001 EBE-18.04-Cover-EN v2 · Suppliers • Advanced Photoelectronics for Automobiles • Elektor...

Transcript of 001 EBE-18.04-Cover-EN v2 · Suppliers • Advanced Photoelectronics for Automobiles • Elektor...

Order N

ow at

mouse

r.co.uk

The Electric Vehicle RevolutionBuilding a shared electric vehicle service

Manufacturing Next-Gen Auto ProductsThe business of direct digital manufacturing

Designing Safe Autonomous VehiclesHIL testing for advanced driver assistance systems

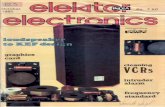

Focus on: AutomotiveBenchmarking IC Development for Automotive Systems • Monitoring Emissions in Modern Vehicles • The Critical Future of Automotive Suppliers • Advanced Photoelectronics for Automobiles • Elektor Business Store • Machine Vision for Automotive Applications• Simulation-Driven Design for Climate Systems • Cellular V2X Communications Toward 5G • ADAS HIL with Sensor Fusion • Infographics • Embedded Systems Vulnerability Assessment • Developing S afety-Critical Embedded Systems • Q&As: MIT’s MapLite Project, New Switch Technology, Co-Created Vehicles, & Electric Vehicle Sharing • ... and more

Edition 4/2018 | € 9.75

TRADESTARTUPINNOVATION

BUSINESS EDITION

001_EBE-18.04-Cover-EN_v2.indd 1 16/07/2018 08:43

30 Elektor Business Edition 4/2018

Current megatrends in the automotive industry are set to unleash unprece-dented changes: self-driving cars, V2X communication (both vehicle to vehicle and vehicle to infrastructure), and elec-tric motors will revolutionise the value creation chains currently in place, while new entrants such as Google, Apple, and Tesla throng into the industry. Mean-while, multi-modal mobility and mobile online services will reshape consumer behaviour entirely. All of this begs the question of whether the European auto-motive suppliers will be able to continue their track record of innovation — and of where and how they fit into this Brave New World.

As it stands, the strategies automotive suppliers have deployed to date are at risk of becoming obsolete. OEMs are extending their sphere of influence ever further into what has, thus far, been sup-plier territory; sooner or later, this will lead to a damaging erosion of suppliers’ unique selling points — and correspon-ding dangers to their profit margins.

And while larger suppliers such as Con-tinental, Bosch, and ZF/TRW have all presented their own (often electric) test vehicles for fully or partially automated driving, here too, it is more often the OEMs — or wholly new would-be market participants such as Google — who have taken the lead when it comes to showing their ability to innovate.

This has left suppliers retreating into their core competences of innovation and development on component level. Yet while they have had sustained success in their specialist areas, it is becoming increasingly clear that this modus ope-randi will hit its limits when it comes to facing the challenges of the future. Clim-bing the technological mountains embo-died by the megatrends on the horizon will require redoubled efforts in which it will not simply be about the ability to implement technological developments as they arrive, but about securing new positions in the rush into the future of mobility: we call this playing field “Sup-plier Inside.”

The situation nowThere is no denying that the larger Euro-pean suppliers have developed a range of activities in the core areas of the new technology megatrends, sometimes with other parts manufacturers, sometimes with OEMs, and sometimes with tech start-ups offering innovative, frequently AI-based solutions. Indeed, measured by the number of patents filed over the last few years, they are not particularly far behind OEMs (Figure 1).

Yet besides the fact that these figures are also influenced by the individual

As far as we can see, there are three potential strategic courses of action which can help to shore up suppliers’ positions. In this article, we will be taking a detai-led look at each of these options: caution (focussing on component development and optimisation); innovation (reaching for system leadership alongside OEMs); and exploration (staking out new territory — e.g., in digital infrastructure).

The story thus farFor the last two decades, the watchword among automotive parts manufacturers has been the pressure on costs applied by carmakers — a pressure which has often led suppliers to neglect innovation, especially when development work was required on complex, cross-component systems. One result is that, since the Bosch/Intel joint development of the CAN bus in the 1980s, there has been no notable innovation in whole-vehicle archi-tecture with substantial supplier partici-pation: LIN, MOST, FlexRay, in-car Ether-net, AUTOSAR — every new standard in recent years has been OEM-driven.

