measurement. It provides guidance to nationalaccredita tion bodies to set u p minim um requirem ents for t he calibra tion of stylus

instruments and gives advice to calibration laboratories to establish practical

procedures. The guideline is based on a national calibration guideline [ref. 1].

In the first part (sections 2, 3 and 4), the general definitions, the reference

sta nda rds t o be used a nd t he t echn ical requirem ents for t he calibrat ion of stylus

measurement instruments are given. The second part of this guideline is of

procedural na ture and g ives pract ica l advice to ca l ibra t ion and tes t ing

laboratories. In section 5 an example of a typical calibration procedure is

present ed. It m ay be am ended or modified to meet t he specific requirem ents of

accreditation.

2 Scop e a n d fie ld o f a p p lica t ion

2.1 T h is gu i de li n e a p p li es t o t h e ca l ib r a t i on of s t yl u s i n st r u m e n t s for t h e

mea sur emen t of sur face roughness by th e profile met hod as defined in ISO 3274

[ref. 2]. The calibrat ion sha ll be car ried out with th e aid of reference sta nda rds.

The guideline is intended only for inst ru ment s with pick-ups with independent

datum.

2.2 Com p on e n t s : The stylus inst rum ent comprises th e basic equipment (indicat or,

evaluat ion a nd cont rol units), a t ra verse unit , a probe (pick-up) with t he st ylus

an d a pr ofile recorder. Only complet e combin at ions of inst ru men ts a re qua lified

for calibration. If the basic equipment is used with several traverse units and

pick-ups, each of th ese instr um ent combina tions sha ll be calibrat ed separ at ely.

2.3 S it e o f ca lib r a t ion : The stylus instrum ent shall be calibrat ed at the place of

use, so that all the ambient conditions which will influence the instrument in

service, are ta ken into considera tion.

No te : Genera l r equ i r emen ts fo r the acc red i t a t ion o f l abo ra to r ie s and

o r g a n i s a t i o n s p e r f o r m i n g s i t e c a l i b r a t i o n s a r e g i v e n i n P u b l i c a t i o n

EAL-R3 [ref. 3].

3 Te r m in o logy

3.1 The surface roughness parameters are defined in ISO/DIS 4287-1.2 [ref. 4]:

P t tota l height of pr ofile over evalu at ion lengt h

R a ar ith met ical mea n deviat ion of roughn ess profile over five samplin g lengt hs

R z aver age height of rough ness pr ofile over five sam pling length s

R z1max ma ximum h eight of roughness profile over one sam pling length

-

8/2/2019 00100_EA-10-01

5/9

P AG E 5 O F 9E D I T I O N 1 ZZ A U G U S T 1 9 9 6

EAL-G20 Z C AL IB R A T IO N O F S T YL U S IN S T R U M E N T S F O R M E A S U R IN G R O U G H N E S S

The measuring conditions are described in ISO/DIS 4287-1.2 [ref. 4] and ISO

4288 [ref. 5] usin g a pr ofile filter accordin g t o ISO 11562 [ref. 6].

4 R e fe r e n ce s t a n d a r d s

4.1 The s tylus ins t rument shall be ca l ibra ted by means of reference standards .

Among other sta nda rds of similar type, the following proved to be appr opriat e:

(a) Optical flat. Reproduces th e residual profile; th e effects of externa l datu m

stra ightness , environmenta l condi t ions and ins t rument noise can be

established.

(b) Depth m easu rem ent st an dar d, type A1 or A2 according to ISO 5436 [ref. 7]

(Fig.1): Reproduces the profile depth Pt ; ensures the traceability of the

vert ical pr ofile component to th e un it of lengt h.

(c) Roughness measur ement st anda rds, preferably type D according to ISO 5436

[ref. 7] (Fig. 2): Reproduce the arithmetic mean deviation R a a n d t h e

ma ximu m height of profile R z and R z1max establishing an overall check of

the ins trument.

4 .2 Dependent on the type and the metrological character is t ics of the ins t rument

to be calibra ted, th e following sta nda rds m ay be used a s well:

(a) inclination s tandard

(b) s ph er e

(c) wavelength m easuremen t st anda rd t ype C according to ISO 5436 [ref. 7].

4 .3 The depth and roughness measurement standards should be ca l ibra ted by a

na tional met rology inst itut e or an accredited la bora tory capable of delivering

th e measu rem ent un certa inty required for t he specific applicat ion in quest ion.

The calibra tion inter val should not exceed 5 years.