“Supplier Inside”Will the European suppliers be left behind as the automotive megatrends race speeds up?By Hanns Peter Becker — CFO, e&Co. AG

New technologies such as AI and electric motors are driving demand for next-generation vehicles and in-cabin features, tools, and apps. The challenge for European automotive suppliers is clear: keep up or get left behind.

e&Co.: Learn More

For several years now, the entrepreneu-rial management consultancy and invest-ment company e&Co. AG has been advi-sing companies in Automotive — both big-name OEMs and suppliers — on strategic and operational issues, with a real focus on current and future mega-trends such as artificial intelligence, con-nectivity, autonomous driving, and electric transport. The company’s motto is “ENABLING VALUE.” You can download the full version of this article at: http://bit.ly/supplierinside.

030-034_EBE_18.04_e&co-Becker - Supplier-Inside + PR Plato_EN.indd 30 16/07/2018 09:20

ebm article tagging

www.eandco.com

Intermediate

Service

Start-Up

Technology

Practical

Beginner

Product

In Business

Production

Theoretical

Professional

Advice

Potential

Regulatory

Mixed

Level:

Website:

Approach:

Advice:

Company Status:

Subject:

Automotive 31

patent-filing customs of the various companies, these impressive statistics also offer no direct indication of who will later go on to lead the field. They offer even less of an indication that — as is so often claimed in the press — suppliers importance in automotive manufactu-ring is increasing and that this is reflec-ted in the rising proportion of electronic components. In sheer terms of where value is created in the vehicle manufac-turing and assembly process, there may be something to this; but even then, that does not say anything about either how profit margins are divvied up or who is dancing to whose tune. After all, no one would claim that Foxconn should have a higher valuation than Apple because Apple doesn’t make its own products.

So, whatever the case, the technological challenges of digitisation and of, more than anything, developing fully-autono-mous vehicles, are immense: “In terms of its effect on innovation, automated driving is going to be in a class with the moon landing.” [1] That is how a man with both a profound understanding of the market and the power to shape it, ZF TRW’s chief engineer for automated driving, Dr. Karl-Heinz Glander, sees the

to the megatrends mentioned in the introduction follow this pattern, and the development processes in which today’s driver assistance functions are to become

issue — and in principal, he is entirely right. There is a key difference, howe-ver, in that the Moon Shot was centrally organised by a state-run agency, NASA, operating with a budget of US$23.9 mil-lion [2] ($157 billion in today’s money) and orchestrating the most important American technology firms of the day, themselves driven by patriotic fervour. Today, however, carmakers, parts sup-pliers, and IT giants are all competing for the same — comparatively limited and, more importantly, fragmented — funding towards the technological break-through. As we shall see in this article, these are not ideal conditions if you are trying to do something which is the equivalent of flying to the moon.

Given this state of play — i.e., the dis-connect between costs pressures on the one hand and astronomical aims on the other — automotive suppliers are falling ever further behind. Too fixated on their customers’ model cycles, their strategic horizons are often limited to how best to set planning goals, which OEM wants which “new features” on the market in which years, and how in-house innova-tion can be made to pay its way within this scope. Even the supplier responses

Figure 1: Autonomous driving patents filed since 2010. (Source: PATENTSCOPE; Cologne Institute for Economic Research, June 6, 2016)

030-034_EBE_18.04_e&co-Becker - Supplier-Inside + PR Plato_EN.indd 31 16/07/2018 09:20

32 Elektor Business Edition 4/2018

the details of the product they have been given. Companies in the semiconductors industry — thus far, suppliers to vehicle parts suppliers — have caught wind of the developments and are now trying to bypass their actual customers (i.e., parts suppliers) and deal with carmakers directly. Here too, however, the pioneers are not contenders who have traditionally played a role in automotive, but rather companies such as Intel or graphics pro-cessor specialist NVIDIA. With their full war chests and need to find new business areas outside of consumer electronics, these entrants have identified Automo-tive as an area in which machine learning and robotics will be applied — the future technologies which will simply swallow up the kind if computing power these companies can produce.

A notable example comes in the form of BMW’s planned cooperation with Intel on developing highly-automated vehic-les (BMW iNext). Intel is looking to build on its broad range of computing plat-forms and, besides the vehicle’s central computer (known as a domain control-ler), is also eyeing up the back end of the new automobile package with cloud computing and connectivity applications. [7] This step is a clearly audible break with the manufacturer-neutral compu-ting platform strategy pursued thus far by the Bavarian carmaker, and should be causing suppliers more than just the odd sleepless night: Is this what it sounds

Although different companies are dealing with the issues differently, this roadmap is currently serving as the signposting for pretty much every participant and entrant.

Suppliers are becoming increasingly limi-ted by the “system trap”: in order to develop convincing solutions for (parti-ally) automated vehicle functions, both cross-component systems competence and a profound understanding of algo-rithms and software development are required. The former is the preserve of the carmakers. The latter is classic sup-plier territory. Yet when efforts on the part of parts manufacturers to develop systems are placed against the progress OEMs are making in developing their soft-ware capabilities, the OEMs come out way out in front.

More than any others, OEMs in the pre-mium segment have been allocating resources to their algorithm and software competences specifically for several years now; they have established partnerships with providers of engineering services and built up specialised subsidiaries in the area, too. In the R&D departments of the larger premium manufacturers, hundreds of experts are at work turning things like highway pilot and remote par-king into algorithms. The results will then have to be integrated into electronic con-trol units (ECU) as “black-box software” by suppliers who will not have access to

tomorrow’s driverless car are especially illustrative of the malaise. As such, we will take a closer look at this area by way of example.

Development in the area is following a road-map which is, to a certain extent, in the hands of semi-national agencies such as BASt [3], NHTSA [4], SAE [5], and NCAP [6] (Figure 2). While the Ger-man BASt and both American organisati-ons have proposed five-to-six stage clas-sification systems for driverless vehicles, running — with some minor differen-ces — from “no assistance systems at all” to “fully autonomous,” EuroNCAP’s focus lies on the driving safety systems in automated vehicles rather than the level of comfort they offer drivers/pass-engers. The body has specified actual accidents and posited potential situati-ons which require attention in the area of active safety (as opposed to pas-sive safety, i.e., air-bags and seatbelt pre-tensioners). An automated vehicle would need to either brake/steer auto-nomously or warn the driver in these cases. Given that these scenarios will be worked into the evaluation criteria in the coming years (or are already a part of them), meaning that new vehicles will only receive top safety marks if they can master these circumstances, this set of standards will be a driving impulse in further development of intelligent driver assistance functions, especially in the area of vehicle environment recognition.

Figure 2: Classifications for driverless vehicles

030-034_EBE_18.04_e&co-Becker - Supplier-Inside + PR Plato_EN.indd 32 16/07/2018 09:20

Automotive 33

the market will this setup leave suppliers in the future?

The suppliers who manage to fill the spaces left are almost certainly going to be those who make efforts to understand the technical and infrastructural prerequi-sites of the Brave New World of Mobility. This new market order will be predica-ted on geo-data and the B2B services adjunct to it — that is, how to connect up data in the transportation infrastructure (V2X, vehicle to infrastructure). The parts business, too, can be shored up as the electronic horizon (high-precision carto-graphy as an additional data requirement for autonomous vehicles) already offered by some suppliers still needs a hardware component to carry it.

Yet here too, our assertion that suppliers have missed chances is backed up by the fact that it was a group of carmakers who staked out this area by buying the digital mapping company Here. (The Nokia com-pany Here was taken over in late 2015 by BMW, Audi, and Daimler for €2.55 billion.) There is no reason why a con-sortium composed of Bosch, Continental, and a few others should not have been able to secure this territory. The same is true of the 5G Automotive Association set up by Audi, BMW, Daimler, Ericsson, Huawei, Intel, and Qualcomm with the aim of making the best possible use of the coming 5G mobile network standard in the move towards autonomous driving, of agreeing joint specifications, and of carrying out pilot projects to influence new standards.