5 E xa m p le o f a ca lib r a t ion p r oc e d u r e

5.1 The following procedure is taken from a nat ional calibrat ion guideline [ref. 1].

It refers to specific reference sta nda rds. Both th e guideline a nd th e reference

standards have proven to be very useful and to lead to excellent agreement

am ong accredit ed labora tories [ref. 8, 9]. Other sta nda rds of similar or differen t

type are available from several manufacturers.

5.2 P rep a r a ti on f or ca l ibr a t i on

5.2 .1 Before ca libra t ion , check t hat the s ty lus ins t rument opera tes cor rect ly as

described in th e ma nu factur er's opera ting inst ru ctions. Additional inform at ion

can be t ak en from [ref. 8] if necessar y.

-

8/2/2019 00100_EA-10-01

6/9

EAL-G20 Z C AL IB R A T IO N O F S T YL U S IN S T R U M E N T S F O R M E A S U R IN G R O U G H N E S S

E D I T I O N 1 ZZ A U G U S T 1 9 9 6P AG E 6 O F 9

5.2.2 Before calibrat ion th e following prepara tions ha ve to be made:

(a) Es t abl ish the effects of ex terna l da tum s t r a ightn ess , environm enta l

conditions and instrument noise by measuring Ra

and Rz

of an optical flat .

The measuring conditions are in accordance with those applied for the

corresponding roughness standards (usually five sampling lengths over a

total evaluation length of ln = 4 mm and a cut-off wavelength of lc = 0,8

mm for t he filter ). The measu red R a and Rz values must be indicated in the

calibration certificate.

(b) Align the plane of the depth m easuremen t sta ndar d to the dat um a xis in

the best possible way, al ign the plane of the roughness measurement

stan dard to within 10 % of the mea suring range.

(c) Always select t he sma llest possible mea sur ing ran ge.

(d) Take measur ements in th e middle of the m easuring ran ge each time.

5.3 Ca l ib ra t ion by m ea n s of a d ep t h m ea su r em en t s ta n d a r d

5.3.1 Measu re each groove in five profile sections (Fig. 5.1). Probe th e grooves

individua lly in succession an d deter mine t he Pt value of the unfiltered profile

(without automatic al ignment) . Indicate the deviation of the mean value

(obtained from t he 5 m easur ed Pt values) from th e value given in t he calibrat ion

cert ificat e of th e depth measu rem ent st an dar d, in percent a nd in micrometers.

5.4 Ca l ib ra t i on b y m ea n s of rou g h n e ss m ea s u r em en t

s t a n d a r d s .

5 .4 .1 C a r r y ou t 1 2 m e a su r e m e n t s on e a ch r ou g h n e ss m e a s u r em e n t s t a n d a r d ,

distributed over the measur ement surface as shown in the measur ement locat ion

pattern (Fig.5.2) . Measuring condit ions: 5 sampling lengths over a total

evaluat ion length ofln = 4 an d a cut -off wavelengt h oflc = 0,8 mm for t he filter .

Calculat e the ar ithm etical mean a nd th e standa rd deviat ion for each roughness

parameter. The deviations (in percent and in micrometers) of the mean from

the value sta ted in th e calibrat ion certificat e of the standa rd a nd th e stan dard

deviat ions a re t o be indicated in t he certificat e.

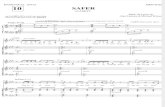

Figure 5.1. Depth setting standard (type A2) with enlarged area of measurement

-

8/2/2019 00100_EA-10-01

7/9

P AG E 7 O F 9E D I T I O N 1 ZZ A U G U S T 1 9 9 6

EAL-G20 Z C AL IB R A T IO N O F S T YL U S IN S T R U M E N T S F O R M E A S U R IN G R O U G H N E S S

Figure 5.2. Roughness standard (type D) with enlarged area of measurement(above) and measurement location pattern with starting points andmeasurement lengths (below).

6 Un ce r t a in t y o f m ea su r em en t

6.1 The uncertainty of measurement shall be calculated according to EAL-R2 [ref.

10] . This means that al l quanti t ies ( input es t imates) contr ibuting to the

measurement resu l t a re t rea ted as random var iab les . The square of the

combined standard uncertainty is obtained by summing the variances of the

input es t imat es . The expan ded un cer ta in ty is g iven wi th a coverage fac tor

k = 2.

6 .2 The uncer ta in ty of the sty lus inst rument ca l ibra t ion cons is ts main ly of the two

components un and u e :

(a ) un is the stan dard u ncerta inty of the m easured value of the st anda rd a s it is

taken from the calibration cert if icate of the s tandard. I t contains the

un iform ity of the reference sta nda rd.