Notes & Web Links

[1] M. Hopp, “Cars Can Learn Anyt-hing,” Drive: the ZF Magazine,

components and functions. Mass-mar-ket volume manufacturers especially — whether in Europe, America, or Asia — are all facing serious challenges here: they need to claw back some of the distance the premium brands have put behind them, even if, for the foreseeable future, a partially automated whole-sys-tem approach will not be affordable in this price-sensitive market segment.

Pursuing this course, however, would require far greater efforts on the parts of the suppliers (i.e., commitments which disregard the narrow business logic of component development and take real strategic, organisational, and technical courage). Only this gutsy approach will lead to a credible supplier system which does what it says on the tin and offers real value. The only way to sustain this kind of effort will be for suppliers to come to robust strategic partnership agree-ments — and go hard on them. These kinds of initiatives will also lead to a jump in complexity as national markets (in some cases, even individual cities) move towards driverless traffic at diffe-rent speeds. Following this path will put a huge strain on supplier-side business development departments as they try to hammer out detailed road-maps for the journey ahead.

Option 3: The explorative approach — Building on and extending the innovative approach, a third strategic option pre-sents itself if the so-frequently posited transformation of carmakers into provi-ders of mobility services is transposed onto suppliers. The coming battle for consumers and — more than anything else — their data is likely to be fought between the vehicle manufacturers and the tech giants. Which empty spaces in

like when an OEM forces the door to the last, as yet undisputed redoubt of the Tier-1 suppliers, viz. electronic hardware design?

Larger parts manufacturers aren’t lis-tening out for burglars, though; in fact, they’re talking incessantly about how, with their environmental sensor techno-logy (radar, cameras, ultrasound, and — coming soon — LiDAR), electronic braking and steering systems, and — for some — their domain controllers, they control all of the key planks in automated dri-ving functionality.

Yet all of this system-level competence is, by and large, purely hypothetical. A system is, after all, more than just the sum of its parts. Each of the individual component areas remains locked in the straightjacket of the profitability goals it has been set; beyond a few token pre-de-velopment initiatives, there is no capacity for intensive cross-disciplinary coopera-tion payable up front. To top it all off, OEMs — or at least premium carmakers — don’t actually want to outsource sys-tem competency in any case.

The strategic optionsFrom our point of view, there are three potential strategies for suppliers looking to respond to the challenges which auto-nomous driving is set to present:

Option 1: The cautious approach — The most obvious course of action is to pur-sue the strategy which has been suc-cessful thus far: specialisation and excel-lence in components manufacturing. The downside of this path, however, is that there will be no escaping bitter compe-tition on costs further down the line. Moreover, with software competence draining to a greater or lesser degree to the OEM, the final destination is the uncomfortable question as to what the supplier can offer that a simple electronic manufacturing service provider like Fox-conn or Flextronic — with more favoura-ble costs structures — cannot.

Option 2: The innovative approach — The option entails taking the system promises made by larger suppliers at face value, making good on them, and actually offe-ring carmakers — especially those ope-rating below the premium segment — a genuinely scalable system for autono-mous driving which encompasses both

The AuthorHanns Peter Becker is CFO of e&Co. AG. He has more than 20 years of experience as a project manager for technical product development and more than 15 years of experience as a consultant in various industries, mainly automotive. Becker is an expert in development management, optimising development processes, designing R&D organisa-tions, and in future automotive electronics areas. He has a successful, sustained track record heading task forces and managing complex development projects (electronics and embedded software).

030-034_EBE_18.04_e&co-Becker - Supplier-Inside + PR Plato_EN.indd 33 16/07/2018 09:20

![8 ebe]o9bWii8 ebe]o9bWii - WordPress.com · 8 ebe]o9bWii8 ebe]o9bWii - WordPress.com ... ƒ⁄žÛ)](https://static.fdocuments.us/doc/165x107/5e491dc915c9f15b980faf4d/8-ebeo9bwii8-ebeo9bwii-8-ebeo9bwii8-ebeo9bwii-wordpresscom-a.jpg)