(b) u e is the st anda rd uncertainty estimat ed by experience for tra nsferring the

measur ed value of the standa rd to the stylus instr umen t. It conta ins the

instrum ent's repeata bility on th e same measur ement length.

-

8/2/2019 00100_EA-10-01

8/9

EAL-G20 Z C AL IB R A T IO N O F S T YL U S IN S T R U M E N T S F O R M E A S U R IN G R O U G H N E S S

E D I T I O N 1 ZZ A U G U S T 1 9 9 6P AG E 8 O F 9

6 .3 The tota l expanded uncerta in ty is given by:

U u un e

= +2 2 2

The va lues rounded to an in tege r pe rcen t fo r the meas u red roughnes s

parameters and rounded to integer hundredths of a micrometer for the groove

depth s ar e to be indicated in t he calibra tion cert ificat e.

Note: Since the su rface of the roughness mea sur ement sta nda rd is not perfectly

uniform, the results of the measurements will scatter, resulting in a random

component of th e uncerta inty, expressed by its experiment al sta nda rd deviation.

This ra ndom component , which is cau sed by th e roughness sta nda rd, is already

included in t he un certaint y un of the roughness stan dard. It must th erefore not

be added to the component u e once more , though th is sca t ter ing of the

measur ement r esults is found a gain when the st ylus instru ment is calibrat ed.

7 Ca lib r a t ion c e r t i fica t e

7.1 The certificate of calibrat ion shall be in conforma nce with EAL-R1 [ref. 11]. In

par ticular it ha s t o cont ain th e following inform at ion:

(a) Identificat ion of all relevan t component s of th e complete instr um ent

combin at ion a ccording to section 2 of th is docum ent .

(b) Site of calibrat ion.

(c) Method of calibrat ion.

d) Type of stan dards used, including their calibrat ion value.

(e) Measur ing conditions (measu ring ran ge, tr averse speed applied, length

probed, wavelength cut off, filter type, stylus t ip ra dius).

(f) Results of the R a a nd R z mea sur ement s on th e optical flat.

(g) The mean measu red profile depth for each groove of the depth measu rement

sta nda rd an d the deviations from th eir calibrat ion values.

(h) The mean measured R a and R z values for each roughness measurement

stan dard, their experimental sta ndar d deviation and the deviations from

th eir calibrat ion values.

(j) Each result h as to be given with i ts uncertainty of measurement.

-

8/2/2019 00100_EA-10-01

9/9

P AG E 9 O F 9E D I T I O N 1 ZZ A U G U S T 1 9 9 6

EAL-G20 Z C AL IB R A T IO N O F S T YL U S IN S T R U M E N T S F O R M E A S U R IN G R O U G H N E S S

8 R e fe r e n ce s

1. DKD - R 4 - 2 . Richt l in ie zum Kalibr ieren von Tas tschnit tger ten im Deutschen

Kalibrierdienst, PTB-Mitteilungen , 102(1992), Nr.1, pp.23-26.

2. ISO 3274 : 1995. Geometrical Product Specification (GPS) - Surface texture

Profile method - Nom inal characteristics of conta ct (stylus) instru m ents

3. E AL -R 3 : 1996. R equirem ents for the Accredita tion of Laboratories and

Organisations Perform ing S ite Calibrations

4. ISO/DIS 4287 - 1.2 : 1995. Geometrical Produ ct Sp ecification (GPS) - S urface

texture - Profile m ethod. Part 1: T erm s, definitions an d param eters of surface

texture.

5. ISO 4288 : 1995. Geometrical Product Specification (GPS) - Surface textureProfile method - Rules and procedures for the assessment of surface texture.

6. ISO 11562 : 1995. Geometrical Product Specification (GPS) Surface texture

Profile m ethod - Metrological characteristics of ph ase correct filters.

7 ISO 5436 : 1985. Calibration specim ens - S tylus instru m ents - Types, calibration

and use of specim ens.

8. Hillmann,W. Komm enta r zur Richtlinie zum Kalibrieren von Tastschn ittgerten

im Deut schen Kalibrierdiens. PTB-Bericht: PTB - F-8, Dezember 1991.

9. Hillmann, W. Calibration of contact stylus instrum ents with in th e DeutscherKalibrierdienst. Techn ische Un iversit t Chem nitz, VIII. Inter na tionales

Oberflchenkolloquium, Chemnitz, 3. - 5. Februar 1992, Band 2, S. 58 - 65.

10. EAL-R2 : 1996.Expression of th e Uncertaint y of Measurement in Calibration.

11. E AL-R1 : 1995. Requirements Concerning Certificates Issued by Accredited

Calibration Laboratories.